Pochopení zásadního rozdílu v elektrické ochraně

Vejděte do železářství a požádejte o “pojistku” a dostanete malou skleněnou nebo keramickou trubičku. Vejděte do závodu na výrobu průmyslových rozvaděčů a požádejte o “pojistku” a budete čelit zásadní otázce: “Potřebujete kompletní sestavu nebo pouze vyměnitelný tavný prvek?” Tento rozdíl není slovíčkařením – je to technická nutnost, která přímo ovlivňuje náklady na pořízení, bezpečnost systému a provozní efektivitu.

Ve společnosti VIOX Electric, výrobci elektrických zařízení B2B, jsme byli svědky toho, jak nákupčí objednávali “pojistky” s očekáváním náhradních dílů $8, jen aby obdrželi palety základen pojistek $180, které nepotřebovali. Opačný scénář – objednávání základen pojistek, když byly potřeba pouze tavné vložky – vytváří stejně nákladné prostoje a zpoždění ve výrobě.

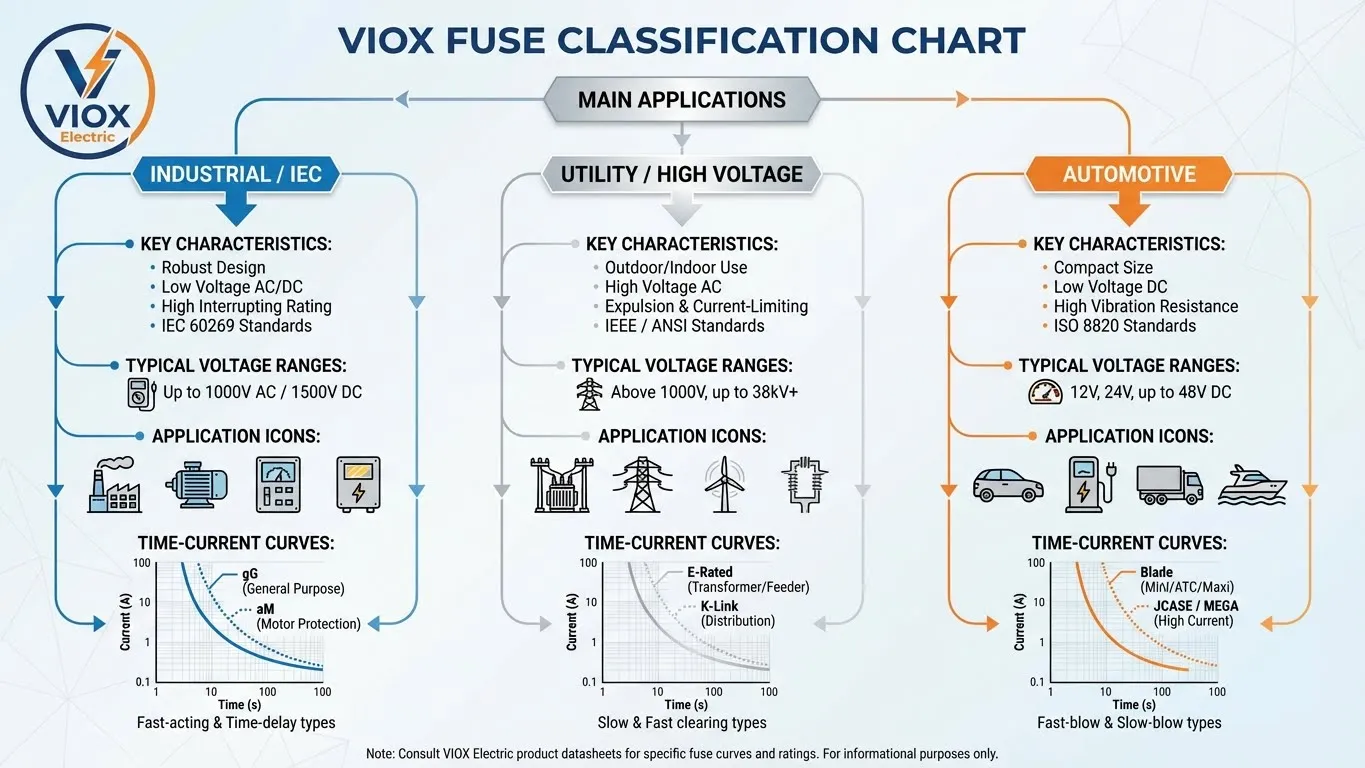

Tato komplexní příručka objasňuje rozdíl mezi pojistka (kompletní ochranný systém) a pojistková vložka (obětovaný prvek) ve třech kritických kontextech: Průmyslové aplikace řízené normami IEC 60269, vysokonapěťové systémy a automobilové elektrické systémy. Pochopení těchto rozdílů ušetří vaší organizaci čas, peníze a potenciální bezpečnostní rizika.

Průmyslové pojistkové systémy: Definice normy IEC 60269

V průmyslové elektrické automatizaci – oblasti, ve které společnost VIOX Electric působí – termíny “pojistka” a “pojistková vložka” představují hierarchický vztah definovaný normami IEC 60269. Tento rozdíl je zásadní pro výrobce rozvaděčů, inženýry automatizace a odborníky v oblasti nákupu.

Kompletní pojistkový systém: Sestava komponent

Podle normy IEC 60269-1:2024 kompletní pojistka není jediná součást, ale funkční sestava navržená k ochraně elektrických obvodů před nadproudem. Norma definuje tento systém jako zahrnující tři primární prvky:

- Základna pojistky (nebo držák): Stacionární montážní prvek přišroubovaný k elektrickému panelu nebo rozvodné desce. Poskytuje mechanickou podporu a elektrické připojení k obvodu.

- Nosič pojistky: U některých konstrukcí (zejména systémů NH) pohyblivý prvek, který drží pojistkovou vložku a usnadňuje bezpečnou instalaci a demontáž.

- Pojistková vložka: Vyměnitelný ochranný prvek obsahující kalibrovaný tavný prvek, který přerušuje proud během poruchových stavů.

Tato hierarchická struktura znamená, že při specifikaci “pojistky” pro průmyslové aplikace technicky objednáváte kompletní ochranný systém. Nicméně pro účely údržby a výměny obvykle potřebujete pouze pojistková vložka– spotřební součást.

