គន្លឹះយក

- ភាពខុសគ្នាជាមូលដ្ឋាន: ប្រអប់ស្ថានីយ ប្រើប្រាស់រចនាសម្ព័ន្ធ ប្លុកស្ថានីយ សម្រាប់ការតភ្ជាប់ដែលមានការរៀបចំ ងាយស្រួលចូលប្រើ និងការថែទាំញឹកញាប់ ខណៈដែល ប្រអប់ប្រសព្វ ការពារការភ្ជាប់ខ្សែអចិន្ត្រៃយ៍ ហើយកម្រត្រូវបានចូលប្រើបន្ទាប់ពីការដំឡើង។.

- លេខកូដអនុលោម៖ ទូដាក់ទាំងពីរត្រូវតែគោរពតាម NEC Article 314, ប៉ុន្តែប្រអប់ស្ថានីយទាមទារជាញឹកញាប់នូវការបោសសំអាតកន្លែងធ្វើការ និងភាពងាយស្រួលចូលប្រើកាន់តែតឹងរ៉ឹង ដោយសារតួនាទីរបស់វាក្នុងការថែទាំ និងការធ្វើតេស្តសកម្ម។.

- ភាពជាក់លាក់នៃការអនុវត្ត៖ បញ្ជាក់ប្រអប់ស្ថានីយសម្រាប់បន្ទះគ្រប់គ្រងឧស្សាហកម្ម ប្រព័ន្ធស្វ័យប្រវត្តិកម្ម និងឧបករណ៍វាស់ស្ទង់។ ប្រើប្រអប់ប្រសព្វសម្រាប់ការខ្សែភ្លើងទូទៅ ការបែងចែកថាមពល និងការការពារការភ្ជាប់។.

- ការពិចារណាលើ ROI៖ ខណៈពេលដែលប្រអប់ស្ថានីយមានតម្លៃសម្ភារៈដំបូងខ្ពស់ជាង វាជួយកាត់បន្ថយពេលវេលាដោះស្រាយបញ្ហា និងពេលវេលារងចាំប្រតិបត្តិការ (OPEX) យ៉ាងខ្លាំង ដែលផ្តល់នូវតម្លៃរយៈពេលវែងដ៏ប្រសើរនៅក្នុងបរិស្ថានឧស្សាហកម្មស្មុគស្មាញ។.

ចម្លើយរហ័ស៖ ប្រអប់ស្ថានីយទល់នឹងប្រអប់ប្រសព្វ

មួយ ប្រអប់ស្ថានីយ គឺជាទូដាក់អគ្គិសនីដែលបំពាក់ដោយការរៀបចំ ប្លុកស្ថានីយ រចនាឡើងសម្រាប់ការចូលប្រើ ការធ្វើតេស្ត និងការកែប្រែការតភ្ជាប់ញឹកញាប់។ វាបម្រើជាចំណុចប្រទាក់គ្រប់គ្រង ឬចំណុចចែកចាយនៅក្នុងប្រព័ន្ធឧស្សាហកម្ម។ ផ្ទុយទៅវិញ ប្រអប់ប្រសព្វ គឺជាទូដាក់ការពារដែលប្រើជាចម្បងដើម្បីផ្ទុកការភ្ជាប់ខ្សែអចិន្ត្រៃយ៍ (ជាធម្មតាភ្ជាប់ដោយគ្រាប់ខ្សែ ឬ crimps) និងការពារពួកវាពីកត្តាបរិស្ថាន។ វាមិនមានបំណងសម្រាប់ការចូលប្រើប្រតិបត្តិការជាប្រចាំទេ។.

សេចក្តីផ្តើម

នៅក្នុងពិភពច្បាស់លាស់នៃវិស្វកម្មអគ្គិសនីឧស្សាហកម្ម ពាក្យ “ប្រអប់ស្ថានីយ” និង “ប្រអប់ប្រសព្វ” ត្រូវបានប្រើជាញឹកញាប់ឆ្លាស់គ្នា ប៉ុន្តែពួកវាជាសមាសធាតុដាច់ដោយឡែកដែលមានមុខងារ ទស្សនវិជ្ជាការរចនា និងតម្រូវការកូដខុសគ្នាខ្លាំង។ សម្រាប់វិស្វករលទ្ធកម្ម និងអ្នករចនាប្រព័ន្ធ ការយល់ច្រឡំទូដាក់ទាំងនេះអាចនាំឱ្យមានការរំលោភលើកូដ គ្រោះថ្នាក់នៃការថែទាំ និងការសម្របសម្រួលភាពជឿជាក់នៃប្រព័ន្ធ។.

ជម្រើសរវាងប្រអប់ស្ថានីយ និងប្រអប់ប្រសព្វ មិនមែនគ្រាន់តែអំពីការដាក់ខ្សែនោះទេ — វាគឺជាការសម្រេចចិត្តជាយុទ្ធសាស្ត្រអំពី ភាពងាយស្រួលចូលប្រើ ភាពងាយស្រួលថែទាំ និងការគ្រប់គ្រងវដ្តជីវិតប្រព័ន្ធ. ។ ក ប្រអប់ប្រសព្វ បម្រើជាខែលឋិតិវន្តសម្រាប់ការតភ្ជាប់អចិន្ត្រៃយ៍ ខណៈពេលដែលប្រអប់ស្ថានីយដើរតួជាចំណុចប្រទាក់ថាមវន្តសម្រាប់ប្រព័ន្ធសកម្ម។.

មគ្គុទ្ទេសក៍នេះផ្តល់នូវការប្រៀបធៀបបច្ចេកទេសច្បាស់លាស់សម្រាប់ឆ្នាំ 2025 ដោយវិភាគលក្ខណៈបច្ចេកទេស តម្រូវការ NEC/NEMA និងលក្ខណៈវិនិច្ឆ័យនៃការអនុវត្ត ដើម្បីធានាថាអ្នកបញ្ជាក់ទូដាក់ត្រឹមត្រូវសម្រាប់ការដំឡើងអគ្គិសនីរបស់អ្នក។.

