Sexta-feira. 16:47.

A reunião de orçamento está quase a terminar. O seu gestor de instalações desliza a cotação elétrica pela mesa e toca num item de linha com a caneta.

“DPS para painel principal: unidade de 300kA, $1.500. DPS para painéis de derivação: unidades de 50kA, $150 cada.”

Ele olha para cima. “Por que precisamos do caro no principal? Não podemos simplesmente usar as unidades baratas de $150 em todos os lugares e economizar $1.200?”

Já ouviu esta pergunta uma dúzia de vezes. E, invariavelmente, a resposta real está enterrada sob jargões técnicos sobre “classificações de corrente de surto” e “degradação de MOV” que fazem os olhos vidrarem em três segundos.

Aqui está a verdade que corta a confusão:

A classificação kA não se refere ao quão bem o DPS bloqueia a tensão. Trata-se de quanto tempo ele sobrevive.

Misture isso — instale uma unidade de barganha de 50kA na sua entrada de serviço para “economizar dinheiro” — e estará a fechar toda a sua instalação em 18 meses para substituir um DPS morto. Às 2 da manhã. Durante o seu turno de produção mais movimentado. Enquanto o seu gerente de fábrica calcula o custo: $12.000 em perda de produção, $800 em horas extras de eletricista de emergência, mais os $150 que pensou ter economizado.

A solução não é comprar o maior número em todos os lugares. É implantar um sistema de defesa tático que chamamos de A Estratégia do Guardião. Veja como dimensionar os seus DPSs corretamente, desde as linhas de frente brutais na sua entrada de serviço até as zonas protegidas no seu chão de fábrica.

A Maior Ideia Errada: As Classificações kA Não São Desempenho, São Vida Útil

Antes de falarmos sobre onde instalar o quê, precisamos destruir o mito que mata a maioria das estratégias de dimensionamento de DPS.

O Mito: “Classificação kA mais alta = Melhor proteção de tensão”

A Realidade: “Classificação kA mais alta = Maior expectativa de vida”

Veja por que essa distinção é importante.

O componente principal dentro de cada DPS é o MOV — o Varistor de Óxido Metálico. Ele funciona como uma válvula de alívio de pressão num sistema de vapor. Quando a tensão sobe acima de um limite, o MOV conduz, desviando o excesso de energia para o terra e limitando a tensão que atinge o seu equipamento.

Um DPS de 50kA pode conter um MOV por fase.

Um DPS de 300kA pode conter uma matriz de 10 MOVs conectados em paralelo por fase.

Aqui está o segredo que o seu representante de vendas não enfatizará:

Ambas as unidades limitarão um surto padrão de 10kA aproximadamente ao mesmo nível de tensão — normalmente em torno de 800-1.200V para um sistema de 480V.

A unidade de 300kA não fornece proteção “melhor” durante esse único evento de surto. Ela não bloqueia a tensão para um nível mais baixo. Ela não responde mais rápido. Durante esse único surto, ambos os DPSs têm um desempenho quase idêntico.

O que é diferente é o que acontece após 500 desses eventos de surto.

Pense em “Profundidade do Piso do Pneu”, Não em “Velocidade Máxima”

A melhor analogia para entender as classificações kA vem do seu veículo.

Imagine dois pneus:

O Pneu de Corrida (DPS de 50kA): Piso fino, otimizado para desempenho. Leve, eficiente, acessível a $150.

O Pneu de Caminhão Off-Road (DPS de 300kA): Piso profundo, construído para punição. Resistente, caro a $1.500.

Agora aqui está a pergunta: Qual pneu pode dirigir a 96 km/h?

Ambos. A classificação kA não se refere à velocidade máxima — refere-se a quanto tempo o pneu dura quando você dirige sobre cascalho todos os dias.

Como os MOVs se Desgastam

Cada vez que um DPS suprime um surto, os seus MOVs internos degradam-se ligeiramente. Os grãos de óxido de zinco dentro do varistor sofrem stress térmico. A microestrutura muda. A tensão de fixação sobe. O tempo de resposta diminui.

Um único surto de 10kA pode degradar um MOV em 2-3%. Isso é invisível. O DPS ainda funciona perfeitamente.

