Potřebujete napájet pět nových třífázových strojů v dílně, 100 metrů od hlavní rozvodny.

Učeň ve vašem týmu vidí dvě možnosti. Možnost A: Natáhnout jeden “obří” 25mm kabel s ocelovým drátěným pancířem (SWA) do nové “podružné rozvodny” panel na stěně dílny. Možnost B: Natáhnout pět “středně velkých” 10mm kabelů – jeden “přímý běh” pro každý stroj.

Těchto pět menších kabelů vypadá levněji na faktuře. Proč tedy všichni zkušení inženýři trvají na plánu “podružné rozvodny”?

Není to otázka “stylu”. Je to zásadní rozdíl mezi “amatérským” krátkodobým myšlením a “profesionálním” návrhem systému. “Podružná rozvodna” vítězí ve 4 kritických bodech: Náklady, bezpečnost, efektivita a připravenost na budoucnost.

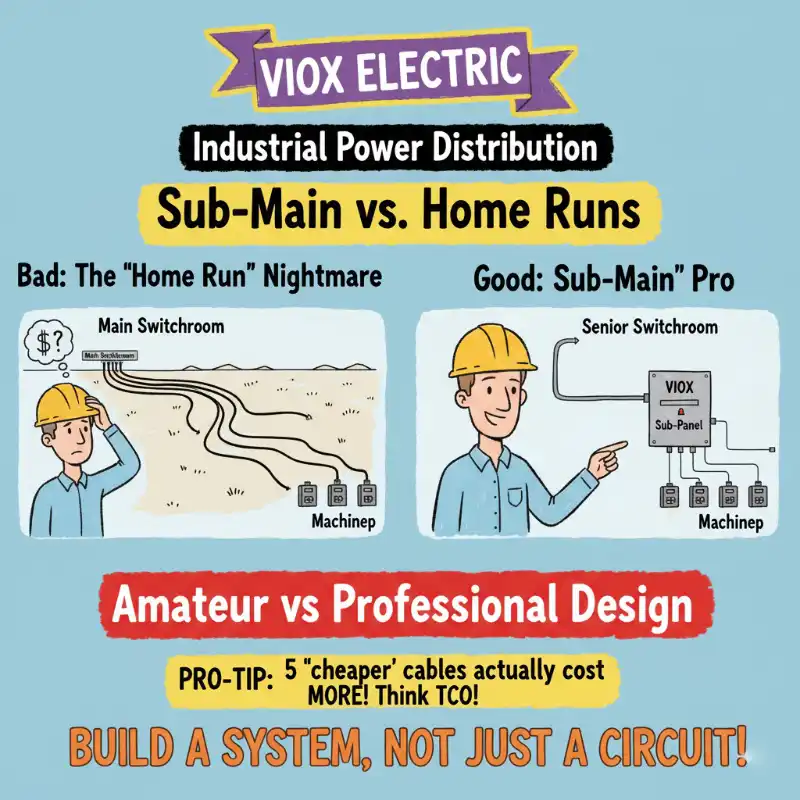

Důvod 1: “Falešná úspora” (Proč 5 “levnějších” kabelů stojí více)

První a nejčastější past je “Falešná úspora”.”

- “Amatérská” matematika (krátkozraká):

(5 x 100 m kabelu 10 mm) < (1 x 100 m kabelu 25 mm) + (1x podružný panel)

Závěr: Pět kabelů je levnějších!

- “Profesionální” matematika (dalekozraká):

Zapomněli jste na jedinou největší položku na jakékoli průmyslové zakázce: Práce.

Tento “levnější” plán vyžaduje:

- 5x kabelové žlaby nebo trubkové rozvody.

- 5x zatažení kabelů.

- 5x sady pro ucpávky a zakončení.

- 5x samostatné testy.

- 5x cenné pozice jističů ve vaší Hlavní (a pravděpodobně přeplněné) rozvodně.

