ຄໍາຕອບໂດຍກົງ: ຜົນກະທົບອັນຕະລາຍຂອງການປົນເປື້ອນຝຸ່ນ

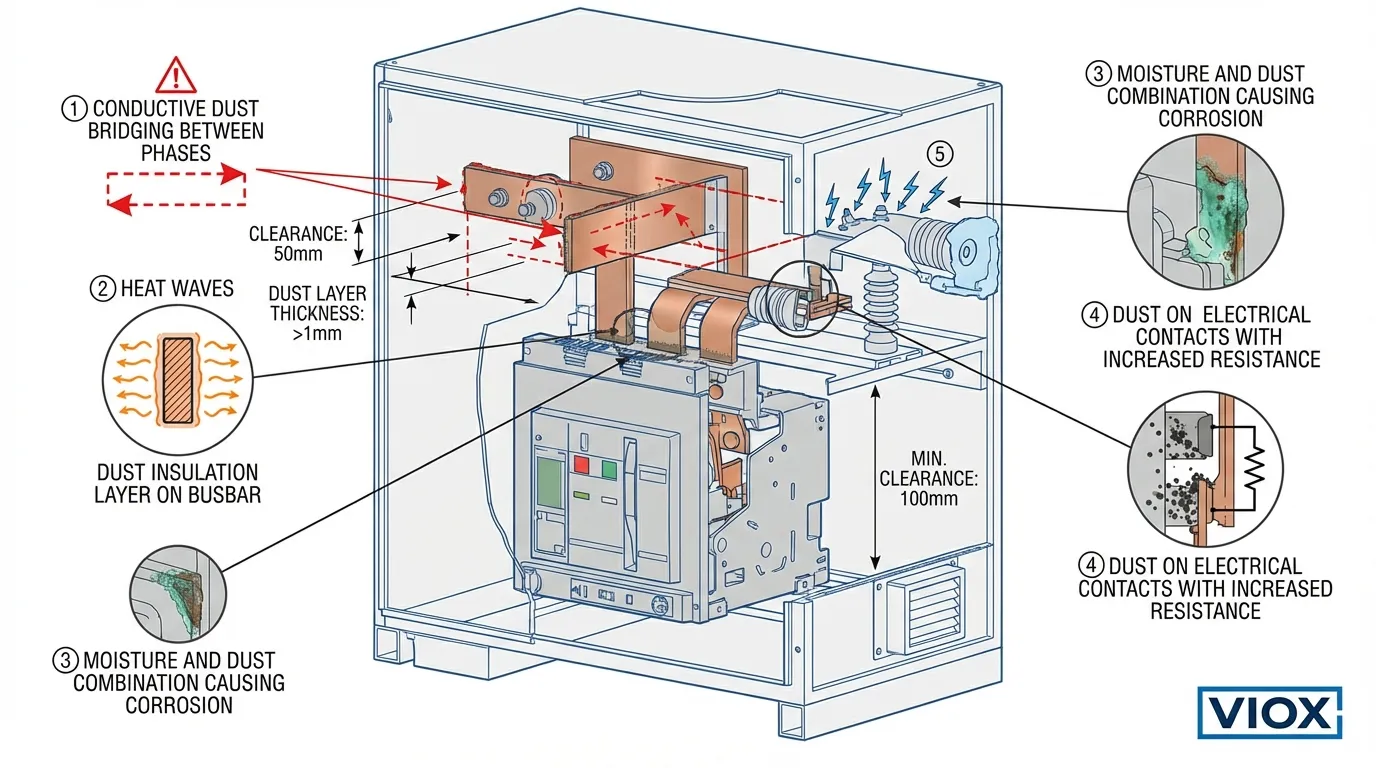

ການສະສົມຂອງຝຸ່ນໃນສະວິດເກຍສ້າງເສັ້ນທາງຄວາມລົ້ມເຫຼວທີ່ສໍາຄັນຫ້າຢ່າງທີ່ທໍາລາຍຄວາມຫນ້າເຊື່ອຖືຂອງລະບົບໄຟຟ້າ: ມັນສ້າງຂົວທີ່ນໍາໄຟຟ້າເຮັດໃຫ້ເກີດວົງຈອນສັ້ນແລະເຫດການ arc flash, ເຮັດຫນ້າທີ່ເປັນ insulation ຄວາມຮ້ອນທີ່ເຮັດໃຫ້ເກີດຄວາມຮ້ອນເກີນແລະການເສື່ອມສະພາບຂອງອົງປະກອບ, ເລັ່ງການກັດກ່ອນເມື່ອລວມກັບຄວາມຊຸ່ມຊື່ນ, ລົບກວນຄວາມຖືກຕ້ອງຂອງ relay ປ້ອງກັນ, ແລະສ້າງເສັ້ນທາງຕິດຕາມໃນ insulators ທີ່ນໍາໄປສູ່ການໄຫຼບາງສ່ວນ. ການສຶກສາຊີ້ໃຫ້ເຫັນວ່າ 85% ຂອງຄວາມລົ້ມເຫຼວທີ່ລົບກວນໃນສະຖານີໄຟຟ້າແມ່ນກ່ຽວຂ້ອງກັບການປົນເປື້ອນສິ່ງແວດລ້ອມ, ໂດຍມີຝຸ່ນເປັນຜູ້ປະກອບສ່ວນຕົ້ນຕໍ. ເຖິງແມ່ນວ່າອະນຸພາກຝຸ່ນທີ່ເບິ່ງຄືວ່າບໍ່ເປັນອັນຕະລາຍທີ່ມີຂະຫນາດ 50-100 ໄມຄອນກໍ່ສາມາດເຮັດໃຫ້ເກີດຄວາມລົ້ມເຫຼວທີ່ຮ້າຍແຮງໃນສະວິດເກຍທີ່ທັນສະໄຫມບ່ອນທີ່ໄລຍະຫ່າງຂອງອົງປະກອບໄດ້ຫຼຸດລົງເພື່ອຮອງຮັບການອອກແບບທີ່ຫນາແຫນ້ນ.

Key Takeaways

- ການປົນເປື້ອນຝຸ່ນເຮັດໃຫ້ເກີດ 5 ຮູບແບບຄວາມລົ້ມເຫຼວທີ່ສໍາຄັນ: ວົງຈອນສັ້ນ, ຄວາມຮ້ອນເກີນ, ການເລັ່ງການກັດກ່ອນ, ການເຮັດວຽກຜິດປົກກະຕິຂອງ relay, ແລະການແຕກແຍກຂອງ insulation