តើប្រអប់ស្ថានីយជាអ្វី?

មួយ ប្រអប់ស្ថានីយ (ជាញឹកញាប់ត្រូវបានគេហៅថា ទូដាក់ស្ថានីយ ឬប្រអប់តភ្ជាប់) គឺជាទូដាក់ដែលត្រូវបានសាងសង់ឡើងដើម្បីផ្ទុក ប្រអប់ប្រសព្វអគ្គិសនីជាមួយស្ថានីយ។. មុខងារចម្បងរបស់វាគឺដើម្បីផ្តល់នូវចំណុចប្រទាក់ដែលមានរចនាសម្ព័ន្ធ រៀបចំ និងងាយស្រួលចូលប្រើ សម្រាប់ការភ្ជាប់ខ្សែភ្លើងទៅប្រព័ន្ធគ្រប់គ្រង ម៉ាស៊ីន ឬបណ្តាញចែកចាយថាមពល។.

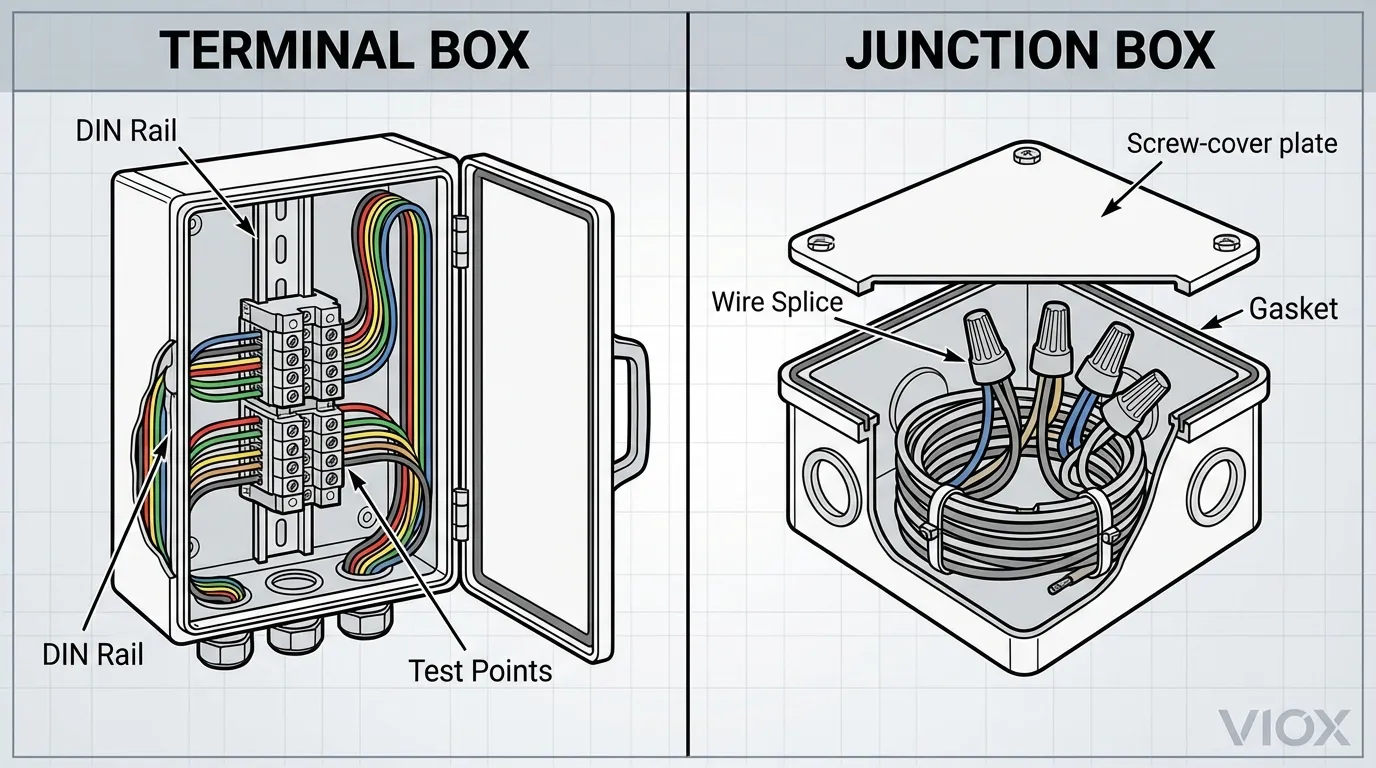

លក្ខណៈសំខាន់ៗ

- សមាសធាតុខាងក្នុង៖ មានផ្លូវដែក DIN ប្លុកស្ថានីយ (វីស គៀបនិទាឃរដូវ ឬរុញចូល) និងស្លាកសញ្ញាសម្គាល់។.

- ភាពងាយស្រួល៖ រចនាឡើងជាមួយនឹងទ្វារហ៊ីង គន្លឹះបញ្ចេញរហ័ស ឬគម្របដែលអាចដកចេញបាន ដើម្បីសម្រួលដល់ការចូលប្រើញឹកញាប់។.

- អង្គការ៖ ខ្សែភ្លើងត្រូវបានបញ្ចប់ដោយឡែកៗពីគ្នា សម្គាល់ និងរៀបចំតាមលំដាប់លំដោយសម្រាប់ការកំណត់អត្តសញ្ញាណបានយ៉ាងងាយស្រួល។.

- ថែទាំ៖ អនុញ្ញាតឱ្យមានការដាច់ចរន្តនីមួយៗ ការធ្វើតេស្ត និងការកែប្រែដោយមិនរំខានដល់ការតភ្ជាប់ដែលនៅជាប់គ្នា។.