Mas após 20 surtos, você está com 40-60% de capacidade a menos. Após 50 surtos, o MOV está a aproximar-se do fim da vida útil. Após 100 surtos, ele falha — entrando em curto-circuito (ativando o desconector térmico se tiver sorte) ou entrando em circuito aberto (deixando o seu equipamento desprotegido se não tiver).

Um DPS de 50kA tem um “piso” fino de capacidade de MOV. Ele pode lidar com 20-30 eventos de surto significativos antes da substituição.

Um DPS de 300kA tem um “piso” espesso.” Ele pode lidar com 200-300 eventos de surto significativos antes do mesmo nível de degradação.

A classificação kA mais alta não torna cada evento de surto “mais seguro”. Significa apenas que você tem mais eventos de surto no banco antes que a unidade precise de substituição.

É por isso que onde você instala o DPS determina qual classificação kA você precisa. Alguns locais sofrem uma surra diária. Outros veem surtos apenas ocasionalmente.

Vamos mapear o campo de batalha.

Zona 1: O “Guardião” na Sua Entrada de Serviço (150-300kA)

A Missão: Sobrevivência

Localização: Quadro de distribuição principal, painel de entrada de serviço ou combinação medidor-principal.

Classificação Recomendada: 150kA mínimo, 300kA para instalações industriais ou áreas de alta incidência de raios.

Por que Este Local é Diferente:

O seu DPS de entrada de serviço é o portão do castelo. Ele enfrenta a brutalidade bruta e não filtrada da rede elétrica. Aqui está o que atinge este local todos os dias:

Descargas Atmosféricas em Postes Próximos: Quando um raio atinge um poste de eletricidade a 150 metros de distância, o surto propaga-se pelas linhas de energia para o seu edifício. Embora as descargas diretas sejam raras, esses surtos induzidos acontecem dezenas de vezes por ano em regiões de incidência moderada de raios.

Transientes de Comutação da Rede: Cada vez que a empresa de serviços públicos comuta bancos de capacitores, religadores ou interruptores de seccionamento no seu sistema de distribuição, gera um transiente de tensão. Você vê isso como oscilações momentâneas. O seu DPS de entrada de serviço vê isso como eventos de surto.

Surtos Induzidos por Vizinhos: Quando a instalação industrial ao lado liga um motor de 200 HP, ou quando o hospital do outro lado da rua liga a sua máquina de ressonância magnética, pode criar uma queda de tensão que ressalta como um surto. A sua entrada de serviço apanha tudo isso.

Eventos de Eliminação de Falhas: Quando um galho de árvore causa uma falha numa linha de distribuição e a proteção da concessionária a elimina, a interrupção e restauração repentinas criam um surto.

A Surra Diária

Aqui está a verdade desconfortável sobre a proteção contra surtos na entrada de serviço:

Embora seja verdade que 99% dos surtos induzidos por raios medem menos de 10kA (de acordo com dados do IEEE), a frequência de eventos neste local é massiva. Uma instalação comercial típica pode experimentar:

- 50-200 eventos de comutação de rede por ano (surtos de 2-8 kA)

- 10-30 eventos induzidos por raios por ano em áreas moderadas (surtos de 5-15 kA)

- 100-500 eventos de comutação de vizinhos/carga por ano (surtos de 1-5 kA)

Isso é 160-730 eventos de surto anualmente atingindo seu DPS na entrada de serviço.

Se você instalar uma unidade barata de 50kA aqui para “economizar $1.200”, eis o que acontece:

Ano 1: O DPS funciona perfeitamente. Você se parabeniza pela economia. Os MOVs estão se degradando, mas invisivelmente.

Ano 2: Depois de absorver 400 pequenos surtos e 5 eventos moderados de raios, o “desgaste” do MOV é de 60%. A unidade ainda funciona, mas a tensão de fixação subiu de 800V para 950V. Seus eletrônicos sensíveis a jusante começam a experimentar desligamentos incômodos.

Mês 18-24: O DPS falha. Ou o desconector térmico dispara (melhor cenário - você recebe um indicador visual de que está morto), ou ele falha em circuito aberto (pior cenário - você pensa que está protegido, mas não está).

O Evento de Substituição: Agora você precisa agendar um desligamento da instalação para acessar o painel principal com segurança. A produção para. Você paga taxas de emergência para o eletricista. Você envia um DPS de substituição durante a noite. Custo total: $150 (novo DPS) + $800 (horas extras do eletricista) + $12.000 (tempo de inatividade da produção) = $12.950.

