What Makes Residential and Utility-Scale Combiner Boxes Different?

Residential PV combiner boxes typically handle 600V DC systems with 2-6 string inputs and operate in single-family installations, while utility-scale combiner boxes manage 1500V DC systems with 12-24+ string inputs across multi-megawatt solar farms. The fundamental difference lies in voltage ratings, current capacity, environmental durability requirements, and cost-per-watt optimization strategies—residential systems prioritize simplicity and code compliance, whereas utility-scale designs focus on LCOE reduction and advanced monitoring capabilities.

គន្លឹះយក

- Voltage Architecture: Residential systems use 600V DC (NEC standard), commercial installations operate at 1000V DC, and utility-scale farms require 1500V DC combiner boxes for optimal economics

- សមត្ថភាពខ្សែ: Residential combiner boxes handle 2-6 strings (often optional for ≤3 strings), while utility-scale units manage 12-24+ strings per box with distributed placement strategies

- Cost Structure: Residential combiner boxes cost $300-$800 per unit; utility-scale systems achieve $8-12 million BOS savings per 100MW through 1500V architecture

- Protection Standards: Both scales require NEC 690 compliance, but utility-scale adds arc-fault detection, remote monitoring, and rapid shutdown integration

- កាលវិភាគ ROI: Residential systems break even in 6-8 years; utility-scale 1500V designs improve LCOE by 15-20% compared to 1000V equivalents

Understanding PV Combiner Box Fundamentals

A photovoltaic combiner box consolidates multiple DC strings from solar panel arrays into a single output circuit that feeds the inverter. This junction point provides three critical functions: overcurrent protection for individual strings through fuses or breakers សៀគ្វី, ការការពារការកើនឡើង against transient voltage spikes, and a centralized disconnection point for maintenance and emergency shutdown. The combiner box essentially transforms a complex web of parallel DC circuits into a manageable, code-compliant power delivery system.

The necessity of a combiner box depends entirely on system architecture. For small residential installations with three or fewer strings, direct connection to the inverter remains permissible under NEC Article 690, eliminating the $400-$800 equipment cost and an additional failure point. However, once a system scales beyond three strings—common in larger residential rooftops, all commercial projects, and universal in utility-scale farms—the combiner box transitions from optional accessory to mandatory infrastructure. សម្រង់