ប្រអប់ស្ថានីយគឺជាឆ្អឹងខ្នងនៃ ស្វ័យប្រវត្តិកម្មឧស្សាហកម្ម, ដែលបម្រើជាចំណុចប្រគល់ដ៏សំខាន់រវាងឧបករណ៍ចាប់សញ្ញា/ឧបករណ៍បញ្ជា និងគណៈរដ្ឋមន្ត្រីគ្រប់គ្រងកណ្តាល។.

តើប្រអប់ប្រសព្វជាអ្វី?

មួយ ប្រអប់ប្រសព្វ (J-box) គឺជាទូដាក់ការពារដែលប្រើដើម្បីភ្ជាប់ខ្សែភ្លើង ជាធម្មតាដើម្បីបំបែកសៀគ្វីថាមពលទៅព្រីភ្លើងច្រើន ឬដើម្បីពង្រីកការរត់។ តួនាទីចម្បងរបស់វាគឺ ការទប់ស្កាត់ និងការការពារ. ។ នៅពេលដែលបានដំឡើង ប្រអប់ប្រសព្វកម្រត្រូវបានបើក លើកលែងតែកំហុសកើតឡើង ឬការកែលម្អត្រូវបានទាមទារ។.

លក្ខណៈសំខាន់ៗ

- សមាសធាតុខាងក្នុង៖ មានការភ្ជាប់ខ្សែដែលភ្ជាប់ដោយឧបករណ៍ភ្ជាប់ខ្សែរមួល (គ្រាប់ខ្សែ) មួក crimp ឬ busbars សាមញ្ញ។ ខ្វះបន្ទះស្ថានីយដែលបានរៀបចំ។.

- ភាពងាយស្រួល៖ ជាញឹកញាប់ត្រូវបានធានាសុវត្ថិភាពជាមួយនឹងគម្របរឹតវីស។ អាចចូលប្រើបាន ប៉ុន្តែមិនត្រូវបានរចនាឡើងសម្រាប់ការចូលយ៉ាងឆាប់រហ័សទេ។.

- ភាពអចិន្ត្រៃយ៍៖ ការតភ្ជាប់មានបំណងជាអចិន្ត្រៃយ៍។ ការកែប្រែសៀគ្វីជាញឹកញាប់តម្រូវឱ្យមានការកាត់ និងភ្ជាប់ខ្សែឡើងវិញ។.

- ភាពសាមញ្ញ៖ ផ្តោតលើការការពារ conductors ពីការខូចខាតរាងកាយ ធូលី និងសំណើម។.

សម្រាប់ការជ្រមុជទឹកកាន់តែជ្រៅទៅក្នុងពូជជាក់លាក់ សូមយោងទៅលើការណែនាំរបស់យើងអំពី ការយល់ដឹងអំពីប្រភេទប្រអប់ប្រសព្វអគ្គិសនី.

ប្រអប់ស្ថានីយទល់នឹងប្រអប់ប្រសព្វ៖ ភាពខុសគ្នាជាស្នូល

ចំពោះភ្នែកដែលមិនបានទទួលការបណ្តុះបណ្តាល ទាំងពីរហាក់ដូចជាប្រអប់សាមញ្ញ។ ទោះយ៉ាងណាក៏ដោយ ភាពខុសគ្នានៃវិស្វកម្មកំណត់ភាពសមស្របរបស់ពួកគេសម្រាប់បរិស្ថានជាក់លាក់។.

1. ស្ថាបត្យកម្មតភ្ជាប់

ភាពខុសគ្នាដ៏សំខាន់បំផុតស្ថិតនៅក្នុងវិធីសាស្ត្រតភ្ជាប់។ ប្រអប់ស្ថានីយប្រើប្រាស់ ប្លុកស្ថានីយ, ដែលផ្តល់នូវការតភ្ជាប់មេកានិចដែលមានសុវត្ថិភាព និងធន់នឹងរំញ័រសម្រាប់ខ្សែនីមួយៗ។ ការរៀបចំនេះអនុញ្ញាតឱ្យ ប្រអប់ប្រសព្វ AC កម្មវិធីដែលភាពសុចរិតនៃសៀគ្វីមានសារៈសំខាន់បំផុត។ ប្រអប់ប្រសព្វពឹងផ្អែកលើ ការភ្ជាប់អណ្តែតដោយសេរី, ដែលអាចក្លាយទៅជាគ្មានសណ្តាប់ធ្នាប់ និងពិបាកតាមដាននៅក្នុងសៀគ្វីស្មុគស្មាញ។.

2. ការថែទាំ និងការដោះស្រាយបញ្ហា

នៅក្នុងសេណារីយ៉ូកំហុសឧស្សាហកម្ម ពេលវេលាគឺជាប្រាក់។ ប្រអប់ស្ថានីយអនុញ្ញាតឱ្យអ្នកបច្ចេកទេសបញ្ចូលការស៊ើបអង្កេត multimeter ដោយផ្ទាល់ទៅក្នុងចំណុចសាកល្បងស្ថានីយ ដើម្បីផ្ទៀងផ្ទាត់វ៉ុល ឬភាពបន្ត។ នៅក្នុងប្រអប់ប្រសព្វ អ្នកបច្ចេកទេសត្រូវតែដោះវីសគម្រប ដោះគ្រាប់ខ្សែ ហើយបំបែកខ្សែដោយរូបភាព ដើម្បីសាកល្បងសៀគ្វី — ដំណើរការដែលយឺត រាតត្បាត និងប្រថុយនឹងការខូចខាត conductors ទង់ដែង។.

3. ទំហំ និងទំហំ

ប្រអប់ស្ថានីយជាធម្មតាមានទំហំធំជាងទាក់ទងទៅនឹងចំនួនខ្សែ ពីព្រោះពួកវាត្រូវតែផ្ទុកផ្លូវដែក DIN ប្លុកស្ថានីយ និងកាំពត់ខ្សែ។ ប្រអប់ប្រសព្វត្រូវបានកំណត់ទំហំដោយផ្អែកលើបរិមាណនៃ conductors និងឧបករណ៍ភ្ជាប់ ដែលជាញឹកញាប់បណ្តាលឱ្យមានស្នាមជើងតូចជាងមុន។ ការកំណត់ទំហំត្រឹមត្រូវគឺមានសារៈសំខាន់។ ពិគ្រោះជាមួយរបស់យើង មគ្គុទ្ទេសក៍ទំហំប្រអប់ប្រសព្វ ដើម្បីធានាបាននូវការអនុលោមតាម។.