E você fará isso a cada 18-24 meses durante a vida útil da instalação.

A Economia do Guardião

Agora vamos calcular os números da unidade de 300kA:

Custo inicial: $1,500

Vida útil esperada na entrada de serviço: 15-20 anos (pode absorver mais de 10.000 eventos de surto antes de atingir 50% de degradação)

Ciclos de Substituição ao Longo de 20 Anos: 1 (instale uma vez, esqueça)

Custo Total: $1.500 + uma taxa de mão de obra de instalação

Compare isso com a estratégia de 50kA:

Custo inicial: $150

Ciclo de Substituição: A cada 18-24 meses

Número de Substituições ao Longo de 20 Anos: 10-13 substituições

Custo por Substituição: $12.950 (DPS + desligamento + mão de obra)

Custo Total: $150 + (11 × $12.950) = $142,600

Você “economizou” $1.200 inicialmente e gastou $141.100 ao longo de 20 anos.

É por isso que engenheiros elétricos experientes não hesitam em DPSs de $1.500 para aplicações de entrada de serviço. Eles não estão pagando por desempenho. Eles estão pagando para evitar o Desligamento às 2 da Manhã.

A Estratégia: Compre capacidade “excessiva” na entrada de serviço. Você não está comprando melhor proteção - você está comprando tranquilidade e eliminando um pesadelo de manutenção recorrente.

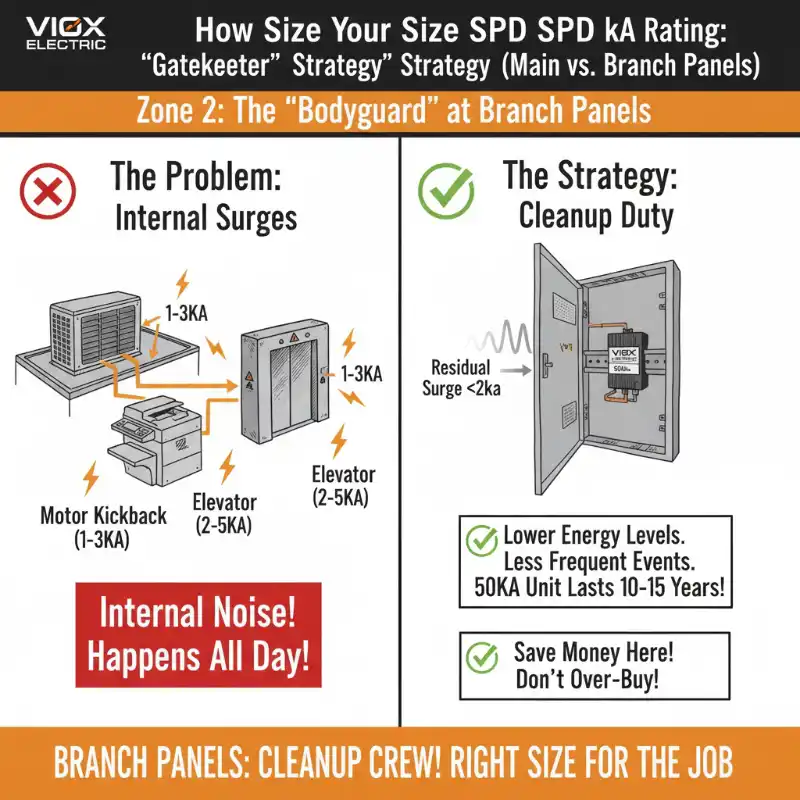

Zona 2: O “Guarda-Costas” nos Painéis de Derivação (50-100kA)

A Missão: Limpeza

Localização: Painéis de distribuição em cada andar, painéis de iluminação, centros de controle de máquinas (CCM), controladores de elevadores.

Classificação Recomendada: 50-80kA (ponto ideal), até 100kA para circuitos de derivação críticos.

Por que Este Local é Diferente:

No momento em que um surto viaja de sua entrada de serviço através de 200 pés de fiação do edifício para atingir um painel de derivação no terceiro andar, algo notável aconteceu:

O Guardião já absorveu a maior parte da energia. Seu DPS na entrada de serviço fixou o surto de raio de entrada de 15kA para um residual de 2kA que agora está se propagando pela fiação do seu edifício.