“Podružná rozvodna” (varianta A) vyžaduje ten jediný od všeho. Jeden žlab, jedno zatažení, jedno zakončení, jeden test.

Na stránkách Celkové náklady na vlastnictví (TCO)—materiály plus práce—jsou téměř vždy mnohem nižší pro jeden “obří” kabel. Nenaleťte na “falešnou úsporu”.”

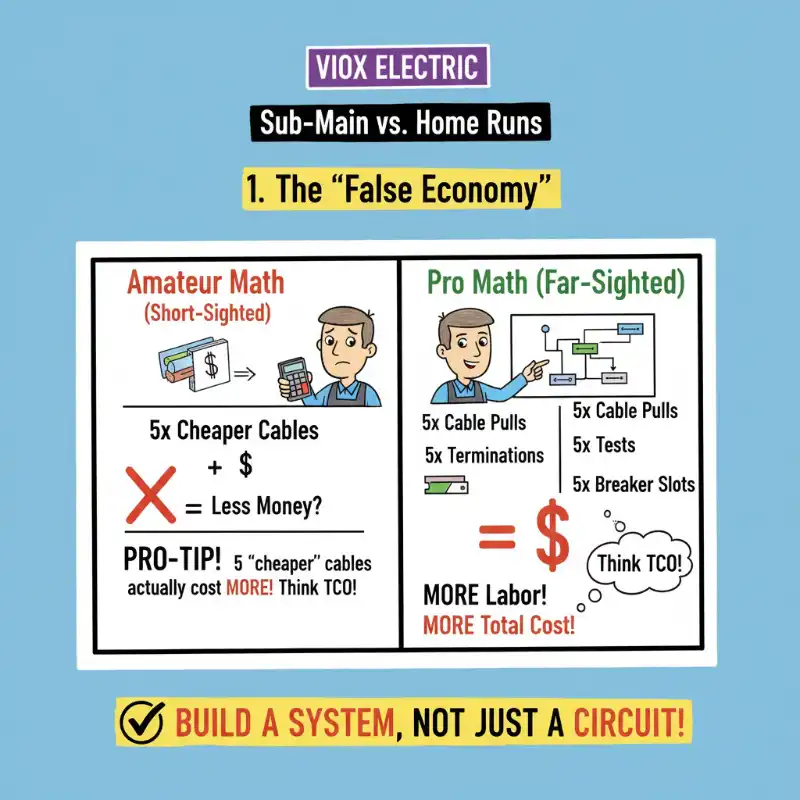

Důvod 2: Bezpečnost a údržba (Vyhnutí se “stometrovému sprintu”)

Toto je nejdůležitější důvod. Je to ten, který odděluje “bezpečný” návrh od “nebezpečného”.

- “Noční můra s přímým během” (varianta B):

CNC frézka hlásí poruchu a zablokuje díl. Operátor stiskne tlačítko nouzového zastavení. Nyní musí váš technik údržby provést uzamčení a označení (LOTO), než se může dotknout stroje.

Kde je jistič?

Je 100 metrů daleko, v hlavní rozvodně, skrytý v masivním panelu s 50 dalšími identickými jističi. Váš technik musí absolvovat “stometrový sprint”,” modlit se, aby byl panel správně označen, a pak se vrátit 100 metrů zpět. Je to pomalé, frustrující a kritický bod selhání LOTO.

- “Podružná rozvodna” pro (varianta A):

Stroj hlásí poruchu. Technik se otočí k podružnému panelu VIOX na stěně dílny, 5 metrů daleko.

Otevře jasně označené dveře, přepne jistič pro “CNC frézku 1” a použije svůj zámek LOTO.

Je “v přímé viditelnosti” svého izolačního bodu. Může vidět panel, zatímco pracuje. To je základní kámen průmyslové bezpečnosti.

PRO-TIP: “Lokální izolace” není “příjemná věc”; je to základní bezpečnostní požadavek. Návrh “přímého běhu” (varianta B) je klasický “amatérský” návrh, který vytváří nezvladatelný a nebezpečný postup LOTO.