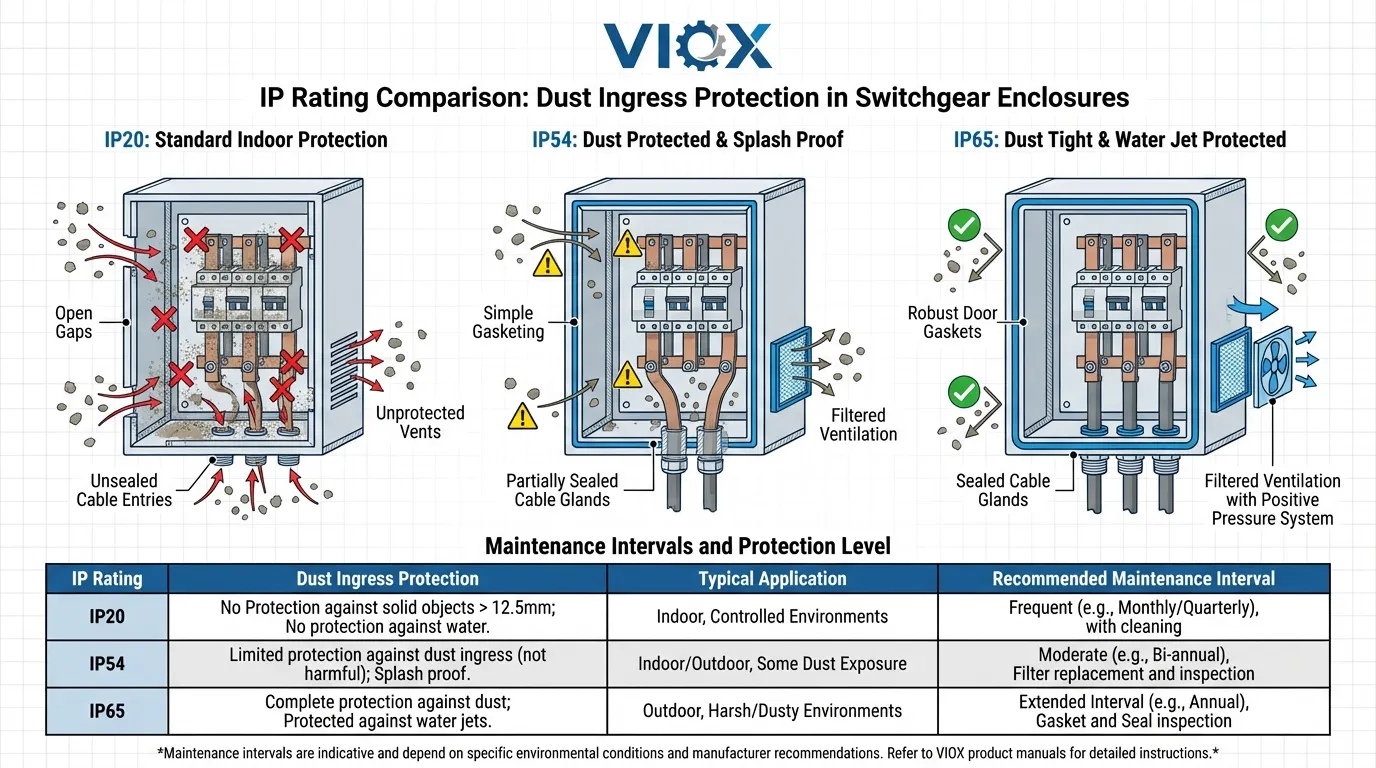

- IP ratings ມີຄວາມສໍາຄັນ: ສະວິດເກຍທີ່ມີການປ້ອງກັນ IP54 ຫຼືສູງກວ່າຫຼຸດຜ່ອນຄວາມລົ້ມເຫຼວທີ່ກ່ຽວຂ້ອງກັບຝຸ່ນຢ່າງຫຼວງຫຼາຍ

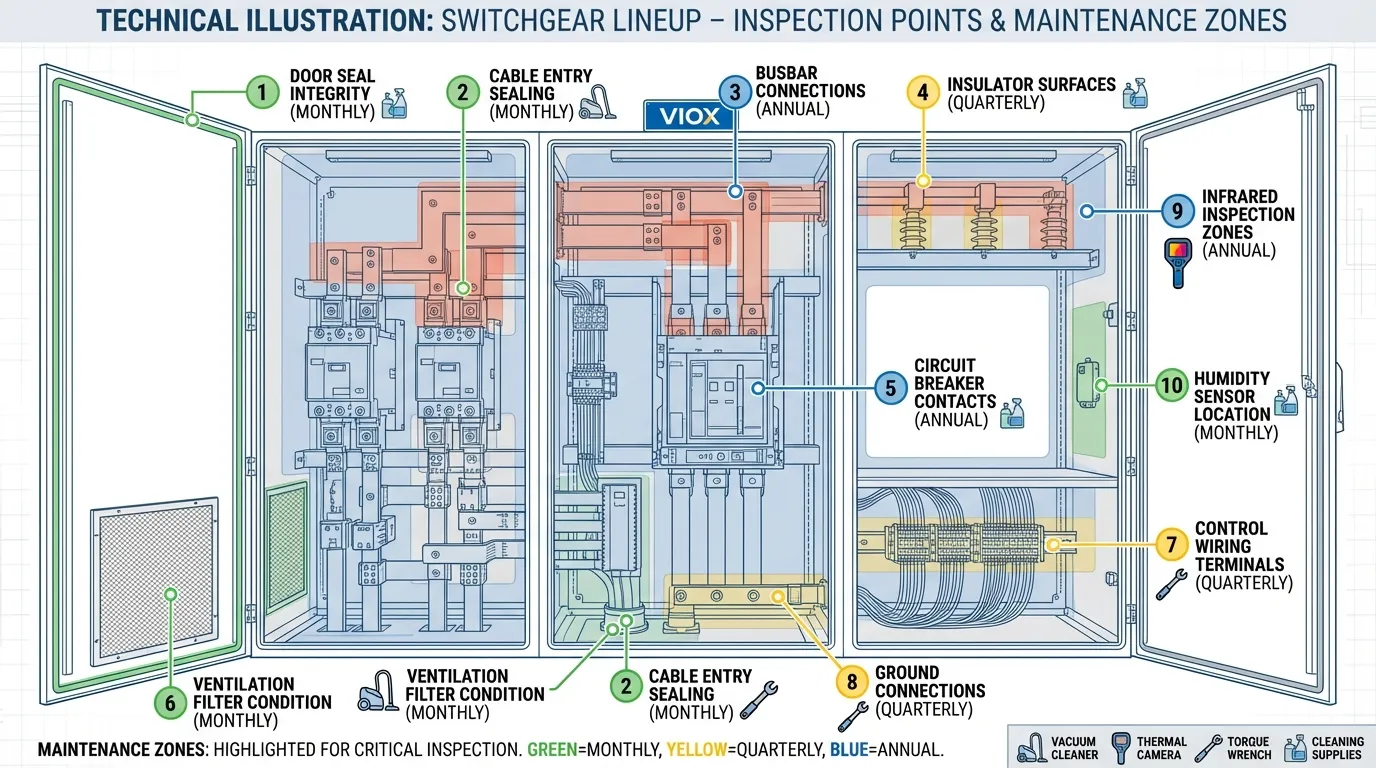

- ໄລຍະການບໍາລຸງຮັກສາແມ່ນສໍາຄັນ: ສະຖານທີ່ໃນສະພາບແວດລ້ອມທີ່ມີຝຸ່ນຕ້ອງການການກວດກາປະຈໍາໄຕມາດທຽບກັບການກວດສອບປະຈໍາປີໃນສະພາບແວດລ້ອມທີ່ສະອາດ

- ຜົນກະທົບດ້ານຄ່າໃຊ້ຈ່າຍແມ່ນສໍາຄັນ: ຄວາມລົ້ມເຫຼວທີ່ກ່ຽວຂ້ອງກັບຝຸ່ນມີຄ່າໃຊ້ຈ່າຍ 3-5 ເທົ່າຫຼາຍກວ່າໂຄງການບໍາລຸງຮັກສາປ້ອງກັນ

- ອຸປະກອນທີ່ທັນສະໄຫມມີຄວາມສ່ຽງຫຼາຍກວ່າ: ໄລຍະຫ່າງຂອງອົງປະກອບທີ່ແຫນ້ນຫນາໃນສະວິດເກຍທີ່ຫນາແຫນ້ນເພີ່ມຄວາມອ່ອນໄຫວຕໍ່ການປົນເປື້ອນຂອງອະນຸພາກ

ເຂົ້າໃຈຝຸ່ນເປັນໄພຂົ່ມຂູ່ທາງໄຟຟ້າ

ສິ່ງທີ່ເຮັດໃຫ້ຝຸ່ນເປັນອັນຕະລາຍໃນສະວິດເກຍ?

ອະນຸພາກຝຸ່ນບໍ່ເປັນກາງທາງໄຟຟ້າ. ອີງຕາມອົງປະກອບຂອງພວກມັນ—ການຍື່ນໂລຫະ, ກາກບອນ, ຝຸ່ນແຮ່ທາດ, ຫຼືສານອິນຊີ—ພວກມັນສະແດງລະດັບການນໍາໄຟຟ້າທີ່ແຕກຕ່າງກັນ. ເມື່ອຝຸ່ນສະສົມຢູ່ໃນອົງປະກອບໄຟຟ້າ, ມັນສ້າງສະຖານະການອັນຕະລາຍຫຼາຍຢ່າງທີ່ການປ້ອງກັນວົງຈອນແບບດັ້ງເດີມບໍ່ສາມາດປ້ອງກັນໄດ້.

