Η Σιωπηλή Αναβάθμιση της Βιομηχανίας: Γιατί οι Μεγάλοι Κατασκευαστές Ανεβάζουν τον Πήχη

Πρόσφατα, ένας διευθυντής προμηθειών έθεσε ένα καίριο ερώτημα σε ένα τεχνικό φόρουμ: “Γιατί μεγάλες μάρκες όπως οι Mersen, Littelfuse και Bussmann επανασημαίνουν αθόρυβα τα ασφάλειες Class R από 200kA σε 300kA ικανότητα διακοπής; Είναι απλώς ένα διαφημιστικό τέχνασμα ή μια πραγματική βελτίωση της ασφάλειας;”

Ο σκεπτικισμός είναι κατανοητός. Σε μια βιομηχανία όπου τα πρότυπα εξελίσσονται αργά και συντηρητικά, ένα άλμα 50% στις προδιαγραφές απόδοσης μοιάζει ύποπτα με μια τακτική πωλήσεων. Εξάλλου, αν τα 200kA (200.000 αμπέρ) ήταν αρκετά για δεκαετίες, γιατί η ξαφνική αλλαγή;

Εδώ είναι η άβολη αλήθεια: Δεν είναι μάρκετινγκ—είναι μια απάντηση σε ένα ολοένα και πιο επικίνδυνο ηλεκτρικό δίκτυο. Η μετάβαση σε ικανότητες διακοπής 300kA δεν αφορά την ανταγωνιστική θέση. είναι ένα σύμπτωμα ενός μετρήσιμου προβλήματος στα βιομηχανικά συστήματα ισχύος. Τα διαθέσιμα ρεύματα σφάλματος στις εισόδους παροχής αυξάνονται λόγω των αναβαθμίσεων της υποδομής των επιχειρήσεων κοινής ωφέλειας, του εκσυγχρονισμού του δικτύου και της αυξημένης πυκνότητας ισχύος στις βιομηχανικές εγκαταστάσεις. Η “τυπική” προστασία του χθες γίνεται επικίνδυνα ανεπαρκής σήμερα.

Στην VIOX Electric, έναν B2B κατασκευαστή ηλεκτρικού εξοπλισμού που ειδικεύεται σε βιομηχανικά συστήματα προστασίας, παρακολουθούμε στενά αυτή την τάση. Η μετάβαση σε υψηλότερη ικανότητα διακοπής δεν είναι προαιρετική—είναι απαραίτητη για την ασφάλεια των εγκαταστάσεων, την προστασία του εξοπλισμού και τη συμμόρφωση με τους κανονισμούς. Αυτό το άρθρο εξηγεί γιατί οι ασφάλειες υψηλής ικανότητας διακοπής (HBC) δεν είναι πλέον μια πολυτελής προδιαγραφή, αλλά η απολύτως ελάχιστη γραμμή προστασίας της εγκατάστασής σας έναντι καταστροφικών συμβάντων βραχυκυκλώματος.

Η Εξέλιξη των 300kA: Όχι Μάρκετινγκ, Αλλά Μηχανική Ανάγκη

Για δεκαετίες, η ικανότητα διακοπής 200kA αντιπροσώπευε την οροφή για τις βιομηχανικές ασφάλειες χαμηλής τάσης. Οι μηχανικοί που σχεδίαζαν συστήματα τη δεκαετία του 1990 και στις αρχές της δεκαετίας του 2000 καθόριζαν με σιγουριά ασφάλειες Class J, Class L και Class R με βαθμολογίες 200kA, υποθέτοντας ότι αυτό υπερέβαινε οποιοδήποτε ρεαλιστικό σενάριο σφάλματος. Ο υπολογισμός ήταν απλός: “Ο μετασχηματιστής μου 1500 kVA δεν μπορεί να δημιουργήσει 200.000 αμπέρ ρεύματος σφάλματος στη δευτερεύουσα πλευρά.”

Αυτή η υπόθεση δεν είναι πλέον καθολικά έγκυρη.

Δύο Βασικές Αιτίες που Οδηγούν σε Υψηλότερα Ρεύματα Σφάλματος

1. Αντικατάσταση Γηρασμένων Υποδομών και Εκσυγχρονισμός του Δικτύου

Οι εταιρείες ηλεκτρικής ενέργειας σε όλη τη Βόρεια Αμερική αντικαθιστούν συστηματικά τους παλιούς μετασχηματιστές διανομής και αναβαθμίζουν τους υποσταθμούς. Οι σύγχρονοι μετασχηματιστές έχουν συνήθως χαμηλότερη σύνθετη αντίσταση από τις μονάδες που εγκαταστάθηκαν πριν από 30-40 χρόνια. Σύμφωνα με τα πρότυπα υπολογισμού ρεύματος σφάλματος IEEE (IEEE 551-2006), η σύνθετη αντίσταση του μετασχηματιστή είναι ο κύριος περιοριστικός παράγοντας στο διαθέσιμο ρεύμα βραχυκυκλώματος.

Όταν μια εταιρεία κοινής ωφέλειας αντικαθιστά έναν μετασχηματιστή σύνθετης αντίστασης 4% με μια νεότερη μονάδα σύνθετης αντίστασης 3,5% στην ίδια ονομαστική τιμή kVA, το διαθέσιμο ρεύμα σφάλματος αυξάνεται κατά περίπου 14% αμέσως—χωρίς καμία αλλαγή στο ηλεκτρικό σύστημα της εγκατάστασής σας. Οι εγκαταστάσεις που σχεδιάστηκαν πριν από δύο δεκαετίες για διαθέσιμο ρεύμα σφάλματος 50kA ενδέχεται τώρα να αντιμετωπίζουν 65kA ή υψηλότερο αποκλειστικά λόγω τροποποιήσεων της εταιρείας κοινής ωφέλειας ανάντη.

2. Πύκνωση Βιομηχανικού Πάρκου και Χαμηλότερη Σύνθετη Αντίσταση Συστήματος

Καθώς τα βιομηχανικά πάρκα επεκτείνονται και η ζήτηση ισχύος αυξάνεται, οι εταιρείες κοινής ωφέλειας εγκαθιστούν μεγαλύτερους μετασχηματιστές πιο κοντά στα κέντρα φορτίου. Οι μικρότερες διαδρομές αγωγών μεταξύ των μετασχηματιστών και των εισόδων παροχής σημαίνουν χαμηλότερες διαδρομές σύνθετης αντίστασης—και υψηλότερα πιθανά ρεύματα βραχυκυκλώματος. Μια εγκατάσταση που αρχικά λάμβανε ρεύμα μέσω 200 ποδιών αγωγού από έναν απομακρυσμένο μετασχηματιστή τοποθετημένο σε βάση μπορεί τώρα να εξυπηρετείται από μια νέα μονάδα που είναι εγκατεστημένη μόλις 50 πόδια από το κτίριο. Αυτή η τετραπλή μείωση του μήκους του αγωγού μπορεί να αυξήσει το διαθέσιμο ρεύμα σφάλματος κατά 20-30%.

Η Πραγματικότητα της Πιστοποίησης UL 248

Η εμφάνιση ασφαλειών με ονομαστική τιμή 300kA δεν είναι κερδοσκοπική μηχανική—αντικατοπτρίζει αυστηρές δοκιμές τρίτων. Σύμφωνα με τα πρότυπα UL 248 (συγκεκριμένα UL 248-8 για Class J, UL 248-10 για Class L και UL 248-12 για ασφάλειες Class R), οι κατασκευαστές πρέπει να αποδείξουν ότι οι ασφάλειες μπορούν να διακόψουν με ασφάλεια το ονομαστικό ρεύμα σφάλματος χωρίς ρήξη, πυρκαγιά ή εκτόξευση αγώγιμων σωματιδίων.

Οι ασφάλειες Class RK1 με ονομαστική τιμή 300kA έχουν περάσει αυτές τις δοκιμές σε συμμετρικό ρεύμα RMS 300.000 αμπέρ—επιδεικνύοντας συγκράτηση, κατάσβεση τόξου και ασφαλή διακοπή σε επίπεδα που θα κατέστρεφαν συσκευές χαμηλότερης ονομαστικής τιμής. Η αναβάθμιση σε 300kA παρέχει ένα μεγαλύτερο περιθώριο ασφάλειας καθώς τα ρεύματα σφάλματος της εταιρείας κοινής ωφέλειας αυξάνονται σταδιακά, διασφαλίζοντας ότι ο εξοπλισμός προστασίας δεν θα γίνει ο ασθενέστερος κρίκος κατά τη διάρκεια ενός καταστροφικού βραχυκυκλώματος.