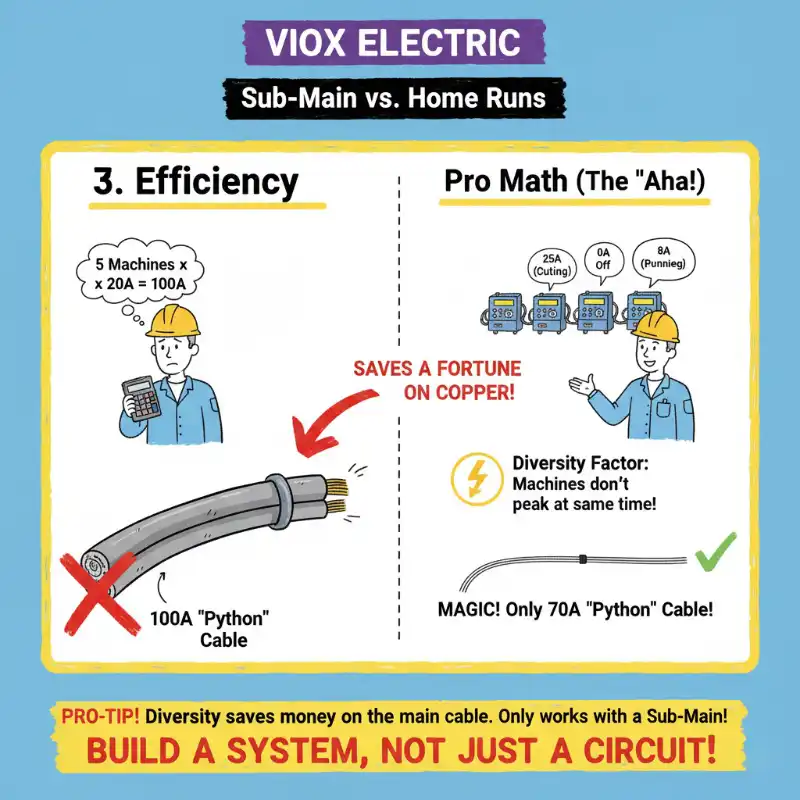

Důvod 3: Efektivita (Ta “magie” koeficientu soudobosti)

Zde je “tajné podání ruky” elektroinženýrů. Tímto způsobem vám plán “podružné rozvodny” ušetří ještě více peněz na jedné “drahé” součásti: obřím kabelu.

- “Amatérská” matematika:

Mám 5 strojů, které dosahují špičky při 20 A. (5 x 20 A = 100 A). Musím potřebovat “obří” kabel dimenzovaný na 100 A!

- “Profesionální” matematika (“Aha!”):

Jaká je pravděpodobnost, že všech 5 strojů dosáhne svého absolutního špičkového zatížení ve stejné milisekundě?

Nula.

Když je stroj A při plném zatížení řezání (20 A), stroj B běží naprázdno (5 A) a stroj C je vypnutý (0 A). Tomu se říká “Diverzita.”

Z tohoto důvodu vám elektrické “předpisy” (jako IEC 60364) umožňují použít “Koeficient diverzity.” Nenavrhujete “python” pro 100 A dosahují špičky součet; navrhujete ho pro pravděpodobné současné zatížení.

“Kouzlo”: Můžete potřebovat pouze kabel “python” o velikosti 80 A nebo dokonce 70 A, abyste bezpečně a v souladu s předpisy napájeli všechny stroje o celkovém odběru 100 A. Toto “kouzlo” pouze funguje s návrhem dílčího rozvaděče a ušetří vám spoustu peněz za měď.