មគ្គុទ្ទេសក៍ប្រៀបធៀបដ៏ទូលំទូលាយ

តារាងទី 1៖ លក្ខណៈបច្ចេកទេស និងលក្ខណៈពិសេស

| លក្ខណៈ | ប្រអប់ស្ថានីយ | សព្វប្រអប់ |

|---|---|---|

| មុខងារបឋម | ការតភ្ជាប់ ការធ្វើតេស្ត និងការថែទាំដែលបានរៀបចំ | ការការពារខ្សែ និងការបែងចែក |

| វិធីសាស្រ្តតភ្ជាប់ | ប្លុកស្ថានីយដែលបានម៉ោនលើផ្លូវដែក DIN | គ្រាប់ខ្សែ, crimps, ឬប្លុកភ្ជាប់ |

| ភាពញឹកញាប់នៃការចូលប្រើ | ខ្ពស់ (ការថែទាំ/ការធ្វើតេស្តជាប្រចាំ) | ទាប (ការដំឡើងអចិន្ត្រៃយ៍) |

| ការរៀបចំខ្សែ | ខ្ពស់ (មានស្លាក, ការបញ្ចប់ខ្សែនីមួយៗ) | ទាប (ការភ្ជាប់ខ្សែបញ្ចូលគ្នា) |

| ការដោះស្រាយបញ្ហា | លឿន (មានចំណុចសម្រាប់ធ្វើតេស្ត) | យឺត (ត្រូវការផ្តាច់ខ្សែដែលបានភ្ជាប់) |

| ភាពធន់នឹងរំញ័រ | ល្អបំផុត (ការគៀបយ៉ាងរឹងមាំ) | មធ្យម (អាស្រ័យលើគុណភាពឧបករណ៍ភ្ជាប់) |

| តម្រូវការទំហំ | ធំជាង (ត្រូវការផ្លូវដែក និងកន្លែងសម្រាប់បត់) | តូចល្មម (ការកំណត់ទំហំដោយផ្អែកលើបរិមាណ) |

| ការចំណាយ | ថ្លៃដើមខ្ពស់ជាង | ថ្លៃដើមទាប |

| វ៉ុលធម្មតា | ទាបទៅខ្ពស់ (24V – 1000V+) | ទាបទៅមធ្យម (120V – 600V) |

| សមត្ថភាពបច្ចុប្បន្ន | ខ្ពស់ (រហូតដល់ 600A+ ជាមួយប្លុក) | កំណត់ដោយកម្លាំងវ៉ុលរបស់មួកខ្សែ/ឧបករណ៍ភ្ជាប់ |

តារាងទី 2: ម៉ាទ្រីសភាពសមស្របនៃការប្រើប្រាស់

| សេណារីយ៉ូកម្មវិធី | ទូដែលបានណែនាំ | ហេតុផល |

|---|---|---|

| បន្ទះគ្រប់គ្រងឧស្សាហកម្ម | ប្រអប់ស្ថានីយ | តម្រូវឱ្យមានការធ្វើតេស្តញឹកញាប់ សៀគ្វីដែលមានស្លាក និងខ្សែដែលបានរៀបចំ។. |

| សៀគ្វីភ្លើងបំភ្លឺលំនៅដ្ឋាន | សព្វប្រអប់ | ការបំបែកសាមញ្ញ កម្រចូលប្រើ ប្រកាន់ខ្ជាប់នឹងតម្លៃ។. |

| ការបញ្ចប់ម៉ូទ័រ | ប្រអប់ស្ថានីយ | បរិយាកាសរំញ័រខ្ពស់; ត្រូវការដុំដែក/ប្លុកដែលមានសុវត្ថិភាព។. |

| ខ្សែឧបករណ៍ចាប់សញ្ញាក្រៅ | ប្រអប់ស្ថានីយ | ត្រូវការការការពារសំណើម និងការជំនួសឧបករណ៍ចាប់សញ្ញាបានយ៉ាងងាយស្រួល។. |

| ការចែកចាយថាមពលអគារ | សព្វប្រអប់ | ការភ្ជាប់ខ្សែអចិន្ត្រៃយ៍សម្រាប់ការរត់ខ្សែវែង។. |

| សញ្ញាឧបករណ៍ | ប្រអប់ស្ថានីយ | ការដាក់ដីការពារ និងសុចរិតភាពសញ្ញាមានសារៈសំខាន់។. |

សម្រាប់ព័ត៌មានលម្អិតអំពីរបៀបដែលទាំងនេះប្រៀបធៀបទៅនឹងប្រអប់ចែកចាយ សូមមើលការវិភាគរបស់យើងអំពី ប្រអប់ប្រសព្វទល់នឹងប្រអប់ចែកចាយទល់នឹងប្រអប់ស្ថានីយ.