Pojistky NH a válcové pojistkové vložky: Praktické příklady

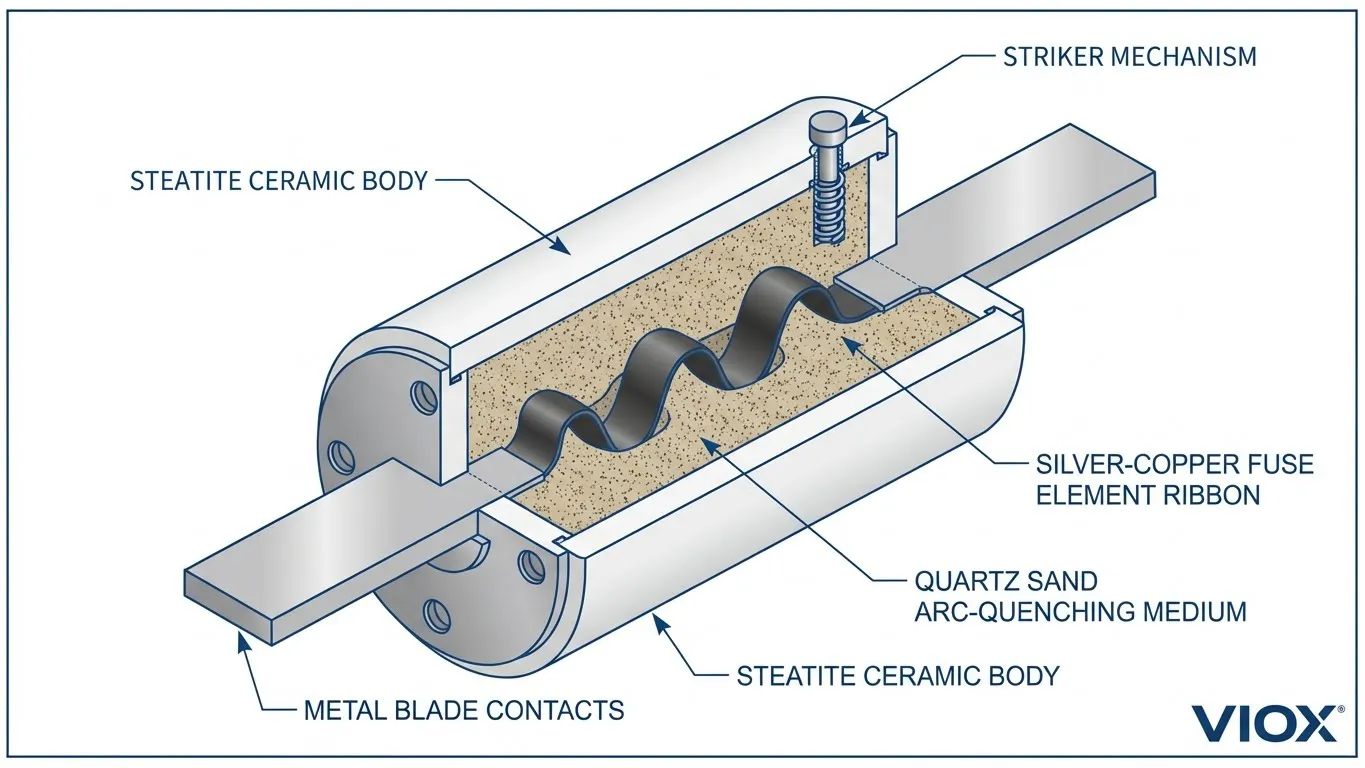

Pojistky NH (nožové) představují nejběžnější průmyslový pojistkový systém, standardizovaný podle normy IEC 60269-2. V této konfiguraci:

- Bílé nebo krémové keramické tělo s kovovými nožovými kontakty = Pojistková vložka

- Černé plastové pouzdro s pružinovými kontakty = Základna pojistky

- Volitelná sestava červené nebo černé rukojeti = Nosič pojistky

Válcové pojistky (například velikosti 10x38mm nebo 22x58mm) se řídí podobnou logikou:

- Keramická trubice s kovovými koncovkami = Pojistková vložka

- Sestava klipového držáku = Základna pojistky

Bez základny nemůže vložka fungovat. Bez vložky je základna pouze otevřený obvod. Tato vzájemná závislost vytváří kompletní ochranný systém.

Pochopení klasifikací pojistek gG a aM

IEC 60269 dále kategorizuje pojistkové vložky podle jejich časově-proudových charakteristik, označených dvoupísmenným kódem. Dvě nejběžnější průmyslové klasifikace jsou:

Pojistky gG (všeobecné použití, ochrana v plném rozsahu)

- “g” (malá písmena) označuje ochranu v celém rozsahu přetížení

- “G” (velká písmena) označuje aplikace pro všeobecné použití

- Poskytuje ochranu kabelů, ochranu transformátorů a ochranu obecných obvodů

- Typická provozní charakteristika: Vybaví během 2-5 sekund při 5× jmenovitém proudu, 0,1-0,2 sekundy při 10× jmenovitém proudu

- Vypínací schopnost běžně přesahuje 100 kA při 400/500V pro systémy NH

Pojistky aM (ochrana motoru, částečný rozsah)

- “a” (malá písmena) označuje ochranu v částečném rozsahu (pouze proti zkratům)

- “M” (velká písmena) označuje aplikace pro motorové obvody

- Odolává záběrovým proudům motoru (typicky 6-8× jmenovitý proud po dobu několika sekund)

- Musí být použity se samostatnou ochranou proti přetížení (motorové ochranné relé nebo tepelné nadproudové ochrany)

- Zásadní pro prevenci nežádoucího vypínání během spouštění motoru

| Typ pojistky | Rozsah ochrany | Typical Application | Reakce na přetížení | Reakce na zkrat |

|---|---|---|---|---|

| gG | Plný rozsah (přetížení + zkrat) | Ochrana kabelů, napáječe transformátorů, obecné obvody | Vybaví při 1,6× In (konvenční tavný proud) | Vypínací schopnost ≥100 kA |

| aM | Částečný rozsah (pouze zkrat) | Motorové obvody, zařízení pro konverzi energie | Odolává 6-8× In během spouštění | Vypínací schopnost ≥100 kA |