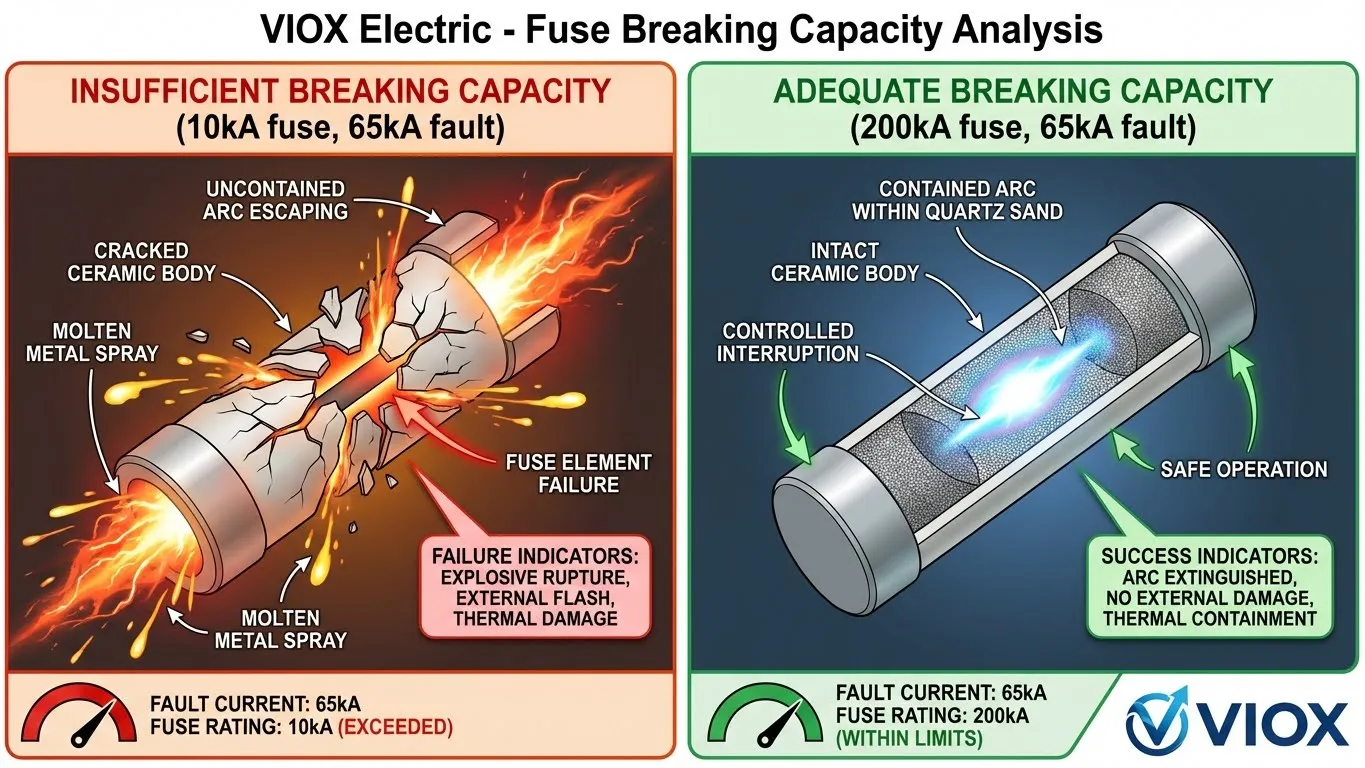

Η Καταστροφική Φυσική της Υπέρβασης της Ικανότητας Διακοπής

Το πιο επικίνδυνο λάθος προμηθειών στην ηλεκτρική προστασία είναι η αγορά με βάση την τιμή αντί για την ικανότητα διακοπής. Όταν συγκρίνετε ασφάλειες, μια γενική συσκευή με ονομαστική τιμή 10kA μπορεί να μοιάζει φυσικά με μια ασφάλεια υψηλής ικανότητας διακοπής (HBC) premium 200kA. Μπορεί να έχουν παρόμοιες διαστάσεις, να ταιριάζουν σε πανομοιότυπους κατόχους και να φέρουν την ίδια ονομαστική τιμή αμπέρ. Η διαφορά τιμής μπορεί να είναι 3:1 ή ακόμα και 5:1.

Αλλά μέσα σε αυτές τις επιφανειακά πανομοιότυπες συσκευασίες, η διαφορά είναι κυριολεκτικά ζωή και θάνατος.

Τι Συμβαίνει Όταν το Ρεύμα Σφάλματος Υπερβαίνει την Ικανότητα Διακοπής

Η ικανότητα διακοπής (ονομάζεται επίσης ονομαστική τιμή διακοπής ή ικανότητα ρήξης) ορίζει το μέγιστο ρεύμα που μπορεί να διακόψει με ασφάλεια μια ασφάλεια χωρίς να καταστραφεί ή να προκαλέσει ηλεκτρικό τόξο με απαράδεκτη διάρκεια. Αυτό δεν είναι ένα προτεινόμενο εύρος λειτουργίας—είναι ένα σκληρό φυσικό όριο.

Εξετάστε ένα ρεαλιστικό σενάριο: Η εγκατάστασή σας έχει διαθέσιμο ρεύμα σφάλματος 65kA στην κύρια είσοδο παροχής (όχι ασυνήθιστο σε μεσαίου μεγέθους βιομηχανικές μονάδες). Κατά τη διάρκεια ενός συμβάντος βραχυκυκλώματος—ίσως από αστοχία εξοπλισμού ή τυχαία επαφή—τα πλήρη 65.000 αμπέρ προσπαθούν να ρέουν μέσω της προστατευτικής ασφάλειας.

Εάν αυτή η ασφάλεια έχει μόνο ικανότητα διακοπής 10kA:

- Τήξη Στοιχείου: Το στοιχείο της ασφάλειας εξατμίζεται όπως έχει σχεδιαστεί, δημιουργώντας ένα τόξο.

- Η Ενέργεια Τόξου Υπερβαίνει τη Συγκράτηση: Το τόξο παράγει θερμοκρασίες που υπερβαίνουν τους 20.000°C και τεράστια πίεση μέσα στο κεραμικό σώμα.

- Η Άμμος Χαλαζία Αποτυγχάνει: Το μέσο κατάσβεσης τόξου (άμμος χαλαζία) δεν μπορεί να απορροφήσει την τεράστια απελευθέρωση ενέργειας αρκετά γρήγορα.

- Η Πίεση Προκαλεί Ρήξη Κεραμικού: Το κεραμικό σώμα—σχεδιασμένο για επίπεδα ενέργειας 10kA—δεν μπορεί να αντέξει τη μηχανική καταπόνηση από την πίεση τόξου 65kA.

- Εκρηκτική Αστοχία: Η ασφάλεια εκρήγνυται, εκτοξεύοντας εξατμισμένο μέταλλο, υπερθερμασμένα αέρια και κεραμικά θραύσματα προς όλες τις κατευθύνσεις.

Αυτό δεν είναι θεωρητικό. Οι αστοχίες πεδίου ασφαλειών με χαμηλή ονομαστική τιμή έχουν προκαλέσει πυρκαγιές σε πίνακες, σοβαρές ζημιές στον εξοπλισμό και τραυματισμούς σε κοντινό προσωπικό. Το άρθρο 110.9 του Εθνικού Ηλεκτρολογικού Κώδικα (NEC) υπάρχει ειδικά για να αποτρέψει αυτό το σενάριο, απαιτώντας ότι “ο εξοπλισμός που προορίζεται να διακόψει το ρεύμα σε επίπεδα σφάλματος πρέπει να έχει ικανότητα διακοπής επαρκή για την ονομαστική τάση του κυκλώματος και το ρεύμα που είναι διαθέσιμο στους ακροδέκτες γραμμής του εξοπλισμού.”