តារាងទី 3: ការវិភាគតម្លៃ និង ROI

| កត្តាចំណាយ | ប្រអប់ស្ថានីយ | សព្វប្រអប់ |

|---|---|---|

| តម្លៃសម្ភារៈ | $$$ (ទូ + ផ្លូវដែក DIN + ប្លុក) | $ (ទូ + មួកខ្សែ) |

| ការងារដំឡើង | $$ (ត្រូវការប្លុកម៉ោន និងការបញ្ចប់ដោយប្រើហ្វែរូល) | $ (ការរមួល/ភ្ជាប់លឿន) |

| ពលកម្មថែទាំ | $ (ការធ្វើតេស្ត និងការកែប្រែរហ័ស) | $$$ (ការដោះស្រាយបញ្ហាដែលស៊ីពេលច្រើន) |

| ហានិភ័យនៃការផ្អាកដំណើរការ | ទាប (ការញែកកំហុសរហ័ស) | ខ្ពស់ (ការរកកំហុសស្មុគស្មាញ) |

| ROI រយៈពេលវែង | ខ្ពស់។ សម្រាប់ប្រព័ន្ធឧស្សាហកម្ម/សំខាន់ | ខ្ពស់។ សម្រាប់ប្រព័ន្ធសាមញ្ញ/ឋិតិវន្ត |