ຂະຫນາດຂອງອະນຸພາກມີຄວາມສໍາຄັນຢ່າງຫຼວງຫຼາຍ. ອະນຸພາກຝຸ່ນລະອຽດ (ຕ່ໍາກວ່າ 100 ໄມຄອນ) ເຈາະເລິກເຂົ້າໄປໃນຫ້ອງສະວິດເກຍແລະຕົກລົງເທິງຫນ້າດິນທີ່ສໍາຄັນເຊັ່ນ: busbars, contacts, ແລະ insulation barriers. ອະນຸພາກຈຸລະທັດເຫຼົ່ານີ້, ເບິ່ງບໍ່ເຫັນໃນການກວດກາແບບທໍາມະດາ, ສະສົມໃນໄລຍະເດືອນເພື່ອສ້າງເງື່ອນໄຂຄວາມລົ້ມເຫຼວ. ເຂົ້າໃຈການກໍ່ສ້າງອົງປະກອບໄຟຟ້າ ຊ່ວຍອະທິບາຍວ່າເປັນຫຍັງຝຸ່ນຈຶ່ງເປັນໄພຂົ່ມຂູ່ທີ່ຍືນຍົງ.

ຫ້າກົນໄກຄວາມລົ້ມເຫຼວ

1. ການເຊື່ອມຕໍ່ໄຟຟ້າແລະວົງຈອນສັ້ນ

ຝຸ່ນທີ່ອຸດົມດ້ວຍໂລຫະຫຼືອະນຸພາກກາກບອນສ້າງເສັ້ນທາງທີ່ນໍາໄຟຟ້າລະຫວ່າງໄລຍະຫຼືລະຫວ່າງພາກສ່ວນທີ່ມີພະລັງງານແລະດິນ. ໃນສະວິດເກຍທີ່ທັນສະໄຫມທີ່ມີການອອກແບບທີ່ຫນາແຫນ້ນ, ການເກັບກູ້ລະຫວ່າງ conductors ໄດ້ຫຼຸດລົງຈາກໄລຍະຫ່າງ 50mm ໃນອະດີດເຖິງຫນ້ອຍກວ່າ 20mm ໃນບາງຄໍາຮ້ອງສະຫມັກ. ການຫຼຸດຜ່ອນນີ້ເຮັດໃຫ້ອຸປະກອນມີຄວາມສ່ຽງຕໍ່ການເຊື່ອມຕໍ່ຝຸ່ນຫຼາຍຂຶ້ນ.

ເມື່ອຝຸ່ນທີ່ນໍາໄຟຟ້າສະສົມ, ມັນຄ່ອຍໆຫຼຸດຜ່ອນຊ່ອງຫວ່າງອາກາດທີ່ມີປະສິດທິພາບລະຫວ່າງ conductors. ພາຍໃຕ້ແຮງດັນປະຕິບັດງານປົກກະຕິ, ການໄຫຼບາງສ່ວນເລີ່ມຕົ້ນ, carbonizing ຝຸ່ນແລະສ້າງເສັ້ນທາງທີ່ນໍາໄຟຟ້າເພີ່ມຂຶ້ນ. ໃນທີ່ສຸດ, ວົງຈອນສັ້ນທີ່ສົມບູນເກີດຂື້ນ, ມັກຈະເຮັດໃຫ້ເກີດເຫດການ arc flash ທີ່ສາມາດທໍາລາຍອຸປະກອນແລະເປັນອັນຕະລາຍຕໍ່ບຸກຄະລາກອນ.

2. Insulation ຄວາມຮ້ອນແລະຄວາມຮ້ອນເກີນ

ຝຸ່ນທີ່ບໍ່ນໍາໄຟຟ້າເຮັດຫນ້າທີ່ເປັນ insulation ຄວາມຮ້ອນ, ເຄືອບຫນ້າດິນທີ່ລະບາຍຄວາມຮ້ອນແລະດັກຄວາມຮ້ອນພາຍໃນອົງປະກອບ. ເຄື່ອງຕັດວົງຈອນ, contactors, ແລະ busbars ສ້າງຄວາມຮ້ອນໃນລະຫວ່າງການປະຕິບັດງານປົກກະຕິ. ຜູ້ຜະລິດອອກແບບອົງປະກອບເຫຼົ່ານີ້ດ້ວຍໂປຣໄຟລ໌ຄວາມຮ້ອນສະເພາະໂດຍສົມມຸດວ່າການໄຫຼວຽນຂອງອາກາດທີ່ພຽງພໍແລະການລະບາຍຄວາມຮ້ອນ.

ຊັ້ນຝຸ່ນ 2mm ສາມາດຫຼຸດຜ່ອນປະສິດທິພາບການລະບາຍຄວາມຮ້ອນໄດ້ 40-60%, ເຮັດໃຫ້ອົງປະກອບເຮັດວຽກສູງກວ່າອຸນຫະພູມທີ່ກໍານົດໄວ້. ການແກ່ຄວາມຮ້ອນທີ່ເລັ່ງນີ້ຫຼຸດຜ່ອນອາຍຸການໃຊ້ງານຂອງອົງປະກອບຈາກ 20-30 ປີທີ່ຄາດໄວ້ເຖິງ 5-10 ປີ. ການເພີ່ມຂຶ້ນຂອງອຸນຫະພູມຍັງມີຜົນກະທົບຕໍ່ການປັບທຽບອຸປະກອນປ້ອງກັນຄວາມຮ້ອນ, ເຊິ່ງອາດຈະເຮັດໃຫ້ເກີດການ tripping nuisance ຫຼື, ຮ້າຍແຮງກວ່າເກົ່າ, ຄວາມລົ້ມເຫຼວທີ່ຈະເດີນທາງໃນລະຫວ່າງເງື່ອນໄຂ overload ຕົວຈິງ.

3. ການດູດຊຶມຄວາມຊຸ່ມຊື່ນແລະການກັດກ່ອນ

ຝຸ່ນແມ່ນ hygroscopic—ມັນດູດຊຶມແລະຮັກສາຄວາມຊຸ່ມຊື່ນຈາກອາກາດ. ໃນສະພາບແວດລ້ອມທີ່ມີການເຫນັງຕີງຂອງຄວາມຊຸ່ມຊື່ນ, ຊັ້ນຝຸ່ນເຮັດຫນ້າທີ່ເປັນອ່າງເກັບນ້ໍາຄວາມຊຸ່ມຊື່ນ, ຮັກສາຄວາມຊຸ່ມຊື່ນໃນທ້ອງຖິ່ນສູງເຖິງແມ່ນວ່າສະພາບແວດລ້ອມຈະດີຂຶ້ນ. ນີ້ສ້າງເງື່ອນໄຂທີ່ເຫມາະສົມສໍາລັບການກັດກ່ອນ electrochemical ຂອງ conductors ທອງແດງແລະອາລູມິນຽມ, contacts ເງິນ, ແລະອົງປະກອບ enclosure ເຫຼັກ.

ການປະສົມປະສານຂອງຄວາມຊຸ່ມຊື່ນແລະຝຸ່ນປະກອບເປັນ electrolyte ທີ່ອ່ອນແອ. ເມື່ອມີແຮງດັນໄຟຟ້າ, ການກັດກ່ອນ galvanic ເລັ່ງ, ໂດຍສະເພາະຢູ່ຈຸດເຊື່ອມຕໍ່ບ່ອນທີ່ໂລຫະທີ່ບໍ່ຄ້າຍຄືກັນພົບກັນ. ເຂົ້າໃຈລະດັບຄວາມຕ້ານທານການກັດກ່ອນ ແມ່ນສິ່ງຈໍາເປັນສໍາລັບການກໍານົດສະວິດເກຍໃນສະພາບແວດລ້ອມທີ່ຮຸນແຮງ.

