Közvetlen válasz

Egy elektromos karbantartási program kiépítése öt alapvető lépést igényel: (1) átfogó berendezés-leltár és állapotfelmérés elvégzése, (2) karbantartási ütemtervek kidolgozása az NFPA 70B szabványok és a gyártói irányelvek alapján, (3) képzett személyzet kijelölése és a felelősségek meghatározása, (4) dokumentációs és nyilvántartási rendszerek bevezetése, és (5) a program hatékonyságának folyamatos nyomon követése és javítása. Egy megfelelően strukturált elektromos karbantartási program (EMP) akár 66%-kal csökkenti a berendezések meghibásodási arányát, megelőzi a költséges leállásokat, biztosítja az NFPA 70B (2023), NFPA 70E és OSHA előírásoknak való megfelelést, és jelentősen javítja a munkahelyi biztonságot az ívzárlati veszélyek és a villamos tüzek mérséklésével.

A legfontosabb tudnivalók

- Az NFPA 70B (2023) mostantól előírja a dokumentált elektromos karbantartási programokat – ez már nem opcionális, hanem szabályozási követelmény

- A berendezések meghibásodási aránya 66%-kal csökken amikor a létesítmények strukturált megelőző karbantartási ütemterveket vezetnek be a reaktív megközelítésekkel szemben

- Hároméves alapkarbantartási ciklusok ajánlottak az ipari szabványok szerint, a berendezés kritikus fontossága és a környezeti feltételek alapján történő kiigazításokkal

- A képzett személyzet képzése nem alku tárgya – az NFPA 70B és 70E megköveteli a munkavállalóktól, hogy bizonyítsák az elektromos biztonság és a karbantartási eljárások terén való jártasságukat

- A digitális dokumentációs rendszerek 20%-kal javítják a karbantartási munkák befejezési arányát, és alapvető megfelelőségi bizonyítékot szolgáltatnak a biztosítási és szabályozási ellenőrzésekhez

Miért van szüksége a létesítményének hivatalos elektromos karbantartási programra?

Az elektromos rendszer meghibásodásai továbbra is az ipari tüzek, a nem tervezett leállások és a munkahelyi sérülések vezető okai közé tartoznak. Az NFPA 2016-2020 közötti adatai szerint az elektromos elosztó- és világítóberendezések az ipari telephelyeken bekövetkezett szerkezeti tüzek 24%-ában voltak érintettek, ami ezen tüzek 20%-ához járult hozzá, és jelentős anyagi károkat és civil sérüléseket okozott.

Az NFPA 70B 2023-as kiadása az elektromos karbantartást az ajánlott gyakorlatból kötelező szabvánnyá alakította. A létesítményeknek mostantól ki kell dolgozniuk, be kell vezetniük és működtetniük egy dokumentált elektromos karbantartási programot (EMP), amely összhangban van az NFPA 70B, az NFPA 70E (Szabvány a munkahelyi elektromos biztonságról) és az OSHA követelményeivel.

Tanulmányok következetesen kimutatják, hogy a menetrend szerinti megelőző karbantartási programokban nem szereplő elektromos berendezések meghibásodási aránya háromszor magasabb mint a megfelelően karbantartott rendszereké. Még kritikusabb, hogy az elektromos rendszer meghibásodásainak több mint kétharmada megelőzhető lenne a rutinszerű megelőző karbantartási tevékenységekkel.

A biztonságon és a megbízhatóságon túl egy jól strukturált karbantartási program mérhető pénzügyi előnyöket is biztosít. A tervezett karbantartás lényegesen kevesebbe kerül, mint a sürgősségi javítások és az általuk okozott járulékos károk. A létesítmények elkerülik a termelési veszteségeket, fenntartják a garanciális fedezetet, megfelelnek a biztosítási követelményeknek, és optimalizált berendezés-teljesítmény révén csökkentik az energiafogyasztást.