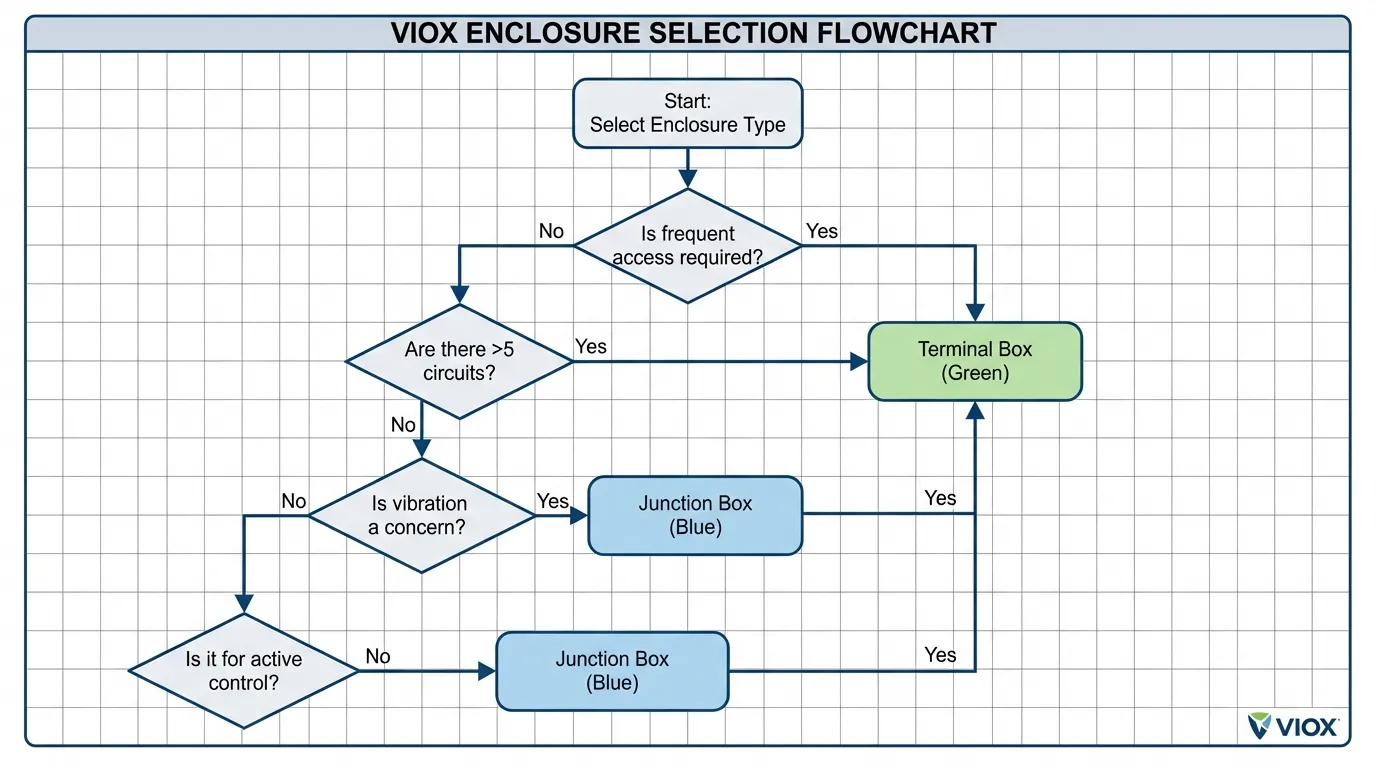

លក្ខណៈវិនិច្ឆ័យជ្រើសរើសលម្អិត

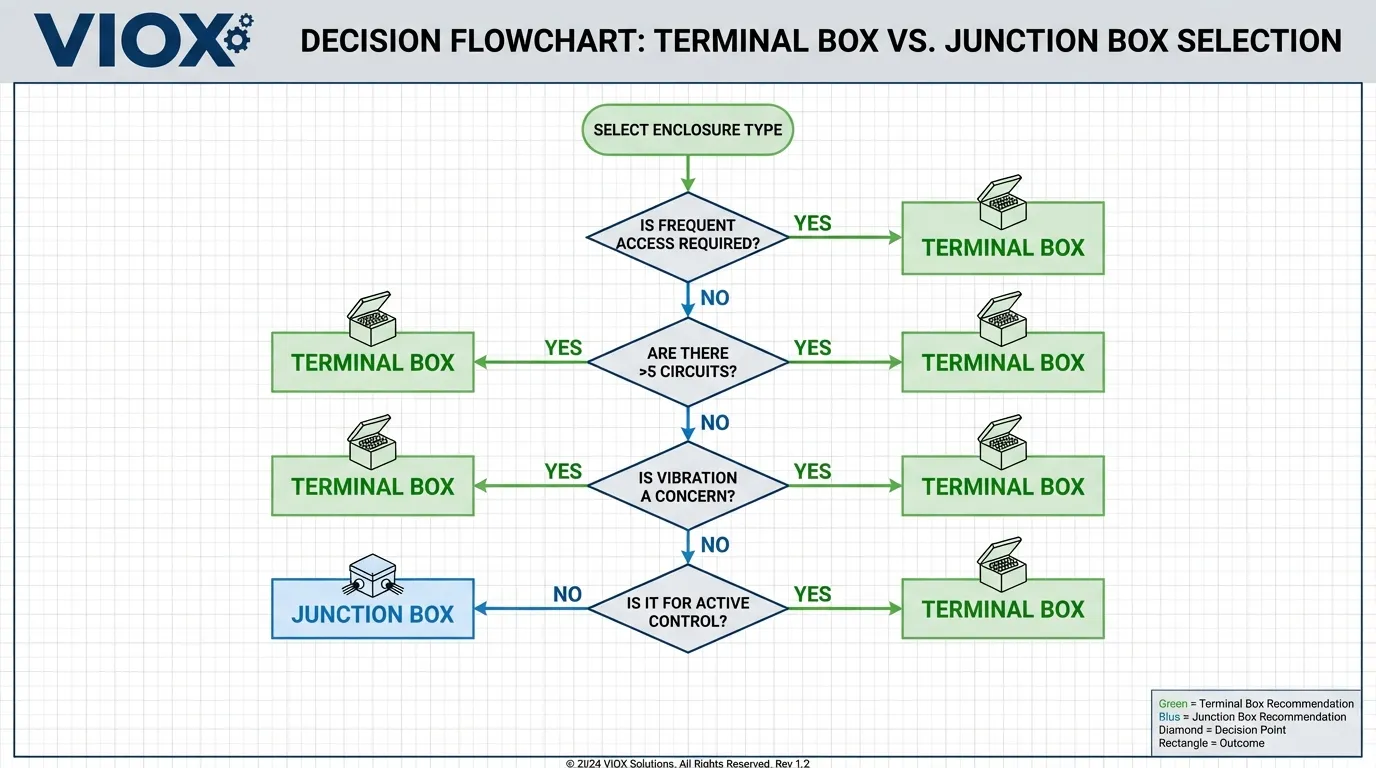

ការជ្រើសរើសប្រអប់ដែលត្រឹមត្រូវពាក់ព័ន្ធនឹងច្រើនជាងតម្លៃ។ ប្រើក្របខ័ណ្ឌការសម្រេចចិត្តនេះដើម្បីជ្រើសរើសដំណោះស្រាយដ៏ល្អប្រសើរសម្រាប់គម្រោងរបស់អ្នក។.

ពេលណាត្រូវជ្រើសរើសប្រអប់ស្ថានីយ

- ខ្សែភ្លើងស្មុគស្មាញ៖ ប្រសិនបើអ្នកមានសៀគ្វីច្រើនជាង 4-5 ដែលចូលក្នុងទតែមួយ។.

- ការពង្រីកអនាគត៖ ប្រសិនបើអ្នករំពឹងថានឹងបន្ថែមឧបករណ៍ចាប់សញ្ញា ឬកែប្រែលូជីខលគ្រប់គ្រង។.

- ប្រព័ន្ធសំខាន់៖ កន្លែងដែលត្រូវកាត់បន្ថយការផ្អាកដំណើរការ ហើយល្បឿននៃការរកកំហុសមានសារៈសំខាន់។.

- ភាពសុចរិតនៃសញ្ញា៖ នៅពេលគ្រប់គ្រងសញ្ញា 4-20mA ដែលមានភាពរសើប ឬខ្សែទិន្នន័យដែលត្រូវការការបញ្ចប់ដីការពារ។.

ពេលណាត្រូវជ្រើសរើសប្រអប់ប្រសព្វ

- ការដំឡើងឋិតិវន្ត៖ ភ្លើងបំភ្លឺ ថាមពលរន្ធ ឬការភ្ជាប់ខ្សែសាមញ្ញដែលនឹងមិនផ្លាស់ប្តូរ។.

- ដែនកំណត់លំហ៖ នៅពេលដាក់ចូលទៅក្នុងចន្លោះពិដាន ឬប្រហោងជញ្ជាំងតូចចង្អៀត។.

- ដែនកំណត់ថវិកា៖ សម្រាប់ការខ្សែភ្លើងទូទៅដែលមិនសំខាន់ ដែលតម្លៃសមាសធាតុជាកត្តាសំខាន់។.

ស្ដង់ដារបច្ចេកទេស និងការអនុលោមតាមកូដ (NEC & NEMA)

ការអនុលោមតាមច្បាប់គឺមិនអាចចរចាបានទេ។ ប្រភេទទូទាំងពីរត្រូវតែបំពេញតាមស្តង់ដារជាក់លាក់ដើម្បីធានាសុវត្ថិភាព និងភាពស្របច្បាប់។.

តម្រូវការមាត្រា 314 នៃ NEC

នេះ។ មាត្រា 314 នៃក្រមអគ្គិសនីជាតិ (NEC) គ្រប់គ្រងការដំឡើងព្រីភ្លើង ឧបករណ៍ ទាញ និងប្រអប់ប្រសព្វ។.

- លទ្ធភាពចូលដំណើរការ (314.29): ប្រអប់ទាំងអស់ត្រូវតែអាចចូលទៅដល់បានដោយមិនចាំបាច់ដកផ្នែកណាមួយនៃរចនាសម្ព័ន្ធអគារចេញទេ។ ប្រអប់ស្ថានីយ ដោយសារតែលក្ខណៈនៃការថែទាំរបស់វា ជារឿយៗត្រូវការ កន្លែងធ្វើការ ចន្លោះសុវត្ថិភាពស្រដៀងនឹងបន្ទះចែកចាយ (NEC 110.26) ប្រសិនបើវាមានសមាសធាតុដែលផ្ទុកថាមពលដែលអាចត្រូវបានថែទាំខណៈពេលដែលកំពុងដំណើរការ។.

- ការបំពេញប្រអប់ (314.16): ប្រអប់ប្រសព្វត្រូវបានកំណត់យ៉ាងតឹងរ៉ឹងដោយបរិមាណ conductor ។ ប្រអប់ស្ថានីយត្រូវតែមានទំហំសមស្របដើម្បីផ្ទុកប្លុកស្ថានីយ និងកន្លែងពត់ខ្សែគ្រប់គ្រាន់ (NEC 312.6)។.