Residential PV Combiner Box Design Specifications

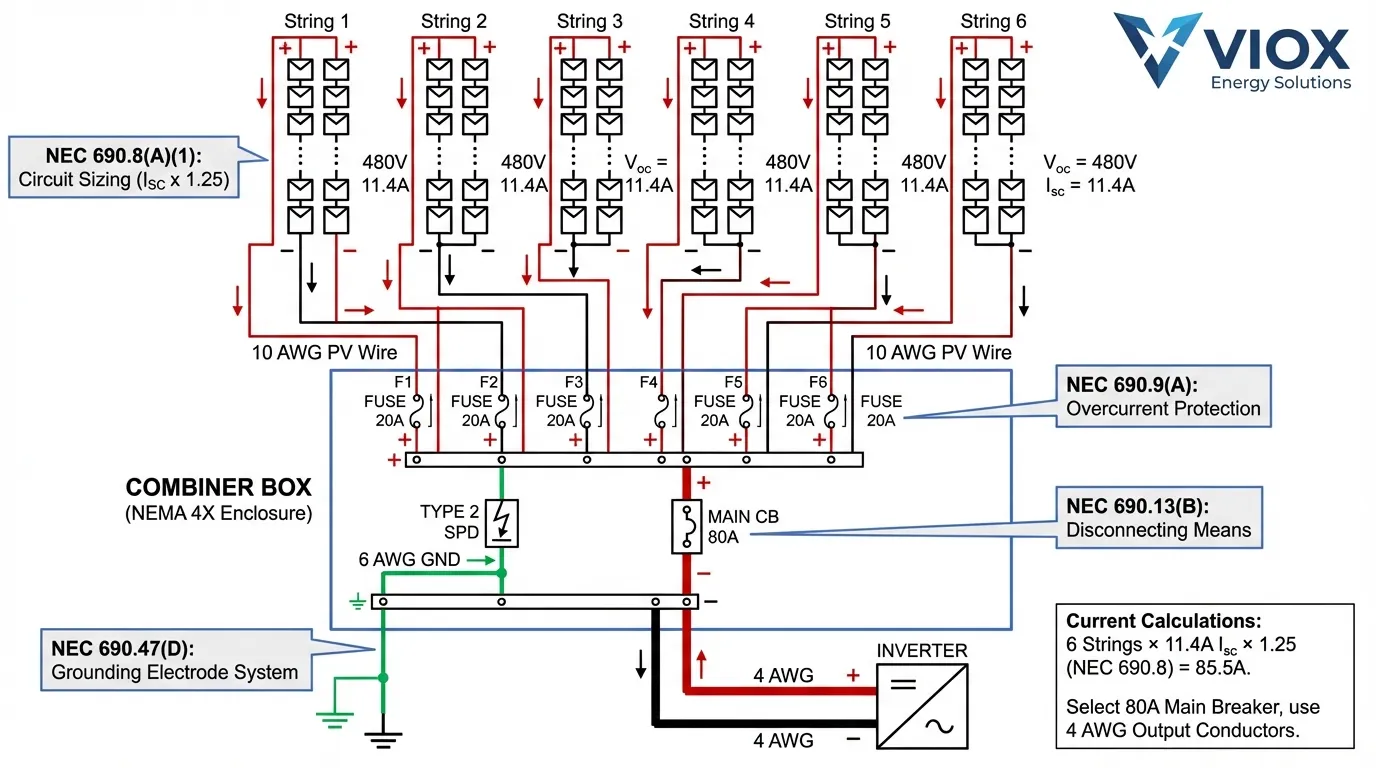

Voltage and Current Requirements

Residential solar installations in North America predominantly operate at 600V DC maximum system voltage, aligning with standard residential inverter specifications and NEC 690.7 requirements. String current calculations follow the fundamental formula: multiply the module’s short-circuit current (Isc) by 1.56 to account for NEC’s continuous duty factor (1.25) and overcurrent protection sizing requirement (1.25), yielding the minimum fuse rating per string. For a typical residential string using 400W panels with 11.4A Isc, the calculation yields 17.78A, requiring a standard 20A fuse per string input.

The combiner box’s main output breaker must accommodate the aggregate current of all strings. A four-string residential system with 11.4A Isc per string generates 45.6A total, which after applying the 1.25 continuous duty multiplier requires a 57A minimum rating—typically satisfied with a standard 60A or 80A main breaker depending on wire sizing and future expansion considerations. សម្រង់

