Při návrhu ovládacích panelů pro průmyslovou automatizaci, systémy HVAC nebo výrobní zařízení může výběr správného provedení časovače významně ovlivnit efektivitu instalace, využití prostoru a dlouhodobé náklady na údržbu. Volba mezi montáží na DIN lištu (17,5 mm) a montáží do panelu (48 mm) představuje více než jen preferenci montáže – je to strategické rozhodnutí, které ovlivňuje celý návrh vašeho elektrického rozvodného systému.

Tato komplexní příručka zkoumá technické specifikace, požadavky na instalaci a aplikačně specifické výhody obou provedení časovačů, aby pomohla elektroinženýrům, výrobcům panelů a systémovým integrátorům činit informovaná rozhodnutí pro jejich projekty.

Pochopení provedení časovačů: Základy

Co je časovač pro montáž na DIN lištu?

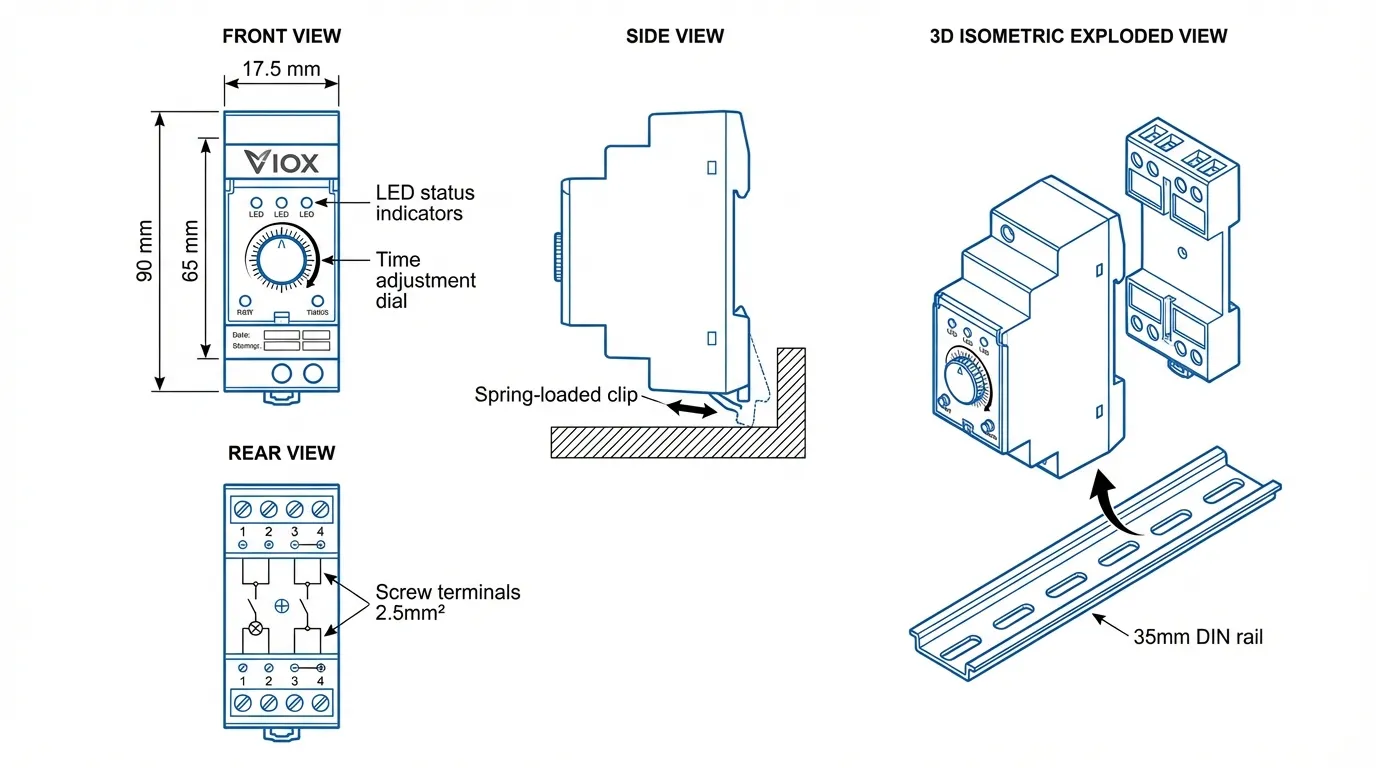

Časovače pro montáž na DIN lištu jsou kompaktní časovací relé navržená pro přímé upevnění na standardní 35mm DIN lišty (také známé jako TH35 lišty). Označení šířky 17,5 mm se vztahuje k šířce modulu, která odpovídá jednomu standardnímu modulárnímu prostoru v rozvaděči. Tyto časovače mají tenký profil, který umožňuje instalaci více jednotek vedle sebe v těsných prostorech.