Το Πλεονέκτημα της Ασφάλειας Υψηλής Ικανότητας Ρήξης

Αντίθετα, μια σωστά βαθμολογημένη Ασφάλεια HRC με ικανότητα διακοπής 200kA που χειρίζεται το ίδιο σφάλμα 65kA λειτουργεί με ασφάλεια:

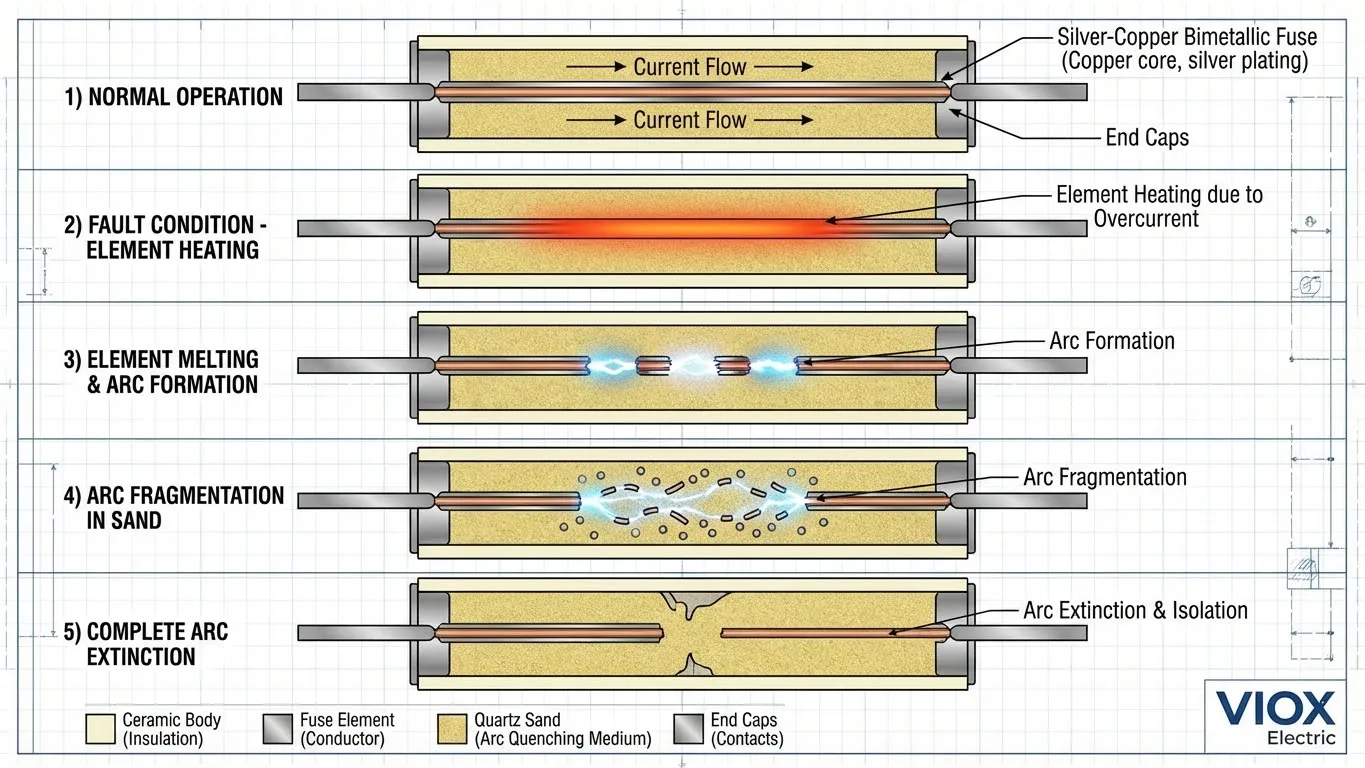

- Τήξη Στοιχείου: Το βαθμονομημένο στοιχείο ασφάλειας αργύρου-χαλκού εξατμίζεται σε προκαθορισμένα επίπεδα ρεύματος.

- Έναρξη Τόξου: Σχηματίζεται τόξο υψηλής θερμοκρασίας σε ελεγχόμενο περιβάλλον.

- Απορρόφηση Άμμου: Η άμμος χαλαζία απορροφά γρήγορα την ενέργεια του τόξου, κατακερματίζοντας το τόξο σε πολλά μικρότερα τόξα και ψύχοντας το πλάσμα.

- Συγκράτηση Πίεσης: Το ενισχυμένο κεραμικό σώμα αντέχει στην εσωτερική πίεση από τα αέρια του τόξου.

- Ασφαλής Κατάσβεση: Το τόξο σβήνει εντελώς μέσα σε χιλιοστά του δευτερολέπτου. το κύκλωμα ανοίγει με ασφάλεια χωρίς εξωτερικές ενδείξεις πέρα από τη λειτουργία του πείρου κρούσης (εάν υπάρχει).

Ολόκληρο το συμβάν—από την έναρξη του σφάλματος έως την πλήρη κατάσβεση του τόξου—συμβαίνει σε 0,004 έως 0,008 δευτερόλεπτα (περίπου το ένα τέταρτο έως το μισό του ηλεκτρικού κύκλου στα 60Hz). Για τον εξωτερικό παρατηρητή, το σύστημα προστασίας απλώς “έκανε κλικ” και απομόνωσε με ασφάλεια το σφάλμα.

Απλοποιημένη Εκτίμηση Ρεύματος Σφάλματος

Το διαθέσιμο ρεύμα σφάλματος μπορεί να εκτιμηθεί χρησιμοποιώντας δεδομένα μετασχηματιστή: ISC = (kVA × 1000) ÷ (√3 × Τάση × %Z) όπου %Z είναι η σύνθετη αντίσταση του μετασχηματιστή εκφρασμένη ως δεκαδικός. Για έναν μετασχηματιστή 1500 kVA με σύνθετη αντίσταση 3,5% που τροφοδοτεί ένα σύστημα 480V: ISC = (1500 × 1000) ÷ (1,732 × 480 × 0,035) = 51.440 αμπέρ. Αυτό αντιπροσωπεύει το μέγιστο ρεύμα σφάλματος στους δευτερεύοντες ακροδέκτες του μετασχηματιστή. το πραγματικό ρεύμα σφάλματος στους απομακρυσμένους πίνακες θα είναι χαμηλότερο λόγω της σύνθετης αντίστασης του αγωγού.

Οι επαγγελματικές μελέτες βραχυκυκλώματος που ακολουθούν τα πρότυπα IEEE 551-2006 ή IEC 60909 λαμβάνουν υπόψη όλες τις σύνθετες αντιστάσεις του συστήματος, τις συνεισφορές του κινητήρα και τις αναλογίες X/R για να παρέχουν ακριβείς τιμές ρεύματος σφάλματος σε κάθε σημείο του συστήματος διανομής.