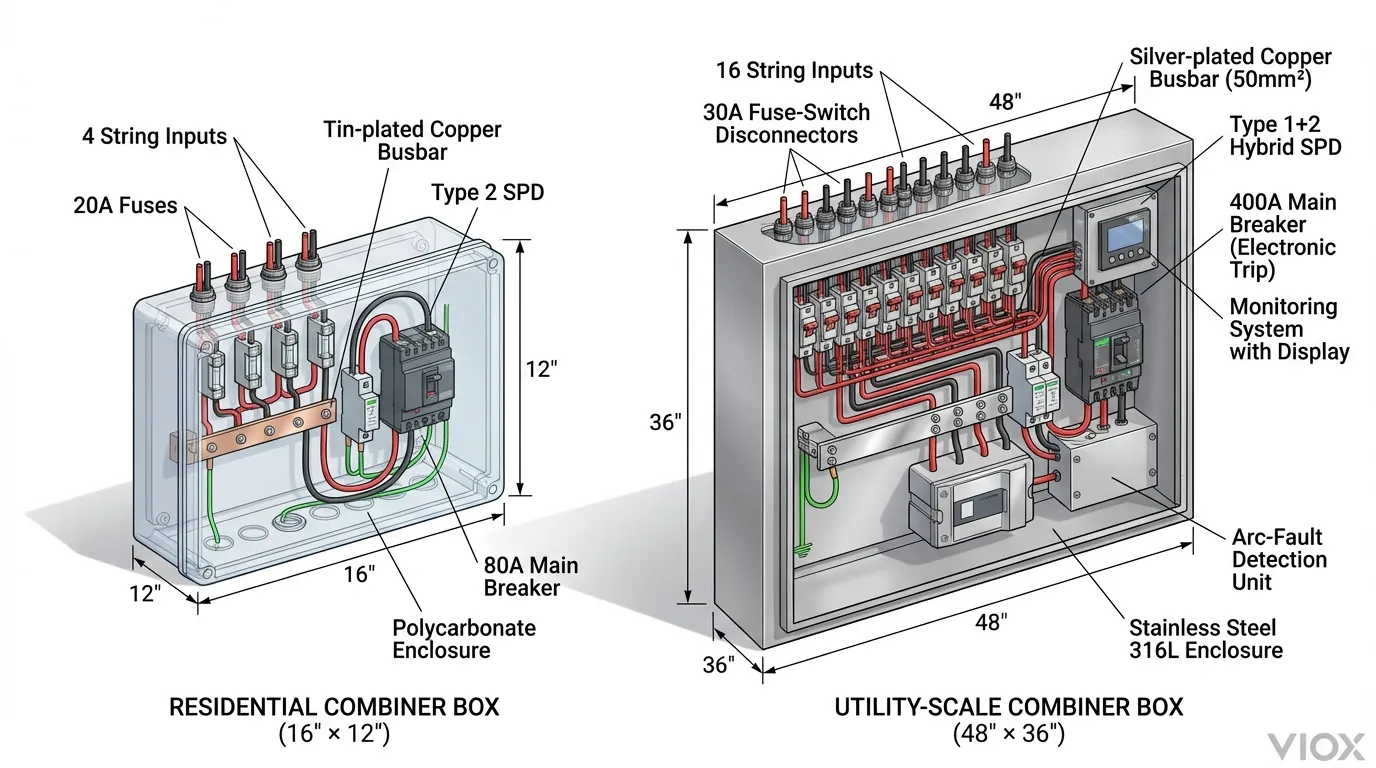

Physical and Environmental Specifications

Residential combiner boxes typically measure 12″ × 16″ × 6″ for 4-6 string configurations, constructed from UV-stabilized polycarbonate or powder-coated steel enclosures. The IP65 rating represents the minimum acceptable ingress protection for outdoor mounting, providing dust-tight sealing and protection against water jets from any direction. Coastal installations or areas with extreme weather exposure should specify IP66 or NEMA 4X ratings, which offer enhanced corrosion resistance through stainless steel hardware and gasket materials resistant to salt spray and temperature cycling. សម្រង់

Temperature derating becomes critical for combiner boxes mounted in direct sunlight or on dark roofing surfaces. Ambient temperatures inside these enclosures can reach 60-70°C (140-158°F), requiring application of NEC Table 310.15(B)(2)(a) correction factors to conductor ampacity calculations. This thermal stress also affects fuse and breaker trip characteristics, making oversized enclosures with adequate ventilation a worthwhile investment for long-term reliability.

Component Selection for Residential Applications

| សមាសភាគ | Residential Specification | លក្ខណៈវិនិច្ឆ័យជ្រើសរើសគន្លឹះ |

|---|---|---|

| String Fuses | 15-20A, 1000V DC rated | PV-specific gPV fuses per IEC 60269-6; avoid AC fuses |

| អ្នកបំបែកមេ | 60-100A, 2-pole DC rated | UL 489 Listed, 10kA minimum interrupt rating |

| SPD (Surge Protection) | Type 2, 600V DC, 20-40kA | Uc ≥ 1.2× Voc(max), remote status indication |

| Busbar | Tin-plated copper, 10-15mm² | Temperature rise < 50K at rated current |

| ឯករភជប់ | Polycarbonate or steel, IP65 | UV-stabilized, -40°C to +70°C operating range |

| Monitoring (Optional) | String-level voltage/current | RS485 or wireless connectivity for 6+ string systems |

The choice between pre-assembled and custom combiner boxes significantly impacts residential project economics. Off-the-shelf units from manufacturers like VIOX អគ្គិសនី provide UL-listed, plug-and-play solutions with standardized 4, 6, or 8-string configurations, reducing installation time to under two hours and eliminating field wiring errors. Custom designs make sense only for unusual roof layouts or when integrating rapid shutdown functionality that isn’t available in standard products.

Utility-Scale PV Combiner Box Engineering

The 1500V DC Architecture Imperative

Utility-scale solar farms above 5MW have universally adopted 1500V DC system architecture, driven by compelling levelized cost of energy (LCOE) improvements. The higher voltage enables 50% longer string lengths compared to 1000V systems, reducing total string count by approximately 37% and proportionally decreasing the number of combiner boxes, DC collection cables, and installation labor hours. A 100MW solar farm designed at 1500V DC saves $8-12 million in balance-of-system costs versus an equivalent 1000V design, while simultaneously reducing DC current by 33% for equivalent power output, which translates to lower I²R losses and approximately 0.3% higher annual energy yield. សម្រង់

This voltage transition introduces significant engineering challenges. Component insulation coordination must account for transient overvoltages reaching 2000V during lightning events or inverter switching operations. Creepage and clearance distances between live parts and ground must increase to prevent tracking and flashover, resulting in physically larger enclosures despite handling fewer strings. Personnel safety protocols become more stringent—1500V DC systems can sustain arcs more readily than lower voltage equivalents, necessitating arc-fault circuit interrupters (AFCI) in many jurisdictions.