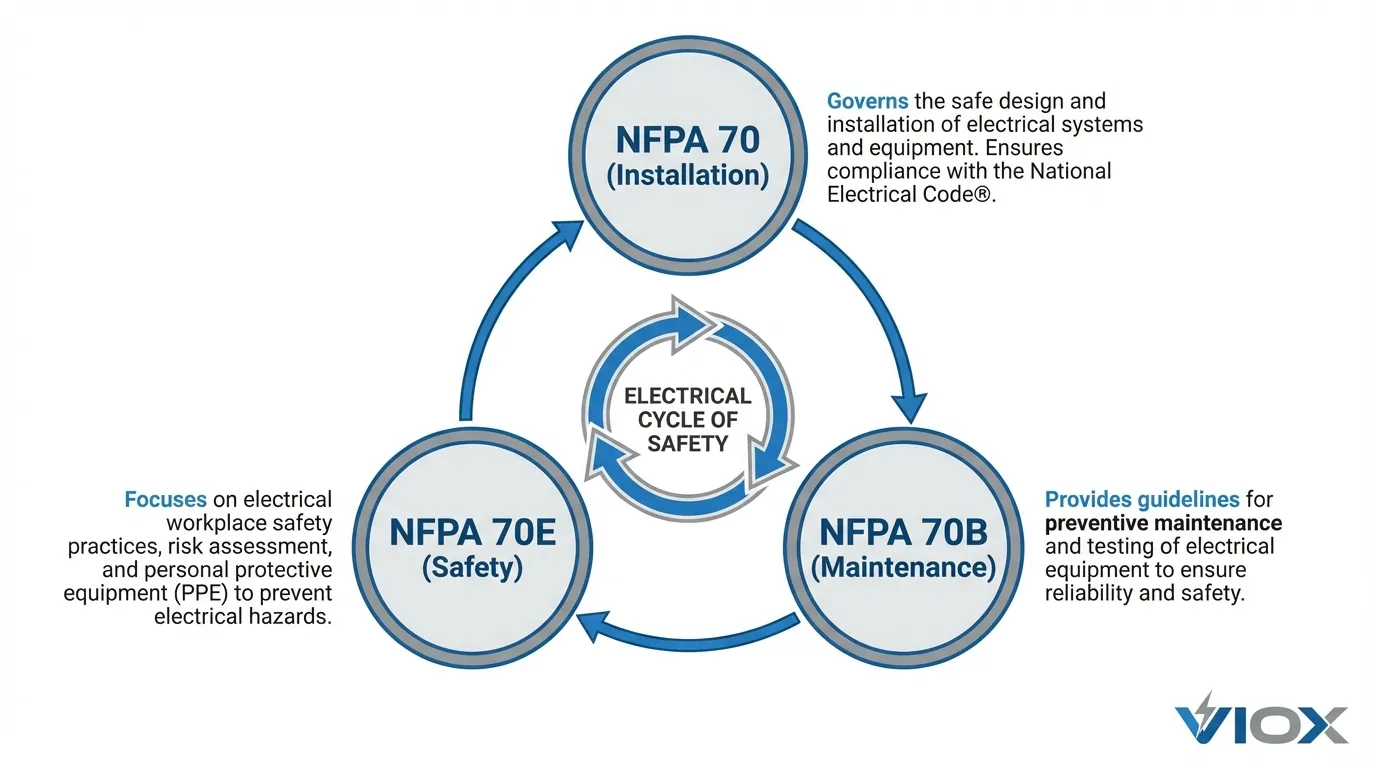

Az elektromos biztonsági ciklus megértése

Az NFPA bevezette az “Elektromos biztonsági ciklus” (ECoS) koncepcióját, amely leírja a három kritikus szabvány közötti összekapcsolt kapcsolatot:

- NFPA 70 (Nemzeti elektromos szabályzat): Az elektromos vezetékek és berendezések biztonságos telepítését szabályozza

- NFPA 70B: Meghatározza az elektromos berendezések karbantartására vonatkozó követelményeket

- NFPA 70E: Szabványokat biztosít a munkahelyi elektromos biztonsághoz

Ezek a szabványok együttműködve átfogó megközelítést alkotnak, biztosítva, hogy minden elektromos rendszert és berendezést biztonságosan telepítsenek, üzemeltessenek és karbantartsanak. Ahol csak egy elem hiányzik, valószínűbbé válnak a megelőzhető események, amelyek veszélyeztetik az embereket, a vagyont és a kritikus folyamatokat.

1. lépés: Berendezés-leltár és állapotfelmérés elvégzése

Bármely hatékony elektromos karbantartási program alapja azzal kezdődik, hogy pontosan megértjük, milyen berendezéseink vannak és azok jelenlegi állapotát. Ez a szisztematikus felmérés biztosítja azokat az adatokat, amelyek szükségesek a megfelelő karbantartási ütemtervek kidolgozásához és az erőforrások prioritásának meghatározásához.

Átfogó berendezés-leltár létrehozása

Dokumentálja a létesítményében található összes elektromos berendezést, beleértve:

- Kapcsolóberendezések és motorvezérlő központok (MCC-k)

- Megszakítók (MCCB-k, MCB-k, ACB-k)

- Elosztó panelek és terhelési központok

- Transformers (száraz és folyadékkal töltött)

- Kontaktorok és motorindítók

- Védőrelék és vezérlőrendszerek

- Túlfeszültség-védelmi eszközök (SPD-k)

- Vészhelyzeti és készenléti energiaellátó rendszerek (automatikus átkapcsolók)

- Földelő és kötő rendszerek

- Gyűjtősín rendszerek és csatlakozóblokkok

Minden egyes berendezéshez rögzítse a gyártó adatait, a modellszámokat, a telepítési dátumokat, a adattábla értékeit és a létesítményen belüli aktuális helyét. Ez a leltár lesz a mester berendezéslista, amely minden későbbi karbantartási tevékenységet vezérel.

A berendezés állapotának felmérése

Az NFPA 70B mostantól megköveteli a létesítményektől, hogy meghatározott kritériumok alapján értékeljék a berendezések állapotát. A 9. fejezet kötelező munkaterületeket és karbantartási intervallumokat tartalmaz a berendezés állapotfelmérése alapján. A berendezéseket állapotkategóriákba kell sorolni:

| Állapotkategória | Leírás | Karbantartási gyakoriság |

|---|---|---|

| Kiváló | Új vagy újszerű berendezés, minimális üzemóra, ideális környezet | Hosszabb intervallumok (3-5 év) |

| Jó | Normál kopás, rendszeres üzemeltetés, ellenőrzött környezet | Standard intervallumok (1-3 év) |

| Fair | Mérsékelt kopás, nagyobb kihasználtság, némi környezeti terhelés | Megnövelt gyakoriság (6-12 hónap) |

| Szegény | Jelentős kopás, zord környezet, kritikus fontosságú a működés szempontjából | Gyakori ellenőrzés (negyedévente) |

A berendezés kritikus fontosságát is értékelni kell. A kritikus berendezések – azok a rendszerek, amelyek meghibásodása biztonsági kockázatokat, jelentős termelési veszteségeket vagy a létesítmény leállását eredményezné – gyakoribb karbantartást igényelnek, függetlenül az állapottól.

Alapdokumentáció összegyűjtése

Gyűjtse össze az elektromos rendszereihez rendelkezésre álló összes dokumentációt:

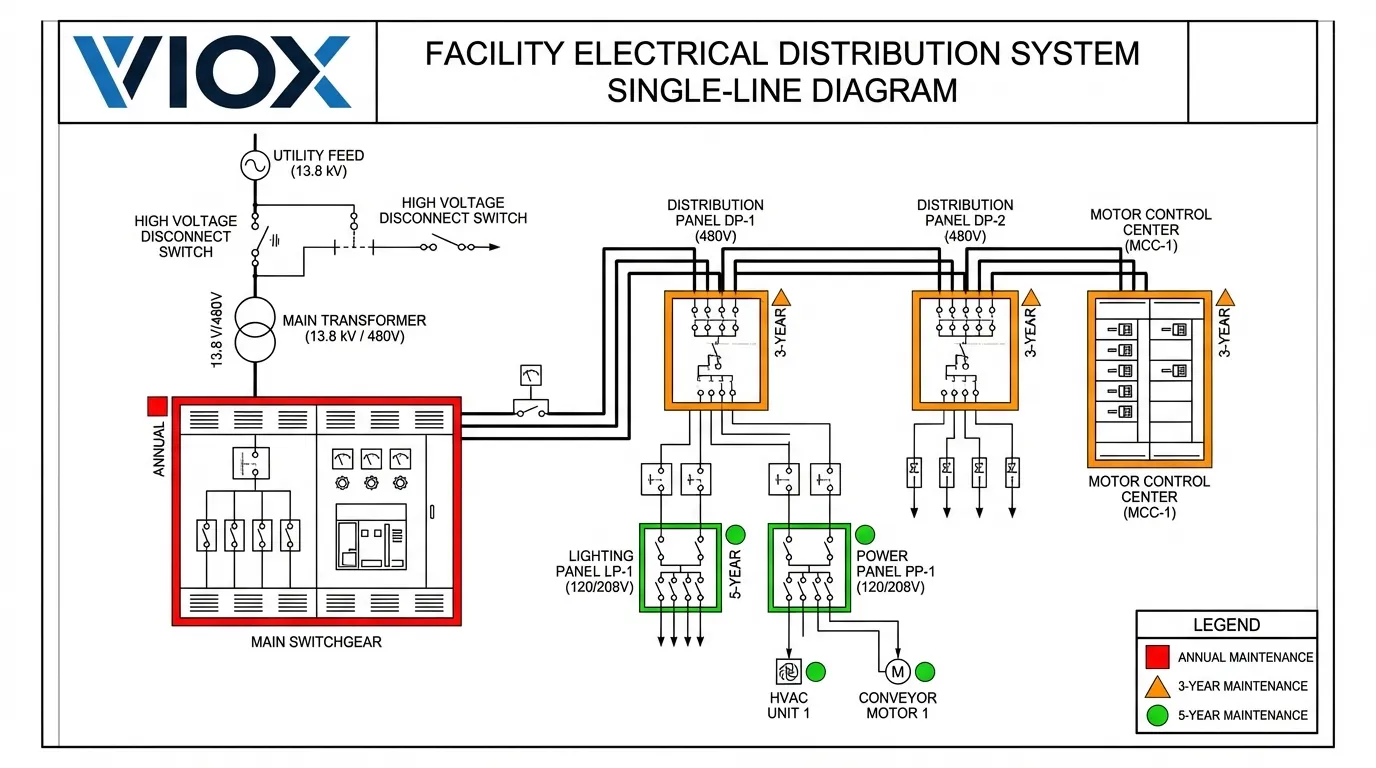

- Egyvonalas diagramok és elektromos rajzok

- Berendezés kézikönyvek és a gyártó karbantartási irányelvei

- Korábbi karbantartási feljegyzések és vizsgálati jelentések

- Rövidzárlati és koordinációs tanulmányok

- Ívzárlati elemzés és címkézés

- Garanciális információk

Az eredeti berendezésgyártó (OEM) dokumentációja alapvető adatokat szolgáltat a karbantartási eljárások kidolgozásához. Ha léteznek gyártói irányelvek, azok felülírják az NFPA 70B gyakorisági táblázatait. Az OEM ajánlások hiányában az NFPA 70B 9.2.2. táblázata szabványosított karbantartási intervallumokat biztosít.

2. lépés: Karbantartási ütemtervek és eljárások kidolgozása

A berendezés-leltár és az állapotfelmérés befejezése után a következő lépés a részletes karbantartási ütemtervek létrehozása, amelyek meghatározzák, hogy milyen feladatokat kell elvégezni, mikor kell elvégezni azokat, és hogyan kell azokat biztonságosan végrehajtani.

A karbantartási intervallumok meghatározása

Az NFPA 70B alapvető karbantartási gyakoriságokat határoz meg, de számos tényező befolyásolja az optimális ütemezést:

Standard alap intervallumok:

- Kapcsolóberendezések és MCC-k: Éves szemrevételezés; átfogó megelőző karbantartás 1-3 évente

- Megszakítók: Éves működtetés; funkcionális tesztelés és karbantartás 1-3 évente

- Transformers: Éves ellenőrzés; részletes tesztelés 3 évente

- Védelmi eszközök: Éves tesztelés; kalibrálás a gyártói specifikációk szerint

- Vészhelyzeti áramellátó rendszerek: Havi működtetés; éves terheléses tesztelés

Korrekciós tényezők:

Növelje a karbantartási gyakoriságot, ha a berendezés a következőket tapasztalja:

- Zord környezeti feltételek (túlzott hő, nedvesség, por, korrozív légkör)

- Magas kihasználtsági arány vagy folyamatos üzem

- Az elvárt élettartamon túli öregedés

- Korábbi megbízhatósági problémák vagy meghibásodási előzmények

- Kritikus működési fontosság

Ezzel szemben az újabb berendezések ellenőrzött környezetben, könnyű terhelési ciklusokkal biztonságosan meghosszabbíthatják az intervallumokat az NFPA 70B irányelvein belül.

Feladat-specifikus eljárások kidolgozása

Minden berendezéstípushoz hozzon létre részletes eljárásokat, amelyek meghatározzák:

Szemrevételezési feladatok:

- Ellenőrizze a fizikai sérüléseket, repedéseket vagy romlást

- Vizsgálja meg a túlmelegedés jeleit (elszíneződés, megolvadt szigetelés)

- Ellenőrizze a megfelelő címkézést és az ívzárlat figyelmeztetéseket

- Vizsgálja meg a korróziót, a nedvesség behatolást vagy a szennyeződést

- Ellenőrizze a megfelelő távolságokat és hozzáférést

- Ellenőrizze a laza csatlakozásokat vagy hardvereket

Mechanikai ellenőrzés és karbantartás:

- Ellenőrizze a rögzítés biztonságát és a szerkezeti integritást

- Tisztítsa meg a port és a törmeléket a berendezésről és a szellőzőutakról

- Kenje meg a mozgó alkatrészeket a gyártó specifikációi szerint

- Működtetés megszakítók és kapcsoló eszközök

- Vizsgálja meg az érintkező felületeket kopás, gödrösödés vagy égés szempontjából

- Ellenőrizze a mechanikai működést és időzítést

Elektromos vizsgálat:

- Szigetelési ellenállás vizsgálata (megohm mérő tesztelés)

- Érintkezési ellenállás mérése

- Túláramvédelmi eszköz tesztelése (kioldási görbék és időzítés)

- Földzárlat és földfolytonosság ellenőrzése

- Védőrelé kalibrálása és funkcionális tesztelése

- Feszültség- és árammérések terhelés alatt

- Hálózati minőség elemzés (harmonikusok, feszültségkiegyensúlyozatlanság)

- Termográfiai ellenőrzés (infravörös szkennelés forró pontokhoz)

Minden eljárásnak hivatkoznia kell az alkalmazandó biztonsági szabványokra, a szükséges egyéni védőeszközökre (PPE), a zárolási/címkézési (LOTO) követelményekre és a szükséges vizsgálóberendezésekre.

