Είναι η έκδοση των μηχανικών ελέγχου για το επιχείρημα “Tab vs. Spaces”.

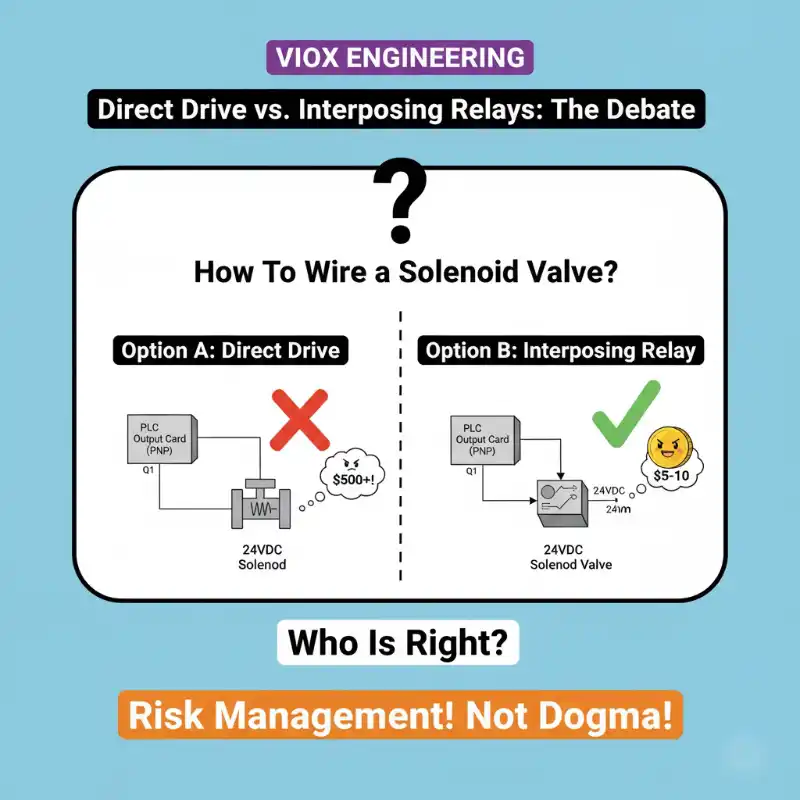

Σχεδιάζετε έναν πίνακα ελέγχου. Έχετε μια ηλεκτρομαγνητική βαλβίδα 24VDC που ελέγχει έναν πνευματικό κύλινδρο. Έχετε μια εφεδρική έξοδο στην κάρτα PLC σας.

Κάνετε:

- A) Συνδέετε τη βαλβίδα απευθείας στην έξοδο του PLC;

- B) Εγκαθιστάτε ένα “ενδιάμεσο ρελέ” μεταξύ του PLC και της βαλβίδας;

Εάν το ρωτήσετε αυτό σε ένα δωμάτιο γεμάτο μηχανικούς (ή στο φόρουμ r/PLC), θα ξεκινήσετε έναν καβγά.

Η “Παλιά Φρουρά” θα σας πει ότι η απευθείας οδήγηση μιας βαλβίδας είναι απερίσκεπτη κακοτεχνία που θα σας κοστίσει χιλιάδες. Οι “Μοντερνιστές” θα σας πουν ότι η προσθήκη ρελέ είναι σπατάλη χώρου και χρημάτων που εισάγει περιττά σημεία αστοχίας.

Και οι δύο πλευρές έχουν δίκιο. Και οι δύο πλευρές κάνουν λάθος.

Η απάντηση δεν αφορά το δόγμα. αφορά Διαχείριση Κινδύνου. Ας αναλύσουμε τη συζήτηση για τον “Θυσιαζόμενο Αμνό” και ας βρούμε τον Χρυσό Κανόνα που θα πρέπει πραγματικά να καθοδηγεί το σχέδιό σας.