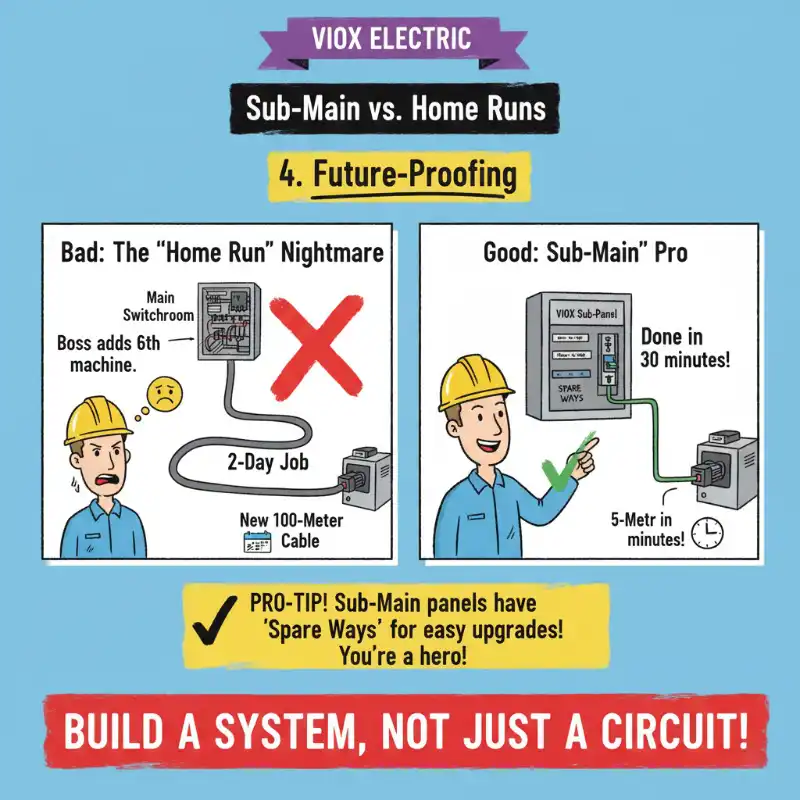

Důvod 4: Budoucí zabezpečení (“30minutová aktualizace”)

Toto je poslední “profi” tah: plánování jedné věci, která se zaručeně stane… změna.

- “Noční můra s přímým během” (varianta B):

O rok později šéf koupí 6. stroj.

Zasténáte. Nyní musíte opakovat celou noční můru: najít další náhradní jistič v hlavním panelu vzdáleném 100 metrů, objednat 100 m kabelu a naplánovat dvoudenní práci na jeho natažení.

- “Podružná rozvodna” pro (varianta A):

Šéf koupí 6. stroj.

Usmíváte se. Otevřete podružnému panelu VIOX (který jste si moudře objednali s několika “Volnými pozicemi” / prázdnými sloty). “Zakliknete” nový VIOX MCB.

Natáhnete 5metrový kabel “malého hada” z místního panelu k novému stroji.

Hotovo máte za 30 minut. Jste hrdina.

Závěr: Není to “styl”, je to “systémové myšlení”

Učňova otázka měla jednoduchou odpověď:

“5 hvězdicových zapojení” (Varianta B) je “Krátkodobé myšlení.” Je to “falešná úspora”, která je dražší na práci, méně bezpečná pro údržbu, méně efektivní s energií a noční můra pro rozšíření.

“Dílčí rozvaděč” (Varianta A) je “Systémové myšlení.” Je to profesionální investice do infrastruktury. Je levnější (TCO), bezpečnější (místní izolace), chytřejší (diverzita) a flexibilní (škálovatelnost).

Nenaleťte na “falešnou úsporu”. Buďte “profík”, který buduje systém, ne jen obvod.

Kompletní řada konfigurovatelných dílčích rozvaděčů, skříní, MCB a MCCB od VIOX jsou nástroje, které potřebujete k vybudování bezpečného, škálovatelného a profesionálního “systému”. Prohlédněte si naše řešení dílčích rozvaděčů ještě dnes.

Technické Přesnost Poznámka

**Odkazované normy a zdroje**.