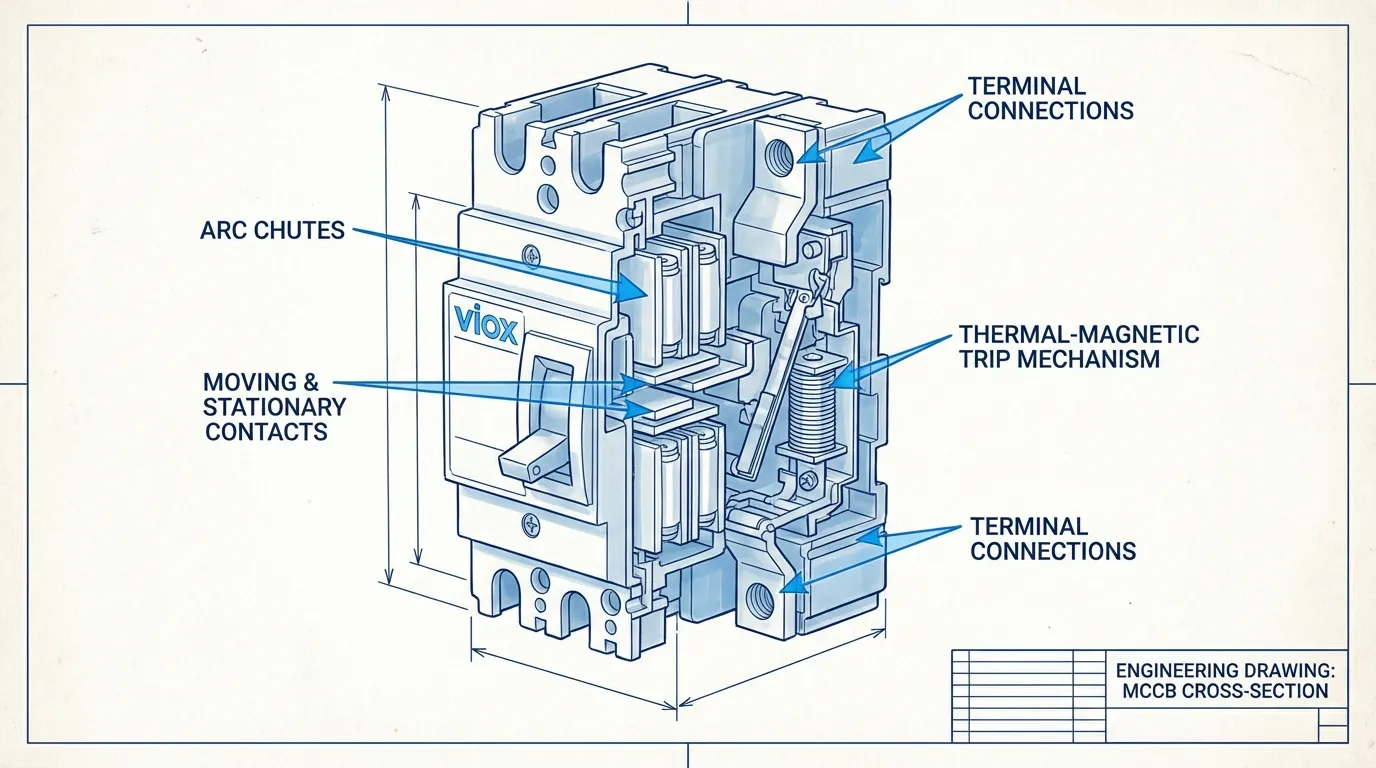

Berendezés-specifikus ellenőrzőlisták létrehozása

A szabványosított ellenőrzőlisták biztosítják a következetességet és a teljességet. Egy átfogó megszakító karbantartási ellenőrzőlista, például a következőket kell tartalmaznia:

- A ház és a rögzítés szemrevételezése

- A megfelelő névleges értékek és beállítások ellenőrzése

- Érintkező ellenőrzése és ellenállásmérése

- Szigetelési ellenállás vizsgálata

- Működési tesztelés (kézi és automatikus kioldási funkciók)

- Időzítés és koordináció ellenőrzése

- Termográfiai ellenőrzés terhelés alatt

- Az összes megállapítás és mérés dokumentálása

A számítógépes karbantartás-kezelő rendszerekkel (CMMS) integrált digitális ellenőrzőlisták 20%-kal javítják a befejezési arányt a papíralapú munkafolyamatokhoz képest, és automatikus dokumentációt és nyomon követést biztosítanak.

3. lépés: Képesített személyzet kijelölése és a felelősségek meghatározása

Az elektromos karbantartási program hatékonysága alapvetően a munkát végző személyzet kompetenciájától függ. Az NFPA 70B kifejezetten kimondja, hogy “az elektromos karbantartást csak képesített személyek végezhetik”.”

A képesített személy meghatározása

Mind az NFPA 70B, mind az NFPA 70E a képesített személyt úgy határozza meg, mint “olyan személy, aki bizonyította az elektromos berendezések és berendezések építésével és üzemeltetésével kapcsolatos készségeket és ismereteket, és biztonsági képzésben részesült a veszélyek azonosítása és a kapcsolódó kockázatok csökkentése érdekében”.”

A képesítés a következőket igényli:

- Elektromos rendszerek és berendezések műszaki ismerete

- Az elektromos veszélyek (áramütés, ívzárlat, robbanás) megértése

- Képzés a biztonságos munkavégzési gyakorlatokban és eljárásokban

- Az alkalmazandó kódok és szabványok ismerete

- Tesztelés vagy tanúsítás révén bizonyított kompetencia

A létesítményeknek dokumentálniuk kell a személyzet képesítéseit, és karbantartaniuk kell a képzési nyilvántartásokat.

Jelöljön ki egy EMP koordinátort

Az NFPA 70B előírja, hogy a létesítmények jelöljenek ki egy Elektromos Karbantartási Program (EMP) koordinátort. Ez a személy – aki lehet a biztonsági vezető, a létesítményvezető vagy egy másik képzett személy – átfogó felelősséggel tartozik a következőkben:

- Programfejlesztés és -végrehajtás

- Karbantartási feladatok kijelölése képzett személyzetnek

- A menetrendek és eljárások betartásának biztosítása

- Szükség esetén harmadik féltől származó szolgáltatókkal való koordináció

- A program felülvizsgálata és frissítése

- Dokumentáció és nyilvántartások vezetése

A koordinátornak nem kell személyesen elvégeznie az összes karbantartási feladatot, de biztosítania kell, hogy a képzett személyek az összes munkát a bevált eljárásoknak megfelelően végezzék el.