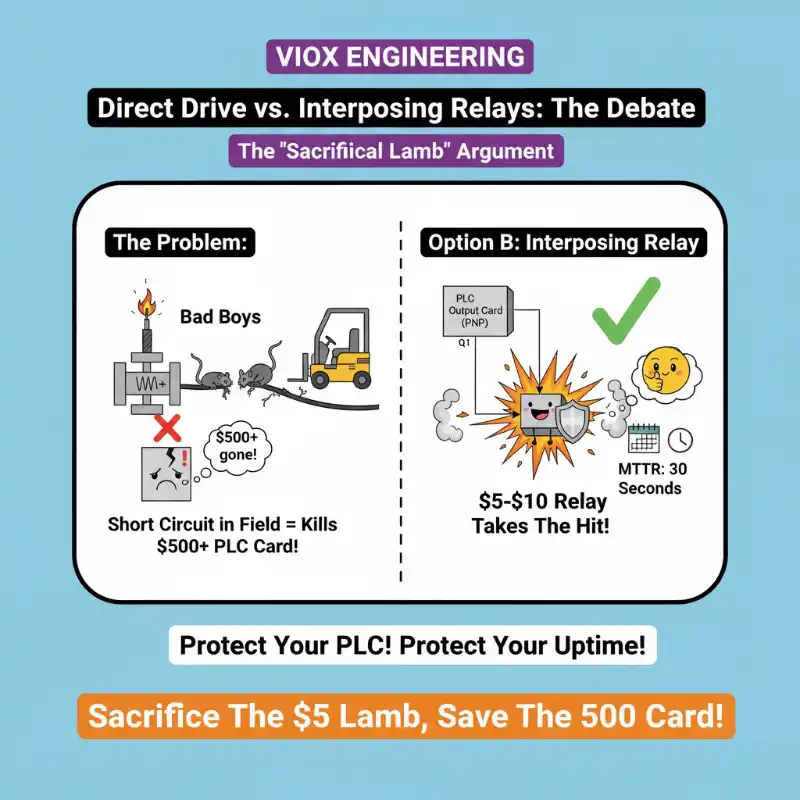

1. Το Συντηρητικό Επιχείρημα: “Ο Θυσιαζόμενος Αμνός”

Για τον μηχανικό που επικεντρώνεται στη συντήρηση, το ενδιάμεσο ρελέ είναι μη διαπραγματεύσιμο. Η λογική τους βασίζεται στην οικονομική ασυμμετρία.

- Το Περιουσιακό Στοιχείο: Μια Μονάδα Εξόδου Allen-Bradley ή Siemens. Κόστος: 300€ – 500€+.

- Η Ασπίδα: Ένα απλό plug-in ρελέ. Κόστος: 5€ – 10€.

Η Λογική:

Οι ηλεκτρομαγνητικές βαλβίδες είναι τα “κακά παιδιά” του βιομηχανικού κόσμου. Βραχυκυκλώνουν. Τα πηνία καίγονται. Τα καλώδια συνθλίβονται από περονοφόρα ανυψωτικά.

Εάν συνδέσετε αυτή τη βαλβίδα απευθείας στην κάρτα PLC των 500€, ένα απλό βραχυκύκλωμα στο πεδίο θα μπορούσε να κάψει το εσωτερικό τρανζίστορ αυτού του καναλιού εξόδου. Στο χειρότερο σενάριο, καπνίζει ολόκληρη την κάρτα.

Τώρα έχετε μια μηχανή εκτός λειτουργίας στις 3:00 π.μ. Για να το διορθώσετε, πρέπει να απενεργοποιήσετε τη ράγα, να ξεβιδώσετε το μπλοκ ακροδεκτών, να αντικαταστήσετε την ακριβή κάρτα (εάν έχετε εφεδρική) και να την επανασυνδέσετε.

Αλλά αν χρησιμοποιήσετε ένα ενδιάμεσο ρελέ; Το ρελέ δέχεται το χτύπημα. Είναι ο Θυσιαζόμενος Αμνός.

Το PLC παραμένει ασφαλές. Ο τεχνικός πλησιάζει, τραβάει το καμένο ρελέ από την υποδοχή του, συνδέει ένα νέο κύβο των 5€ και η μηχανή λειτουργεί σε 30 δευτερόλεπτα.

Επαγγελματική συμβουλή: Για τον “Συντηρητικό” μηχανικό, ο στόχος δεν είναι μόνο η προστασία του υλικού. είναι η προστασία του Μέσου Χρόνου Επισκευής (MTTR). Μια αλλαγή ρελέ είναι ταχύτερη από μια αλλαγή μονάδας κάθε φορά.