4. ຄວາມຕ້ານທານການຕິດຕໍ່ແລະ Arcing

ການປົນເປື້ອນຝຸ່ນໃນ contacts ໄຟຟ້າເພີ່ມຄວາມຕ້ານທານການຕິດຕໍ່, ເຊິ່ງສ້າງຄວາມຮ້ອນເພີ່ມເຕີມຢູ່ຈຸດເຊື່ອມຕໍ່. ຄວາມຮ້ອນໃນທ້ອງຖິ່ນນີ້ເຮັດໃຫ້ຫນ້າດິນຕິດຕໍ່ເສື່ອມໂຊມຕື່ມອີກ, ສ້າງວົງຈອນຄວາມລົ້ມເຫຼວທີ່ກ້າວຫນ້າ. ໃນ contactors ແລະ circuit breakers, ຄວາມຕ້ານທານການຕິດຕໍ່ທີ່ເພີ່ມຂຶ້ນມີຜົນກະທົບຕໍ່ທັງຄວາມສາມາດໃນການບັນທຸກກະແສໄຟຟ້າແລະການປະຕິບັດການຂັດຂວາງ.

contacts ຄວາມຕ້ານທານສູງຍັງຜະລິດ arcing ໃນລະຫວ່າງການປະຕິບັດງານ switching. Arcing ຫຼາຍເກີນໄປເຊາະເຈື່ອນຫນ້າດິນຕິດຕໍ່, ເງິນຝາກກາກບອນ, ແລະໃນທີ່ສຸດກໍ່ນໍາໄປສູ່ການເຊື່ອມໂລຫະຕິດຕໍ່ຫຼືຄວາມລົ້ມເຫຼວທີ່ສົມບູນ. ໃນຄໍາຮ້ອງສະຫມັກຄວບຄຸມມໍເຕີ, ນີ້ສາມາດເຮັດໃຫ້ບໍ່ສາມາດຕັດການເຊື່ອມຕໍ່ມໍເຕີໃນລະຫວ່າງເຫດສຸກເສີນ.

5. ການຕິດຕາມ Insulation ແລະການໄຫຼບາງສ່ວນ

ເມື່ອຝຸ່ນສະສົມຢູ່ເທິງຫນ້າດິນ insulation, ມັນສ້າງຊັ້ນທີ່ນໍາໄຟຟ້າຫຼືເຄິ່ງນໍາໄຟຟ້າ. ພາຍໃຕ້ຄວາມກົດດັນຂອງແຮງດັນ, ໂດຍສະເພາະໃນສະພາບທີ່ມີຄວາມຊຸ່ມຊື່ນສູງ, ການຕິດຕາມຫນ້າດິນເກີດຂື້ນ—ການເສື່ອມສະພາບທີ່ກ້າວຫນ້າບ່ອນທີ່ເສັ້ນທາງ carbonized ສ້າງຂຶ້ນທົ່ວຫນ້າດິນ insulator. ປະກົດການນີ້ແມ່ນມີບັນຫາໂດຍສະເພາະໃນ ສະວິດເກຍແຮງດັນປານກາງ ບ່ອນທີ່ຄວາມກົດດັນຂອງແຮງດັນແມ່ນສໍາຄັນ.

ກິດຈະກໍາການໄຫຼບາງສ່ວນເລັ່ງການແກ່ insulation. ການຄົ້ນຄວ້າຊີ້ໃຫ້ເຫັນວ່າ 85% ຂອງຄວາມລົ້ມເຫຼວທີ່ລົບກວນໃນສະຖານີໄຟຟ້າແມ່ນກ່ຽວຂ້ອງກັບການໄຫຼບາງສ່ວນ, ໂດຍມີຝຸ່ນແລະຄວາມຊຸ່ມຊື່ນເປັນຜູ້ປະກອບສ່ວນຕົ້ນຕໍ. ກິດຈະກໍາການໄຫຼອອກຜະລິດ ozone, ອາຊິດ nitric, ແລະຄວາມຮ້ອນ, ເຮັດໃຫ້ວັດສະດຸ insulation ເສື່ອມໂຊມຕື່ມອີກໃນຂະບວນການຄວາມລົ້ມເຫຼວ cascading.

ຕາຕະລາງປຽບທຽບຜົນກະທົບຂອງຝຸ່ນ

| ກົນໄກຄວາມລົ້ມເຫຼວ | ເວລາທີ່ຈະລົ້ມເຫຼວ | ສັນຍານເຕືອນ | ຄ່າໃຊ້ຈ່າຍໃນການສ້ອມແປງປົກກະຕິ | ວິທີການປ້ອງກັນ |

|---|---|---|---|---|

| ການເຊື່ອມຕໍ່ໄຟຟ້າ | 6-18 ເດືອນ | ສັນຍານເຕືອນຄວາມຜິດພາດຂອງດິນເພີ່ມຂຶ້ນ, arcing ທີ່ເບິ່ງເຫັນໄດ້ | $15,000-$50,000 | enclosures IP54+, ການທໍາຄວາມສະອາດປະຈໍາໄຕມາດ |

| Thermal Overload | 12-36 ເດືອນ | ຈຸດຮ້ອນ infrared, discoloration, ກິ່ນ insulation | $8,000-$25,000 | ການຖ່າຍຮູບຄວາມຮ້ອນ, ຕົວກອງລະບາຍອາກາດ |

| ການກັດກ່ອນ | 18-48 ເດືອນ | ເງິນຝາກສີຂຽວ / ສີຂາວ, ການເຊື່ອມຕໍ່ loosening | $5,000-$20,000 | Dehumidification, enclosures ປະທັບຕາ |

| ການເສື່ອມສະພາບຂອງໜ້າສຳຜັດ | 12-24 ເດືອນ | Chattering, coil burnout, ການດໍາເນີນງານທີ່ຫຍຸ້ງຍາກ | $3,000-$15,000 | ການທໍາຄວາມສະອາດການຕິດຕໍ່, ການຫລໍ່ລື່ນທີ່ເຫມາະສົມ |

| ການຕິດຕາມ Insulation | 24-60 ເດືອນ | ການກວດສອບການໄຫຼບາງສ່ວນ, corona ທີ່ເບິ່ງເຫັນໄດ້ໃນຕອນກາງຄືນ | $20,000-$100,000+ | ການທໍາຄວາມສະອາດເປັນປົກກະຕິ, ການຕິດຕາມກວດກາການໄຫຼບາງສ່ວນ |

ປັດໃຈສິ່ງແວດລ້ອມແລະອັດຕາການສະສົມຂອງຝຸ່ນ

ຄວາມທ້າທາຍດ້ານຂີ້ຝຸ່ນສະເພາະອຸດສາຫະກໍາ

ອຸດສາຫະກໍາທີ່ແຕກຕ່າງກັນປະເຊີນກັບໂປຣໄຟລ໌ການປົນເປື້ອນຂີ້ຝຸ່ນທີ່ແຕກຕ່າງກັນ:

ການຜະລິດແລະການເຮັດວຽກໂລຫະ: ຂີ້ຝຸ່ນໂລຫະຈາກການຂັດ, ການຕັດ, ແລະການປະຕິບັດງານເຄື່ອງຈັກແມ່ນມີການນໍາໄຟຟ້າສູງ. ສະຖານທີ່ທີ່ມີເຄື່ອງ CNC, ການປະຕິບັດງານເຊື່ອມໂລຫະ, ຫຼືການຜະລິດໂລຫະສ້າງອະນຸພາກໂລຫະລະອຽດທີ່ເດີນທາງຜ່ານລະບົບລະບາຍອາກາດແລະຕົກລົງໃນຫ້ອງໄຟຟ້າ.

