Nei moderni sistemi elettrici, i guasti di cortocircuito possono rilasciare quantità devastanti di energia in pochi millisecondi. Una corrente di guasto prospettica di 50.000 ampere genera forze magnetiche sufficientemente potenti da deformare le sbarre collettrici, energia termica abbastanza intensa da vaporizzare conduttori in rame e pericoli di flashover dell'arco che mettono a rischio il personale. Eppure, gran parte di questa distruzione è prevenibile.

Gli interruttori limitatori di corrente rappresentano un progresso fondamentale nella tecnologia di protezione dei circuiti. A differenza degli interruttori convenzionali che interrompono i guasti allo zero naturale dell'onda AC, gli interruttori limitatori agiscono in pochi millisecondi per soffocare la corrente di guasto prima che raggiunga il suo picco distruttivo. Questa rapida intervento riduce drasticamente lo stress meccanico e termico sulle apparecchiature elettriche, protegge i componenti elettronici sensibili dai danni e mitiga significativamente i pericoli di flashover dell'arco.

Per i progettisti elettrici che progettano sistemi di distribuzione, i costruttori di quadri che selezionano dispositivi di protezione e i responsabili delle strutture responsabili delle infrastrutture critiche, comprendere la tecnologia limitatrice è essenziale. Questa guida spiega come funzionano gli interruttori limitatori di corrente, le specifiche chiave che ne definiscono le prestazioni e quando questa tecnologia offre vantaggi cruciali rispetto alla protezione standard dei circuiti.

Cos'è un Interruttore Limitatore di Corrente?

Un interruttore limitatore di corrente è un dispositivo di protezione progettato per interrompere una corrente di cortocircuito prima che raggiunga il suo valore di picco prospettico massimo. Questa capacità lo distingue dagli interruttori convenzionali, che tipicamente permettono alla corrente di guasto di raggiungere il suo picco completo prima di interromperla allo zero naturale.

Quando si verifica un cortocircuito in un sistema elettrico, la corrente inizia a salire a un tasso estremamente elevato, potenzialmente raggiungendo decine di migliaia di ampere in pochi millisecondi. Un interruttore standard rileva questa condizione di guasto e innesca il suo meccanismo di scatto, ma il processo di interruzione richiede tempo. Durante questo breve intervallo, la corrente di guasto può raggiungere il suo picco prospettico completo, rilasciando un'energia tremenda che sollecita conduttori, sbarre collettrici e apparecchiature a valle.