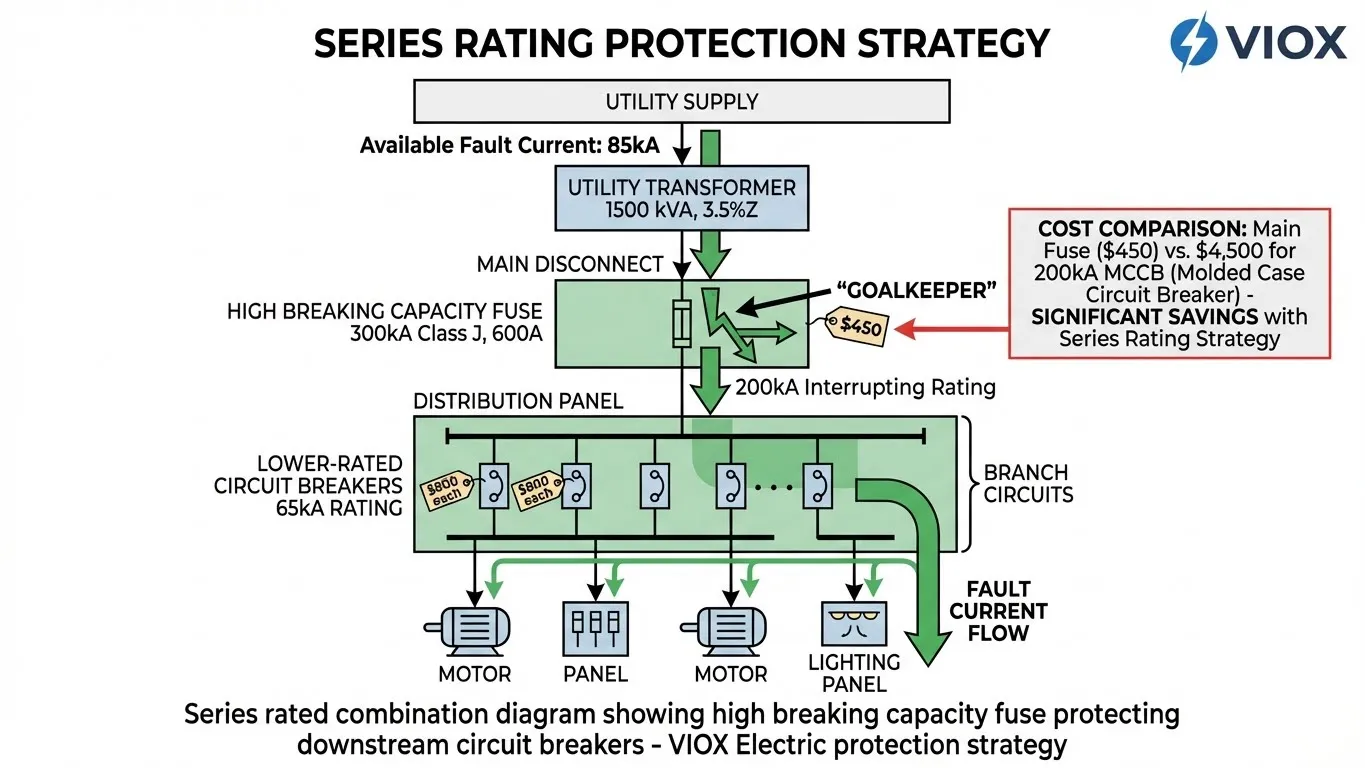

Πλεονέκτημα Περιορισμού Ρεύματος: Η Στρατηγική του Τερματοφύλακα

Όταν συγκρίνουμε μεθόδους προστασίας για εγκαταστάσεις με υψηλό ρεύμα σφάλματος, ανακύπτει ένα θεμελιώδες ερώτημα: “Γιατί να μην χρησιμοποιήσουμε απλώς διακόπτες κυκλώματος με υψηλές ικανότητες διακοπής;”

Η απάντηση έγκειται στη φυσική και την οικονομία. Η μηχανική ενός molded case circuit breaker (MCCB) για την ασφαλή διακοπή 100kA ή 200kA απαιτεί μαζική ενίσχυση—μεγαλύτερους αγωγούς τόξου, βαριά συστήματα επαφών και σύνθετες διατάξεις διαχωρισμού τόξου. Αυτές οι τροποποιήσεις αυξάνουν δραματικά το φυσικό μέγεθος, το βάρος και το κόστος. Ένας αυτόματος διακόπτης ονομαστικής τιμής 200kA σε πλαίσιο 600A μπορεί να κοστίσει €3.500-€5.500, ενώ μια μονάδα ονομαστικής τιμής 300kA (εάν είναι διαθέσιμη σε αυτή την αμπερομετρία) μπορεί να πλησιάσει τα €8.000-€12.000.

Φυσική Απόδοση Περιορισμού Ρεύματος

Οι ασφάλειες, αντίθετα, είναι εγγενώς συσκευές περιορισμού ρεύματος. Αυτό το χαρακτηριστικό παρέχει βαθιά πλεονεκτήματα σε εφαρμογές υψηλού ρεύματος σφάλματος.

Περιορισμός ρεύματος σημαίνει ότι η ασφάλεια λειτουργεί τόσο γρήγορα κατά τη διάρκεια σφαλμάτων υψηλού μεγέθους, ώστε το πραγματικό μέγιστο ρεύμα (συμπεριλαμβανομένου του αρχικού ασύμμετρου στοιχείου) είναι σημαντικά μικρότερο από αυτό που θα έρρεε εάν η ασφάλεια αντικαθίστατο από έναν συμπαγή αγωγό. Μια ασφάλεια Class J 200kA που διακόπτει ένα πιθανό σφάλμα 100kA μπορεί να περιορίσει το πραγματικό μέγιστο ρεύμα μόνο σε 35kA-40kA και να καθαρίσει το σφάλμα σε λιγότερο από 0,004 δευτερόλεπτα (ένας τέταρτος κύκλος).

Αυτός ο περιορισμός ρεύματος έχει δύο κρίσιμες συνέπειες:

- Μείωση Ενέργειας Διέλευσης: Η ενέργεια I²t (αμπέρ στο τετράγωνο επί δευτερόλεπτα) που βιώνει ο κατάντη εξοπλισμός μειώνεται δραστικά—συχνά κατά 90% ή περισσότερο σε σύγκριση με την πλήρη διάρκεια του σφάλματος.

- Μετριασμός Μηχανικής Καταπόνησης: Οι ηλεκτρομαγνητικές δυνάμεις σε αγωγούς και εξοπλισμό (ανάλογες του ρεύματος στο τετράγωνο) ελαχιστοποιούνται, αποτρέποντας φυσικές ζημιές σε ράβδους ζυγών, καλώδια και συνδεδεμένες συσκευές.

Σειριακή Ονομαστική Τιμή: Η Στρατηγική του Τερματοφύλακα

Η ιδιότητα περιορισμού ρεύματος επιτρέπει μια κομψή και οικονομική αρχιτεκτονική προστασίας που ονομάζεται σειριακή ονομαστική τιμή (επιτρέπεται σύμφωνα με το NEC 240.86). Αυτή η στρατηγική χρησιμοποιεί μια ασφάλεια υψηλής ικανότητας διακοπής ως “τερματοφύλακα” για την προστασία αυτόματων διακοπτών κατάντη χαμηλότερης ονομαστικής τιμής.

Η Αρχιτεκτονική:

- Προστασία Κύριας Υπηρεσίας: Εγκαταστήστε μια ασφάλεια υψηλής ικανότητας διακοπής (200kA ή 300kA Class J, RK1 ή L) στην είσοδο της υπηρεσίας όπου το διαθέσιμο ρεύμα σφάλματος είναι υψηλότερο.

- Δράση Περιορισμού Ρεύματος: Κατά τη διάρκεια ενός κατάντη σφάλματος, η δράση περιορισμού ρεύματος της κύριας ασφάλειας μειώνει το πραγματικό μέγεθος και τη διάρκεια του ρεύματος σφάλματος πριν φτάσει στους αυτόματους διακόπτες του κλάδου.

- Αυτόματοι Διακόπτες Κατάντη: Καθορίστε αυτόματους διακόπτες χαμηλότερης ονομαστικής τιμής (65kA ή 100kA) για κυκλώματα κλάδου, γνωρίζοντας ότι η κύρια ασφάλεια περιορίζει την ενέργεια σφάλματος σε επίπεδα που αυτοί οι διακόπτες μπορούν να χειριστούν με ασφάλεια.

Οικονομικός Αντίκτυπος:

| Μέθοδος προστασίας | Κύρια Συσκευή | Προστασία Κλάδου | Συνολικό Κόστος (πίνακας 6 κυκλωμάτων) |

|---|---|---|---|

| Πλήρως Ονομαστικοί MCCB | 200kA MCCB, 600A: €4.500 | 200kA MCCB, 100A (6×): €2.400/ea × 6 = €14.400 | $18,900 |

| Σειριακή Ονομαστική Τιμή με Ασφάλεια HBC | 300kA Class J Fuse, 600A: €450 | 65kA MCCB, 100A (6×): €800/ea × 6 = €4.800 | $5,250 |

| Εξοικονόμηση κόστους | $13,650 (72%) |

Η προσέγγιση σειριακής ονομαστικής τιμής παρέχει πανομοιότυπη προστασία με μείωση κόστους 70%+. Η κύρια ασφάλεια κοστίζει €450 έναντι €4.500 για έναν αυτόματο διακόπτη ισοδύναμης ονομαστικής τιμής, ενώ οι κατάντη διακόπτες κοστίζουν €800 έναντι €2.400 ο καθένας—όλα αυτά παρέχοντας ταχύτερους χρόνους εκκαθάρισης και ανώτερα χαρακτηριστικά ενέργειας διέλευσης.

Ζητήματα Επιλεκτικού Συντονισμού

Ενώ οι συνδυασμοί σειριακής ονομαστικής τιμής προσφέρουν οικονομικά πλεονεκτήματα, οι μηχανικοί πρέπει να κατανοήσουν τις ανταλλαγές. Οι σειριακοί συνδυασμοί δεν μπορούν να συντονιστούν επιλεκτικά επειδή η ασφάλεια στην πλευρά της γραμμής πρέπει να λειτουργεί σε συνδυασμό με τον αυτόματο διακόπτη στην πλευρά του φορτίου κατά τη διάρκεια συνθηκών σφάλματος μέσης έως υψηλής έντασης.