ການຂຸດຄົ້ນບໍ່ແຮ່ແລະຊີມັງ: ຂີ້ຝຸ່ນແຮ່ທາດທີ່ມີເນື້ອໃນ silica ສູງແມ່ນຂັດແລະດູດຊຶມຄວາມຊຸ່ມ. ສະຖານທີ່ເຫຼົ່ານີ້ປະສົບກັບອັດຕາການສະສົມຂີ້ຝຸ່ນສູງສຸດ, ມັກຈະຕ້ອງການໄລຍະການບໍາລຸງຮັກສາປະຈໍາເດືອນແທນທີ່ຈະເປັນຕາຕະລາງປະຈໍາໄຕມາດມາດຕະຖານ.

ການປຸງແຕ່ງອາຫານ: ຂີ້ຝຸ່ນອິນຊີລວມກັບຄວາມຊຸ່ມຊື່ນສູງສ້າງເງື່ອນໄຂທີ່ຮຸນແຮງໂດຍສະເພາະ. ແປ້ງ, ນໍ້າຕານ, ແລະຂີ້ຝຸ່ນເມັດພືດສາມາດນໍາໄຟຟ້າໄດ້ເມື່ອປຽກແລະຍັງດຶງດູດສັດຕູພືດທີ່ສ້າງການປົນເປື້ອນເພີ່ມເຕີມ.

ສູນຂໍ້ມູນແລະຫ້ອງສະອາດ: ເຖິງແມ່ນວ່າຢູ່ໃນສະພາບແວດລ້ອມທີ່ຄວບຄຸມ, ຂີ້ຝຸ່ນຈາກການດູດອາກາດພາຍນອກ, ກິດຈະກໍາການກໍ່ສ້າງ, ຫຼືການສວມໃສ່ອຸປະກອນສະສົມຕາມການເວລາ. ມູນຄ່າສູງຂອງເວລາເຮັດວຽກໃນສະຖານທີ່ເຫຼົ່ານີ້ເຮັດໃຫ້ການຢຸດເຮັດວຽກທີ່ກ່ຽວຂ້ອງກັບຂີ້ຝຸ່ນມີລາຄາແພງໂດຍສະເພາະ.

ສະພາບອາກາດແລະການປ່ຽນແປງຕາມລະດູການ

ສະຖານທີ່ຕັ້ງພູມສາດມີຜົນກະທົບຢ່າງຫຼວງຫຼາຍຕໍ່ຮູບແບບການສະສົມຂີ້ຝຸ່ນ. ສະຖານທີ່ຢູ່ໃນເຂດແຫ້ງແລ້ງປະເຊີນກັບຄວາມເຂັ້ມຂົ້ນຂອງຂີ້ຝຸ່ນໃນອາກາດສູງກວ່າ, ໃນຂະນະທີ່ການຕິດຕັ້ງແຄມຝັ່ງທະເລຈັດການກັບຂີ້ຝຸ່ນທີ່ມີເກືອທີ່ເລັ່ງການກັດກ່ອນ. ການປ່ຽນແປງຕາມລະດູການກໍ່ມີຄວາມສໍາຄັນເຊັ່ນກັນ—ລະອອງເກສອນໃນລະດູໃບໄມ້ປົ່ງ, ຂີ້ຝຸ່ນກະສິກໍາໃນລະດູໃບໄມ້ປົ່ງ, ແລະອະນຸພາກລະບົບຄວາມຮ້ອນໃນລະດູຫນາວລ້ວນແຕ່ປະກອບສ່ວນເຂົ້າໃນວົງຈອນການປົນເປື້ອນ.

ລະດັບການປ້ອງກັນ IP Rating

ຄວາມເຂົ້າໃຈ ການຈັດອັນດັບ IP ແມ່ນສິ່ງຈໍາເປັນສໍາລັບການກໍານົດການປ້ອງກັນ switchgear ທີ່ເຫມາະສົມ. ມາດຕະຖານ IEC 60529 ກໍານົດລະດັບການປ້ອງກັນ ingress ໂດຍໃຊ້ລະຫັດສອງຕົວເລກ.

ການປຽບທຽບ IP Rating ສໍາລັບການນໍາໃຊ້ Switchgear

| ການຈັດອັນດັບ IP | ປ້ອງກັນຝຸ່ນ | ການປົກປ້ອງຄວາມຊຸ່ມຊື່ນ | Typical Application | ໄລຍະການບໍາລຸງຮັກສາ |

|---|---|---|---|---|

| IP20 | ປ້ອງກັນນິ້ວມື/ວັດຖຸຂະຫນາດໃຫຍ່ເທົ່ານັ້ນ | ບໍ່ມີການປົກປ້ອງ | ສະພາບແວດລ້ອມພາຍໃນ, ສະອາດເທົ່ານັ້ນ | ການກວດກາປະຈໍາເດືອນ |

| IP31 | ປ້ອງກັນວັດຖຸ >2.5mm | ປ້ອງກັນນ້ໍາ dripping | Switchgear ພາຍໃນມາດຕະຖານ | ການທໍາຄວາມສະອາດປະຈໍາໄຕມາດ |

| IP41 | ປ້ອງກັນວັດຖຸ >1mm | ປ້ອງກັນນ້ໍາ splashing | ອຸດສາຫະກຳເບົາ | ການທໍາຄວາມສະອາດປະຈໍາໄຕມາດ |

| IP54 | ປ້ອງກັນຂີ້ຝຸ່ນ (ingress ຈໍາກັດ) | ປ້ອງກັນການສີດນ້ໍາ | ສະພາບແວດລ້ອມອຸດສາຫະກໍາ | ທໍາຄວາມສະອາດເຄິ່ງປີ |

| IP65 | ຂີ້ຝຸ່ນແຫນ້ນ (ບໍ່ມີ ingress) | ປ້ອງກັນ jets ນ້ໍາ | ອຸດສາຫະກໍາທີ່ຮຸນແຮງ, ກາງແຈ້ງ | ທໍາຄວາມສະອາດປະຈໍາປີ |

| IP66 | ຂີ້ຝຸ່ນແຫນ້ນ | ປ້ອງກັນ jets ນ້ໍາທີ່ມີອໍານາດ | ທະເລ, ນອກຝັ່ງ, ສະພາບແວດລ້ອມທີ່ຮຸນແຮງ | ທໍາຄວາມສະອາດປະຈໍາປີ |

ສໍາລັບຄໍາຮ້ອງສະຫມັກອຸດສາຫະກໍາສ່ວນໃຫຍ່, IP54 ສະແດງເຖິງລະດັບການປ້ອງກັນທີ່ຍອມຮັບໄດ້ຕໍ່າສຸດ. ການຈັດອັນດັບນີ້ຮັບປະກັນວ່າ ingress ຂີ້ຝຸ່ນຖືກຈໍາກັດໃນປະລິມານທີ່ບໍ່ແຊກແຊງການດໍາເນີນງານຂອງອຸປະກອນ. ການຄັດເລືອກວັດສະດຸ enclosure ໄຟຟ້າ ຄວນພິຈາລະນາທັງຄວາມຕ້ອງການ IP rating ແລະປັດໃຈການກັດກ່ອນຂອງສິ່ງແວດລ້ອມ.