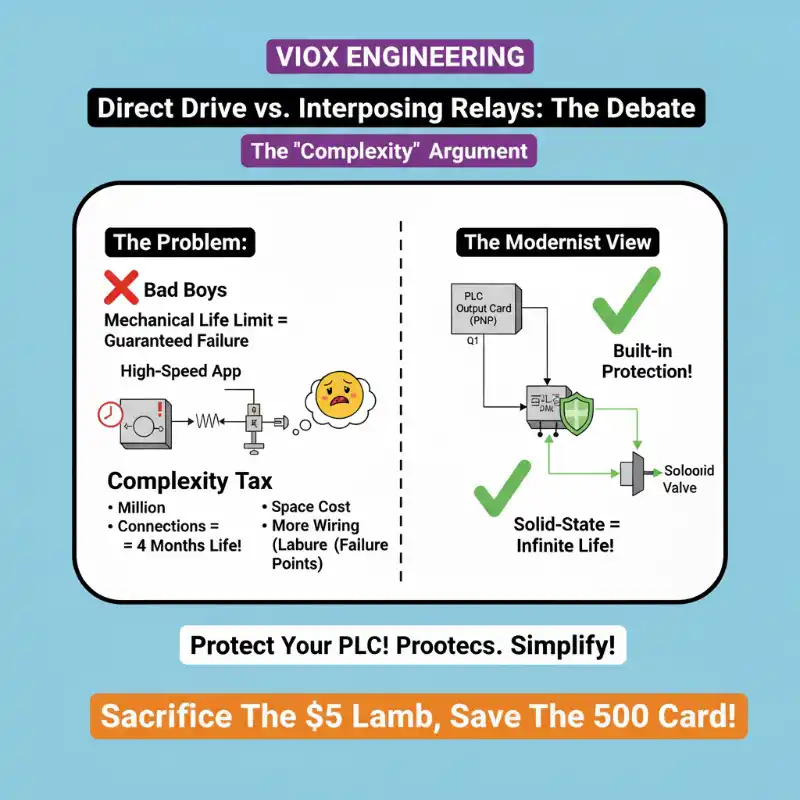

2. Το Μοντερνιστικό Επιχείρημα: “Ο Φόρος Πολυπλοκότητας”

Η άλλη πλευρά του τραπεζιού υποστηρίζει ότι η στρατηγική του “Θυσιαζόμενου Αμνού” είναι ξεπερασμένη σκέψη από τη δεκαετία του 1980.

1. Τα σύγχρονα PLC δεν είναι εύθραυστα

Πριν από είκοσι χρόνια, οι κάρτες εξόδου ήταν ευαίσθητες. Σήμερα; Οι περισσότερες ποιοτικές μονάδες εξόδου τρανζίστορ έχουν ενσωματωμένη ηλεκτρονική προστασία βραχυκυκλώματος. Εάν μια βαλβίδα βραχυκυκλώσει, η κάρτα το ανιχνεύει, απενεργοποιεί το κανάλι και περιμένει να καθαρίσει το σφάλμα. Προστατεύει τον εαυτό της. Δεν χρειάζεται ανάγκη σωματοφύλακα.

2. Όρια Μηχανικής Ζωής

Ένα ρελέ είναι μια μηχανική συσκευή. Έχει κινούμενα μέρη. Έχει έναν κύκλο ζωής (ίσως 100.000 έως 1 εκατομμύριο κύκλους).

Εάν έχετε μια εφαρμογή διαλογής υψηλής ταχύτητας όπου μια βαλβίδα πυροδοτεί κάθε 2 δευτερόλεπτα, αυτό το ρελέ θα αποτύχει μηχανικά σε λίγους μήνες.

Μια έξοδος τρανζίστορ PLC είναι στερεάς κατάστασης. Η θεωρητική της ζωή είναι άπειρη. Προσθέτοντας ένα ρελέ, παίρνετε ένα ισχυρό σύστημα και προσθέτετε ένα “αναλώσιμο” που εγγυάται μελλοντική συντήρηση.