Porovnání časově-proudových charakteristik

| Úroveň proudu | Pojistková vložka gG 20A | Pojistková vložka aM 20A |

|---|---|---|

| 1,6× In (32A) | ~1-2 hodiny | Nevybaví (navržená tolerance) |

| 3× In (60A) | ~30-60 sekund | ~5-10 minut |

| 5× In (100A) | 2-5 sekund | 15-30 sekund |

| 10× In (200A) | 0,1-0,2 sekundy | 0,2-0,5 sekundy |

Osvědčené postupy pro nákup průmyslových pojistek

Zásadní pravidlo: Nikdy nespecifikujte pouze “pojistka” bez úplných podrobností v kusovníku (BOM).

Nesprávná specifikace:

- “Pojistka 100A”

- “NH pojistka pro panel”

Správná specifikace:

- Pro výměnu: “Pojistková vložka NH00, 100A, gG, 500V AC” (IEC 60269-2)

- Pro novou instalaci: “Pojistková spodina NH00, 3-pólová, s pojistkovými vložkami 100A gG” (kompletní systém)

- Pro motorové obvody: “Pojistková vložka NH1, 63A, aM, 690V AC”

Tato přesnost eliminuje chyby při nákupu, snižuje náklady na zpětnou přepravu a zajišťuje kompatibilitu se stávajícími instalacemi.

Aplikace ve vysokonapěťových rozvodných sítích: Vypínací pojistky a propojovací vodiče

V sektoru rozvodných sítí a vysokonapěťového rozvodu evokuje “pojistková vložka” zcela odlišný vizuální obraz. K tomuto zmatení kontextu často dochází, když distributoři manipulují s průmyslovými i rozvodnými produkty.