A impedância da fiação o amortizou ainda mais. A resistência e a indutância de 200 pés de cobre AWG 3 atuam como um filtro, reduzindo esse residual de 2kA para um evento de 0,5-1kA no momento em que atinge o painel de derivação.

O que resta é um surto pequeno e gerenciável - normalmente abaixo de 2kA.

Mas os painéis de derivação enfrentam uma ameaça diferente que a entrada de serviço nunca vê:

Geração Interna de Surto

Cada peça de equipamento rotativo ou indutivo em seu edifício gera surtos quando é ligado:

Motores HVAC: Quando uma unidade de telhado de 10 HP é ligada, a corrente de irrupção pode ser de 60-80 amperes. Quando para, o campo magnético em colapso nas bobinas do motor gera um pico de tensão - normalmente 1-3 kA - que volta pela fiação do circuito de derivação.

Motores de Elevador: Ligar e desligar um elevador cria surtos de irrupção (partida) e de recuo indutivo (parada). Estes são tipicamente eventos de 2-5 kA, dependendo do tamanho do elevador.

Equipamento de soldadura: Soldadores a arco, soldadores por resistência e aquecedores de indução criam transientes de alta frequência quando são ligados. Estes variam de 0,5-2 kA.

Drivers de LED e VFDs: Quando grandes conjuntos de LEDs ou acionamentos de frequência variável são ligados, seus capacitores de entrada carregam violentamente, criando um mini-surto que se propaga para trás no painel de derivação.

Fotocopiadoras, Impressoras a Laser e Cafeteiras: Sim, até mesmo equipamentos de escritório criam surtos. Aquela grande copiadora colorida aquecendo seu fusor? Esse é um evento de surto de 0,2-0,5 kA.

O trabalho do DPS do painel de derivação é limpar este ruído interno para proteger computadores sensíveis, controladores PLC e equipamentos digitais.

Por que kA Inferior Funciona Aqui

Porque os níveis de energia são mais baixos (principalmente abaixo de 2kA) e porque a frequência é menor (talvez 50-100 eventos por ano em vez de 500+), você não precisa da capacidade massiva de uma unidade de entrada de serviço.

Um DPS de 50kA em um painel de derivação normalmente dura 10-15 anos antes que a substituição seja necessária. Isso é aceitável—especialmente porque substituir um DPS de painel de derivação não requer um desligamento completo da instalação. Você pode fazê-lo durante uma janela de manutenção programada, transferindo a carga temporariamente.

O Ponto Ideal: 50-80kA para painéis de derivação padrão. Guarde as classificações de 150kA+ para a entrada de serviço, onde a punição real acontece.

A Estratégia: Não gaste demais aqui. Uma unidade de 50kA fornece proteção adequada para surtos internos e surtos externos residuais que passaram pelo Gatekeeper. Se o painel de derivação servir equipamentos críticos (como um painel de sala de servidores ou um centro de controle de máquina CNC), aumente para 100kA para maior longevidade.