3. Ο “Φόρος Πολυπλοκότητας”

Κάθε εξάρτημα που προσθέτετε είναι ένα πιθανό σημείο αστοχίας. Η προσθήκη ενός ρελέ σημαίνει:

- Προσθήκη μιας υποδοχής (Κόστος χώρου).

- Προσθήκη 4+ σημείων σύνδεσης (Κίνδυνος χαλαρής βίδας).

- Προσθήκη επιπλέον καλωδίου (Κόστος εργασίας).

Το Μοντερνιστικό επιχείρημα είναι: “Αγοράζετε μια ψευδή αίσθηση ασφάλειας πληρώνοντας έναν φόρο σε χώρο, εργασία και πολυπλοκότητα.”

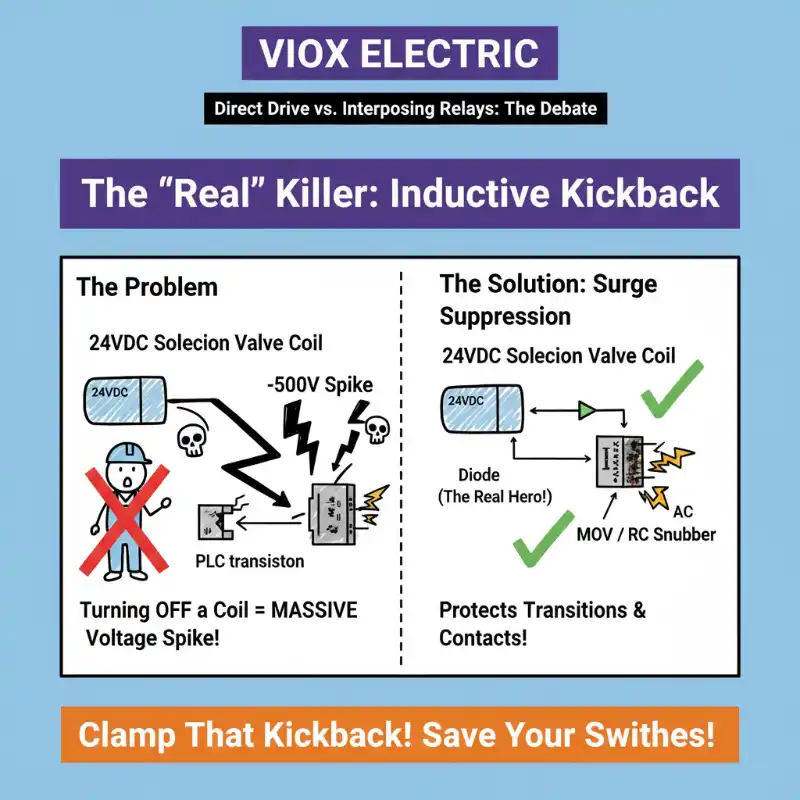

3. Ο “Πραγματικός” Δολοφόνος: Η Επαγωγική Αντίδραση

Ενώ οι Συντηρητικοί και οι Μοντερνιστές διαφωνούν για το πώς πώς να αλλάξετε το φορτίο, συχνά αγνοούν το τι τι σκοτώνει τον διακόπτη.

Ο πραγματικός εχθρός δεν είναι το βραχυκύκλωμα. Είναι η Επαγωγική Αντίδραση (Υπέρταση).

Ένα πηνίο σωληνοειδούς είναι ένας επαγωγέας. Όταν απενεργοποιείτε off την τροφοδοσία σε ένα μαγνητικό πηνίο, το καταρρέον μαγνητικό πεδίο δημιουργεί μια τεράστια ανάστροφη αιχμή τάσης. Ένα πηνίο 24V μπορεί να δημιουργήσει μια αιχμή -500V έως -1000V σε ένα μικροδευτερόλεπτο.

- Εάν χρησιμοποιείτε PLC: Αυτή η αιχμή διαπερνά τη σύνδεση του τρανζίστορ.

- Εάν χρησιμοποιείτε Ρελέ: Αυτή η αιχμή δημιουργεί τόξο στις επαφές, συγκολλώντας τις ή απανθρακώνοντάς τις.