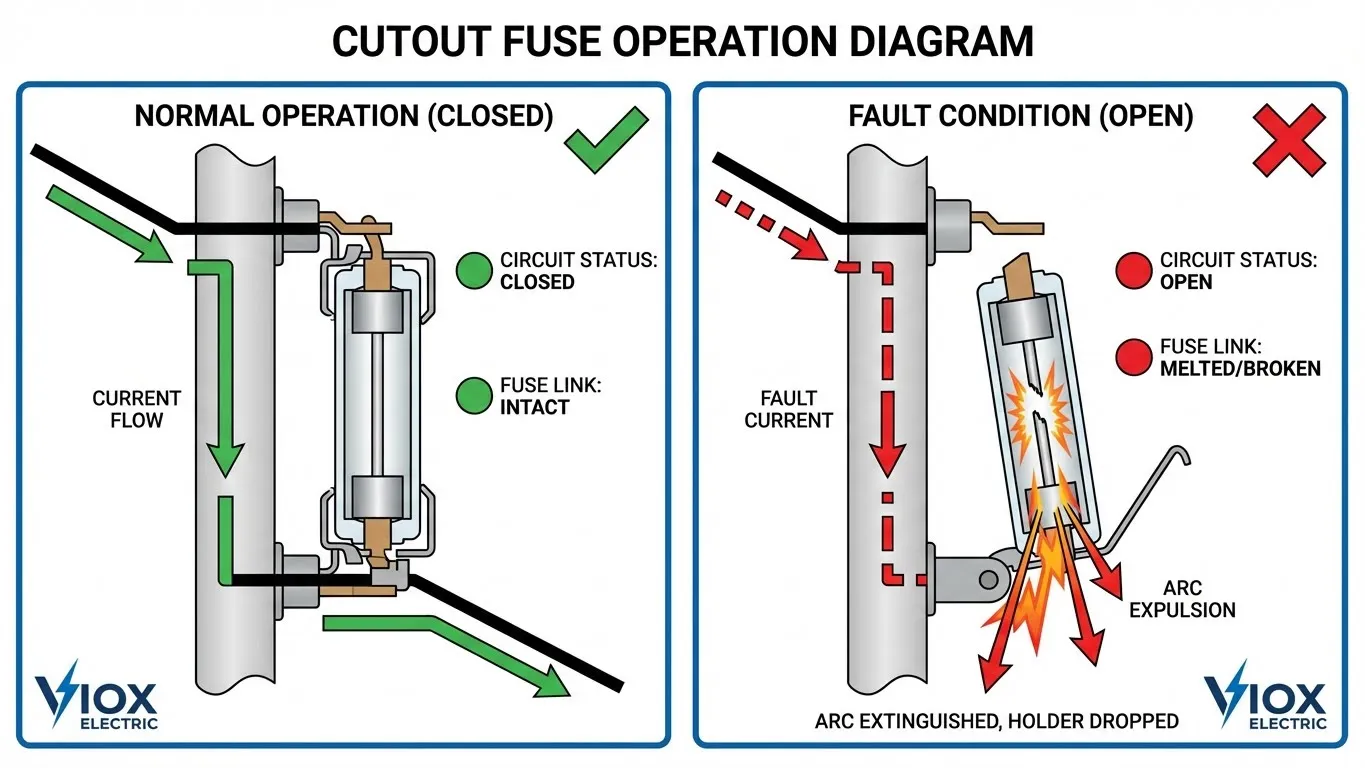

Ochrana transformátorů montovaných na sloupech

Transformátory montované na sloupech rozvodných sítí – viditelné v celých distribučních sítích – vyžadují robustní nadproudovou ochranu proti poruchám vedení, poruchám zařízení a přetížení. Ochranné zařízení namontované na těchto sloupech je vypínací pojistka (také nazývaná pojistkový vypínač nebo výklopná pojistka), typicky dimenzovaná pro aplikace 11-36 kV.

Propojovací vodič pojistky: Odlišná filozofie návrhu

Na rozdíl od keramických trubičkových pojistkových vložek používaných v průmyslových systémech NH se rozvodné pojistkové vložky podobají krátkým kabelům:

- Fyzický vzhled: Knoflíková hlava na jednom konci, ohebný lankový vodič na druhém konci (odtud “propojovací vodič”)

- Způsob instalace: Provlečená trubicí držáku pojistky a zajištěná pod mechanickým napětím

- Mechanismus fungování: Když poruchový proud roztaví vodič, mechanické napětí se uvolní, což způsobí, že se držák pojistky fyzicky vyklopí (vypadne)

- Vizuální indikace: Vyklopená poloha poskytuje okamžité vizuální potvrzení provozu

Tento mechanismus vyklopení slouží dvojímu účelu: přerušení poruchového proudu a poskytnutí vizuální indikace místa poruchy posádkám rozvodných sítí z úrovně země.

Pojistkové vložky typu K vs. typu T

Rozvodné pojistkové vložky jsou kategorizovány podle rychlostních charakteristik podle IEEE C37.42-2016:

Typ K (rychle působící)

- Určeno pro ochranu vedení

- Rychlá odezva na poruchové proudy