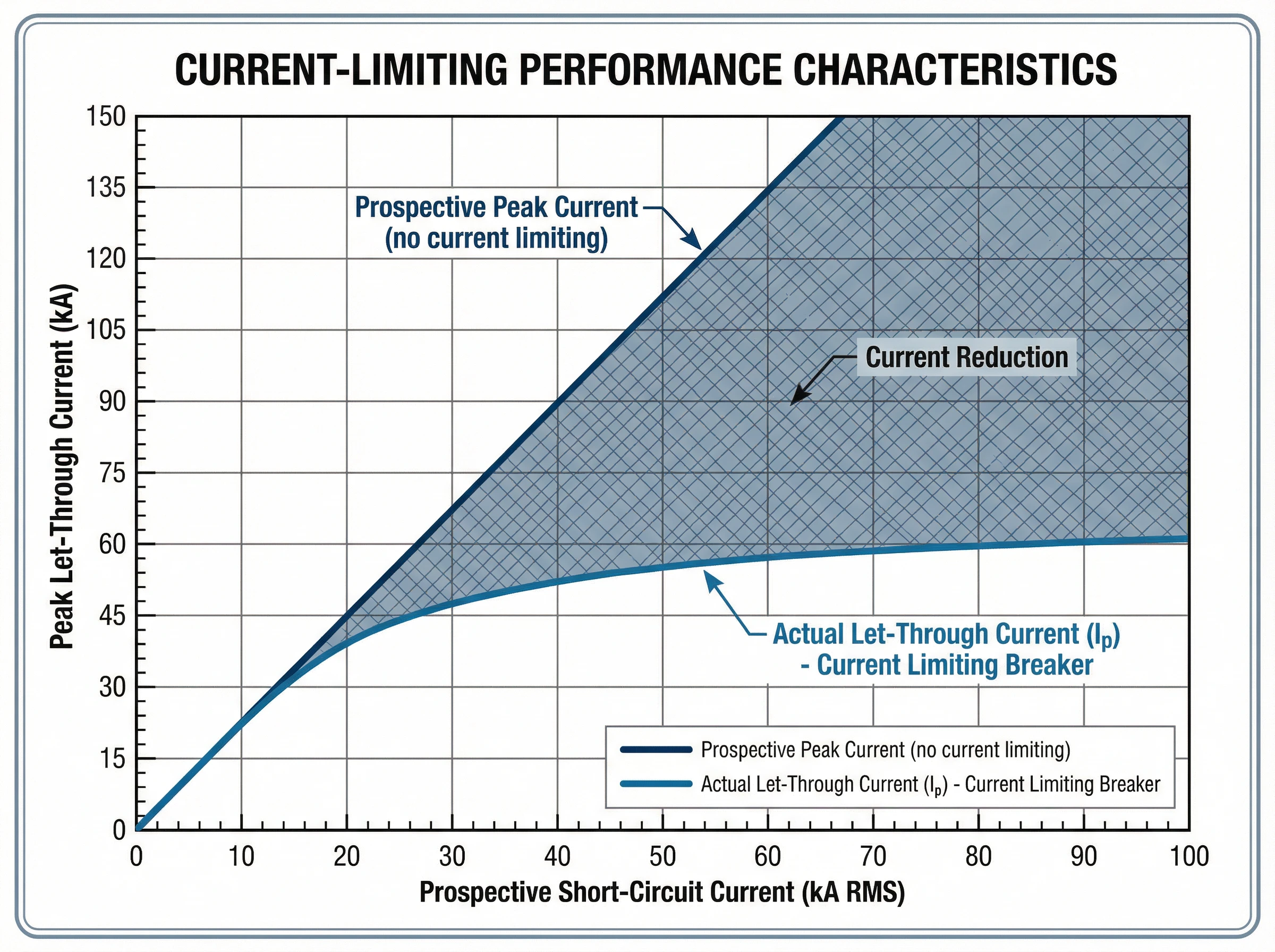

Gli interruttori limitatori di corrente, al contrario, agiscono con una velocità straordinaria. Secondo la norma UL 489 (lo standard nordamericano per gli interruttori automatici in cassetta), un interruttore si qualifica come “limitante di corrente” se elimina il guasto in meno di mezzo ciclo, tipicamente sotto i 10 millisecondi. Questa rapida risposta introduce un'alta tensione d'arco che si oppone alla tensione del sistema, soffocando efficacemente il flusso di corrente e forzando la corrente di picco effettivamente lasciata passare a un valore molto inferiore rispetto alla corrente di guasto prospettica.

Il risultato è drastico: mentre una corrente di guasto prospettica potrebbe essere di 50.000 ampere RMS simmetrica, un interruttore limitatore potrebbe limitare la corrente di picco effettiva a 15.000 ampere o meno. Questa riduzione della corrente di picco e dell'energia totale di guasto protegge le apparecchiature a valle dalle forze meccaniche, dai danni termici e dai pericoli di flashover dell'arco che altrimenti si verificherebbero.