Για εφαρμογές που απαιτούν επιλεκτικό συντονισμό—όπως εγκαταστάσεις υγειονομικής περίθαλψης (NEC 517.17), συστήματα έκτακτης ανάγκης (NEC 700.27), νομικά απαιτούμενα εφεδρικά συστήματα (NEC 701.18), κυκλώματα ανελκυστήρων (NEC 620.62) και κρίσιμα συστήματα ισχύος λειτουργιών (NEC 708.54)—ένα πλήρως ασφαλισμένο σύστημα με ασφάλειες κατάλληλου μεγέθους σε κάθε επίπεδο παρέχει αξιόπιστο επιλεκτικό συντονισμό χρησιμοποιώντας δημοσιευμένες αναλογίες επιλεκτικότητας ασφαλειών.

Συνολική Σύγκριση: Κλάσεις Ασφαλειών και Ικανότητα Διακοπής

| Κλάση Ασφαλειών UL | Εκτίμηση Τάσης | Τρέχον εύρος | Τυπική Ονομαστική Τιμή Διακοπής | Διαθέσιμη Επιλογή 300kA | Κύρια Εφαρμογές | Βασικά πρότυπα |

|---|---|---|---|---|---|---|

| Class J | 600V AC | 1A – 600A | 200kA | ✓ Ναι | Κέντρα ελέγχου κινητήρων, βιομηχανικός εξοπλισμός μεταγωγής, προστασία μετασχηματιστών | UL 248-8, CSA C22.2 No. 248.8 |

| Κλάση L | 600V AC | 601A – 6000A | 200kA | ✓ Ναι | Είσοδος υπηρεσίας, μεγάλοι τροφοδότες, κύρια διανομή | UL 248-10, CSA C22.2 No. 248.10 |

| Class RK1 | 250V/600V AC | 1A – 600A | 200kA | ✓ Ναι | Βιομηχανικοί πίνακες, κυκλώματα κινητήρων, εφαρμογές υψηλής απόδοσης | UL 248-12, CSA C22.2 No. 248.12 |

| Class RK5 | 250V/600V AC | 1A – 600A | 200kA | Περιορισμένη | Γενική βιομηχανική χρήση, αντικατάσταση για Class H | UL 248-12, CSA C22.2 No. 248.12 |

| Class R (Generic) | 250V/600V AC | 1A – 600A | 200kA | ✓ Ναι (RK1) | Τυπική βιομηχανική προστασία | UL 248-12, CSA C22.2 No. 248.12 |

Σημείωση: Οι ασφάλειες κατηγορίας J και κατηγορίας L είναι περιορισμού ρεύματος και δεν μπορούν να ανταλλαγούν με οποιαδήποτε άλλη κατηγορία ασφαλειών λόγω των χαρακτηριστικών απόρριψης διαστάσεων. Οι ασφάλειες κατηγορίας R περιλαμβάνουν χαρακτηριστικά απόρριψης που εμποδίζουν την εγκατάσταση σε βάσεις ασφαλειών κατηγορίας H.

Διαθέσιμο Ρεύμα Βραχυκυκλώματος ανά Τύπο Εγκατάστασης

| Τύπος εγκατάστασης | Τυπικό Μέγεθος Παροχής | Τυπικός Μετασχηματιστής | Εκτιμώμενο Διαθέσιμο Ρεύμα Βραχυκυκλώματος | Συνιστώμενη Ελάχιστη Ικανότητα Διακοπής |

|---|---|---|---|---|

| Μικρές Εμπορικές Εγκαταστάσεις (λιανική, γραφεία) | 200A-400A, 208V/120V | 75-150 kVA | 10kA – 25kA | 65kA (επαρκές περιθώριο) |

| Μεσαίες Εμπορικές Εγκαταστάσεις (αποθήκη, μικρή μεταποίηση) | 400A-800A, 480V/277V | 300-750 kVA | 25kA – 50kA | 100kA – 200kA |

| Μεγάλες Βιομηχανικές Εγκαταστάσεις (μεταποίηση, επεξεργασία) | 1200A-3000A, 480V/277V | 1000-3000 kVA | 10kA – 200kA | 200kA – 300kA |

| Βαριές Βιομηχανικές Εγκαταστάσεις (χάλυβας, χημικά, κέντρο δεδομένων) | 3000A+, 480V ή μέση τάση | 3000+ kVA | 85kA – 150kA+ | 300kA (απαραίτητο) |

Οι τιμές του ρεύματος βραχυκυκλώματος είναι προσεγγίσεις στην είσοδο παροχής. Οι πραγματικές τιμές εξαρτώνται από την σύνθετη αντίσταση του μετασχηματιστή, το μήκος του αγωγού και την ισχύ της πηγής του δικτύου. Συνιστάται επαγγελματική μελέτη βραχυκυκλώματος για κρίσιμες εφαρμογές.

Πρακτικές Οδηγίες Επιλογής για Μηχανικούς Εγκαταστάσεων

Η επιλογή της κατάλληλης προστασίας ικανότητας διακοπής απαιτεί κατανόηση τόσο του τρέχοντος ηλεκτρικού σας συστήματος όσο και των πιθανών μελλοντικών αλλαγών. Οι ακόλουθες οδηγίες καλύπτουν κοινά σενάρια που αντιμετωπίζουν οι μηχανικοί εγκαταστάσεων και οι επαγγελματίες προμηθειών.

Υπολογισμός Διαθέσιμου Ρεύματος Βραχυκυκλώματος (Απλοποιημένη Μέθοδος)

Για προκαταρκτική ανάλυση, εκτιμήστε το τριφασικό ρεύμα βραχυκυκλώματος στο δευτερεύον του μετασχηματιστή χρησιμοποιώντας: ISC = (kVA × 1000) ÷ (√3 × Τάση × %Z). Για διαδρομές αγωγών από τον μετασχηματιστή, προσαρμόστε για σύνθετη αντίσταση: ISC adjusted = ISC transformer × (Z transformer ÷ (Z transformer + Z conductor)).

Επαγγελματικές μελέτες βραχυκυκλώματος θα πρέπει να εκτελούνται από εξειδικευμένους μηχανικούς σύμφωνα με το IEEE 551-2006 για συστήματα σε εμπορικά κτίρια ή το IEEE 242 για βιομηχανικά και εμπορικά συστήματα ισχύος. Αυτές οι μελέτες λαμβάνουν υπόψη τη συνεισφορά του κινητήρα (συνήθως 4-6 φορές το ρεύμα πλήρους φορτίου του κινητήρα), ασύμμετρους παράγοντες που βασίζονται σε λόγους X/R και όλες τις σύνθετες αντιστάσεις σε όλο το σύστημα διανομής.

Απαιτήσεις NEC: Άρθρα 110.9 και 110.24

NEC 110.9 (Ικανότητα Διακοπής) επιβάλλει ότι ο εξοπλισμός που προορίζεται να διακόψει το ρεύμα σε επίπεδα βραχυκυκλώματος “πρέπει να έχει ικανότητα διακοπής στην ονομαστική τάση κυκλώματος επαρκή για το ρεύμα που είναι διαθέσιμο στους ακροδέκτες γραμμής του εξοπλισμού”. Αυτή η απαίτηση ισχύει για όλες τις διατάξεις προστασίας από υπερένταση - ασφάλειες, διακόπτες κυκλώματος και συνδυασμούς αυτών.

NEC 110.24 (Διαθέσιμο Ρεύμα Βραχυκυκλώματος) απαιτεί ο εξοπλισμός παροχής, εκτός από κατοικίες ενός και δύο οικογενειών, να φέρει ευανάγνωστη σήμανση στο πεδίο με το μέγιστο διαθέσιμο ρεύμα βραχυκυκλώματος. Η σήμανση πρέπει να περιλαμβάνει την ημερομηνία εκτέλεσης του υπολογισμού. Αυτό επιτρέπει σε μελλοντικούς επιθεωρητές, ηλεκτρολόγους και μηχανικούς να επαληθεύσουν ότι οι εγκατεστημένες συσκευές προστασίας έχουν επαρκείς ικανότητες διακοπής.