Η ετυμηγορία: Δεν έχει σημασία αν χρησιμοποιείτε ρελέ ή όχι—αν δεν χρησιμοποιείτε Καταστολή Υπέρτασης (μια δίοδος για DC, ή ένα MOV/RC snubber για AC), θα καταστρέψετε τη συσκευή μεταγωγής σας.

Επαγγελματική συμβουλή: Μην εγκαταστήσετε ποτέ μια ηλεκτρομαγνητική βαλβίδα χωρίς μια δίοδο (δίοδος ανάστροφης τάσης) κατά μήκος του πηνίου. Πολλοί σύγχρονοι σύνδεσμοι βαλβίδων (σύνδεσμοι DIN) διαθέτουν ενσωματωμένα LED και διόδους. Χρησιμοποιήστε τους. Είναι η πραγματικό φθηνή ασφάλεια.

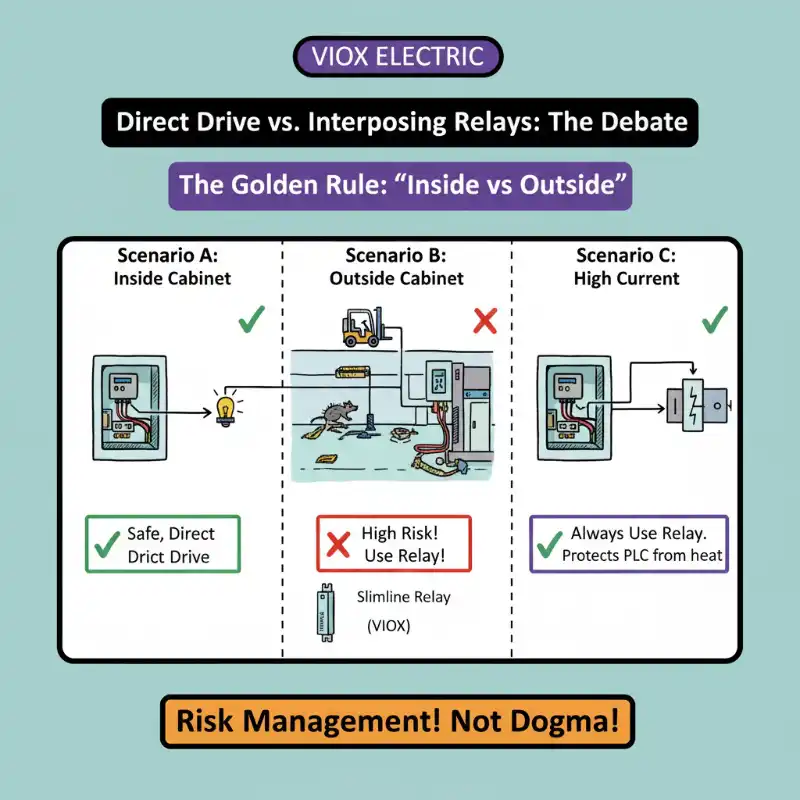

4. Ο Χρυσός Κανόνας: “Μέσα εναντίον Έξω”

Λοιπόν, ποιος κερδίζει;

Η συζήτηση διευθετήθηκε από έναν πραγματιστικό “Χρυσό Κανόνα” που χρησιμοποιούν έμπειροι system integrators. Αποφασίζει πότε να χρησιμοποιήσετε ένα ρελέ με βάση την τοποθεσία.

Σενάριο Α: Το Φορτίο είναι ΕΣΩΤΕΡΙΚΑ του Πίνακα

- Παραδείγματα: Ενδεικτικές λυχνίες, άλλες είσοδοι PLC, μικρά ρελέ ελέγχου, σήματα ενεργοποίησης VFD.

- Ετυμηγορία: Άμεση Οδήγηση.

- Γιατί: Το περιβάλλον είναι ελεγχόμενο. Δεν υπάρχουν περονοφόρα ανυψωτικά που να οδηγούν μέσα από τον πίνακα σας. Ο κίνδυνος βραχυκυκλώματος είναι σχεδόν μηδενικός. Η χρήση ενός ρελέ εδώ είναι σπατάλη χρημάτων και χώρου.

Σενάριο Β: Το Φορτίο είναι ΕΞΩΤΕΡΙΚΑ του Πίνακα (Το Πεδίο)

- Παραδείγματα: Ηλεκτρομαγνητικές βαλβίδες στο μηχάνημα, επαφές κινητήρα, κόρνες.