Come Funzionano gli Interruttori Limitatore di Corrente

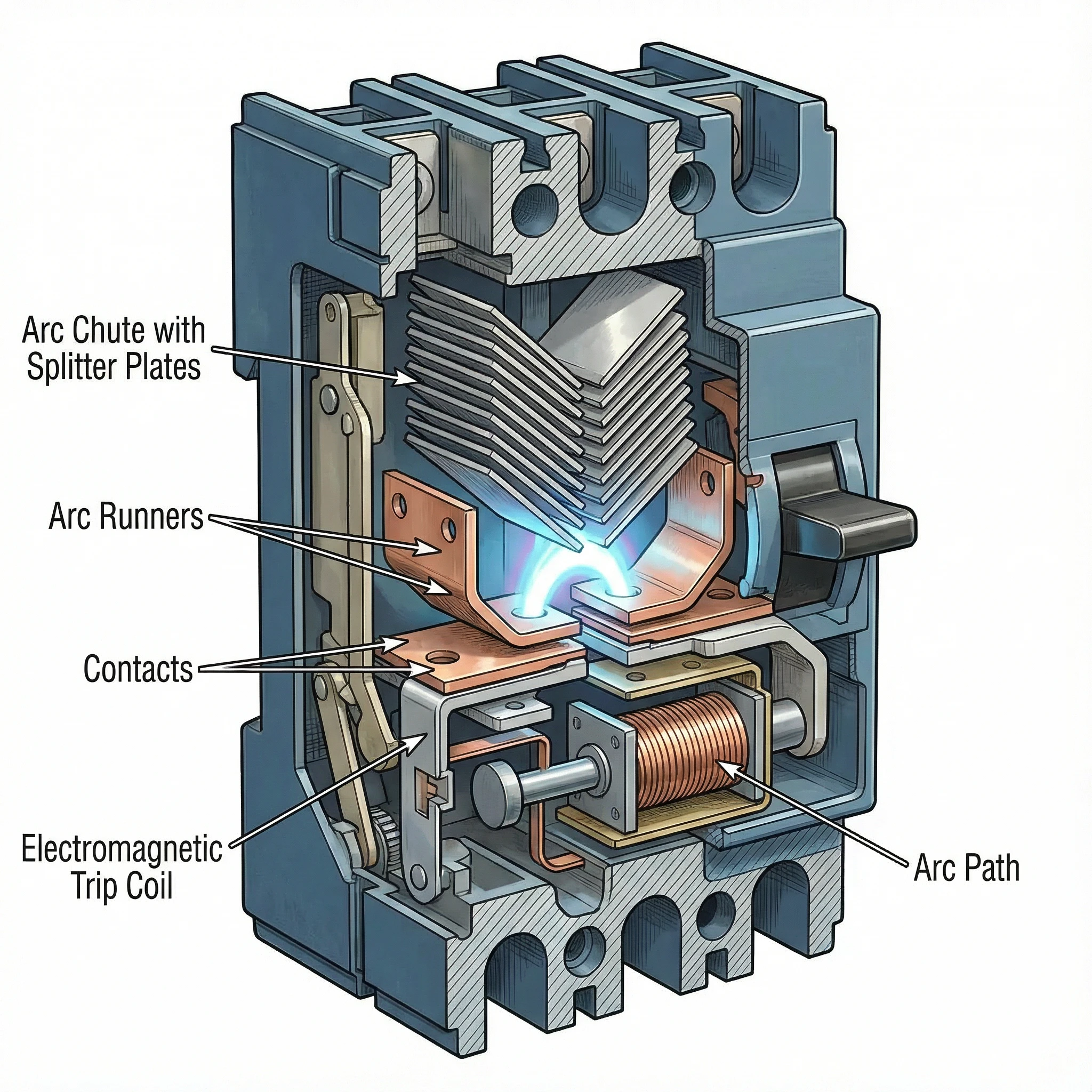

La capacità limitatrice di questi interruttori deriva da una combinazione progettata con cura di design meccanico, fisica elettromagnetica e gestione dell'arco. Il processo si svolge in millisecondi attraverso diversi meccanismi coordinati.

Separazione Elettrodinamica dei Contatti

Il primo elemento critico è la separazione ultra-rapida dei contatti. Quando un'elevata corrente di guasto scorre attraverso i contatti dell'interruttore, gli enormi campi magnetici generati da questa corrente creano potenti forze elettrodinamiche. Gli interruttori limitatori sono progettati con configurazioni di contatto che sfruttano queste forze per favorire la separazione: i contatti sono disposti in modo che il campo magnetico crei una forza repulsiva che letteralmente spinge i contatti a separarsi.

Questa “repulsione elettrodinamica” significa che correnti di guasto più elevate accelerano effettivamente la separazione dei contatti. L'interruttore non fa affidamento esclusivamente sulla forza meccanica del meccanismo di scatto; la corrente di guasto stessa contribuisce con energia per aprire i contatti più velocemente. Ciò garantisce una separazione dei contatti estremamente rapida, spesso entro 1-2 millisecondi dall'inizio del guasto.