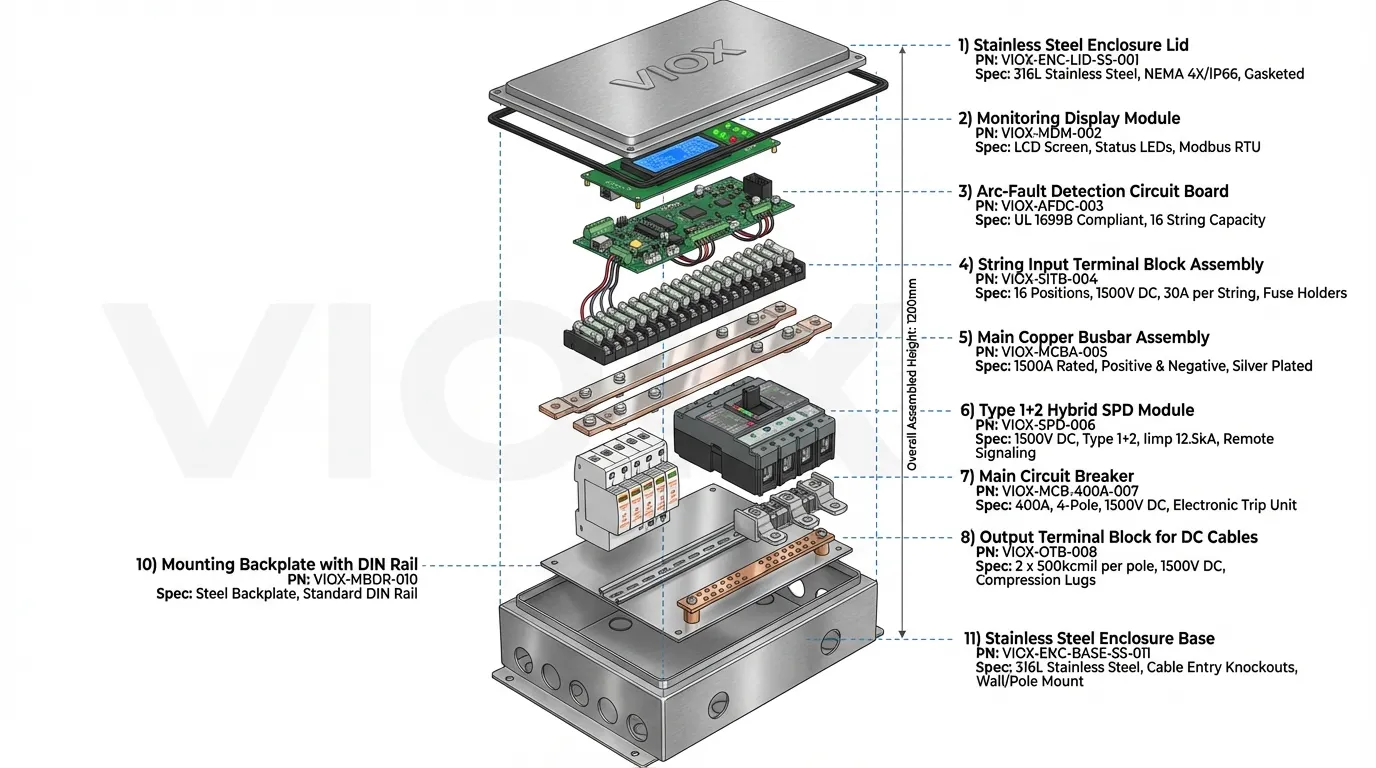

String Capacity and Distributed Placement Strategy

Utility-scale combiner boxes typically accommodate 12-24 string inputs, with the optimal configuration determined by inverter MPPT channel count, DC cable voltage drop calculations, and site topology. A 5MW ground-mount solar farm might deploy 30-40 combiner boxes distributed throughout the array, each consolidating 16-20 strings before feeding into central inverters or distributed string inverters via DC collection cables. This distributed placement strategy minimizes DC cable runs, reduces voltage drop losses, and enables modular construction sequencing during the EPC phase.

The string-to-combiner ratio calculation balances multiple factors: higher string counts per box reduce equipment and installation costs but increase DC cable gauge requirements and complicate maintenance access. Modern utility-scale designs typically target 15-18 strings per combiner box as the economic optimum, providing sufficient consolidation while maintaining manageable enclosure sizes and wire termination accessibility. សម្រង់