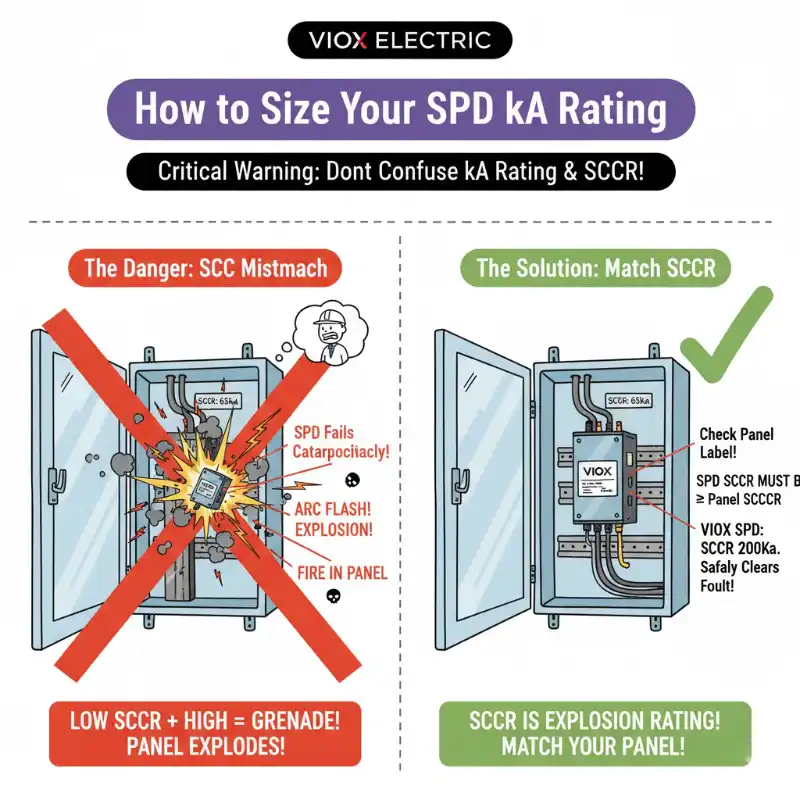

Aviso Crítico: Não Confunda kA com SCCR (Ou Arrisque uma Explosão)

Temos discutido “classificações de kA” por 1.500 palavras. Agora precisamos abordar uma confusão que causou explosões literais em painéis elétricos.

Existem dois números “kA” diferentes em cada etiqueta de DPS, e misturá-los pode transformar seu DPS em uma granada de fragmentação.

As Duas Classificações de kA

1. Classificação de Corrente de Surto (por exemplo, 200kA)

Isso é tudo o que temos discutido—a “Barra de Saúde”, a medida de quantos eventos de surto o DPS pode absorver antes de se desgastar. Quanto maior, melhor para a longevidade.

2. SCCR – Classificação de Corrente de Curto-Circuito (por exemplo, 200kA)

This is the Classificação de Explosão—a corrente de falta máxima que o DPS pode interromper com segurança sem criar um risco de incêndio ou explosão. Isso deve corresponder ou exceder a corrente de falta disponível do seu painel.

Por que o SCCR Importa

Aqui está o que acontece dentro de um DPS quando ele atinge o fim da vida útil:

Idealmente, o desconector térmico do DPS é ativado. Ele desconecta com segurança os MOVs degradados do circuito. Um indicador LED fica vermelho ou uma bandeira aparece. Você vê que o DPS está morto e agenda uma substituição.

Mas se o DPS falhar catastroficamente (curto-circuito interno), ele de repente se parece com um curto total da linha para o terra. Seu painel tenta fornecer toda a corrente de falta que é capaz de—que poderia ser 65kA em uma instalação industrial—através de um dispositivo que foi projetado apenas para lidar com segurança com 5kA.

Se o SCCR do DPS for apenas 5kA, e seu painel puder fornecer 65kA, o DPS não se desconectará com segurança.

Em vez disso, ele irá:

- Formar arco internamente enquanto os contatos tentam se abrir sob corrente massiva

- Gerar plasma dentro do recinto

- Explodir, enviando estilhaços e metal fundido para dentro do painel

- Iniciar um incêndio no invólucro do painel

Isso não é teórico. Isso aconteceu. Repetidamente.

Como Evitar Isso

Regra 1: Sempre verifique a corrente de falta disponível (AFC) no local de instalação. Isso é tipicamente impresso na etiqueta do painel ou pode ser calculado a partir do tamanho e impedância do transformador.

Regra 2: Selecione um DPS com um SCCR que atenda ou exceda a AFC. Se o seu painel mostrar 65kA AFC, seu DPS deve ter um SCCR mínimo de 65kA. A maioria dos DPSs de qualidade tem 200kA SCCR, o que cobre a vasta maioria das instalações.

Regra 3: Não assuma que “200kA” na etiqueta do DPS significa 200kA SCCR. Leia as letras miúdas. Alguns DPSs baratos têm 200kA de Classificação de Surto, mas apenas 5kA SCCR. Estes não são adequados para instalações industriais.

O Aviso: A Classificação de Corrente de Surto e o SCCR são especificações completamente independentes. Um DPS pode ter uma classificação de surto de 300kA e 5kA SCCR (perigoso para uso industrial), ou uma classificação de surto de 50kA e 200kA SCCR (seguro para uso industrial, apenas não durará tanto).

Sempre verifique ambos os números.

A Estratégia do Gatekeeper: Onde Gastar Seu Orçamento

Não existe uma “fórmula mágica” única para dimensionar DPSs, mas existe uma lógica econômica clara. Projetar um sistema de proteção é sobre alocar seu orçamento onde o desgaste é maior.

Zona 1: Entrada de Serviço (Painel Principal)

Classificação: 150-300kA

Porquê: Este local recebe a pancada diária de surtos da rede, raios e eventos dos vizinhos. Frequência de eventos: 200-700 por ano.