Οι πίνακες βιομηχανικού ελέγχου (NEC 409.22), τα κέντρα ελέγχου κινητήρων (NEC 430.99), οι πίνακες διανομής και οι πίνακες (NEC 408.6) και ο εξοπλισμός κλιματισμού (NEC 440.10) έχουν όλες συγκεκριμένες απαιτήσεις για την τεκμηρίωση του ρεύματος βραχυκυκλώματος και τις ονομαστικές τιμές ρεύματος βραχυκυκλώματος.

Πότε να Καθορίσετε 200kA έναντι 300kA

Καθορίστε ικανότητα διακοπής 200kA όταν:

- Το διαθέσιμο ρεύμα βραχυκυκλώματος είναι αξιόπιστα κάτω από 125kA (παρέχοντας περιθώριο ασφαλείας 60%)

- Η υποδομή του δικτύου ηλεκτρισμού είναι σταθερή χωρίς προγραμματισμένες αναβαθμίσεις

- Το ηλεκτρικό σύστημα της εγκατάστασης είναι ώριμο χωρίς σχέδια επέκτασης

- Η βελτιστοποίηση του κόστους είναι κρίσιμη και τα 200kA παρέχουν επαρκές περιθώριο

Καθορίστε ικανότητα διακοπής 300kA όταν:

- Το διαθέσιμο ρεύμα βραχυκυκλώματος υπερβαίνει τα 125kA ή πλησιάζει τα 200kA

- Η παροχή τροφοδοτείται από πηγή χαμηλής σύνθετης αντίστασης (μεγάλος μετασχηματιστής, σύντομες διαδρομές αγωγών)

- Ο πάροχος ηλεκτρικής ενέργειας έχει ανακοινώσει ή εφαρμόσει τον εκσυγχρονισμό του δικτύου στην περιοχή σας

- Η εγκατάσταση βρίσκεται σε αναπτυσσόμενο βιομηχανικό πάρκο με αυξανόμενη πυκνότητα ισχύος

- Προβλέπονται μελλοντικές επεκτάσεις ή αναβαθμίσεις υπηρεσιών εντός 10-20 ετών

- Επιθυμείται μέγιστο περιθώριο ασφαλείας για κρίσιμες ή υψηλού κινδύνου εγκαταστάσεις

Προειδοποιητικά Σημάδια Προμηθειών: Εντοπισμός Ανεπαρκούς Προστασίας

Προειδοποιητικά σημάδια ανεπαρκών προδιαγραφών ικανότητας διακοπής:

- Απροσδιόριστη Ικανότητα Διακοπής: Ο προμηθευτής αναφέρει “ασφάλεια, 100A, 600V” χωρίς να καθορίζει την ικανότητα διακοπής ή την κατηγορία ασφάλειας

- Ασυνήθιστα Χαμηλή Τιμολόγηση: Οι γενικές ασφάλειες που προσφέρονται σε 30%-40% κάτω από την τιμολόγηση επώνυμων Class J/L/R ενδέχεται να έχουν ονομαστικές τιμές 10kA-50kA

- Αόριστη Συμμόρφωση με τα Πρότυπα: Ισχυρισμοί για “βιομηχανική ποιότητα” χωρίς αναφορά στα πρότυπα της σειράς UL 248

- Αντικατάσταση Class H: Προσφορά ασφαλειών Class H (τυπική ικανότητα διακοπής 10kA) για βιομηχανικές εφαρμογές

- Έλλειψη Πιστοποίησης Περιορισμού Ρεύματος: Οι ασφάλειες που δεν φέρουν την ένδειξη “Περιορισμός Ρεύματος” σύμφωνα με τα πρότυπα UL δεν διαθέτουν κρίσιμο έλεγχο ενέργειας let-through

Βέλτιστες πρακτικές για προδιαγραφές προμηθειών:

- Να καθορίζετε πάντα: Τάξη ασφάλειας (J, L, RK1, κ.λπ.), Ονομαστική τιμή αμπέρ, Ονομαστική τιμή τάσης και Ικανότητα διακοπής

- Παράδειγμα: “Ασφάλεια τάξης RK1, 100A, 600V AC, ικανότητα διακοπής 300kA, UL 248-12, χρονικής καθυστέρησης”

- Απαιτήστε τεκμηρίωση πιστοποίησης από τρίτους (αριθμοί αρχείων UL)

- Επαληθεύστε ότι οι διαστατικές προδιαγραφές ταιριάζουν με τις υπάρχουσες βάσεις ασφαλειών (αποτρέψτε τυχαίες υποβαθμίσεις)

- Συμπεριλάβετε τη φράση “ή εγκεκριμένο ισοδύναμο” με ρητές απαιτήσεις απόδοσης

Λύσεις ασφαλειών υψηλής ικανότητας διακοπής VIOX

Η VIOX Electric κατασκευάζει ολοκληρωμένες σειρές ασφαλειών υψηλής ικανότητας διακοπής για βιομηχανικές, εμπορικές και κρίσιμες εφαρμογές υποδομής:

Ασφάλειες περιορισμού ρεύματος VIOX Class J

- Ονομαστική τάση 600V AC, 1A έως 600A

- Επιλογές ικανότητας διακοπής 200kA ή 300kA

- Χαρακτηριστικά χρονικής καθυστέρησης για ανοχή εισροής κινητήρα και μετασχηματιστή

- Συμπαγείς διαστάσεις 13/16″ × 1-3/4″ έως 3″ × 9-1/16″ ανάλογα με την ένταση του ρεύματος

- Εφαρμογές: Κέντρα ελέγχου κινητήρων, βιομηχανικοί πίνακες διανομής, δευτερεύοντα μετασχηματιστών

Ασφάλειες υψηλής αμπερομετρίας VIOX Class L

- Ονομαστική τάση 600V AC, 601A έως 6000A

- Ικανότητα διακοπής 200kA ή 300kA

- Περιορισμός ρεύματος με εξαιρετικά χαρακτηριστικά διέλευσης I²t

- Εφαρμογές: Προστασία εισόδου παροχής, κύρια διανομή, μεγάλα κυκλώματα τροφοδοσίας

Ασφάλειες διπλού στοιχείου VIOX Class RK1

- Ονομαστική τάση 250V/600V AC, 1A έως 600A

- Ικανότητα διακοπής 300kA

- Ανώτερη απόδοση χρονικής καθυστέρησης (διατηρεί 500% ονομαστικού ρεύματος ελάχιστο 10 δευτερόλεπτα)

- Εφαρμογές: Κυκλώματα διακλάδωσης κινητήρα, συνδυασμένοι ελεγκτές κινητήρα, προστασία υψηλής απόδοσης όπου απαιτείται επιλεκτικός συντονισμός με συσκευές ανάντη

Όλες οι ασφάλειες VIOX συμμορφώνονται με τα πρότυπα της σειράς UL 248 και φέρουν πιστοποίηση CSA για τις αγορές της Βόρειας Αμερικής. Τα προϊόντα ελέγχονται για πλήρη ονομαστική ικανότητα διακοπής και πιστοποιούνται για διαστατική εναλλαξιμότητα με υπάρχοντα συστήματα ασφαλειών με ταξινόμηση UL.

Συχνές Ερωτήσεις

Τι είναι η ικανότητα διακοπής και γιατί είναι σημαντική;

Η ικανότητα διακοπής (ονομάζεται επίσης ονομαστική ικανότητα διακοπής ή ικανότητα θραύσης) είναι το μέγιστο ρεύμα σφάλματος που μια ασφάλεια μπορεί να διακόψει με ασφάλεια χωρίς ρήξη, πυρκαγιά ή επικίνδυνη διάδοση τόξου. Έχει σημασία επειδή εάν το ρεύμα σφάλματος υπερβαίνει την ικανότητα διακοπής, η ασφάλεια μπορεί να εκραγεί αντί να ανοίξει με ασφάλεια το κύκλωμα, δημιουργώντας κινδύνους πυρκαγιάς και ζημιές στον εξοπλισμό. Η ικανότητα διακοπής πρέπει να υπερβαίνει το διαθέσιμο ρεύμα σφάλματος στο σημείο εγκατάστασης με επαρκές περιθώριο ασφαλείας.