Advanced Protection and Monitoring Systems

| លក្ខណៈ | Utility-Scale Implementation | Business Justification |

|---|---|---|

| Arc-Fault Detection | Series and parallel arc detection per UL 1699B | Prevents 80% of DC-side fire risks; insurance requirement in many markets |

| ការត្រួតពិនិត្យកម្រិតខ្សែ | Voltage, current, temperature per string | Identifies underperforming strings; improves O&M efficiency by 40% |

| Remote Disconnect | Motorized switch with SCADA integration | Enables emergency shutdown without site access; firefighter safety |

| Environmental Sensors | Ambient temp, humidity, enclosure temp | Predictive maintenance; prevents thermal-related failures |

| Communication Protocol | Modbus RTU/TCP, DNP3, or IEC 61850 | Integration with plant SCADA; real-time performance monitoring |

| ការបិទយ៉ាងរហ័ស | Module-level or combiner-level per NEC 690.12 | Code compliance; reduces arc-flash hazard during maintenance |

String-level monitoring in utility-scale combiner boxes provides granular performance data that directly impacts project bankability. Investors and lenders increasingly require real-time visibility into array performance to validate production forecasts and identify revenue-impacting faults. A single underperforming string in a 100MW farm can cost $3,000-$5,000 annually in lost generation—monitoring systems that detect these issues within days rather than months deliver measurable ROI through improved capacity factors. សម្រង់

Utility-Scale Component Specifications

| សមាសភាគ | Utility-Scale Specification | Key Differences from Residential |

|---|---|---|

| String Fuses | 20-30A, 1500V DC rated | Higher voltage insulation; often use fuse-switch disconnectors |

| អ្នកបំបែកមេ | 400-630A, 4-pole DC rated | 65kA interrupt rating; electronic trip units with communication |

| SPD | Type 1+2 hybrid, 1500V DC, 100kA | Higher energy handling; coordinated with array-level SPDs |

| Busbar | Silver-plated copper, 50-120mm² | Lower contact resistance; designed for 30+ year lifespan |

| ឯករភជប់ | Stainless steel 316L, IP66/NEMA 4X | Corrosion resistance; passive cooling with heat sinks |

| ក្រពេញខ្សែកាប | EMC-rated, IP68 | Electromagnetic compatibility; submersible rating for flood zones |

The material specifications for utility-scale combiner boxes reflect the harsh operating environment and 30+ year design life expectation. Stainless steel 316L enclosures with powder-coated finishes resist corrosion in desert, coastal, and agricultural settings where residential-grade polycarbonate would degrade within 10-15 years. Internal components use silver-plated copper busbars rather than tin-plated alternatives to minimize contact resistance and ensure stable performance across temperature cycling from -40°C to +85°C. សម្រង់

Critical Design Differences: Side-by-Side Comparison

System Architecture Comparison

| ប៉ារ៉ាម៉ែត្រ | Residential Systems | Utility-Scale Systems |

|---|---|---|

| វ៉ុលប្រព័ន្ធ | 600V DC (NEC standard) | 1500V DC (industry standard post-2020) |

| ចំនួនខ្សែ | 2-6 strings (often ≤3 = no combiner needed) | 12-24+ strings per combiner box |

| Total System Size | 5-15 kW typical | 5-500+ MW |

| Combiner Box Quantity | 0-1 per installation | 30-200+ per farm |

| String Length | 8-12 panels per string | 24-32 panels per string |

| ប្រភេទ Inverter | String inverter (single unit) | Central or string inverters (multiple units) |

Cost and Economic Analysis

| កត្តាចំណាយ | លំនៅដ្ឋាន | ខ្នាតឧបករណ៍ប្រើប្រាស់ |

|---|---|---|

| Combiner Box Unit Cost | $300-$800 | $2,500-$8,000 |

| Cost Per Watt | $0.05-$0.08/W | $0.01-$0.02/W |

| ការងារដំឡើង | 2-4 ម៉ោង។ | 4-8 hours per box (but amortized over MW) |

| BOS Cost Impact | 3-5% of total system cost | 8-12% of total system cost |

| Monitoring Cost | $0-$200 (often omitted) | $500-$1,500 per box (mandatory) |

| ចន្លោះពេលថែទាំ | ៥-១០ ឆ្នាំ។ | 2-3 years (preventive) |

The per-watt cost differential reveals the fundamental economic distinction between residential and utility-scale solar. While a residential combiner box represents a larger percentage of total system cost, the absolute dollar amount remains modest ($300-$800). Utility-scale projects achieve dramatically lower per-watt costs through volume procurement, standardized designs, and the ability to amortize engineering costs across hundreds of megawatts. However, the total capital expenditure on combiner boxes for a 100MW farm can exceed $500,000-$800,000, making component selection and supplier qualification critical procurement activities. សម្រង់