Economia: Gaste $1.500 uma vez para uma vida útil de 15-20 anos vs. gaste $150 a cada 18 meses mais $2.000 por desligamento.

Estratégia: Compre capacidade excessiva. É desejável que esta unidade dure uma década sem manutenção.

SCCR: Mínimo de 200kA para instalações industriais.

Zona 2: Painéis de Derivação (Painéis de Distribuição)

Classificação: 50-100kA

Porquê: O Gatekeeper absorveu a maioria das sobretensões externas. Este local lida principalmente com o contragolpe interno do motor e comutação de equipamentos. Frequência: 50-150 eventos por ano.

Economia: Uma unidade de 50kA durará 10-15 anos neste local, e substituí-la não requer o desligamento total da instalação.

Estratégia: Economize dinheiro aqui. Não compre em excesso. 50-80kA é o ponto ideal.

SCCR: Combine com o AFC do seu painel (normalmente 65kA para painéis de derivação, 200kA para MCCs).

Zona 3: Ponto de Uso (Equipamentos Críticos)

Classificação: Unidades dedicadas de 20-50kA

Porquê: Para máquinas de milhões de dólares (equipamentos CNC, scanners de ressonância magnética, ferramentas de fabricação de semicondutores), instale um DPS dedicado diretamente no equipamento.

Economia: O equipamento em si custa de 500.000 a 5.000.000 de dólares. Um DPS dedicado de 500 dólares é um seguro.

Estratégia: Esta é a terceira camada de defesa. A entrada de serviço e os DPS do painel de derivação já removeram 95% da energia de surto. Esta camada final protege contra os últimos 5% e contra o ruído local.

SCCR: Combine as especificações da placa de identificação do equipamento.

O ROI da Defesa em Camadas

Quando você implanta todas as três zonas, você cria o que o IEEE chama de “coordenação em cascata” - cada camada reduz a energia de surto, de modo que a próxima camada lida com eventos progressivamente menores:

Entrada de Serviço (300kA): Fixa um surto de raio de 20kA para baixo para 2kA

↓

Painel de Derivação (50kA): Fixa o residual de 2kA para baixo para 0,3kA

↓

Ponto de Uso (20kA): Fixa o residual final de 0,3kA para baixo para 0,05kA (essencialmente nada)

Seu equipamento sensível vê Redução de 99,75% da energia de surto original.

Investimento Total:

- Entrada de Serviço: 1.500 dólares

- 5 Painéis de Derivação: 5 × 200 dólares = 1.000 dólares

- 3 Unidades de Equipamentos Críticos: 3 × 500 dólares = 1.500 dólares

- Total: 4.000 dólares

Alternativa: DPSs Baratos em Todos os Lugares

- Entrada de Serviço 50kA: 150 dólares (substituído 11 vezes ao longo de 20 anos = 2.950 dólares por substituição × 11 = 142.450 dólares)

- 5 Painéis de Derivação: Sem proteção (economizando 1.000 dólares)

- Falhas de equipamentos ao longo de 20 anos: $250,000-$1,000,000 (estimativa baseada no tempo de inatividade médio e nos custos de reparo)

A Estratégia Gatekeeper não é a mais barata inicialmente. É a mais barata ao longo da vida útil da instalação.

Normas Técnicas e Soluções VIOX

Normas Regulamentadoras

IEEE C62.41.2-2002: Prática Recomendada sobre a Caracterização de Surtos em Circuitos de Potência CA de Baixa Tensão

- Define categorias de ambiente de surto:

- Categoria C: Entrada de serviço, circuitos externos (alta exposição: surtos de 10kV/10kA possíveis)

- Categoria B: Circuitos de derivação, alimentadores (exposição média: surtos típicos de 6kV/3kA)

- Essas categorias orientam a seleção de DPS para cada zona

UL 1449 (5ª Edição): Norma para Dispositivos de Proteção contra Surtos

- Publicado em janeiro de 2021, aprovado pela ANSI em dezembro de 2022

- Define requisitos de teste, padrões SCCR e requisitos de desconexão de segurança

- Todos os DPSs devem ser listados na UL 1449 para instalações na América do Norte, de acordo com os requisitos do NEC

Compreendendo a Degradação do MOV

A degradação do MOV é definida por uma mudança na tensão do varistor (V₁mA - a tensão na qual o MOV começa a conduzir 1 mA de corrente). Surtos repetidos causam envelhecimento térmico dos limites de grão de óxido de zinco.