ຍຸດທະສາດການບໍາລຸງຮັກສາປ້ອງກັນ

ໂປຣໂຕຄອນການກວດກາແລະທໍາຄວາມສະອາດ

ການຄຸ້ມຄອງຂີ້ຝຸ່ນທີ່ມີປະສິດທິພາບຮຽກຮ້ອງໃຫ້ມີໂຄງການກວດກາແລະທໍາຄວາມສະອາດຢ່າງເປັນລະບົບທີ່ເຫມາະສົມກັບສະພາບແວດລ້ອມ. ການສ້າງໂຄງການບໍາລຸງຮັກສາໄຟຟ້າ ຄວນປະກອບມີອົງປະກອບສະເພາະຂີ້ຝຸ່ນເຫຼົ່ານີ້:

ການກວດກາສາຍຕາ (ປະຈໍາເດືອນໃນສະພາບແວດລ້ອມທີ່ມີຂີ້ຝຸ່ນ):

- ກວດເບິ່ງການສະສົມຂີ້ຝຸ່ນທີ່ເຫັນໄດ້ຊັດເຈນໃນພື້ນຜິວ enclosure

- ກວດກາປະທັບຕາປະຕູແລະ gaskets ສໍາລັບຄວາມສົມບູນ

- ຊອກຫາຫຼັກຖານຂອງ ingress ຂີ້ຝຸ່ນປະມານການເຂົ້າສາຍ

- ເອກະສານເງື່ອນໄຂທີ່ມີຮູບຖ່າຍສໍາລັບການວິເຄາະແນວໂນ້ມ

Infrared Thermography (ປະຈໍາໄຕມາດ):

- ສະແກນ busbars, ການເຊື່ອມຕໍ່, ແລະອຸປະກອນປ່ຽນສໍາລັບຈຸດຮ້ອນ

- ປຽບທຽບລາຍເຊັນຄວາມຮ້ອນກັບການວັດແທກພື້ນຖານ

- ກໍານົດພື້ນທີ່ທີ່ insulation ຂີ້ຝຸ່ນເຮັດໃຫ້ອຸນຫະພູມສູງຂຶ້ນ

- ກໍານົດເວລາທໍາຄວາມສະອາດກ່ອນທີ່ຈະເກີດຄວາມເສຍຫາຍຄວາມຮ້ອນ

ການທໍາຄວາມສະອາດພາຍໃນລາຍລະອຽດ (ຄວາມຖີ່ໂດຍອີງໃສ່ສະພາບແວດລ້ອມ):

- De-energize ອຸປະກອນດັ່ງຕໍ່ໄປນີ້ ຂັ້ນຕອນການປິດ/ tagout

- ໃຊ້ອຸປະກອນສູນຍາກາດ HEPA-filtered (ບໍ່ເຄີຍໃຊ້ອາກາດບີບອັດ, ເຊິ່ງແຈກຢາຍຂີ້ຝຸ່ນຄືນໃຫມ່)

- ເຮັດຄວາມສະອາດ insulators ດ້ວຍສານລະລາຍທີ່ໄດ້ຮັບການອະນຸມັດ

- ກວດກາແລະເຮັດຄວາມສະອາດການຕິດຕໍ່, ກວດສອບການ pitting ຫຼື erosion

- ກວດສອບແຮງບິດໃນການເຊື່ອມຕໍ່ bolted ທັງຫມົດ

- ທົດສອບການດໍາເນີນງານຂອງ interlocks ກົນຈັກແລະກົນໄກການດໍາເນີນງານ

ເຕັກໂນໂລຊີການຕິດຕາມກວດກາ

ລະບົບຕິດຕາມກວດກາສະວິດເກຍທີ່ທັນສະໄໝໃຫ້ການເຕືອນໄພລ່ວງໜ້າກ່ຽວກັບການເສື່ອມສະພາບທີ່ກ່ຽວຂ້ອງກັບຂີ້ຝຸ່ນ:

ການຕິດຕາມກວດກາການປ່ອຍອາຍບາງສ່ວນ: ເຊັນເຊີ ultrasonic ແລະ electromagnetic ກວດພົບກິດຈະກໍາການປ່ອຍອາຍບາງສ່ວນທີ່ເກີດຈາກການປົນເປື້ອນຂອງພື້ນຜິວກ່ອນທີ່ຈະເກີດຄວາມລົ້ມເຫຼວທີ່ຮ້າຍແຮງ.

ການຕິດຕາມກວດກາອຸນຫະພູມ: ເຊັນເຊີອຸນຫະພູມຢ່າງຕໍ່ເນື່ອງໃນອົງປະກອບທີ່ສໍາຄັນກໍານົດບັນຫາຄວາມຮ້ອນທີ່ເກີດຈາກ insulation ຂີ້ຝຸ່ນ. ຄວາມເຂົ້າໃຈກ່ຽວກັບຂອບເຂດຈໍາກັດການເພີ່ມຂຶ້ນຂອງອຸນຫະພູມ ຊ່ວຍສ້າງຕັ້ງຂອບເຂດການເຕືອນທີ່ເຫມາະສົມ.

ການຕິດຕາມກວດກາຄວາມຊຸ່ມຊື່ນ: ການຕິດຕາມຄວາມຊຸ່ມຊື່ນພາຍໃນ enclosures ຊ່ວຍໃຫ້ຄາດຄະເນຄວາມສ່ຽງຕໍ່ການກັດກ່ອນແລະເພີ່ມປະສິດທິພາບລະບົບ dehumidification.

ການແກ້ໄຂການອອກແບບສໍາລັບການຫຼຸດຜ່ອນຂີ້ຝຸ່ນ

ຄຸນສົມບັດການອອກແບບ Enclosure

ສະວິດເກຍທີ່ທັນສະໄໝປະກອບມີຄຸນສົມບັດການອອກແບບຫຼາຍຢ່າງເພື່ອຫຼຸດຜ່ອນການເຂົ້າຂອງຂີ້ຝຸ່ນ:

ລະບົບຄວາມກົດດັນໃນທາງບວກ: ການສະຫນອງອາກາດທີ່ກັ່ນຕອງຮັກສາຄວາມກົດດັນໃນທາງບວກເລັກນ້ອຍພາຍໃນ enclosures, ປ້ອງກັນການ infiltration ຂີ້ຝຸ່ນຜ່ານຊ່ອງຫວ່າງຂະຫນາດນ້ອຍ. ວິທີການນີ້ແມ່ນທົ່ວໄປໃນ ສະວິດເກຍແຮງດັນຕໍ່າ ສໍາລັບຄໍາຮ້ອງສະຫມັກທີ່ສໍາຄັນ.

Labyrinth Seals: ການອອກແບບປະຕູທີ່ມີພື້ນຜິວຊ້ອນກັນແລະເສັ້ນທາງ tortuous ຫຼຸດຜ່ອນການເຂົ້າຂອງຂີ້ຝຸ່ນຢ່າງຫຼວງຫຼາຍໂດຍບໍ່ຈໍາເປັນຕ້ອງມີການບີບອັດ gasket ທີ່ສົມບູນແບບ.

ການກັນນ້ຳທາງເຂົ້າສາຍໄຟ: ຕ່ອມສາຍເຄເບີ້ນ ທີ່ມີລະດັບ IP ທີ່ເຫມາະສົມປ້ອງກັນການເຂົ້າຂອງຂີ້ຝຸ່ນຜ່ານການເຈາະສາຍເຄເບີ້ນ, ເຊິ່ງມັກຈະເປັນຈຸດທີ່ອ່ອນແອທີ່ສຸດໃນຄວາມສົມບູນຂອງ enclosure.

Compartmentalization: ການແຍກພາກສ່ວນແຮງດັນສູງ, ແຮງດັນຕໍ່າ, ແລະການຄວບຄຸມຈໍາກັດການແຜ່ກະຈາຍຂອງການປົນເປື້ອນແລະອະນຸຍາດໃຫ້ມີການບໍາລຸງຮັກສາເປົ້າຫມາຍ.