Πώς μπορώ να γνωρίζω την ικανότητα διακοπής που χρειάζομαι για την εγκατάστασή μου;

Προσδιορίστε το διαθέσιμο ρεύμα σφάλματος στην είσοδο παροχής σας μέσω επαγγελματικής ανάλυσης βραχυκυκλώματος σύμφωνα με τα πρότυπα IEEE 551-2006. Ως απλοποιημένη εκτίμηση, υπολογίστε το ρεύμα σφάλματος δευτερεύοντος μετασχηματιστή χρησιμοποιώντας: ISC = (kVA × 1000) ÷ (√3 × Τάση × %Z). Επιλέξτε ασφάλειες με ικανότητα διακοπής τουλάχιστον 25% υψηλότερη από το υπολογισμένο ρεύμα σφάλματος. Για βιομηχανικές εγκαταστάσεις με διαθέσιμο ρεύμα σφάλματος 50kA+, καθορίστε 200kA ελάχιστο. για 125kA+ ή περιοχές υψηλής ανάπτυξης, καθορίστε 300kA.

Ποια είναι η διαφορά μεταξύ της ικανότητας διακοπής και της ονομαστικής τιμής ρεύματος βραχυκυκλώματος (SCCR);

Ικανότητα διακοπής (IR) ισχύει για μεμονωμένες συσκευές προστασίας από υπερένταση (ασφάλειες, διακόπτες κυκλώματος) και ορίζει το μέγιστο ρεύμα που μπορούν να διακόψουν με ασφάλεια. Ονομαστική τιμή ρεύματος βραχυκυκλώματος (SCCR) ισχύει για πλήρη συγκροτήματα (κέντρα ελέγχου κινητήρων, βιομηχανικοί πίνακες ελέγχου, πίνακες διανομής) και ορίζει το μέγιστο ρεύμα σφάλματος που μπορεί να αντέξει ολόκληρο το συγκρότημα όταν προστατεύεται από καθορισμένες συσκευές υπερέντασης. Το SCCR του εξοπλισμού πρέπει να πληροί ή να υπερβαίνει το διαθέσιμο ρεύμα σφάλματος σύμφωνα με το NEC 110.9.

Μπορώ να χρησιμοποιήσω μια ασφάλεια 200kA εάν το ρεύμα σφάλματος είναι μόνο 50kA;

Ναι—αυτό είναι στην πραγματικότητα μια συνιστώμενη πρακτική. Η χρήση μιας ασφάλειας με υψηλότερη ονομαστική τιμή από τις ελάχιστες απαιτήσεις παρέχει περιθώριο ασφαλείας για μελλοντικές αλλαγές στις εγκαταστάσεις, τροποποιήσεις του συστήματος ή αβεβαιότητες υπολογισμού. Η ασφάλεια 200kA θα λειτουργήσει πανομοιότυπα με μια ασφάλεια 100kA υπό κανονικές συνθήκες και ρεύματα σφάλματος έως 100kA. Η υψηλότερη ονομαστική τιμή απλώς διασφαλίζει την ασφαλή λειτουργία εάν τα ρεύματα σφάλματος αυξηθούν. Δεν υπάρχει επίπτωση από την υπερβολική προδιαγραφή της ικανότητας διακοπής (σε αντίθεση με την υπερβολική αύξηση της ονομαστικής τιμής αμπέρ, η οποία καθυστερεί την προστασία από υπερένταση).

Γιατί οι ασφάλειες 300kA δεν είναι σημαντικά ακριβότερες από τις ασφάλειες 200kA;

Η αναβάθμιση της ικανότητας διακοπής ασφαλειών από 200kA σε 300kA συνήθως απαιτεί ελάχιστες αλλαγές σχεδιασμού — κυρίως βελτιωμένα υλικά απόσβεσης τόξου και ενισχυμένα κεραμικά σώματα. Αυτές οι τροποποιήσεις προσθέτουν 1%-2% στο κόστος κατασκευής, μεταφράζοντας σε μέτριες αυξήσεις τιμών (50-150 $ ανάλογα με την ονομαστική τιμή αμπέρ). Αντίθετα, η αναβάθμιση των διακοπτών κυκλώματος από 100kA σε 200kA απαιτεί ουσιαστική μηχανική ενίσχυση, μεγαλύτερους αγωγούς τόξου και εξαρτήματα βαρέως τύπου, συχνά διπλασιάζοντας ή τριπλασιάζοντας την τιμή. Αυτή η διαφορά κόστους καθιστά τις ασφάλειες υψηλής ικανότητας διακοπής εξαιρετικά οικονομικές για προστασία από υψηλό ρεύμα σφάλματος.

Τι συμβαίνει εάν εγκαταστήσω μια ασφάλεια με ανεπαρκή ικανότητα διακοπής;

Κατά τη διάρκεια ενός σφάλματος που υπερβαίνει την ικανότητα διακοπής της ασφάλειας, η ενέργεια τόξου που παράγεται υπερβαίνει την ικανότητα συγκράτησης της ασφάλειας. Το κεραμικό σώμα ρήγνυται υπό εσωτερική πίεση, εκτοξεύοντας εξατμισμένο μέταλλο, υπερθερμασμένα αέρια και κεραμικά θραύσματα. Αυτό δημιουργεί δευτερεύοντα βραχυκυκλώματα σε παρακείμενες φάσεις ή γείωση, προκαλεί πυρκαγιές στον πίνακα, καταστρέφει τον περιβάλλοντα εξοπλισμό και ενέχει σοβαρό κίνδυνο τραυματισμού για το κοντινό προσωπικό. Η έρευνα μετά την αστοχία συχνά αποκαλύπτει εκτεταμένες παράπλευρες ζημιές που κοστίζουν 10x-100x περισσότερο από τη διαφορά κόστους μεταξύ επαρκών και ανεπαρκών ασφαλειών.

Πόσο συχνά πρέπει να επαναξιολογείται η ικανότητα διακοπής;

Εκτελέστε ανάλυση ρεύματος σφάλματος όταν: (1) Ο πάροχος ηλεκτρικής ενέργειας σας ειδοποιήσει για αναβαθμίσεις μετασχηματιστών ή αλλαγές στην παροχή, (2) Η εγκατάσταση προσθέσει σημαντικά φορτία που απαιτούν αναβάθμιση της παροχής, (3) Εγκαθίσταται νέος εξοπλισμός που αλλάζει τη συμβολή του ρεύματος σφάλματος (μεγάλοι κινητήρες, γεννήτριες, συστήματα UPS), (4) Σημαντικές ανακαινίσεις τροποποιούν την αρχιτεκτονική διανομής, ή (5) Τουλάχιστον κάθε 5-7 χρόνια ως μέρος του προγράμματος προληπτικής συντήρησης. Το NEC 110.24 απαιτεί σήμανση πεδίου με την ημερομηνία υπολογισμού του ρεύματος σφάλματος, επιτρέποντας την παρακολούθηση του πότε απαιτείται επανεκτίμηση.

Είναι οι ασφάλειες με υψηλότερη ικανότητα διακοπής πιο ευαίσθητες ή επιρρεπείς σε ενοχλητικές διακοπές;

Όχι. Η ικανότητα διακοπής επηρεάζει μόνο την ικανότητα της ασφάλειας να διακόπτει με ασφάλεια υψηλά ρεύματα σφάλματος — δεν επηρεάζει τα κανονικά λειτουργικά χαρακτηριστικά, τις καμπύλες χρόνου-ρεύματος ή την ευαισθησία σε υπερφορτώσεις. Μια ασφάλεια χρονικής καθυστέρησης 300kA Class RK1 100A θα έχει πανομοιότυπα λειτουργικά χαρακτηριστικά με μια ασφάλεια χρονικής καθυστέρησης 200kA Class RK1 100A υπό όλες τις κανονικές συνθήκες και συνθήκες υπερφόρτωσης. Η διαφορά γίνεται σχετική μόνο κατά τη διάρκεια συμβάντων βραχυκυκλώματος που πλησιάζουν ή υπερβαίνουν τα 200kA, όπου η ασφάλεια 300kA διατηρεί ασφαλή λειτουργία ενώ η ασφάλεια 200kA πλησιάζει τα όρια σχεδιασμού της.

Τεχνικά πρότυπα και αναφορές συμμόρφωσης

Η κατανόηση των ισχυόντων προτύπων διασφαλίζει τη σωστή επιλογή, εγκατάσταση και συμμόρφωση των ασφαλειών με τις κανονιστικές απαιτήσεις:

Σειρά UL 248: Ασφάλειες χαμηλής τάσης

- UL 248-8 (Ασφάλειες Class J): Καλύπτει ασφάλειες περιορισμού ρεύματος με ονομαστική τιμή 600A ή λιγότερο και 600V AC, με τυπική ικανότητα διακοπής 200kA και προαιρετική ονομαστική τιμή 300kA. Ορίζει διαστατικά πρότυπα που εμποδίζουν την εναλλαξιμότητα με άλλες τάξεις, απαιτήσεις δοκιμής χρονικής καθυστέρησης (ελάχιστο 10 δευτερόλεπτα στο 500% του ονομαστικού ρεύματος) και όρια ενέργειας διέλευσης.