Moderní časovače na DIN lištu obvykle obsahují LED indikátory stavu, otočné ovladače nebo digitální ovládací prvky pro nastavení času a šroubové svorky pro připojení vodičů. Jsou navrženy pro rychlou instalaci a demontáž bez nutnosti úprav panelu nebo výřezů.

Co je časovač pro montáž do panelu?

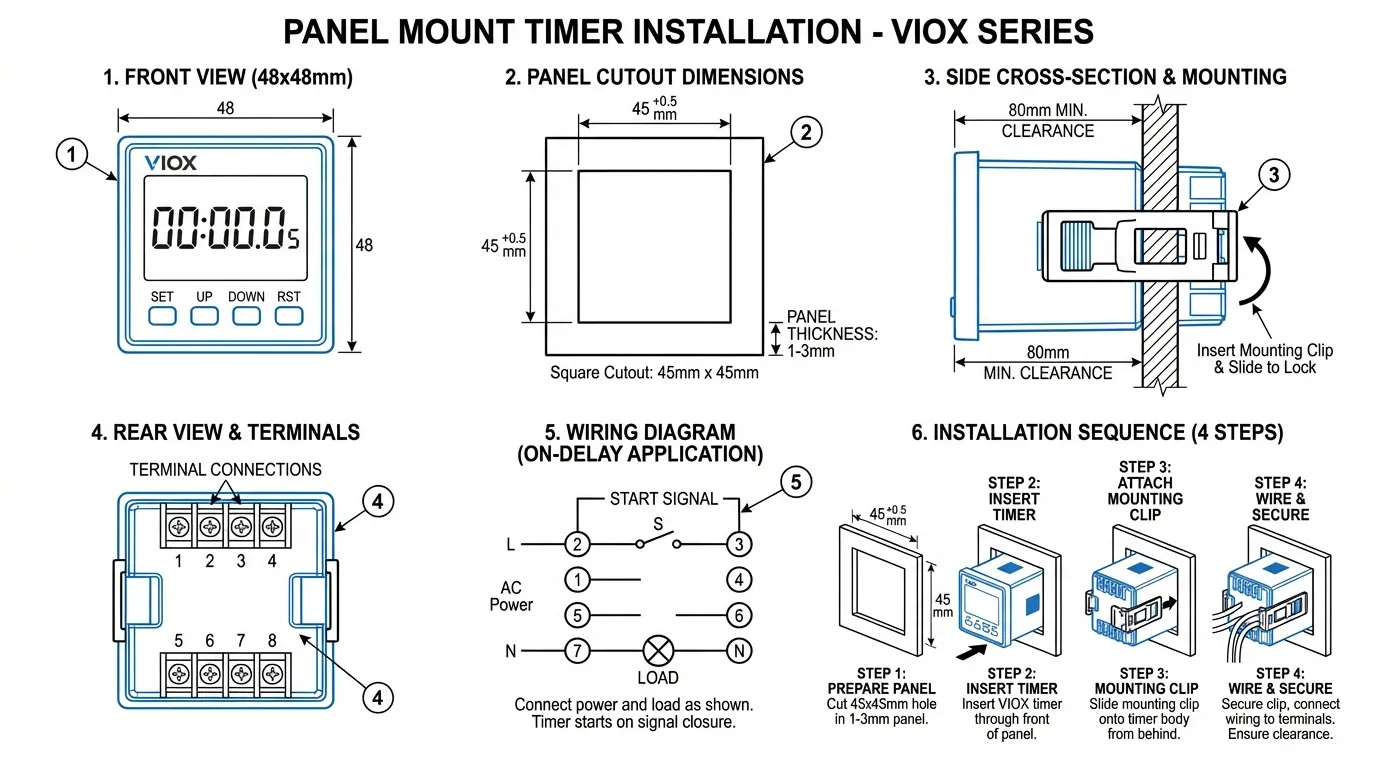

Časovače pro montáž do panelu, běžně dostupné ve formátu 48x48 mm (1/16 DIN), jsou navrženy pro instalaci zepředu do panelu prostřednictvím čtvercového výřezu ve dveřích skříně nebo v čelní straně panelu. Tyto časovače mají větší zobrazovací plochu, komplexnější uživatelská rozhraní a často poskytují pokročilé programovací možnosti ve srovnání s jejich protějšky na DIN lištu.

Časovače pro montáž do panelu obvykle nabízejí LCD nebo LED displeje s více číslicemi, membránové klávesnice nebo otočné enkodéry pro programování a terminálové připojení na zadní straně. Jejich výrazná přítomnost na předním panelu je ideální pro aplikace vyžadující častou interakci operátora nebo vizuální monitorování.