Formazione ed Elongazione dell'Arco

Mentre i contatti si separano ad alta velocità, si forma un arco elettrico nel traferro. Piuttosto che essere un problema da sopprimere, questo arco diventa lo strumento principale per la limitazione di corrente. La geometria interna dell'interruttore è progettata per costringere questo arco a spostarsi rapidamente lontano dai contatti e verso una camera dell'arco appositamente progettata, chiamata cassetta di estinzione.

Magnetic fields generated by the current flow and the physical shape of the arc runners guide the arc upward into the arc chute. As the arc moves and stretches, its length increases dramatically. A longer arc requires higher voltage to sustain it, and this arc voltage opposes the system voltage driving the fault current.

Arc Commutation and Splitting

The arc chute contains a series of metal plates arranged in a specific configuration (often V-shaped), called arc splitters or arc dividers. As the arc is driven into the chute, it contacts these plates and “commutates”—transferring from the main arc path to the splitter plates.

This process effectively splits the single high-energy arc into multiple smaller arcs in series. Each small arc develops its own voltage drop. If the arc chute contains, for example, 20 splitter plates, the total arc voltage can reach many times the system voltage. When the cumulative arc voltage exceeds the system voltage, the current is forced to decrease rapidly.

Arc Cooling and Extinction

The metal splitter plates also serve as heat sinks, rapidly cooling the arcs. The plates increase the arc’s surface area and conduct heat away. Combined with surrounding air or arc-quenching gases, this cooling reduces the arc’s conductivity.

The interplay of high arc voltage (opposing current flow) and arc cooling (reducing conductivity) forces the current toward zero. The breaker extinguishes the arc and clears the fault—all within a fraction of a cycle, before the fault current reaches its prospective peak.

This entire sequence—from fault detection through contact separation, arc elongation, splitting, and extinction—occurs in under 10 milliseconds. The current is interrupted not at a natural zero crossing but forcibly, by creating conditions where the arc cannot be sustained.

Specifiche tecniche chiave

Understanding current-limiting performance requires familiarity with three critical specifications that define how effectively a breaker limits fault current and protects downstream equipment.

Let-Through Current (Ip)

Il let-through current (Ip) is the actual peak current that flows through the breaker during a fault, measured in amperes. This value represents the breaker’s current-limiting effectiveness: a lower Ip indicates better current limitation.

Manufacturers provide let-through current data in the form of characteristic curves. These graphs plot the peak let-through current (Ip) on the vertical axis against the prospective short-circuit current (RMS symmetrical amperes) on the horizontal axis. For any given prospective fault level at the installation point, the curve shows the maximum peak current that will actually flow.

For example, if the available fault current at a panelboard is 42,000 amperes RMS symmetrical, a current-limiting breaker might limit the actual peak current to just 18,000 amperes. This reduction from prospective to actual peak current protects busbars from bending, prevents conductor overheating, and reduces mechanical stress on all downstream components.

Thermal Stress (I²t)

Il I²t value (pronounced “I-squared-t”), measured in ampere-squared seconds (A²s), quantifies the thermal energy let through by the breaker during fault clearing. It represents the integral of the current squared over the total clearing time.

This specification is critical for protecting cables and sensitive electronic equipment. The insulation of cables has a specific thermal withstand rating expressed as I²t. If the protective device lets through more thermal energy than the cable can withstand, the insulation will be damaged even if the cable doesn’t physically melt.

Current-limiting breakers dramatically reduce I²t compared to standard breakers. For the same prospective fault current, a current-limiting device might have an I²t value 50-80% lower than a conventional breaker. This reduced thermal stress prevents conductor damage, protects cable insulation, and extends equipment life.

Manufacturers provide I²t curves similar to let-through current curves, showing the maximum thermal energy as a function of prospective fault current. Some standards define energy-limiting classes for circuit breakers based on their I²t performance.

Breaking Capacity (Icu and Ics)

Il capacità di interruzione defines the maximum fault current the breaker can safely interrupt. Two ratings are relevant under IEC 60947-2 (the international standard for low-voltage circuit breakers):

- Capacità di rottura finale (Icu): The maximum fault current the breaker can interrupt without being destroyed. After interrupting a fault at Icu level, the breaker may not be suitable for continued service and might require replacement. This represents the breaker’s absolute upper limit.