Classificações de kA mais altas são alcançadas pela conexão em paralelo de vários MOVs, o que compartilha a corrente de surto entre vários dispositivos. Isso reduz o estresse térmico em cada MOV individual, estendendo a vida útil agregada do conjunto.

Exemplo: Um surto de 10kA através de um único MOV pode causar 5% de degradação. O mesmo surto de 10kA através de 10 MOVs paralelos (cada um transportando 1kA) pode causar apenas 0,5% de degradação por MOV. O conjunto dura 10× mais.

Soluções VIOX SPD

A VIOX fabrica uma linha completa de dispositivos de proteção contra surtos listados na UL 1449, projetados para a Estratégia Gatekeeper:

DPSs de Entrada de Serviço (Tipo 1):

- Classificações: corrente de surto de 150kA, 200kA, 300kA

- SCCR: 200kA padrão (atende aos requisitos do painel industrial)

- Configurações de montagem em trilho DIN ou painel

- Indicação de alarme visual e remoto

- Desconexão térmica com design à prova de falhas

DPSs de Painel de Derivação (Tipo 2):

- Classificações: corrente de surto de 50kA, 80kA, 100kA

- SCCR: opções de 65kA ou 200kA

- Montagem compacta em trilho DIN

- Indicadores de status LED

- Módulos de substituição plug-in para fácil manutenção

Todos os DPS VIOX apresentam:

- Listagem completa UL 1449 5ª Edição

- Ampla compatibilidade de faixa de tensão (120V-690V)

- Faixa de temperatura de operação: -40°C a +85°C

- Garantia de cinco anos

- Projetado e testado para sistemas elétricos norte-americanos

Quando estiver pronto para implementar a Estratégia do Gatekeeper com DPSs que combinam confiabilidade de nível industrial com economia direta, a VIOX oferece a solução.

Conclusão: Não Veja kA como Força — Veja Como Investimento em “Tempo Até a Substituição”

Você começou este artigo em uma reunião de orçamento, encarando uma diferença de preço de US$ 1.200 e se perguntando se isso importava.

Agora você entende:

A classificação kA não é uma medida de quão bem um DPS bloqueia a tensão durante um único evento de surto. Tanto a unidade de 50kA quanto a unidade de 300kA fixam aproximadamente a mesma tensão. Ambos fornecem a mesma “proteção” durante esse único evento.

A classificação kA é uma medida de quantos eventos de surto o DPS pode suportar antes de morrer.

Pense nisso como a profundidade do sulco do pneu. O pneu de corrida e o pneu de caminhão dirigem a 96 km/h. Mas dirija sobre cascalho todos os dias, e o pneu de corrida fica careca em um mês. O pneu de caminhão dura 10 anos.

A Estratégia do Gatekeeper é simples:

Zona 1 (Entrada de Serviço): Instale capacidade de 150-300kA. Este local recebe a surra diária — 200 a 700 eventos de surto por ano de raios, comutação de rede e cargas de vizinhos. Gaste o dinheiro uma vez. Obtenha 15-20 anos de operação livre de manutenção. Evite o desligamento às 2 da manhã.

Zona 2 (Painéis de Derivação): Instale capacidade de 50-100kA. O Gatekeeper já absorveu os surtos externos. Este local lida com o contragolpe interno do motor e a comutação de equipamentos. Uma unidade de 50kA durará de 10 a 15 anos aqui. É aqui que você economiza dinheiro sem sacrificar a proteção.

Zona 3 (Equipamento Crítico): Instale DPSs de ponto de uso dedicados de 20-50kA para máquinas de milhões de dólares. Isso é seguro.

E sempre verifique se o SCCR corresponde à corrente de falta do seu painel. Não deixe que um DPS barato com SCCR inadequado se transforme em uma granada de fragmentação.

Os números são claros: Gaste US$ 1.500 uma vez na entrada de serviço ou gaste US$ 42.600 ao longo de 20 anos substituindo unidades baratas e pagando por desligamentos de instalações.

A escolha não é sobre comprar o maior número. É sobre implantar a capacidade certa no local certo — e entender que você não está comprando desempenho, está comprando tempo.