Porovnání technických specifikací

| Specifikace | Montáž na DIN lištu (17,5 mm) | Montáž do panelu (48 mm) |

|---|---|---|

| Fyzické rozměry | 17,5 mm (Š) × 90 mm (V) × 65 mm (H) | 48 mm (Š) × 48 mm (V) × 80-100 mm (H) |

| Způsob montáže | Zacvaknutí na 35mm DIN lištu | Výřez v předním panelu s montážními klipy |

| Požadovaný prostor na panelu | Šířka 17,5 mm na DIN liště | Výřez 45 mm × 45 mm + mezera |

| Typ displeje | Malé LED indikátory nebo 3místný LCD | Velký LCD/LED, 4-6 číslic |

| Časový rozsah | 0,1 s až 999 hodin (typické) | 0,05 s až 9999 hodin (rozšířené) |

| Programovací rozhraní | Otočné ovladače nebo 2tlačítkové ovládání | Klávesnice nebo otočný enkodér |

| Jmenovitý výstup | 5-8A @ 250V AC (typické) | 5-10A @ 250V AC (typické) |

| Napájecí napětí | 24-240V AC/DC (univerzální) | 24-240V AC/DC (univerzální) |

| Počet funkcí | 8-18 časovacích funkcí | 10-30+ časovacích funkcí |

| Stupeň krytí IP | IP20 (standard) | IP65 (přední panel, při instalaci) |

| Doba instalace | 30 sekund (zacvaknutí) | 5-10 minut (výřez + zapojení) |

| Snadnost výměny | Demontáž bez použití nářadí | Vyžaduje přístup k panelu |

| Typické cenové rozpětí | $15-$45 | $35-$85 |

Analýza efektivity prostoru

Montáž na DIN lištu: Maximalizace vertikálního prostoru

Šířka 17,5 mm časovačů na DIN lištu představuje významnou prostorovou výhodu v moderních ovládacích panelech, kde je horizontální prostor na liště prémiový. Jeden standardní 200mm úsek DIN lišty může pojmout až 11 časovačů na DIN lištu (každý 17,5 mm), ve srovnání s pouhými 4 časovači pro montáž do panelu vyžadujícími 48mm výřezy s mezerami.

Příklad výpočtu prostoru:

- Konfigurace DIN lišty: 200 mm lišta ÷ 17,5 mm = 11,4 pozic (11 časovačů)

- Konfigurace montáže do panelu: 200 mm šířka ÷ (48 mm + 10 mm mezera) = 3,4 pozic (3 časovače)

Tato 3,6x prostorová efektivita činí z časovačů na DIN lištu preferovanou volbu pro aplikace s vysokou hustotou, jako jsou systémy automatizace budov, průmyslové řízení procesů a vícezónové instalace HVAC.

Montáž do panelu: Upřednostnění viditelnosti a přístupnosti

Zatímco časovače pro montáž do panelu zabírají více prostoru, jejich větší půdorys přináší výhody v aplikacích orientovaných na obsluhu. Zobrazovací plocha 48 mm × 48 mm poskytuje 2 304 mm² vizuálního prostoru ve srovnání s přibližně 300 mm² u typických displejů časovačů na DIN lištu – 7,7x nárůst zobrazitelné plochy.

Tato vylepšená viditelnost se stává kritickou v aplikacích, kde operátoři potřebují sledovat stav časování z dálky, například ve výrobních linkách, testovacích zařízeních nebo stanicích řízení procesů, kde lze panel sledovat ze vzdálenosti 3-5 metrů.

Požadavky a postupy instalace

Proces instalace na DIN lištu

Potřebné nástroje: Žádné (instalace zacvaknutím bez použití nářadí)

Kroky instalace:

- Zajistěte, aby byla DIN lišta bezpečně připevněna k zadní desce panelu

- Umístěte časovač do požadovaného místa na liště

- Nakloňte časovač dopředu a zahákněte horní klip na lištu

- Zatlačte na spodní část časovače, dokud nezapadne na místo

- Připojte vodiče ke šroubovým svorkám

- Nastavení parametrů časování pomocí předních ovládacích prvků

Doba instalace: 30-60 sekund na jednotku

Výhody:

- Není nutná úprava panelu

- Snadné přemístění během uvádění do provozu

- Zjednodušená výměna bez přístupu k panelu

- Snížení nákladů na práci při instalaci

Proces instalace pro montáž do panelu

Potřebné nástroje: Děrovač panelů nebo stupňovitý vrták, šroubovák, kleště na odizolování drátů

Kroky instalace:

- Označte umístění výřezu 45 mm × 45 mm na panelu

- Vytvořte čtvercový výřez pomocí děrovače panelů nebo vrtáku

- Vložte časovač z přední strany panelu

- Zajistěte pomocí montážních spon nebo držáků ze zadní strany

- Veďte kabeláž k zadním svorkám

- Připojte kabeláž a zajistěte kryty svorek

- Naprogramujte časovač pomocí předního rozhraní

Doba instalace: 5-10 minut na jednotku (kromě přípravy výřezu)