- ការដាក់ស្លាក: ប្រអប់ស្ថានីយទាមទារការកំណត់អត្តសញ្ញាណសៀគ្វីលម្អិត។.

សម្រាប់ការពិនិត្យឡើងវិញដ៏ទូលំទូលាយនៃលក្ខណៈជាក់លាក់នៃកូដ សូមអានការណែនាំរបស់យើងអំពី លេខកូដ NEC សម្រាប់ប្រអប់ប្រសព្វរបស់យើង.

ការវាយតម្លៃ NEMA សម្រាប់បរិស្ថាន

ការជ្រើសរើសត្រឹមត្រូវ ការវាយតម្លៃ NEMA មានសារៈសំខាន់សម្រាប់ប្រភេទទាំងពីរ៖

- NEMA 1: ក្នុងផ្ទះ គោលបំណងទូទៅ (ការិយាល័យ/ឃ្លាំង)។.

- NEMA 12: ក្នុងផ្ទះ ធន់នឹងធូលី (ជាន់រោងចក្រ)។.

- NEMA 4/4X: ខាងក្រៅ/លាងសម្អាត ធន់នឹងទឹក និងធន់នឹងច្រេះ (កែច្នៃអាហារ សមុទ្រ)។.

- NEMA 7/9: ទីតាំងគ្រោះថ្នាក់ (ធន់នឹងការផ្ទុះ)។.

នៅពេលសម្រេចចិត្តរវាងវត្ថុធាតុដើម សូមពិចារណាលើបរិស្ថាន។. ប្រអប់ប្រសព្វដែកធៀបនឹងផ្លាស្ទិក ផ្តល់អត្ថប្រយោជន៍ខុសៗគ្នាទាក់ទងនឹងការដាក់ដី ភាពធន់ និងភាពធន់នឹងច្រេះ។.

ការដំឡើង និងការដោះស្រាយបញ្ហា ការអនុវត្តល្អបំផុត

ការណែនាំអំពីការដំឡើង

- ការដាក់ស្លាក: នៅក្នុងប្រអប់ស្ថានីយ សូមដាក់ស្លាកខ្សែនីមួយៗ និងចំណុចស្ថានីយនីមួយៗ។ នៅក្នុងប្រអប់ប្រសព្វ សូមដាក់ស្លាកបណ្តុំខ្សែដែលមានលេខសៀគ្វី។.

- សមត្ថភាពទំនេរ: តែងតែធ្វើមាត្រដ្ឋានប្រអប់ស្ថានីយដែលមានទំហំទំនេរ 20% សម្រាប់ផ្លូវដែក DIN សម្រាប់ការធ្វើឱ្យប្រសើរឡើងនាពេលអនាគត។.

- ការបញ្ចូលខ្សែ: ប្រើក្រពេញខ្សែកាបដែលបានវាយតម្លៃ (ការធូរស្រាលនៃភាពតានតឹង) ដើម្បីរក្សាការវាយតម្លៃ NEMA នៃស្រោម។.

- ដី: ត្រូវប្រាកដថាទ្វារស្រោមនៃប្រអប់ស្ថានីយត្រូវបានភ្ជាប់ទៅដី ជាពិសេសប្រសិនបើវាផ្ទុកភ្លើងសញ្ញា ឬកុងតាក់។.

ការដោះស្រាយបញ្ហាទូទៅ

- ការតភ្ជាប់រលុង: វដ្តកម្ដៅអាចធ្វើឱ្យវីសរលុង។ ប្រអប់ស្ថានីយដែលមានស្ថានីយទ្រុងនិទាឃរដូវកាត់បន្ថយបញ្ហានេះ។ គ្រាប់ខ្សែប្រអប់ប្រសព្វអាចរលុង ប្រសិនបើមិនបានបង្វិលត្រឹមត្រូវ។.

- ការជ្រាបចូលសំណើម: ជាញឹកញាប់បណ្តាលមកពីការដាក់កៅស៊ូមិនត្រឹមត្រូវ ឬច្រក conduit ដែលមិនបានផ្សាភ្ជាប់។.

- ការចង្អៀត: ការរំលោភទូទៅនៅក្នុងប្រអប់ប្រសព្វ (ការបំពេញប្រអប់) ដែលនាំឱ្យឡើងកំដៅ។ ប្រអប់ស្ថានីយការពារបញ្ហានេះដោយការរចនា តាមរយៈចន្លោះថេរ។.

សំណួរដែលសួរញឹកញាប់ (FAQ)

សំណួរទី 1: តើខ្ញុំអាចប្រើប្រអប់ប្រសព្វជាប្រអប់ស្ថានីយបានទេ?

Technically, yes, if you install a DIN rail and terminal blocks inside. However, standard junction boxes may lack the depth or mounting bosses required for proper terminal block installation. It is better to purchase a purpose-built terminal enclosure.

សំណួរទី 2: តើប្រអប់ស្ថានីយត្រូវការទំហំធំជាងប្រអប់ប្រសព្វដែរឬទេ?

Yes. Terminal boxes require internal clearance for the terminal blocks and organized wire routing. A junction box can be more compact because wires are bundled together, but this sacrifices organization.

សំណួរទី 3: តើប្រអប់ស្ថានីយត្រូវបានទាមទារដោយកូដសម្រាប់គ្រឿងម៉ាស៊ីនឧស្សាហកម្មដែរឬទេ?

ខណៈពេលដែលមិនត្រូវបាន “ទាមទារ” យ៉ាងច្បាស់លាស់ឱ្យក្លាយជាប្រភេទជាក់លាក់មួយ NFPA 79 (ស្តង់ដារអគ្គិសនីសម្រាប់គ្រឿងម៉ាស៊ីនឧស្សាហកម្ម) គាំទ្រយ៉ាងខ្លាំងដល់ការប្រើប្រាស់ប្លុកស្ថានីយសម្រាប់ការតភ្ជាប់ខ្សែភ្លើងទាំងអស់ ដើម្បីធានាសុវត្ថិភាព ការកំណត់អត្តសញ្ញាណ និងលទ្ធភាពថែទាំ។.