ການຄັດເລືອກວັດສະດຸ

ການເລືອກວັດສະດຸທີ່ທົນທານຕໍ່ການກັດກ່ອນຊ່ວຍຫຼຸດຜ່ອນຄວາມສ່ຽງຕໍ່ການກັດກ່ອນທີ່ເລັ່ງໃສ່ຂີ້ຝຸ່ນ:

- ຕູ້ສະແຕນເລດ ສໍາລັບສະພາບແວດລ້ອມທາງທະເລແລະສານເຄມີ

- Tin-plated ຫຼື silver-plated busbars ເພື່ອຕ້ານການ oxidation (ການປຽບທຽບ busbar plating)

- Sealed contactors ທີ່ມີຫ້ອງຕິດຕໍ່ທີ່ປິດລ້ອມ

- Conformal coating ໃນກະດານວົງຈອນຄວບຄຸມ

ການວິເຄາະຄ່າໃຊ້ຈ່າຍ: ການປ້ອງກັນທຽບກັບການສ້ອມແປງ

ຜົນກະທົບທາງດ້ານການເງິນຂອງຄວາມລົ້ມເຫຼວທີ່ກ່ຽວຂ້ອງກັບຂີ້ຝຸ່ນ

ຄ່າໃຊ້ຈ່າຍທີ່ແທ້ຈິງຂອງການປົນເປື້ອນຂີ້ຝຸ່ນຂະຫຍາຍອອກໄປນອກເຫນືອຈາກຄ່າໃຊ້ຈ່າຍໃນການສ້ອມແປງທັນທີ:

ຄ່າໃຊ້ຈ່າຍໂດຍກົງ:

- ແຮງງານສ້ອມແປງສຸກເສີນ (ມັກຈະເປັນ 2-3x ອັດຕາປົກກະຕິ)

- ອົງປະກອບທົດແທນແລະການຂົນສົ່ງແບບເລັ່ງລັດ

- ການທົດສອບແລະການມອບຫມາຍຫຼັງຈາກການສ້ອມແປງ

- ການກວດກາແລະເອກະສານກົດລະບຽບ

ຄ່າໃຊ້ຈ່າຍທາງອ້ອມ:

- ການຢຸດເຮັດວຽກຂອງການຜະລິດ (50,000-500,000+ ຕໍ່ຊົ່ວໂມງໃນຫຼາຍອຸດສາຫະກໍາ)

- ຜະລິດຕະພັນທີ່ເສຍຫາຍຫຼືຂະບວນການຂັດຂວາງ

- ການລົງໂທດຂອງລູກຄ້າສໍາລັບການຈັດສົ່ງທີ່ພາດໂອກາດ

- ຄວາມເສຍຫາຍຕໍ່ຊື່ສຽງຂອງບໍລິສັດ

ການວິເຄາະຄ່າໃຊ້ຈ່າຍປຽບທຽບ:

- ໂຄງການບໍາລຸງຮັກສາປ້ອງກັນປະຈໍາປີ: 5,000-15,000 ຕໍ່ແຖວສະວິດເກຍ

- ການສ້ອມແປງຄວາມລົ້ມເຫຼວທີ່ກ່ຽວຂ້ອງກັບຂີ້ຝຸ່ນປົກກະຕິ: 25,000-75,000 ບວກກັບຄ່າໃຊ້ຈ່າຍໃນການຢຸດເຮັດວຽກ

- ເຫດການ arc flash ທີ່ຮ້າຍແຮງ: 100,000-500,000+ ບວກກັບການບາດເຈັບທີ່ອາດເກີດຂຶ້ນ

ຜົນຕອບແທນການລົງທຶນສໍາລັບການປ້ອງກັນຂີ້ຝຸ່ນທີ່ເຫມາະສົມໂດຍທົ່ວໄປແມ່ນຕັ້ງແຕ່ 300-500%, ເຮັດໃຫ້ມັນເປັນຫນຶ່ງໃນການປັບປຸງຄວາມຫນ້າເຊື່ອຖືທີ່ມີປະສິດທິພາບດ້ານຄ່າໃຊ້ຈ່າຍຫຼາຍທີ່ສຸດ.

ມາດຕະຖານແລະຂໍ້ກໍານົດການປະຕິບັດຕາມ

ມາດຕະຖານສາກົນທີ່ກ່ຽວຂ້ອງ

- IEC 62271-200: ກໍານົດຂໍ້ກໍານົດສໍາລັບສະວິດເກຍແລະເຄື່ອງຄວບຄຸມທີ່ປິດດ້ວຍໂລຫະ AC, ລວມທັງການທົດສອບສິ່ງແວດລ້ອມແລະຂໍ້ກໍານົດການຈັດອັນດັບ IP.

- IEC 60529: ກໍານົດຂັ້ນຕອນການທົດສອບການຈັດອັນດັບ IP ແລະການຈັດປະເພດສໍາລັບການປ້ອງກັນຂີ້ຝຸ່ນແລະການເຂົ້າຂອງນ້ໍາ.

- IEC 61439: ມາດຕະຖານການປະກອບສະວິດເກຍແລະເຄື່ອງຄວບຄຸມແຮງດັນຕໍ່າ, ລວມທັງຂໍ້ກໍານົດສໍາລັບການແຍກພາຍໃນແລະການປ້ອງກັນປັດໃຈສິ່ງແວດລ້ອມ.

- NFPA 70B: ການປະຕິບັດທີ່ແນະນໍາສໍາລັບການບໍາລຸງຮັກສາອຸປະກອນໄຟຟ້າ, ໃຫ້ຄໍາແນະນໍາກ່ຽວກັບໄລຍະການກວດກາແລະຂັ້ນຕອນການທໍາຄວາມສະອາດ.

ຄວາມເຂົ້າໃຈ ຄໍາສັບ IEC ທຽບກັບ NEC ຊ່ວຍນໍາທາງຂໍ້ກໍານົດໃນທົ່ວຂອບເຂດກົດລະບຽບທີ່ແຕກຕ່າງກັນ.

FAQ: ຂີ້ຝຸ່ນໃນສະວິດເກຍ

ຖາມ: ຄວນເຮັດຄວາມສະອາດສະວິດເກຍເລື້ອຍໆສໍ່າໃດໃນສະພາບແວດລ້ອມອຸດສາຫະກໍາ?

A: ຄວາມຖີ່ຂອງການທໍາຄວາມສະອາດແມ່ນຂຶ້ນກັບສະພາບແວດລ້ອມ. ສະພາບແວດລ້ອມອຸດສາຫະກໍາແສງສະຫວ່າງໂດຍທົ່ວໄປຕ້ອງການການທໍາຄວາມສະອາດປະຈໍາໄຕມາດ, ໃນຂະນະທີ່ການຜະລິດຫນັກ, ການຂຸດຄົ້ນບໍ່ແຮ່, ຫຼືການຕິດຕັ້ງກາງແຈ້ງອາດຈະຕ້ອງການຄວາມສົນໃຈປະຈໍາເດືອນ. ສ້າງພື້ນຖານໂດຍຜ່ານການກວດກາເບື້ອງຕົ້ນປະຈໍາເດືອນ, ຫຼັງຈາກນັ້ນປັບຄວາມຖີ່ໂດຍອີງໃສ່ອັດຕາການສະສົມຂີ້ຝຸ່ນຕົວຈິງ.

ຖາມ: ຂີ້ຝຸ່ນສາມາດເຮັດໃຫ້ ເຄື່ອງຕັດວົງຈອນ ລົ້ມເຫລວໂດຍບໍ່ມີການເຕືອນ?

A: ແມ່ນແລ້ວ. ການສະສົມຂີ້ຝຸ່ນສາມາດເຮັດໃຫ້ການປ່ຽນແປງການປັບທຽບຄວາມຮ້ອນ, ເຮັດໃຫ້ breakers ເດີນທາງໃນລະດັບປະຈຸບັນທີ່ບໍ່ຖືກຕ້ອງຫຼືລົ້ມເຫລວໃນການເດີນທາງໃນລະຫວ່າງສະພາບຄວາມຜິດຕົວຈິງ. ນີ້ແມ່ນເຫດຜົນທີ່ວ່າ ການກວດກາຮູບພາບຄວາມຮ້ອນ ມີຄວາມສໍາຄັນ—ພວກເຂົາກວດພົບບັນຫາກ່ອນທີ່ຈະເກີດຄວາມລົ້ມເຫຼວ.

ຖາມ: ລະດັບ IP ໃດທີ່ແນະນໍາສໍາລັບສະພາບແວດລ້ອມທີ່ມີຝຸ່ນຫຼາຍ?