Egyértelmű felelősségek meghatározása

| Szerep | Felelősségek |

|---|---|

| EMP koordinátor | Programfelügyelet, megfelelőség ellenőrzése, erőforrás-elosztás, folyamatos fejlesztés |

| Karbantartó technikusok | Ütemezett feladatok végrehajtása, megállapítások dokumentálása, anomáliák jelentése, rutinszerű javítások elvégzése |

| Villamosmérnökök | Rendszervizsgálatok, védelmi eszközök koordinálása, műszaki útmutatás, komplex hibaelhárítás |

| Biztonsági személyzet | LOTO eljárások, PPE követelmények, ívállóság elemzés, baleset kivizsgálás |

| Üzemeltetési személyzet | Berendezésekkel kapcsolatos problémák jelentése, ütemezett leállások támogatása, hézagok fenntartása |

Folyamatos képzés biztosítása

Az elektromos karbantartó személyzet rendszeres képzést igényel a következőkben:

- NFPA 70E elektromos biztonság (háromévente frissítve)

- Ívállóság veszélyeinek tudatosítása és PPE kiválasztása

- Kizárási/kitáblázási eljárások elektromos rendszerekhez

- Berendezés-specifikus karbantartás technikák

- Vizsgáló berendezések működtetése és értelmezése

- Sürgősségi reagálás eljárások

Dokumentáljon minden képzési tevékenységet, és vezessen egyéni képzési nyilvántartásokat a program dokumentációjának részeként.

4. lépés: Dokumentációs és nyilvántartási rendszerek bevezetése

Az átfogó dokumentáció számos kritikus célt szolgál: a megfelelőség igazolása auditok során, a berendezések teljesítményének nyomon követése, a garanciális igények támogatása, a biztosítási követelmények teljesítése és a folyamatos fejlesztés lehetővé tétele. Az NFPA 70B meghatározott dokumentációs követelményeket ír elő, amelyeket a létesítményeknek fenn kell tartaniuk.

Alapvető programdokumentáció

Az elektromos karbantartási programnak tartalmaznia kell:

1. Írásos EMP szabályzat és eljárások

- A program hatóköre és célkitűzései

- Szervezeti felépítés és felelősségek

- Karbantartási filozófiák és stratégiák

- Biztonsági követelmények és protokollok

- Vészhelyzeti reagálási eljárások

2. Berendezés törzslista

- Teljes leltár egyedi azonosítókkal

- Berendezés specifikációk és névleges értékek

- Telepítési dátumok és helyek

- Kritikus besorolások

- Hozzárendelt karbantartási ütemtervek

3. Karbantartási ütemtervek

- Feladatleírások és gyakoriságok

- Hozzárendelt személyzet vagy vállalkozók

- Szükséges eszközök és vizsgáló berendezések

- Biztonsági követelmények és LOTO eljárások

- Becsült időtartam és erőforrásigény

4. Szabványos működési eljárások (SOP-k)

- Lépésről lépésre történő feladatutasítások

- Biztonsági óvintézkedések és PPE követelmények

- Szükséges mérések és elfogadási kritériumok

- Hibaelhárítási útmutató

- Hivatkozás az alkalmazandó szabványokra

Karbantartási tevékenység nyilvántartások

Dokumentáljon minden elvégzett karbantartási tevékenységet, beleértve:

- A munka dátuma és időpontja

- Berendezés azonosítása

- A munkát végző személyzet

- Elvégzett feladatok

- Vizsgálati eredmények és mérések

- Azonosított hiányosságok

- Végrehajtott korrekciós intézkedések

- Kicserélt alkatrészek

- Berendezés állapotának felmérése

- Javaslatok a jövőbeli intézkedésekre

Ezeket a nyilvántartásokat a létesítmény szabályzatának, a hatósági követelményeknek és a berendezés életciklusának megfelelően kell megőrizni. Sok létesítmény a berendezés teljes élettartama alatt, valamint a kivonás után még több évig megőrzi a nyilvántartásokat.

Rendszervizsgálatok és műszaki dokumentáció

Tartsa karban a következő dokumentumok aktuális verzióit:

- Egyvonalas rajzok amelyeken minden fontosabb berendezés és csatlakozás látható

- Rövidzárlati vizsgálatok a rendelkezésre álló zárlati áramok kiszámításával

- Védelmi eszközök koordinációs vizsgálatai a megfelelő szelektivitás biztosítása

- Ívvillanás veszélyelemzése felcímkézett berendezésekkel

- Terheléseloszlási vizsgálatok a rendszer optimalizálása érdekében

- Hálózati minőség felmérések és harmonikus analízis

Az NFPA 70B előírja, hogy a rendszervizsgálatoknak kötelező felülvizsgálati időközei legyenek, és az egyvonalas rajzoknak olvashatóknak, pontosaknak és naprakészeknek kell lenniük. Az elektromos rendszer változásakor azonnal frissítse az összes vonatkozó rajzot és karbantartási ütemtervet.

Használja ki a digitális rendszereket

A számítógépes karbantartás-kezelő rendszerek (CMMS) jelentős előnyöket kínálnak a papíralapú dokumentációval szemben:

A digitális dokumentáció előnyei:

- Automatikus munkalap generálás ütemezések alapján

- Mobil hozzáférés a terepen dolgozó technikusok számára

- Integrált ellenőrző listák digitális aláírásokkal

- Automatikus adatgyűjtés és trendelemzés

- Központosított dokumentumtárolás és -visszakeresés

- Megfelelőségi jelentéskészítés és audit nyomvonalak

- Prediktív analitika a meghibásodások megelőzésére

A digitális ellenőrző listákat használó szervezetek a karbantartási csapat termelékenységében 20%-os javulást tapasztalnak a papíralapú munkafolyamatokhoz képest. A modern CMMS platformok integrálhatók az állapotfigyelő rendszerekkel, valós idejű berendezés-állapotadatokat biztosítva, amelyek lehetővé teszik a prediktív karbantartási stratégiákat.

5. lépés: Figyelje, vizsgálja felül és folyamatosan fejlessze

Az elektromos karbantartási program nem egy statikus dokumentum, hanem egy élő rendszer, amely rendszeres értékelést és finomítást igényel. Az NFPA 70B ötévente, míg az NFPA 70E legalább háromévente írja elő az elektromos biztonsági programok felülvizsgálatát.