- Vhodné pro aplikace vyžadující okamžité přerušení

- Typické aplikace: Distribuční napáječe, ochrana odbočných obvodů

Typ T (pomalu působící)

- Určeno pro ochranu transformátoru

- Toleruje magnetizační nárazové proudy během zapnutí transformátoru

- Zabraňuje rušivým provozům během spínacích přechodových jevů

- Typické aplikace: Distribuční transformátory, kondenzátorové baterie

| Charakteristický | Rozvodná vypínací pojistka | Průmyslová NH pojistka |

|---|---|---|

| Napětí | 11-36 kV | 400-1000V AC |

| Forma pojistkové vložky | Ohebný propojovací vodič | Pevná keramická trubička |

| Provozní mechanismus | Mechanické vyklopení | Pevná poloha (vyžaduje ruční odstranění) |

| Vizuální indikace | Samozřejmé (vyklopené otevřené) | Indikační kolík nebo okénko |

| Typické náklady | $5-15 (pouze vložka) | $8-50 (pouze odkaz) |

| Celkové náklady na sestavení | $200-800 | $150-400 |

Tavné spoje v automobilech: Skrytý prvek ochrany

V automobilových elektrických systémech se terminologie opět mění. Zatímco většina lidí zná ploché pojistky (typu ATO/ATC) v pojistkové skříňce vozidla, tavné spoje představují nebezpečnější prvek kvůli svému klamnému vzhledu.

Co je to tavný spoj v automobilu?

Tavný spoj v automobilových aplikacích je krátký úsek nízkonapěťového kabelu, typicky umístěný v blízkosti kladného pólu baterie nebo alternátoru. Toto ochranné zařízení vypadá téměř identicky se standardním automobilovým vodičem, což vytváří problémy s identifikací.