ຕອບ: IP54 ແມ່ນຕໍາ່ສຸດທີ່ສໍາລັບສະພາບແວດລ້ອມອຸດສາຫະກໍາທີ່ມີຝຸ່ນປານກາງ. ສະພາບແວດລ້ອມທີ່ມີຝຸ່ນໜັກຕ້ອງການ IP65 ຫຼື IP66. ຕົວເລກທໍາອິດ (5 ຫຼື 6) ຊີ້ບອກລະດັບການປ້ອງກັນຝຸ່ນ—6 ຫມາຍຄວາມວ່າກັນຝຸ່ນໄດ້ຢ່າງສົມບູນ, ໃນຂະນະທີ່ 5 ອະນຸຍາດໃຫ້ມີການເຂົ້າເລັກນ້ອຍທີ່ຈະບໍ່ມີຜົນກະທົບຕໍ່ການດໍາເນີນງານ.

ຖາມ: ອາກາດບີບອັດປອດໄພສໍາລັບການທໍາຄວາມສະອາດສະວິດເກຍບໍ?

ຕອບ: ບໍ່. ອາກາດບີບອັດແຈກຢາຍຝຸ່ນຄືນໃໝ່ໄປຫາພື້ນທີ່ອື່ນໆ ແລະສາມາດບັງຄັບອະນຸພາກເຂົ້າໄປໃນອຸປະກອນໄດ້ເລິກກວ່າ. ໃຊ້ອຸປະກອນສູນຍາກາດທີ່ກັ່ນຕອງ HEPA ທີ່ຖືກອອກແບບມາສະເພາະສໍາລັບການບໍາລຸງຮັກສາໄຟຟ້າ. ຖອດອຸປະກອນອອກຈາກພະລັງງານສະເໝີກ່ອນທໍາຄວາມສະອາດ.

ຖາມ: ຝຸ່ນມີຜົນກະທົບແນວໃດ ອຸປະກອນປ້ອງກັນກະແສໄຟຟ້າ?

ຕອບ: ການສະສົມຂອງຝຸ່ນໃນອົງປະກອບ SPD ສາມາດສ້າງເສັ້ນທາງຕິດຕາມທີ່ເຮັດໃຫ້ເກີດຄວາມລົ້ມເຫຼວກ່ອນໄວອັນຄວນຫຼືຫຼຸດຜ່ອນປະສິດທິພາບການສະກັດກັ້ນແຮງດັນ. ການກວດກາສະຖານະຕົວຊີ້ບອກ SPD ເປັນປະຈໍາແລະການຖ່າຍຮູບຄວາມຮ້ອນຂອງການເຊື່ອມຕໍ່ແມ່ນມີຄວາມຈໍາເປັນ.

ຖາມ: ສະວິດເກຍທີ່ຜະນຶກເຂົ້າກັນທີ່ທັນສະໄໝສາມາດກໍາຈັດບັນຫາຝຸ່ນໄດ້ບໍ?

ຕອບ: ໃນຂະນະທີ່ສະວິດເກຍທີ່ຜະນຶກເຂົ້າກັນດ້ວຍລະດັບ IP65/66 ຫຼຸດຜ່ອນການເຂົ້າຂອງຝຸ່ນຢ່າງຫຼວງຫຼາຍ, ບໍ່ມີຕູ້ໃດທີ່ສາມາດຕ້ານທານໄດ້ຢ່າງສົມບູນ. ການເຂົ້າສາຍເຄເບີ້ນ, ປະທັບຕາປະຕູ, ແລະເສັ້ນທາງລະບາຍອາກາດຍັງຄົງເປັນຈຸດເຂົ້າທີ່ອາດມີ. ການກວດກາເປັນປະຈໍາແມ່ນຍັງມີຄວາມຈໍາເປັນເຖິງແມ່ນວ່າສໍາລັບອຸປະກອນທີ່ມີລະດັບ IP ສູງ.

ສະຫຼຸບ: ການຄຸ້ມຄອງຝຸ່ນຢ່າງຕັ້ງໜ້າຊ່ວຍປະຢັດເງິນ ແລະປ້ອງກັນຄວາມລົ້ມເຫຼວ

ການປົນເປື້ອນຂອງຝຸ່ນເປັນຕົວແທນໃຫ້ໜຶ່ງໃນສາເຫດທີ່ສາມາດປ້ອງກັນໄດ້ຫຼາຍທີ່ສຸດຂອງຄວາມລົ້ມເຫຼວຂອງສະວິດເກຍ, ແຕ່ມັນຍັງຄົງເປັນຜູ້ປະກອບສ່ວນນໍາໜ້າຕໍ່ການຢຸດເຮັດວຽກທີ່ບໍ່ໄດ້ວາງແຜນໄວ້ ແລະຄວາມເສຍຫາຍຂອງອຸປະກອນ. ກົນໄກຄວາມລົ້ມເຫຼວຫ້າຢ່າງ—ການເຊື່ອມຕໍ່ທີ່ນໍາໄຟຟ້າ, ການສນວນຄວາມຮ້ອນ, ການເລັ່ງການກັດກ່ອນ, ການເສື່ອມສະພາບຂອງການຕິດຕໍ່, ແລະການຕິດຕາມການສນວນ—ເຮັດວຽກເປັນສ່ວນບຸກຄົນແລະຮ່ວມກັນເພື່ອເຮັດໃຫ້ຄວາມຫນ້າເຊື່ອຖືຂອງລະບົບໄຟຟ້າຫຼຸດລົງ.

ການປະຕິບັດຍຸດທະສາດການຄຸ້ມຄອງຝຸ່ນທີ່ສົມບູນແບບໃຫ້ຜົນຕອບແທນທີ່ສາມາດວັດແທກໄດ້ໂດຍຜ່ານອາຍຸການໃຊ້ງານຂອງອຸປະກອນທີ່ຍາວນານ, ອັດຕາຄວາມລົ້ມເຫຼວທີ່ຫຼຸດລົງ, ແລະການສ້ອມແປງສຸກເສີນທີ່ຖືກກໍາຈັດ. ການປະສົມປະສານຂອງຕູ້ທີ່ໄດ້ຮັບການຈັດອັນດັບ IP ທີ່ເຫມາະສົມ, ໂປໂຕຄອນການບໍາລຸງຮັກສາລະບົບ, ແລະເຕັກໂນໂລຢີການຕິດຕາມກວດກາທີ່ທັນສະໄຫມໃຫ້ການປົກປ້ອງທີ່ເຂັ້ມແຂງຕໍ່ກັບຄວາມລົ້ມເຫຼວທີ່ກ່ຽວຂ້ອງກັບຝຸ່ນ.

ສໍາລັບຜູ້ຈັດການສິ່ງອໍານວຍຄວາມສະດວກແລະວິສະວະກອນໄຟຟ້າ, ຂໍ້ຄວາມແມ່ນຈະແຈ້ງ: ຝຸ່ນບໍ່ແມ່ນບັນຫາເຄື່ອງສໍາອາງ—ມັນເປັນໄພຂົ່ມຂູ່ຕໍ່ຄວາມຫນ້າເຊື່ອຖືທີ່ຮຽກຮ້ອງໃຫ້ມີຄວາມສົນໃຈຢ່າງເປັນລະບົບ. ການລົງທຶນໃນການປ້ອງກັນຄ່າໃຊ້ຈ່າຍສ່ວນຫນຶ່ງຂອງການຕອບສະຫນອງຕໍ່ຄວາມລົ້ມເຫຼວ, ໃນຂະນະທີ່ໃຫ້ເວລາເຮັດວຽກແລະຄວາມປອດໄພທີ່ດີກວ່າ.

ພ້ອມທີ່ຈະປົກປ້ອງພື້ນຖານໂຄງລ່າງໄຟຟ້າຂອງທ່ານບໍ? VIOX Electric ຜະລິດ ສະວິດເກຍລະດັບອຸດສາຫະກໍາ ທີ່ມີຄຸນສົມບັດການປ້ອງກັນຝຸ່ນແບບພິເສດແລະໃຫ້ຄໍາແນະນໍາການບໍາລຸງຮັກສາທີ່ສົມບູນແບບສໍາລັບຄວາມຫນ້າເຊື່ອຖືສູງສຸດໃນສະພາບແວດລ້ອມທີ່ທ້າທາຍ.