Kövesse nyomon a legfontosabb teljesítménymutatókat (KPI-ket)

Figyelje ezeket a mutatókat a program hatékonyságának felméréséhez:

| KPI | Cél | Jelentőség |

|---|---|---|

| Megelőző karbantartás befejezési aránya | >95% | Méri az ütemterv betartását |

| Átlagos üzemidő meghibásodások között (MTBF) | Növekvő tendencia | A berendezés megbízhatóságának javulását jelzi |

| Sürgősségi karbantartási arány | A teljes munka <10%-a | A megelőző megközelítés hatékonyságát mutatja |

| Berendezés leállási ideje | Csökkenő tendencia | Tükrözi a program hatását a működésre |

| Biztonsági incidensek | Nulla elektromos sérülés | Elsődleges biztonsági célkitűzés |

| Megfelelőségi arány | 100% | Szabályozási és szabványos megfelelés |

Végezzen rendszeres programfelülvizsgálatokat

Ütemezzen be formális programfelülvizsgálatokat a következőkhöz:

- Értékelje a KPI trendeket és a célkitűzésekhez viszonyított teljesítményt

- Értékelje a karbantartási intervallumok megfelelőségét

- Tekintse át a berendezések meghibásodási mintáit és a kiváltó okokat

- Határozza meg a képzési igényeket és a kompetenciahiányokat

- Frissítse az eljárásokat a tanulságok alapján

- Építse be az új berendezéseket vagy rendszerbeli változásokat

- Ellenőrizze a hatályos szabványoknak való megfelelést

- Igazítsa ki az erőforrás-elosztást és a költségvetést

Vezessen be prediktív karbantartási technológiákat

Míg a megelőző karbantartás időalapú ütemezést követ, a prediktív karbantartás állapotfelügyeletet használ a problémák azonosítására, mielőtt a hiba bekövetkezne:

Állapotfelügyeleti technológiák:

- Termográfiai képalkotás forró pontokat észlel, amelyek laza csatlakozásokra vagy túlterhelt áramkörökre utalnak

- Ultrahangos vizsgálat azonosítja a koronakisülést és a nyomkövetést a nagyfeszültségű berendezésekben

- Rezgéselemzés figyeli a forgó berendezéseket, például a motoros megszakítókat

- Olajanalízis felméri a transzformátor és a kapcsolóberendezés szigetelőfolyadékának állapotát

- Részleges kisülés vizsgálata középfeszültségű berendezések szigetelésének károsodását észleli

A prediktív technológiák integrálása a megelőző karbantartási programba lehetővé teszi az állapotalapú karbantartási stratégiákat, amelyek optimalizálják az erőforrás-kihasználást, miközben maximalizálják a berendezések megbízhatóságát.

Dokumentáció frissítése

Tartsa naprakészen a programot:

- Az eljárások felülvizsgálata, ha a berendezések vagy a szabványok megváltoznak

- Az egyvonalas ábrák frissítése minden elektromos módosítás után

- Új berendezések hozzáadása a karbantartási ütemtervekhez azonnal a telepítés után

- A hibákból vagy majdnem bekövetkezett eseményekből származó tanulságok beépítése

- Minden programváltozás dokumentálása verziókövetéssel

Gyakori megvalósítási kihívások és megoldások

1. kihívás: Korlátozott erőforrások és költségvetési korlátok

Megoldás: Rangsoroljon a berendezések kritikus jellege és kockázata alapján. A kezdeti erőfeszítéseket a biztonságkritikus rendszerekre és azokra a berendezésekre összpontosítsa, amelyek meghibásodása a legnagyobb működési hatást okozná. Alkalmazzon szakaszos megközelítést, fokozatosan bővítve a program hatókörét, amint az erőforrások lehetővé teszik. Fontolja meg harmadik féltől származó szolgáltatók igénybevételét speciális teszteléshez vagy olyan berendezésekhez, amelyek karbantartásához nincs belső szakértelme.

2. kihívás: Karbantartás ütemezése a működés megzavarása nélkül

Megoldás: Hangolja össze a karbantartási ütemterveket a termeléstervezéssel a tervezett leállások vagy az alacsony kereslet időszakai alatt. A kritikus, éjjel-nappal működő rendszerek esetében tervezzen redundanciával rendelkező rendszereket, amelyek lehetővé teszik az egyik alkatrész karbantartását, miközben a többi üzemben marad. Alkalmazzon prediktív felügyeletet a megbízható berendezések intervallumainak meghosszabbítására, miközben az erőforrásokat a problémás rendszerekre összpontosítja.

3. kihívás: Képzett személyzet hiánya

Megoldás: Fektessen be képzési programokba a belső kompetencia fejlesztése érdekében. Működjön együtt a berendezésgyártókkal speciális képzésekhez. Fontolja meg tapasztalt elektromos karbantartási szakemberek felvételét vagy képzett szolgáltatókkal való szerződéskötést. Dokumentálja egyértelműen a képesítési követelményeket, és ellenőrizze a vállalkozó hitelesítő adatait, mielőtt engedélyezné a rendszereken végzett munkát.

4. kihívás: Hiányos vagy elavult dokumentáció

Megoldás: Kezdje egy átfogó létesítménybejárással a pontos, a megvalósult állapotot tükröző rajzok elkészítéséhez. Használja ki ezt a lehetőséget, hogy minden berendezést egyedi azonosítókkal lásson el. Vezessen be egy változáskezelési folyamatot, amely megköveteli a dokumentáció frissítését minden elektromos módosítás esetén. Fontolja meg szakmai mérnöki szolgáltatások igénybevételét a hiányzó rendszertervek kidolgozásához.

Megfelelőségi szempontok: NFPA, OSHA és biztosítás

NFPA 70B megfelelőség

Az NFPA 70B 2023-as kiadása kötelező követelményeket állapít meg az elektromos karbantartási programokra vonatkozóan. Bár az NFPA szabványok nem szövetségi törvények, az államok és a helyi joghatóságok széles körben elfogadják őket. Ennél is fontosabb, hogy az OSHA az NFPA szabványokat használja a végrehajtás mércéjeként az Általános Kötelesség záradék alapján.

A létesítmények OSHA idézésekkel szembesülhetnek, ha nem követik a bevált ipari szabványokat, például az NFPA 70B-t, még akkor is, ha azokat nem írták bele kifejezetten a szabályozásokba. Az elektromos eseményeket követő vizsgálatok során az OSHA ellenőrei gyakran hivatkoznak az NFPA 70E és 70B szabványokra a bevált gyakorlatok bizonyítékaként.