- UL 248-10 (Ασφάλειες Class L): Ισχύει για ασφάλειες περιορισμού ρεύματος με ονομαστική τιμή 601A έως 6000A και 600V AC. Καθορίζει τυπική ικανότητα διακοπής 200kA με διαθέσιμες επιλογές 300kA. Καλύπτει προστασία μεγάλου αμπεράζ για εισόδους παροχής και κύριους τροφοδότες με διαστατικά πρότυπα για μεγέθη πλαισίου 800A έως 6000A.

- UL 248-12 (Ασφάλειες Class R): Ορίζει απαιτήσεις για ασφάλειες Class R (συμπεριλαμβανομένων των RK1 και RK5) με ονομαστική τιμή 600A ή λιγότερο στα 250V ή 600V AC. Οι ασφάλειες Class RK1 έχουν ανώτερα χαρακτηριστικά περιορισμού ρεύματος και ικανότητες διακοπής 200kA ή 300kA. Περιλαμβάνει χαρακτηριστικά απόρριψης που εμποδίζουν την εγκατάσταση σε βάσεις Class H.

Εθνικός Ηλεκτρολογικός Κώδικας (NFPA 70)

- NEC 110.9 (Ικανότητα διακοπής): Επιβάλλει ότι ο εξοπλισμός που προορίζεται να διακόψει ρεύμα σε επίπεδα σφάλματος πρέπει να έχει ικανότητα διακοπής επαρκή για την τάση και το διαθέσιμο ρεύμα. Θεμελιώδης απαίτηση που διασφαλίζει ότι όλες οι συσκευές υπερέντασης μπορούν να χειριστούν με ασφάλεια τα προοπτικά ρεύματα σφάλματος.

- NEC 110.24 (Διαθέσιμο ρεύμα σφάλματος): Απαιτεί σήμανση του εξοπλισμού παροχής με το μέγιστο διαθέσιμο ρεύμα σφάλματος και την ημερομηνία υπολογισμού για μονάδες άλλες από κατοικίες. Επιτρέπει την επαλήθευση των επαρκών ονομαστικών τιμών της συσκευής προστασίας.

- NEC 240.86 (Ονομαστικές τιμές σειράς): Επιτρέπει συνδυασμούς ασφαλειών και διακοπτών κυκλώματος με ονομαστική τιμή σειράς όπου δοκιμάζονται και επισημαίνονται στον εξοπλισμό, παρέχοντας οικονομική εναλλακτική λύση σε συστήματα πλήρους ονομαστικής τιμής όπου δεν απαιτείται επιλεκτικός συντονισμός.

Πρότυπα IEEE

- IEEE 551-2006 (Υπολογισμός ρευμάτων βραχυκυκλώματος): Παρέχει συνιστώμενη πρακτική για τον υπολογισμό των ρευμάτων βραχυκυκλώματος σε βιομηχανικά και εμπορικά συστήματα ισχύος, συμπεριλαμβανομένης της συνεισφοράς του μετασχηματιστή, της συνεισφοράς του κινητήρα, της σύνθετης αντίστασης του αγωγού και των ασύμμετρων παραμέτρων. Βασική αναφορά για επαγγελματική ανάλυση ρεύματος σφάλματος.

Πρότυπα CSA (Καναδικά ισοδύναμα)

- CSA C22.2 No. 248.8 (Class J), CSA C22.2 No. 248.10 (Class L), CSA C22.2 No. 248.12 (Class R): Εναρμονισμένα τριμερή εθνικά πρότυπα (ΗΠΑ/Καναδάς/Μεξικό) που διασφαλίζουν την εναλλαξιμότητα των προϊόντων και τις συνεπείς απαιτήσεις απόδοσης στις αγορές της Βόρειας Αμερικής.

Συμπέρασμα: Μηχανική ανταπόκριση στην πραγματικότητα του δικτύου

Η αθόρυβη μετάβαση της ηλεκτρικής βιομηχανίας από ικανότητες διακοπής 200kA σε 300kA δεν είναι μια άσκηση μάρκετινγκ — είναι μια μηχανική ανταπόκριση σε μετρήσιμες αλλαγές στην υποδομή διανομής ισχύος. Τα διαθέσιμα ρεύματα σφάλματος στις βιομηχανικές εισόδους παροχής αυξάνονται λόγω του εκσυγχρονισμού του δικτύου κοινής ωφέλειας, των αντικαταστάσεων μετασχηματιστών με μονάδες χαμηλότερης σύνθετης αντίστασης και της αυξημένης πυκνότητας ισχύος σε βιομηχανικές εγκαταστάσεις.

Για τους μηχανικούς εγκαταστάσεων, τους διαχειριστές προμηθειών και τους ηλεκτρολόγους εργολάβους, οι επιπτώσεις είναι σαφείς: οι προδιαγραφές ικανότητας διακοπής που ήταν επαρκείς πριν από 15-20 χρόνια μπορεί να είναι οριακές ή ανεπαρκείς σήμερα. Η διαφορά κόστους μεταξύ των ασφαλειών 200kA και 300kA — συνήθως 1%-2% — αντιπροσωπεύει ασήμαντη ασφάλιση έναντι καταστροφικής αστοχίας του συστήματος προστασίας.

Οι ασφάλειες υψηλής ικανότητας διακοπής παρέχουν την πιο οικονομική λύση για προστασία από υψηλό ρεύμα σφάλματος, συνδυάζοντας ανώτερη απόδοση διακοπής με χαρακτηριστικά περιορισμού ρεύματος που προστατεύουν τον κατάντη εξοπλισμό. Η στρατηγική ονομαστικής τιμής σειράς, χρησιμοποιώντας μια ασφάλεια υψηλής ικανότητας διακοπής ως “τερματοφύλακα” για την προστασία διακοπτών κυκλώματος κατάντη χαμηλότερης ονομαστικής τιμής, μπορεί να μειώσει το κόστος του συστήματος προστασίας κατά 70% διατηρώντας ή βελτιώνοντας την απόδοση ασφάλειας σε σύγκριση με συστήματα διακοπτών κυκλώματος πλήρους ονομαστικής τιμής.

Η αόρατη ασπίδα που προστατεύει την εγκατάστασή σας από καταστροφές βραχυκυκλώματος δεν είναι το μεγαλύτερο εξάρτημα ή το πιο ακριβό — είναι η ασφάλεια με την κατάλληλη ονομαστική τιμή που δεν θα γίνει ποτέ αντιληπτή κατά τη διάρκεια της κανονικής λειτουργίας, αλλά θα αποδώσει άψογα κατά τη διάρκεια του καταστροφικού σφάλματος που θα μπορούσε να καταστρέψει τον εξοπλισμό και να θέσει σε κίνδυνο το προσωπικό.

Είστε έτοιμοι να επαληθεύσετε ότι η προστασία της εγκατάστασής σας είναι επαρκής; Η τεχνική ομάδα της VIOX Electric παρέχει δωρεάν ανάλυση ρεύματος σφάλματος και αξιολογήσεις συστήματος προστασίας για βιομηχανικές και εμπορικές εγκαταστάσεις. Οι μηχανικοί εφαρμογών μας μπορούν να αξιολογήσουν το υπάρχον σύστημά σας, να προτείνουν κατάλληλες αναβαθμίσεις ικανότητας διακοπής και να καθορίσουν ολοκληρωμένες λύσεις προστασίας που πληρούν τις απαιτήσεις NEC και τις βέλτιστες πρακτικές του κλάδου.

Επικοινωνήστε με την VIOX Electric σήμερα για τεχνική συμβουλή σχετικά με την επιλογή ασφαλειών υψηλής ικανότητας διακοπής, την ανάλυση ρεύματος σφάλματος ή τον πλήρη σχεδιασμό συστήματος προστασίας. Επειδή όταν 200.000 αμπέρ ρεύματος σφάλματος δοκιμάζουν τις άμυνες της εγκατάστασής σας, θέλετε να είστε βέβαιοι ότι η αόρατη ασπίδα σας είναι αρκετά ισχυρή.