- Capacità di rottura del servizio (Ics): The maximum fault current the breaker can interrupt multiple times while remaining fully functional and reliable for continued service. Ics is expressed as a percentage of Icu (typically 50%, 75%, or 100%). For critical applications requiring high reliability, breakers with Ics = 100% Icu are preferred.

The fundamental selection rule is straightforward: the breaker’s Icu must be equal to or greater than the prospective short-circuit current at the point of installation. Current-limiting breakers can achieve high breaking capacities (50kA, 85kA, or higher) in compact form factors because the current-limiting action itself reduces the energy the breaker must handle.

The Interrelationship of Specifications

These specifications work together to define protection performance. When a fault occurs up to the breaker’s Icu rating, the current-limiting action reduces both the peak current (Ip) and the total thermal energy (I²t) to values far below what the prospective fault would produce. This coordinated reduction in peak mechanical stress and thermal damage is what makes current-limiting breakers essential for protecting modern electrical systems with high available fault currents.

Standards and Compliance

Current-limiting circuit breakers are governed by rigorous international and regional standards that define performance requirements, testing procedures, and safety criteria.

IEC 60947-2: International Standard

Norma IEC 60947-2 is the international standard for low-voltage circuit breakers used in industrial and commercial applications. This comprehensive standard establishes:

- Performance categories: The standard distinguishes between Category A breakers (no intentional short-circuit time delay) and Category B breakers (with short-time withstand capability). Most modern current-limiting MCCBs are Category A devices.

- Breaking capacity verification: IEC 60947-2 specifies rigorous test sequences to verify both ultimate breaking capacity (Icu) and service breaking capacity (Ics). These tests involve multiple making and breaking operations under specified fault conditions.

- Current-limiting performance: While the standard doesn’t mandate current limitation, it provides test procedures to verify and document let-through current and I²t performance for breakers claiming current-limiting capability.

- Coordination and selectivity: The standard establishes requirements for back-up protection (cascading), where a current-limiting breaker upstream protects a downstream breaker with lower breaking capacity than the prospective fault current at its location.

UL 489: North American Standard

UL 489 is the Underwriters Laboratories standard for molded case circuit breakers in North America. Key provisions include:

- Current-limiting definition: UL 489 specifies that a circuit breaker qualifies as “current limiting” if it clears a fault in less than half a cycle (typically under 10 milliseconds for 60 Hz systems).

- Let-through testing: The standard requires extensive testing to generate let-through current curves that show the actual peak current as a function of prospective fault current.

- Short-circuit ratings: UL 489 defines interrupting ratings (IR) and establishes test procedures to verify breaker performance at rated voltage and current levels.

Conformità e certificazione

For electrical system designers and specifiers, standards compliance ensures:

- Verified performance: Certified breakers have undergone rigorous third-party testing to confirm their current-limiting capability and breaking capacity.

- Design confidence: Engineers can rely on published let-through curves and I²t data for equipment protection analysis and arc flash calculations.

- Regulatory acceptance: Standards-compliant breakers meet electrical code requirements in their respective markets (IEC zones or North American installations).

VIOX current-limiting circuit breakers are designed and tested to meet both IEC 60947-2 and UL 489 requirements, ensuring global applicability and verified protection performance.

Applicazioni e Casi d'Uso

Current-limiting circuit breakers deliver critical benefits in electrical systems where high available fault currents threaten equipment integrity and personnel safety.

Data Centers and Critical IT Infrastructure

Modern data centers face extraordinary fault current challenges. High-density server racks, powerful UPS systems, and multiple utility feeds create available fault currents that can exceed 65kA or more. Current-limiting breakers are essential in these environments:

- IT equipment protection: Servers, storage arrays, and networking gear contain sensitive electronics vulnerable to even brief overcurrent events. Current-limiting breakers reduce the fault energy to levels that prevent component damage.

- Coordinamento selettivo: Data center reliability depends on isolating faults without cascading outages. Current-limiting breakers facilitate coordination between upstream and downstream protection, ensuring only the affected circuit trips.

- Arc flash mitigation: Maintenance personnel work on energized equipment regularly. By reducing peak fault current and clearing time, current-limiting breakers dramatically lower arc flash incident energy, improving worker safety and potentially reducing PPE requirements.