Biztosítási követelmények

A biztosítók egyre inkább megkövetelik a dokumentált elektromos karbantartási programokat a fedezet feltételeként. A biztosítók:

- Karbantartási nyilvántartásokat kérhetnek a kockázatvállalás során

- Megkövetelhetik az NFPA 70B szabványnak való megfelelés bizonyítékát

- Meghatározhatnak konkrét vizsgálati gyakoriságokat a nagy értékű berendezések esetében

- Prémiumcsökkentést kínálhatnak a robusztus programokkal rendelkező létesítmények számára

- Karbantartási dokumentációt kérhetnek a kárigények kivizsgálásakor

A berendezésgyártók gyakran megkövetelik a megelőző karbantartás bizonyítékát a garancia érvényesítéséhez. A berendezések gyártói irányelveknek megfelelő karbantartásának elmulasztása érvénytelenítheti a garanciális fedezetet, és a létesítményeket anyagilag felelőssé teheti a berendezések idő előtti meghibásodásáért.

Ívkisülés megfelelőség

Az NFPA 70E előírja a munkáltatók számára, hogy ívkisülés-veszélyelemzést végezzenek, és a berendezéseket megfelelő figyelmeztetésekkel lássák el. Ennek az elemzésnek figyelembe kell vennie az elektromos berendezések “karbantartási állapotát”. A rosszul karbantartott berendezések, amelyek laza csatlakozásokkal, szennyeződéssel vagy leromlott szigeteléssel rendelkeznek, nagyobb ívkisülés-veszélyt jelentenek, mint a megfelelően karbantartott rendszerek.

Az Ön elektromos karbantartási programja közvetlenül támogatja az ívkisülés megfelelőséget azáltal, hogy biztosítja a berendezések tervezési paramétereken belüli működését és a védelmi eszközök megfelelő működését. Ívkisülés címkék frissíteni kell, ha rendszerbeli változások következnek be, vagy ha a karbantartás a becsapódási energia számításait befolyásoló körülményeket tár fel.

A program felépítése: Gyakorlati következő lépések

Ha a létesítményében nincs formális elektromos karbantartási program, vagy frissítenie kell az NFPA 70B (2023) megfelelőségre:

Azonnali intézkedések (1-2. hét):

- Jelöljön ki egy EMP koordinátort felhatalmazással és erőforrásokkal

- Állítson össze egy több funkciót átfogó csapatot (karbantartás, mérnöki munka, biztonság, üzemeltetés)

- Tekintse át a jelenlegi karbantartási tevékenységeket és dokumentációt

- Azonosítsa a kritikus hiányosságokat a megfelelőségben vagy a biztonságban

Rövid távú intézkedések (1-3. hónap):

- Végezzen teljes berendezésleltárt és állapotfelmérést

- Dolgozzon ki kezdeti karbantartási ütemterveket a kritikus berendezésekhez

- Készítsen vagy frissítsen egyvonalas ábrákat

- Hozzon létre dokumentációs rendszereket (ha lehetséges, vezessen be CMMS-t)

- Végezzen NFPA 70E képzést a karbantartó személyzet számára

- Dolgozzon ki szabványos működési eljárásokat a gyakori feladatokhoz

Középtávú intézkedések (3-12. hónap):

- Hajtsa végre a kezdeti karbantartási tevékenységeket a megállapított ütemtervek szerint

- Bővítse a program hatókörét, hogy az összes elektromos berendezést tartalmazza

- Végezzen vagy frissítsen rendszer tanulmányokat (zárlat, koordináció, ívfény)

- Vezessen be prediktív karbantartási technológiákat

- Hozzon létre KPI nyomon követést és jelentéstételt

- Végezze el az első hivatalos programfelülvizsgálatot

Hosszú távú intézkedések (2+ év):

- Finomítsa az ütemterveket a teljesítményadatok és a tapasztalatok alapján

- Optimalizálja az erőforrás-elosztást prediktív analitikával

- Folyamatosan javítsa az eljárásokat a tanulságok alapján

- Tartsa fenn a megfelelőséget a fejlődő szabványokkal

- Hasonlítsa össze az iparági legjobb gyakorlatokkal

GYIK

K: Milyen gyakran kell elektromos karbantartást végezni?

V: Az NFPA 70B a legtöbb elektromos berendezés esetében háromévente egyszeri alapgyakoriságot javasol. Az optimális karbantartási gyakoriság azonban a berendezés típusától, életkorától, kritikus jellegétől, működési környezetétől és a gyártó ajánlásaitól függ. A kritikus berendezések, az öregedő rendszerek vagy a zord környezetben lévő berendezések gyakoribb karbantartást igényelnek - potenciálisan negyedévente vagy félévente. A szabályozott környezetben lévő újabb berendezések biztonságosan meghosszabbíthatók ötéves intervallumokra. Ha rendelkezésre áll, mindig a gyártó irányelveit helyezze előtérbe.

K: A házon belüli személyzet végezheti az elektromos karbantartást, vagy szerződést kell kötnünk vállalkozókkal?

V: A házon belüli személyzet végezhet elektromos karbantartást, ha megfelel az NFPA 70B és 70E minősítési követelményeinek. A személyzetnek bizonyítania kell a műszaki ismereteket, megfelelő biztonsági képzésben kell részesülnie, és rendelkeznie kell a konkrét feladatokhoz szükséges készségekkel. Az egyszerű feszültségmentesített ellenőrzéseket és tisztításokat a kikapcsolási/címkézési eljárásokat követő képzett személyzet végezheti. A feszültség alatt végzett munkák, a védőrelé kalibrálása, a rendszer tanulmányok és a speciális tesztelés azonban gyakran engedéllyel rendelkező villanyszerelőket vagy mérnököket igényel. Sok létesítmény hibrid megközelítést alkalmaz: a rutinkarbantartást belső személyzet végzi, a speciális tesztelést pedig képzett vállalkozók.

K: Milyen dokumentációt kell vezetni a megfelelőség érdekében?

V: A lényeges dokumentáció a következőket tartalmazza: (1) írásos EMP politika és eljárások, (2) teljes berendezésleltár karbantartási ütemtervekkel, (3) az összes karbantartási tevékenység nyilvántartása a vizsgálati eredményekkel és megállapításokkal, (4) a személyzet képzési és képesítési nyilvántartásai, (5) aktuális egyvonalas diagramok, (6) rendszer tanulmányok (zárlat, koordináció, ívfény), (7) berendezés kézikönyvek és gyártói irányelvek, és (8) korrekciós intézkedések nyomon követése. Őrizze meg a nyilvántartásokat a berendezés teljes életciklusa alatt, plusz néhány évig. A digitális CMMS platformok leegyszerűsítik a dokumentációkezelést, és ellenőrzési nyomvonalakat biztosítanak a megfelelőség ellenőrzéséhez.