- Ετυμηγορία: Ενδιάμεσο Ρελέ (ή Ασφαλισμένη Ακροδέκτης).

- Γιατί: Το πεδίο είναι μια εμπόλεμη ζώνη. Τα καλώδια σκαλώνουν, το νερό εισέρχεται στα κουτιά διακλάδωσης και οι αρουραίοι μασούν τα καλώδια. Ο κίνδυνος βραχυκυκλώματος είναι υψηλός.

- Ο Συμβιβασμός: Δεν χρειάζεστε ένα μεγάλο, ογκώδες ρελέ “Ice Cube”. Χρησιμοποιήστε Λεπτά Ρελέ (όπως τα 6mm από την Phoenix Contact, Finder ή VIOX). Καταλαμβάνουν το ίδιο πλάτος με ένα μπλοκ ακροδεκτών, αλλά προσφέρουν πλήρη απομόνωση.

Σενάριο Γ: Η Εξαίρεση “Υψηλού Ρεύματος”

- Ετυμηγορία: Εάν το σωληνοειδές τραβάει περισσότερα από 0,5 Amps (ή κοντά στο όριο της κάρτας PLC), Να χρησιμοποιείτε πάντα ένα ρελέ.

- Γιατί: Η λειτουργία μιας κάρτας PLC στο 90% της χωρητικότητας παράγει θερμότητα και μειώνει τη διάρκεια ζωής της. Αφήστε ένα φτηνό ρελέ να χειριστεί τη βαριά εργασία.

Σύνοψη: Μην είστε Δογματικοί, να είστε Στρατηγικοί

Η συζήτηση “Άμεση έναντι Ρελέ” δεν είναι δυαδική. Είναι μια κυλιόμενη κλίμακα κινδύνου.

- Αξιολογήστε τον Κίνδυνο: Το καλώδιο τρέχει σε ένα εργοστασιακό δάπεδο; Ρελέ. Απέχει δύο ίντσες στην ίδια οπίσθια πλακέτα; Άμεση.

- Καταστείλτε την Υπέρταση: Σφίξτε με δίοδο κάθε πηνίο DC. Χωρίς εξαιρέσεις.

- Εξοικονομήστε Χώρο: Εάν χρησιμοποιείτε ρελέ, χρησιμοποιήστε το εξαιρετικά λεπτό στυλ διεπαφής 6mm.

- Εξετάστε τις Ασφαλισμένες Ακροδέκτες: Ένα ασφαλισμένο μπλοκ ακροδεκτών είναι ένα εξαιρετικό ενδιάμεσο έδαφος. Προστατεύει το καλώδιο PLC από ένα βραχυκύκλωμα πεδίου χωρίς τη μηχανική φθορά ενός ρελέ.

Δεν χρειάζεται να “θυσιάσετε ένα αρνί” για κάθε έξοδο. Αλλά αν στέλνετε 24V στην άγρια, άγρια δύση του εργοστασιακού δαπέδου, είναι ωραίο να έχετε έναν σωματοφύλακα που στέκεται μπροστά από τον ελεγκτή σας.

Τεχνική Σημείωση Ακρίβεια

Πρότυπα & Πηγές Αναφέρεται: Οι έννοιες ευθυγραμμίζονται με NFPA 79 (Ηλεκτρικό Πρότυπο για Βιομηχανικά Μηχανήματα) σχετικά με την προστασία από υπερβολικό ρεύμα και τον διαχωρισμό των κυκλωμάτων ελέγχου.

Ορολογία: “Ο όρος ”Ενδιάμεσο Ρελέ" αναφέρεται σε ένα ρελέ που χρησιμοποιείται ειδικά για να απομονώσει έναν ελεγκτή χαμηλής ισχύος (PLC) από ένα φορτίο υψηλότερης ισχύος ή υψηλότερου κινδύνου.

Επικαιρότητα: Οι βέλτιστες πρακτικές σχετικά με την προστασία εξόδου στερεάς κατάστασης και τα λεπτά ρελέ είναι τρέχουσες από τον Νοέμβριο του 2025.