- Compact installations: Current-limiting technology enables high breaking capacity (50kA-100kA) in compact MCCBs, supporting dense power distribution without requiring oversized switchgear.

Industrial Manufacturing Facilities

Industrial plants with large motors, transformers, and extensive distribution networks face fault currents that can damage production equipment:

- Centri di controllo motore: Protecting motor starters, variable frequency drives, and control electronics from fault current stress. Current-limiting breakers prevent damage to expensive drive electronics and ensure production continuity.

- High-capacity feeders: Where multiple power sources or large transformers create fault currents exceeding 50kA, current-limiting breakers provide protection without requiring expensive high-interrupting-capacity switchgear throughout the system.

- Attrezzature di protezione: Busbars, cable trays, and panel components have mechanical strength limits. Current-limiting breakers reduce the magnetic forces during faults, preventing physical damage to distribution infrastructure.

Commercial Buildings with High Power Density

Office towers, hospitals, and retail centers increasingly deploy high-power systems:

- Main and sub-main distribution: Current-limiting breakers on main service entrances and distribution boards protect against utility-supplied fault currents while enabling effective downstream coordination.

- Sistemi di alimentazione di emergenza: Generator and transfer switch protection where multiple sources increase available fault current.

- Renovation and expansion: Adding capacity to existing buildings often increases fault current levels. Current-limiting breakers can sometimes eliminate the need for complete system upgrades by providing adequate protection within existing infrastructure ratings.

Cascading Protection (Back-Up Protection)

One of the most valuable applications is enabling cascading or series rating. A current-limiting breaker installed upstream can protect downstream breakers with lower breaking capacity than the prospective fault current at their location. This allows:

- Ottimizzazione dei costi: Using less expensive, lower-rated breakers downstream while maintaining full protection.

- Simplified specification: Standardizing on common breaker types throughout the facility while the current-limiting main breaker provides system-wide protection.

- System flexibility: Adding circuits or loads without necessarily upgrading all downstream protection devices.

Current Limiting vs Standard Circuit Breakers

Understanding the distinction between current-limiting and standard circuit breakers clarifies when each technology is appropriate.

Interruption Method

Standard Breakers: Conventional circuit breakers detect a fault and initiate the trip mechanism, but allow the fault current to rise to its prospective peak value. Interruption occurs at or near a natural current zero crossing, typically after 0.5 to 1.5 cycles (8-25 milliseconds at 60 Hz). During this time, the full fault current stresses the system.

Current-Limiting Breakers: These devices act within milliseconds to forcibly interrupt the current before it reaches its prospective peak. Through electrodynamic contact separation and arc voltage build-up, they clear the fault in less than half a cycle (under 10 milliseconds), dramatically reducing both peak current and total fault energy.

Peak Current and Mechanical Stress

Standard Breakers: The full prospective fault current flows, creating maximum magnetic forces. For a 50kA prospective fault, the full 50kA (70kA peak asymmetrical) generates enormous mechanical stress on busbars, terminals, and connections.

Current-Limiting Breakers: The let-through current is significantly reduced. For the same 50kA prospective fault, a current-limiting breaker might limit the actual peak to 15-20kA, reducing magnetic forces by 60-70%.

Thermal Energy (I²t)

Standard Breakers: Longer clearing time and higher peak current result in substantial thermal energy release. Cables, busbars, and connections absorb significant heat, potentially damaging insulation.

Current-Limiting Breakers: Reduced peak current and ultra-fast clearing dramatically lower I²t values, often by 50-80%. This protects cable insulation, prevents conductor annealing, and safeguards sensitive electronics from thermal stress.

Arc Flash Incident Energy

Standard Breakers: Higher fault current and longer clearing time increase arc flash incident energy, requiring higher-level PPE and creating greater safety hazards for maintenance personnel.

Current-Limiting Breakers: Reduced fault current magnitude and duration significantly decrease arc flash energy. This can lower the arc flash boundary, reduce PPE requirements, and improve overall electrical safety.

Cost and Complexity Trade-offs

Standard Breakers: Generally less expensive per unit. Suitable for applications where fault currents are moderate and equipment ratings adequately exceed available fault levels.