Kritické specifikace:

- Určení velikosti průřezu vodiče: Typicky o čtyři velikosti American Wire Gauge (AWG) menší než obvod, který chrání

- Typ izolace: Speciální nehořlavá izolace, která při tavení vytváří bubliny nebo zuhelnatí, ale nevznítí se

- Délka: Obvykle 6-9 palců

- Umístění: Mezi zdroji vysokého proudu (baterie, alternátor) a distribučními body

Příklad: Obvod používající vodič 10 AWG by byl chráněn tavným spojem 14 AWG.

Bezpečnostní riziko: Proč je správná identifikace důležitá

Hlavní nebezpečí tavných spojů pramení z jejich vzhledu podobného vodiči. Nezkušení technici si často spletou spálený tavný spoj s poškozenou kabeláží a “opraví” jej spojením se standardním automobilovým vodičem. Tato náhrada eliminuje nadproudovou ochranu a vytváří vážné nebezpečí požáru.

Důsledky nesprávné výměny:

- Další zkratová událost nezpůsobí ochranné přerušení

- Standardní vodič vede poruchový proud, dokud se izolace neroztaví

- Potenciální riziko požáru kabelového svazku a poškození vozidla

- Riziko výbuchu baterie v důsledku trvalého zkratu

Správný postup výměny:

- Tavné spoje vždy vyměňujte za komponenty specifikované výrobcem OEM nebo za komponenty s ekvivalentními parametry

- Nikdy nenahrazujte standardním vodičem jakéhokoli průřezu

- Ujistěte se, že náhradní vodič obsahuje vysokoteplotní izolaci zpomalující hoření

- Ujistěte se, že je průřez vodiče správně dimenzován (o čtyři průřezy menší než chráněný obvod)

Tavný spoj vs. standardní plochá pojistka

| Funkce | Tavný spoj | Plochá pojistka (ATO/ATC) |

|---|---|---|

| Fyzická forma | Segment vodiče | Plastové tělo s kovovými kontakty |

| Umístění | Pod kapotou, v blízkosti baterie | Pojistková skříňka, interiér |

| Identifikace | Obtížná (vypadá jako vodič) | Snadná (barevně odlišeno, jmenovité hodnoty) |

| Úroveň ochrany | Obvody s vysokým proudem (60-150A) | Obvody s nízkým až středním proudem (typicky 3-30A) |

| Obtížnost výměny | Střední (vyžaduje pájení/krimpování) | Jednoduchá (zásuvná) |

| Vizuální indikace | Žádná (roztavený vodič) | Viditelné přerušené vlákno |

Komplexní srovnání: Všechny tři kontexty

| Kontext aplikace | Název systému | Vyměnitelný prvek | Primární použití | Rozsah napětí | Typická vypínací schopnost |

|---|---|---|---|---|---|

| Průmyslové (IEC) | Pojistkový systém NH | Pojistková vložka NH (keramická patrona) | Ochrana panelů, motorové obvody, ochrana kabelů | 400-1000V AC | 100-120 kA |

| Průmyslové (IEC) | Válcová pojistka | Válcová pojistková vložka | Řídicí obvody, elektronika | 250-690V AC | 50-100 kA |

| Energetické (VN) | Vypínací pojistka | Pojistková vložka s vývodem | Ochrana transformátoru, dělení vedení | 11-36 kV | 6-10 kA (vymetací) |

| Automobilový průmysl | Sestava tavné pojistky | Drát tavné pojistky | Ochrana baterie/alternátoru | 12-48V DC | 500-1000A |

| Automobilový průmysl | Pouzdro ploché pojistky | Plochá pojistka | Příslušenství obvodů | 12-48V DC | Maximálně 60-100A |