ការអនុលោមតាមច្បាប់ និងស្តង់ដារ

| តម្រូវការ | Residential Application | Utility-Scale Application |

|---|---|---|

| Primary Code | NEC មាត្រា 690 | NEC Article 690 + utility interconnection standards |

| ការការពារចរន្តលើស | NEC 690.9 (1.56× Isc minimum) | NEC 690.9 + coordination study required |

| ដី | NEC 690.41-690.47 | Enhanced grounding grid; soil resistivity testing |

| ការដាក់ស្លាក | NEC 690.31 (basic warning labels) | Arc-flash labels per NFPA 70E; detailed one-line diagrams |

| ការបិទយ៉ាងរហ័ស | NEC 690.12 (module-level or array-level) | NEC 690.12 + utility-specific requirements |

| Testing/Commissioning | Visual inspection + voltage verification | Full acceptance testing per IEC 62446; IR thermography |

Both residential and utility-scale installations must comply with NEC Article 690, but utility-scale projects face additional layers of regulatory scrutiny. Utility interconnection agreements often impose requirements beyond the NEC minimum, including specific arc-fault detection technologies, remote disconnect capabilities, and real-time monitoring with utility SCADA integration. These supplementary requirements can add 15-25% to combiner box costs but are non-negotiable for project approval and commercial operation date (COD) achievement. សម្រង់

Selection Criteria: Choosing the Right Combiner Box

For Residential Installations (5-15 kW)

Step 1: Determine if a combiner box is necessary. Calculate your total string count based on roof layout and shading analysis. If your system has three or fewer strings, connect directly to the inverter and save $400-$800 plus installation labor. This direct connection approach is explicitly permitted by NEC 690.9 and represents the most cost-effective solution for small residential arrays.

Step 2: Calculate electrical specifications. Multiply your panel’s Isc by 1.56 to determine minimum fuse rating per string. Sum the total current from all strings and multiply by 1.25 to determine main breaker rating. Verify that your selected combiner box voltage rating exceeds the string’s maximum open-circuit voltage (Voc) by at least 20% safety margin.

Step 3: Evaluate environmental requirements. Roof-mounted combiner boxes in direct sunlight require IP65 minimum, with IP66 preferred for longevity. Coastal installations within 10 miles of saltwater should specify NEMA 4X stainless steel enclosures with marine-grade gaskets and hardware. Consider thermal derating if ambient temperatures regularly exceed 40°C (104°F).

Step 4: Assess monitoring needs. For systems with six or more strings, string-level monitoring provides valuable diagnostic capability that can identify underperforming panels or wiring issues. The $200-$400 incremental cost for monitoring-enabled combiner boxes typically pays for itself within 2-3 years through improved system availability and faster fault resolution. សម្រង់

For Utility-Scale Projects (5+ MW)

Step 1: Confirm system voltage architecture. For projects above 5MW, 1500V DC architecture should be the default design basis unless site-specific constraints dictate otherwise. The LCOE improvement of 15-20% compared to 1000V systems makes this decision straightforward from a financial modeling perspective.

Step 2: Optimize string-to-combiner ratio. Perform a detailed economic analysis balancing combiner box quantity against DC cable costs and voltage drop losses. The optimal ratio typically falls between 15-18 strings per combiner box, but site topology and inverter specifications may shift this target. Use DC cable voltage drop calculations to verify that combined string current doesn’t exceed 3% voltage loss at maximum power point.

Step 3: Specify protection and monitoring systems. Arc-fault detection is mandatory for bankability and insurance underwriting in most markets. String-level voltage and current monitoring should be standard specification—the incremental cost of $50-$80 per string is negligible compared to the revenue protection value. Integrate combiner box monitoring with plant SCADA using Modbus TCP or DNP3 protocols for centralized visibility.

Step 4: Evaluate supplier qualifications. Utility-scale combiner boxes represent critical infrastructure with 30-year design life expectations. Supplier selection should prioritize manufacturers with IEC 61439-2 certification, proven track record in multi-megawatt projects, and comprehensive warranty coverage (minimum 10 years for enclosure, 5 years for electronics). Request third-party test reports for short-circuit withstand, temperature rise, and IP rating verification. សម្រង់

កំហុសរចនាទូទៅ និងវិធីជៀសវាងពួកវា

Residential System Pitfalls

Mistake #1: Using AC-rated fuses in DC applications. Standard AC fuses lack the arc-quenching capability required for DC circuits, where the absence of zero-crossing makes arc extinction significantly more challenging. Always specify PV-specific gPV fuses rated per IEC 60269-6, which incorporate enhanced arc-quenching chambers designed for DC interruption. The cost difference is negligible ($3-5 per fuse), but the safety implications are profound. សម្រង់

Mistake #2: Inadequate wire sizing for temperature derating. Combiner boxes mounted on dark roofing or in direct sunlight experience ambient temperatures of 60-70°C, requiring application of NEC Table 310.15(B)(2)(a) correction factors. A 10 AWG conductor rated for 40A at 30°C ambient derated to 70°C ambient can only carry 24A safely. Failure to apply these correction factors creates fire hazards and code violations.