Current-Limiting Breakers: Higher initial cost, but can reduce total system cost by:

- Allowing lighter-duty downstream components

- Enabling cascading protection with lower-rated breakers

- Reducing panel reinforcement requirements

- Protecting expensive equipment from damage

- Lowering arc flash mitigation costs

Quando scegliere ciascun tipo

Choose Standard Breakers when:

- Available fault current is well below the system’s short-circuit rating

- Budget constraints are paramount and fault levels don’t justify current-limiting protection

- Coordination can be achieved without current limitation

Choose Current-Limiting Breakers when:

- Available fault currents exceed 20-25kA

- Protecting sensitive electronic equipment (data centers, control systems)

- Seeking arc flash hazard reduction

- Enabling cascading protection to reduce costs

- Facility expansion has increased fault levels beyond original equipment ratings

Criteri di selezione

Selecting the right current-limiting circuit breaker requires evaluating several technical and application factors.

Calculate Available Fault Current

The first step is determining the prospective short-circuit current at the installation point. This requires:

- Utility transformer capacity and impedance

- Conductor lengths and sizes

- Impedance of distribution components

- Contribution from motors and generators

Many utilities provide fault current data, or qualified electrical engineers can perform short-circuit calculations using industry-standard methods (IEC 60909 or IEEE standards). The breaker’s ultimate breaking capacity (Icu) must meet or exceed this calculated fault current.

Evaluate Equipment Protection Requirements

Consider what needs protection:

- Elettronica sensibile: Data centers, control systems, and telecommunications equipment benefit significantly from reduced let-through current and I²t.

- Busbar and conductor ratings: If fault currents approach or exceed the short-circuit withstand ratings of busbars, cables, or panel components, current limitation becomes essential.

- Existing equipment: When expanding facilities, current-limiting breakers can sometimes protect existing infrastructure without requiring complete replacement.

Assess Arc Flash Hazard Mitigation Needs

If arc flash studies indicate high incident energy levels requiring extensive PPE or creating unacceptable worker hazards, current-limiting breakers can significantly reduce arc flash energy. Review arc flash calculations to determine if current limitation would lower the hazard category and improve safety.

Consider Coordination Requirements

Selective coordination—ensuring only the breaker nearest the fault trips—is critical in many applications:

- Cascading protection: If downstream breakers have breaking capacities lower than available fault current, a current-limiting breaker upstream can provide back-up protection.

- Critical loads: Data centers, hospitals, and industrial processes require fault isolation without unnecessary outages. Current-limiting breakers facilitate coordination by reducing let-through energy.

Review Let-Through Current Curves

Manufacturers provide let-through current (Ip) and I²t curves for their current-limiting breakers. Compare these curves against:

- Equipment withstand ratings

- Cable I²t limits

- Arc flash energy reduction targets

- Coordination requirements with downstream devices

Verify Standards Compliance

Ensure the breaker meets applicable standards:

- Norma IEC 60947-2 for international/industrial applications

- UL 489 for North American installations

- Local electrical codes and certification requirements

Conclusione

Current-limiting circuit breakers represent a critical advancement in electrical protection technology, addressing the fundamental challenge of high fault currents in modern power systems. By interrupting faults in milliseconds and dramatically reducing peak let-through current and thermal stress, these devices protect expensive equipment, improve personnel safety, and enable more flexible system designs.

For electrical engineers and facility managers working with high-power distribution systems—particularly data centers, industrial facilities, and commercial buildings with fault currents exceeding 25kA—current-limiting technology delivers measurable benefits in equipment protection, arc flash mitigation, and coordination flexibility. The key specifications (let-through current Ip, thermal stress I²t, and breaking capacity Icu) provide the engineering data needed to verify protection performance and ensure safe, reliable operation.

VIOX Electric manufactures current-limiting circuit breakers engineered to IEC 60947-2 and UL 489 standards, offering breaking capacities from 35kA to 100kA and comprehensive let-through performance curves. For technical specifications, application guidance, or to discuss your specific protection requirements, contact VIOX’s engineering team.

Protect your critical infrastructure with proven current-limiting technology. Contatto VIOX Electric to discuss your circuit protection needs.