Specifikace velikostí pojistek IEC

| Velikost NH | Rozsah jmenovitého proudu | Fyzické rozměry (D × Š) | Typické aplikace | Vypínací schopnost @ 500V |

|---|---|---|---|---|

| NH000 | 2-160A | 185 mm × 65 mm | Ovládací panely, malé motory | 120 kA |

| NH00 | 2-160A | 140 mm × 50 mm | Rozvodné desky, střední motory | 120 kA |

| NH0 | 4-100A | 95 mm × 45 mm | Podružné rozvody, menší motory | 120 kA |

| NH1 | 10-160A | 115 mm × 54 mm | Hlavní rozvod, řídicí centra motorů | 120 kA |

| NH2 | 125-250A | 150 mm × 69 mm | Průmyslové napáječe, velké motory | 120 kA |

| NH3 | 200-630A | 215 mm × 100 mm | Hlavní rozvaděče, sekundární vinutí transformátorů | 120 kA |

| NH4 | 500-1250A | 330 mm × 155 mm | Vstupní přípojka, velké průmyslové zátěže | 80-100 kA |

Profesionální pokyny pro nákup

Osvědčené postupy pro objednávání specifické pro dané odvětví

Pro průmyslové aplikace/aplikace pro stavbu panelů:

- Nové instalace: Specifikujte kompletní systémy

- “Pojistkový odpínač NH1, 3-pólový, 160A, včetně pojistkových vložek gG”

- Vždy uveďte, zda je požadována funkce odpínače

- Údržba/výměna: Specifikujte pouze vložky

- “Pojistková vložka NH00, 63A, gG, 500V AC, IEC 60269-2”

- Pokud je kritická kompatibilita, uveďte stávajícího výrobce základny

- Obvody motoru: Vždy specifikujte klasifikaci aM

- “Pojistková vložka NH2, 200A, aM, 690V AC” (ne gG)

- Koordinujte s nastavením relé motorové ochrany

Pro aplikace v energetice/vysokém napětí:

- Kompletní sestavy:

- “Sestava pojistky s výřezem 15 kV, polymerový izolátor, jmenovitý proud 100A”

- Náhradní vložky:

- “Pojistková vložka typu K, 15 kV, 40A” nebo “Pojistková vložka typu T, 15 kV, 65A”

- Ověřte typ K vs. typ T na základě aplikace (vedení vs. transformátor)

Pro automobilové/flotilové aplikace:

- Nikdy nespecifikujte “drát” pro tavné pojistky

- “Tavná pojistka, 12V, 14 AWG, délka 9 palců, vysokoteplotní izolace”

- Pokud jsou k dispozici, vždy uvádějte čísla dílů OEM

Běžné chyby při nákupu, kterým je třeba se vyhnout

| Chyba | Následek | Správný postup |

|---|---|---|

| Objednání “pojistky 100A” bez specifikace | Obdržení kompletní sestavy, když je potřeba pouze vložka (překročení nákladů) | Specifikujte “pojistkovou vložku NH00, 100A, gG” |

| Použití pojistek gG v motorových obvodech | Nežádoucí vypínání během spouštění motoru | Specifikujte pojistky aM pro motorové obvody |

| Objednávání pojistkových vložek bez ověření kompatibility patice | Rozměrová neshoda, nepoužitelné díly | Odkaz na stávající typ pojistkového systému (NH, BS88 atd.) |

| Nahrazení tavných vložek standardním drátem | Nebezpečí požáru, ztráta ochrany | Používejte pouze OEM nebo jmenovité náhradní tavné vložky |

| Míchání napěťových hodnot | Bezpečnostní riziko, porušení předpisů | Vždy odpovídejte nebo překračujte jmenovité napětí systému |

Doporučení produktů VIOX Electric

Ve společnosti VIOX Electric vyrábíme komplexní pojistková řešení pro průmyslové aplikace:

- Pojistkové vložky NH: Dostupné ve velikostech NH000 až NH4, s charakteristikami gG i aM, jmenovitá vypínací schopnost do 120 kA

- Pojistkové patice a držáky: Navrženo pro nožové systémy NH se snadným přístupem pro údržbu

- Pojistkové odpínače: Kombinovaná ochrana a izolace v jedné sestavě

- Válcové pojistkové vložky: Velikosti 10x38mm, 14x51mm a 22x58mm pro aplikace v řídicích obvodech

Všechny pojistkové produkty VIOX splňují normy IEC 60269-1:2024 a IEC 60269-2:2024, což zajišťuje globální kompatibilitu a spolehlivý výkon v náročných průmyslových prostředích.