Mistake #3: Omitting surge protection. While not universally required by code, Type 2 SPDs in residential combiner boxes provide critical protection against indirect lightning strikes and utility switching transients. The $80-150 incremental cost is trivial compared to the $3,000-8,000 cost of inverter replacement after a surge event. Specify SPDs with remote status indication to enable proactive replacement before failure.

Utility-Scale System Pitfalls

Mistake #1: Undersizing for future expansion. Utility-scale projects often phase construction over 12-24 months, with initial combiner box installations occurring before final array layout is confirmed. Specifying combiner boxes with 20-30% spare capacity (unused string inputs) costs $200-400 per box but eliminates the need for field modifications or supplementary combiner box additions during later construction phases.

Mistake #2: Inadequate grounding and bonding. Large solar farms with multiple combiner boxes require comprehensive grounding grid design with soil resistivity testing and ground fault coordination studies. Simply connecting each combiner box to a local ground rod creates ground loops and can result in circulating currents that cause nuisance tripping or equipment damage. Engage a qualified electrical engineer to design the grounding system per IEEE 80 and NEC 690.41-690.47.

Mistake #3: Neglecting thermal management. Utility-scale combiner boxes handling 400-600A combined current generate significant internal heat, especially in desert climates where ambient temperatures exceed 45°C (113°F). Passive cooling through oversized enclosures, heat sinks on busbars, and strategic ventilation placement should be standard design practice. Active cooling (fans) introduces maintenance requirements and failure points that undermine long-term reliability. សម្រង់

未来趋势与技术演进

The solar combiner box market is experiencing rapid innovation driven by digitalization, cost reduction pressures, and evolving safety standards. Smart combiner boxes with integrated string-level monitoring, predictive maintenance algorithms, and cloud connectivity are transitioning from premium options to standard specifications in utility-scale projects. These intelligent systems use machine learning to identify degradation patterns, predict component failures before they occur, and optimize maintenance scheduling to minimize downtime.

Residential markets are seeing convergence between combiner box functionality and rapid shutdown requirements, with integrated solutions that combine string consolidation, overcurrent protection, and module-level shutdown in a single enclosure. This integration reduces installation complexity, improves aesthetics, and ensures code compliance as NEC 690.12 requirements become more stringent in successive code cycles.

The industry’s migration toward 1500V DC systems in utility-scale applications will continue accelerating, with forecasts indicating 85% market penetration by 2028 for projects above 1MW. Component suppliers are focusing R&D investment on 1500V-rated products, allowing 1000V product lines to mature without further optimization. This transition creates procurement challenges for projects in the design phase today—specifying 1000V equipment may result in limited supplier options and higher costs as the industry supply chain pivots to 1500V as the new standard. សម្រង់

ធនធាន VIOX ដែលទាក់ទង

For deeper technical guidance on specific aspects of PV combiner box design and selection, explore these comprehensive resources:

- តើប្រអប់បញ្ចូលថាមពលព្រះអាទិត្យធ្វើអ្វី? – Fundamental overview of combiner box function and necessity

- Solar Combiner Box Voltage Ratings: 600V vs 1000V vs 1500V Guide – Detailed voltage architecture comparison with ROI analysis

- តើចំនួនខ្សែប៉ុន្មានក្នុងប្រអប់បញ្ចូលគ្នា គឺល្អបំផុតសម្រាប់ប្រព័ន្ធថាមពលពន្លឺព្រះអាទិត្យក្នុងផ្ទះ? – Residential sizing calculations with NEC compliance guidance

- Solar Combiner Box Sizing Guide: Expansion Planning – Future-proofing strategies for growing installations

- 1000V Solar Combiner Box Design & Compliance Guide – Commercial-scale design specifications

- PV Combiner Box Enclosure Selection: Thermal & UV Comparison – Material selection for environmental durability

- Solar Combiner Box Inspection Checklist: UL/IEC Guide – Commissioning and maintenance procedures

- Troubleshooting Solar Combiner Box Faults & Fixes – Common failure modes and diagnostic techniques

- Solar Combiner Box Overheating: Causes & Solutions – Thermal management best practices

- DC Circuit Breaker Sizing: NEC 690 vs IEC 60947-2 Guide – Overcurrent protection device selection

- What is a Surge Protection Device (SPD)? – Surge protection fundamentals for PV systems

- DC Circuit Breaker vs Fuse: Which is Better? – Protection device comparison for solar applications

- Electrical Enclosure Material Selection Guide – Enclosure material properties and application guidance

- Junction Box Sizing Guide – NEC box fill calculations and sizing methodology

- Low vs Medium vs High Voltage Classification Guide – Voltage classification standards and safety implications

ជាញឹកញាប់បានសួរសំណួរ

Q: Can I use a residential combiner box for a small commercial installation?