K: Milyen következményei vannak annak, ha nincs elektromos karbantartási program?

V: A megfelelő elektromos karbantartási programmal nem rendelkező létesítmények számos súlyos következménnyel szembesülnek: (1) a berendezés meghibásodási aránya háromszor magasabb, mint a karbantartott rendszereké, (2) megnövekedett az elektromos tüzek, az ívfényes események és a munkavállalói sérülések kockázata, (3) potenciális OSHA idézések az Általános Kötelesség záradék alapján, (4) biztosítási fedezeti problémák vagy elutasított követelések, (5) érvénytelenített berendezés garanciák, (6) költséges sürgősségi javítások és nem tervezett leállások, (7) csökkentett berendezés élettartam, és (8) magasabb energiaköltségek a nem hatékony működés miatt. A reaktív karbantartás pénzügyi és biztonsági költségei messze meghaladják a proaktív programba történő befektetést.

K: Hogyan kapcsolódik az NFPA 70B az NFPA 70E-hez és a Nemzeti Elektromos Kódexhez?

V: Ez a három szabvány alkotja az “Elektromos Biztonsági Ciklust”. Az NFPA 70 (Nemzeti Elektromos Kódex) szabályozza az elektromos rendszerek biztonságos telepítését. Az NFPA 70B karbantartási követelményeket állapít meg a berendezések biztonságának és megbízhatóságának megőrzése érdekében azok teljes életciklusa alatt. Az NFPA 70E munkahelyi biztonsági szabványokat biztosít az elektromos berendezéseken vagy azok közelében dolgozó személyzet számára. Átfogóan együttműködnek: megfelelő telepítés (70), folyamatos karbantartás (70B) és biztonságos munkavégzési gyakorlatok (70E). Az NFPA 70E kifejezetten megköveteli, hogy az elektromos biztonsági programok figyelembe vegyék a “karbantartás állapotát”, közvetlen kapcsolatot teremtve a 70B megfelelőséggel.

K: Mi a különbség a megelőző és a prediktív karbantartás között?

V: A megelőző karbantartás időalapú ütemterveket követ (pl. évente ellenőrizze a megszakítókat) a berendezés állapotától függetlenül. Megakadályozza a meghibásodásokat a rendszeres szervizeléssel, mielőtt problémák merülnének fel. A prediktív karbantartás állapotfigyelő technológiákat (termográfia, rezgéselemzés, olajvizsgálat) használ a berendezés tényleges állapotának felmérésére és annak előrejelzésére, hogy mikor van szükség karbantartásra. A prediktív megközelítések optimalizálják az erőforrás-kihasználást azáltal, hogy csak akkor végeznek karbantartást, ha a mutatók azt sugallják, hogy szükséges, nem pedig rögzített ütemtervek szerint. A leghatékonyabb programok mindkettőt kombinálják: a megelőző karbantartás az alap, a prediktív technológiák pedig a kritikus berendezésekre vannak rétegezve.

K: Hogyan állapíthatom meg, hogy egy berendezés kritikus-e, és gyakoribb karbantartást igényel-e?

V: Értékelje a berendezés kritikus jellegét a következő tényezők felhasználásával: (1) Biztonsági hatás—a meghibásodás sérüléseket vagy haláleseteket okozhat, (2) Működési hatás—a meghibásodás leállítaná a termelést vagy a kritikus folyamatokat, (3) Pénzügyi hatás—a meghibásodás jelentős bevételkiesést vagy javítási költségeket eredményezne, (4) Redundancia—nincs rendelkezésre álló biztonsági mentési rendszer, ha a berendezés meghibásodik, (5) Szabályozási követelmények—a berendezés elengedhetetlen a megfelelőséghez, és (6) További hatások—a meghibásodás károsíthat más berendezéseket vagy rendszereket. A több kritériumnak megfelelő berendezéseket kritikusnak kell minősíteni, és fokozott karbantartási gyakoriságot, állapotfigyelést és alkatrész-készletet kell kapniuk.

Következtetés

A hatékony elektromos karbantartási program kiépítése szisztematikus tervezést, képzett személyzetet, átfogó dokumentációt és a folyamatos fejlesztés iránti folyamatos elkötelezettséget igényel. A 2023-as NFPA 70B szabvány az elektromos karbantartást az opcionális legjobb gyakorlatból kötelező követelménnyé alakította, így a programfejlesztés elengedhetetlen a szabályozási megfelelőség, a biztosítási fedezet és a működési kiválóság szempontjából.

Azok a létesítmények, amelyek strukturált elektromos karbantartási programokba fektetnek be, mérhető előnyöket realizálnak: 66% csökkenés a berendezés meghibásodásában, a költséges sürgősségi javítások kiküszöbölése, a berendezés élettartamának meghosszabbítása, a jobb energiahatékonyság, a fokozott munkahelyi biztonság és az ipari szabványoknak való megfelelés bizonyítása. A kérdés már nem az, hogy bevezessünk-e elektromos karbantartási programot, hanem az, hogy milyen gyorsan tudunk kifejleszteni és bevezetni egy olyat, amely megvédi az embereket, a vagyont és a folyamatokat.

Kezdje az útmutatóban felvázolt öt alapvető lépéssel: végezzen berendezésleltárt és állapotfelmérést, állapítson meg karbantartási ütemterveket az NFPA 70B és a gyártó irányelvei alapján, rendeljen hozzá képzett személyzetet egyértelmű felelősségi körökkel, vezessen be robusztus dokumentációs rendszereket, és folyamatosan figyelje és javítsa a program hatékonyságát. Akár a semmiből épít programot, akár a meglévő gyakorlatokat frissíti a jelenlegi szabványoknak megfelelően, ezek az alapvető elemek hosszú távú sikerre pozícionálják létesítményét.

Azok a létesítmények számára, amelyek speciális berendezéseket igényelnek, mint például MCCB-k, kontaktorok, túlfeszültség-védelmi eszközök, és elosztó berendezések, a VIOX Electric ipari minőségű elektromos alkatrészeket kínál, amelyeket a megbízhatóságra és a hosszú élettartamra terveztek. Termékeink megfelelnek a nemzetközi szabványoknak, és támogatják az átfogó elektromos karbantartási programok igényes követelményeit.