Odkaz na technické normy

Pochopení platných norem zajišťuje shodu a správnou specifikaci:

Řada IEC 60269 (Nízkonapěťové pojistky)

IEC 60269-1:2024 (Všeobecné požadavky, Vydání 5.0)

- Stanovuje základní požadavky pro všechny pojistkové vložky s jmenovitou vypínací schopností ≥6 kA

- Definuje terminologii: pojistka, pojistková vložka, pojistková patice, pojistkový držák

- Specifikuje testovací protokoly pro časově-proudové charakteristiky a vypínací schopnost

- Platí pro AC obvody do 1000V

IEC 60269-2:2024 (Průmyslové pojistky, Konsolidované vydání)

- Doplňkové požadavky pro pojistky používané pouze oprávněnými osobami

- Pokrývá standardizované pojistkové systémy A až K

- Zahrnuje nožové pojistky NH (nejběžnější průmyslový typ)

- Definuje požadavky na charakteristiky gG a aM

- Specifikuje mechanické rozměry pro zaměnitelnost

IEC 60269-6:2010 (Fotovoltaické pojistky)

- Doplňkové požadavky pro DC pojistky v solárních aplikacích

- Jmenovité napětí do 1500V DC

- Řeší jedinečné problémy s přerušením DC oblouku

IEEE Standards (Utility Applications)

IEEE C37.42-2016 (Distribuční pojistky a příslušenství)

- Požadavky na výkon pro vysokonapěťové pojistky výtlačného typu

- Pokrývá pojistkové odpínače, pojistkové odpojovače

- Specifikuje jmenovité vypínací proudy do 10 kA symetricky

- Definuje charakteristiky typu K a typu T

IEEE C37.41-2024 (Proudově omezující pojistky)

- Návrhové testy pro vysokonapěťové proudově omezující pojistky

- Platí pro ochranu transformátorů v rozvodných sítích

- Pokrývá pojistky s označením E pro koordinaci výtlačného provozu

Tyto normy zajišťují, že pojistkové produkty od různých výrobců se shodnými parametry budou fungovat konzistentně, což umožňuje bezpečnou substituci a spolehlivou ochranu systému.

Závěr: Přesnost v terminologii se rovná úsporám nákladů

Rozdíl mezi “pojistkou” (kompletní ochranný systém) a “pojistkovou vložkou” (vyměnitelný prvek) přesahuje pouhou sémantiku – představuje zásadní pochopení, které přímo ovlivňuje náklady na nákup, bezpečnost systému a provozní spolehlivost.

Klíčové poznatky:

- Průmyslový kontext: “Pojistka” = základna + nosič + tavný prvek; “Pojistkový tavný prvek” = keramická patrona s kontakty

- Kontext energetiky: “Venkovní pojistka” = kompletní sestava; “Pojistkový tavný prvek” = drátový prvek s vývodem

- Kontext automobilového průmyslu: “Tavitelný spoj” = speciální drátový segment; nikdy nenahrazujte standardním drátem

- Pravidlo pro nákup: Vždy specifikujte kompletní technické detaily (velikost, jmenovitý proud, typ, napětí, norma)

- Bezpečnostní zásada: Používejte pouze komponenty navržené pro konkrétní aplikaci – žádné náhrady

Ve VIOX Electric chápeme, že zákazníci B2B vyžadují více než jen produkty – potřebují technické znalosti, přesné specifikace a spolehlivá partnerství. Naše průmyslové pojistkové systémy splňují normy IEC 60269 a poskytují vypínací schopnost, selektivitu a trvanlivost požadovanou moderními elektrickými instalacemi.

Ať už specifikujete novou rozvodnou skříň, udržujete stávající zařízení nebo hledáte náhradní komponenty, pochopení rozdílu mezi pojistkou a pojistkovým tavným prvkem zajistí, že si objednáte správně hned napoprvé – čímž eliminujete nákladné prostoje, vracení zboží a bezpečnostní kompromisy.

Jste připraveni specifikovat správnou ochranu pro vaši aplikaci? Kontakt VIOX Electric‘technický tým pro doporučení specifická pro danou aplikaci, kompletní technické listy a konkurenční nabídky na průmyslové pojistkové systémy navržené pro spolehlivost a výkon.