A: Residential-grade combiner boxes can technically serve small commercial systems up to approximately 25kW if the string count and current ratings align with specifications. However, commercial installations typically require enhanced monitoring capabilities, longer warranty periods, and more robust enclosure materials to satisfy insurance and building code requirements. The incremental cost of commercial-grade equipment ($200-400) is usually justified by improved reliability and compliance assurance.

Q: How do I calculate the correct fuse size for my strings?

A: Multiply your solar panel’s short-circuit current (Isc, found on the datasheet) by 1.56 to determine the minimum fuse rating. This factor accounts for NEC’s 125% continuous duty requirement (1.25) and the 125% overcurrent protection device sizing rule (1.25), yielding 1.56 total. Round up to the next standard fuse size. For example, a panel with 11.4A Isc requires 11.4 × 1.56 = 17.78A minimum, so specify a 20A fuse.

Q: Is monitoring necessary in a residential combiner box?

A: Monitoring is optional for residential systems but highly recommended for installations with six or more strings. String-level monitoring enables rapid identification of underperforming panels, wiring issues, or fuse failures that would otherwise go undetected until annual production analysis. The $200-400 incremental cost typically pays for itself within 2-3 years through improved system availability and reduced troubleshooting time.

សំណួរ៖ តើអាយុកាលធម្មតានៃប្រអប់បញ្ចូលគ្នាគឺជាអ្វី?

A: Residential combiner boxes with quality components typically last 15-20 years, limited primarily by enclosure UV degradation and connector oxidation. Utility-scale combiner boxes are designed for 30+ year operational life, using stainless steel enclosures and silver-plated copper busbars that resist environmental degradation. Internal components like fuses and SPDs require replacement every 5-10 years depending on surge activity and operating conditions.

Q: Can I add more strings to an existing combiner box later?

A: Only if the combiner box has unused string input terminals and the main output breaker has sufficient capacity for the additional current. Calculate the new total current (sum of all string Isc values × 1.25) and verify it doesn’t exceed the main breaker rating. Also confirm that output conductors have adequate ampacity for the increased current. If either limit is exceeded, you’ll need a second combiner box or a complete replacement with higher-rated equipment.

Q: Why are utility-scale combiner boxes so much more expensive?

A: Utility-scale combiner boxes cost $2,500-$8,000 versus $300-$800 for residential units due to several factors: 1500V insulation requirements, higher current capacity (400-600A vs 60-100A), stainless steel construction, integrated monitoring systems, arc-fault detection, remote disconnect capability, and enhanced environmental ratings (IP66 vs IP65). However, on a per-watt basis, utility-scale boxes are actually cheaper ($0.01-$0.02/W vs $0.05-$0.08/W) due to the larger system size.

Q: Do I need arc-fault detection in my combiner box?

A: Arc-fault circuit interrupters (AFCI) are mandatory in residential installations per NEC 690.11 for systems installed after the 2017 code cycle, though the requirement can be satisfied at the inverter level rather than in the combiner box. Utility-scale projects typically implement arc-fault detection in combiner boxes as a risk mitigation measure and insurance requirement, even when not explicitly mandated by local code.

Q: What IP rating do I need for outdoor installation?

A: IP65 represents the minimum acceptable rating for outdoor combiner boxes, providing dust-tight sealing and protection against water jets. Upgrade to IP66 for installations in high-rainfall areas or where pressure washing may occur during maintenance. Coastal installations within 10 miles of saltwater should specify NEMA 4X stainless steel enclosures with IP66 rating to resist salt spray corrosion.

Q: Can I use a 1000V combiner box on a 1500V system?

A: Absolutely not. Using a combiner box with inadequate voltage rating creates severe safety hazards including insulation breakdown, tracking, and arc-flash risk. The voltage rating must exceed the system’s maximum open-circuit voltage under all operating conditions, including cold temperature scenarios where Voc increases by 10-15%. Always verify that the combiner box voltage rating provides at least 20% margin above maximum system Voc.

Q: How often should combiner boxes be inspected?

A: Residential systems should undergo visual inspection annually, with detailed electrical testing (IR thermography, torque verification, insulation resistance) every 5 years. Utility-scale installations require quarterly visual inspections and annual comprehensive testing as part of preventive maintenance programs. Any combiner box that has experienced a surge event or fault condition should be thoroughly inspected and tested before returning to service, regardless of the regular maintenance schedule.