សំណួរទី 4: តើមួយណាកាន់តែថ្លៃជាង: ប្រអប់ស្ថានីយ ឬប្រអប់ប្រសព្វ?

ប្រអប់ស្ថានីយមានតម្លៃ BOM (បញ្ជីសម្ភារៈ) ខ្ពស់ជាងដោយសារតែស្រោម ផ្លូវដែក ប្លុក ចានចុង និងសញ្ញាសម្គាល់។ ទោះជាយ៉ាងណាក៏ដោយ ការសន្សំកម្លាំងពលកម្មក្នុងអំឡុងពេលដាក់ឱ្យដំណើរការ និងការដោះស្រាយបញ្ហា ជារឿយៗធ្វើឱ្យវាកាន់តែថោកជាងក្នុងរយៈពេលពេញមួយជីវិតរបស់ប្រព័ន្ធ។.

សំណួរទី 5: តើខ្ញុំអាចភ្ជាប់ខ្សែនៅខាងក្នុងប្រអប់ស្ថានីយបានទេ?

It is poor practice. If a wire is too short, use a feed-through terminal block to extend it. Avoid using wire nuts inside a terminal box as it defeats the purpose of an organized enclosure.

សំណួរទី 6: តើខ្ញុំធ្វើមាត្រដ្ឋានប្រអប់ស្ថានីយដោយរបៀបណា?

Calculate the total width of all terminal blocks, end stops, and accessories. Add 20% for spares. Ensure there is sufficient depth for the blocks plus wire bending radius (typically 2-3 inches clearance from block to wall).

សំណួរទី 7: តើខ្ញុំត្រូវការប្រអប់ស្ថានីយដែក ឬផ្លាស្ទិក?

ប្រើ ដែក (ដែកអ៊ីណុក ឬដែកកាបូន) សម្រាប់តំបន់ដែលមានផលប៉ះពាល់ខ្ពស់ ការការពារ EMI ឬកំដៅខ្លាំង។ ប្រើ ផ្លាស្ទិក (ប៉ូលីកាបូណាត/សរសៃកញ្ចក់) សម្រាប់បរិស្ថានដែលច្រេះ ភាពថ្លា Wi-Fi/RF និងអ៊ីសូឡង់អគ្គិសនី។.

សំណួរទី 8: តើអ្វីជាភាពខុសគ្នារវាងប្រអប់ចែកចាយ និងប្រអប់ស្ថានីយ?

A distribution box typically contains protective devices (fuses, breakers) to split power into subsidiary circuits. A terminal box is primarily for connecting/passing through wires without overcurrent protection, though some terminal blocks can include fuses.

សេចក្តីសន្និ

ភាពខុសគ្នារវាង ប្រអប់ស្ថានីយ និងមួយ ប្រអប់ប្រសព្វ កំណត់ទស្សនវិជ្ជាប្រតិបត្តិការនៃប្រព័ន្ធអគ្គិសនីរបស់អ្នក។ ប្រអប់ប្រសព្វគឺជាវិធានការការពារ “កំណត់វាហើយបំភ្លេចវា” ដែលល្អសម្រាប់ហេដ្ឋារចនាសម្ព័ន្ធឋិតិវន្ត។ ប្រអប់ស្ថានីយគឺជាឧបករណ៍គ្រប់គ្រងសកម្ម ដែលចាំបាច់សម្រាប់តម្រូវការថាមវន្ត និងភាពជឿជាក់ខ្ពស់នៃឧស្សាហកម្មទំនើប។.

សម្រាប់បន្ទះឧស្សាហកម្ម ស្វ័យប្រវត្តិកម្ម និងការចែកចាយថាមពលសំខាន់ៗ ប្រអប់ស្ថានីយ គឺជាជម្រើសដ៏ល្អបំផុត ដែលផ្តល់នូវអង្គការ សុវត្ថិភាព និងល្បឿនថែទាំដែលមិនអាចប្រៀបផ្ទឹមបាន។ ខណៈពេលដែលការវិនិយោគដំបូងខ្ពស់ជាង ការត្រឡប់មកវិញលើការវិនិយោគតាមរយៈការកាត់បន្ថយពេលវេលារងចាំ និងការបង្កើនសុវត្ថិភាពគឺមិនអាចប្រកែកបាន។.

ត្រៀមខ្លួនរួចរាល់ហើយដើម្បីធ្វើឱ្យប្រសើរឡើងនូវហេដ្ឋារចនាសម្ព័ន្ធអគ្គិសនីរបស់អ្នក? VIOX Electric ផលិតប្រអប់ស្ថានីយ និងប្រអប់ប្រសព្វដែលបានវាយតម្លៃ NEMA ពិសេសដែលត្រូវបានរចនាឡើងសម្រាប់កម្មវិធីឧស្សាហកម្មដែលទាមទារបំផុត។ ពីស្រោមស្ថានីយដែលបានកំណត់រចនាសម្ព័ន្ធតាមបំណង រហូតដល់ប្រអប់ប្រសព្វដែលធន់នឹងការផ្ទុះ ក្រុមវិស្វកម្មរបស់យើងធានាថាគម្រោងរបស់អ្នកបំពេញតាមកូដ និងស្តង់ដារការអនុវត្តនីមួយៗ។.

ស្វែងយល់ពីដំណោះស្រាយប្រអប់ស្ថានីយ VIOX ឬ ទាក់ទងវិស្វកររបស់យើង ថ្ងៃនេះសម្រាប់ការពិគ្រោះយោបល់ដោយឥតគិតថ្លៃលើគម្រោងបន្ទាប់របស់អ្នក។.