Výhody:

- Profesionální vzhled předního panelu

- Chráněné ovládací prvky (lze utěsnit na IP65)

- Snadnější přístup obsluhy pro programování

- Vhodnější pro venkovní nebo drsná prostředí

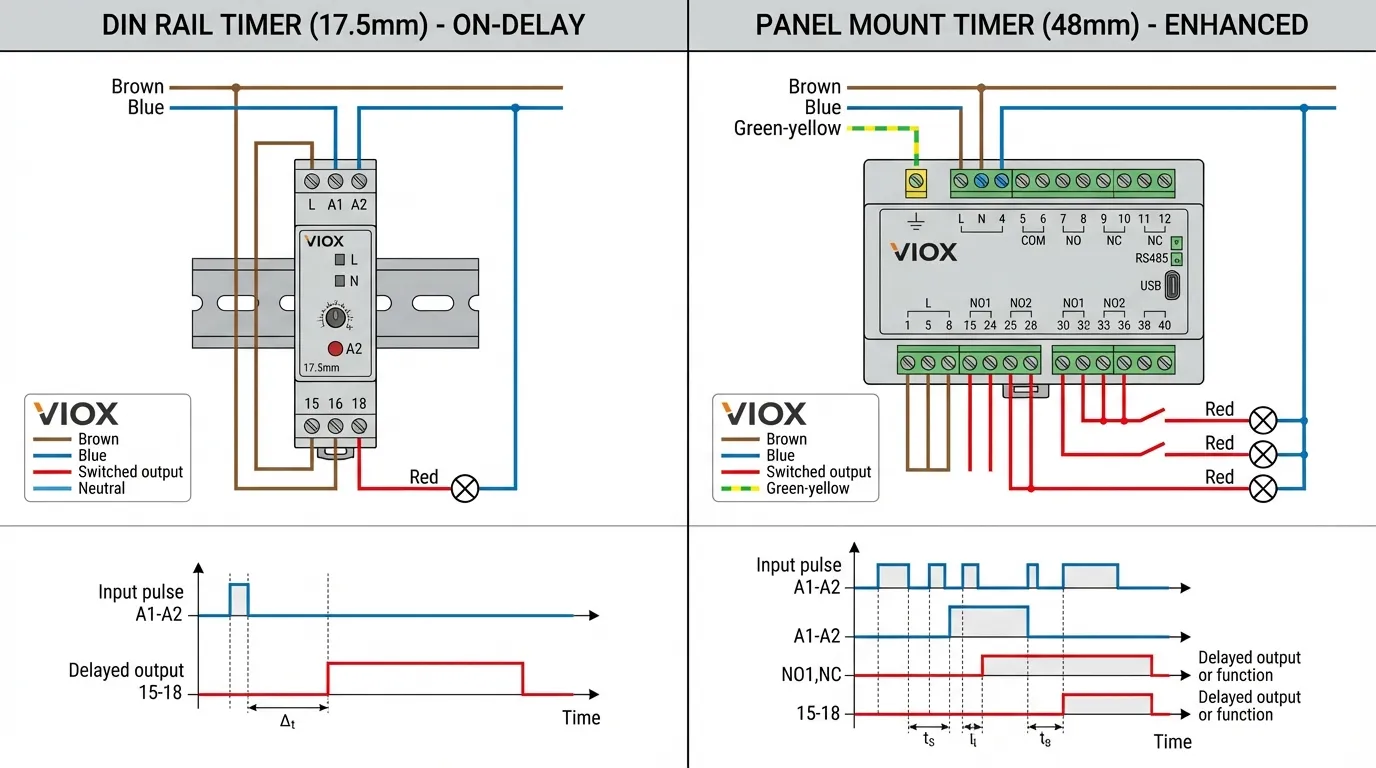

Funkční možnosti a režimy časování

Běžné funkce časování (oba formáty)

Časovače pro DIN lištu i pro montáž do panelu obvykle podporují standardní funkce časování, včetně:

| Funkce | Popis | Typické aplikace |

|---|---|---|

| Zpožděné zapnutí (A) | Výstup se aktivuje po nastaveném zpoždění | Měkký start motoru, sekvenční spouštění |

| Zpožděné vypnutí (B) | Výstup se deaktivuje po nastaveném zpoždění | Doběh chladicího ventilátoru, doběh čerpadla |

| Monostabilní (C) | Časovaný impuls při spuštění | Ovládání ventilů, potvrzení alarmu |

| Interval (D) | Cyklický provoz zapnutí/vypnutí | Přerušované míchání, periodické vzorkování |

| Blikač (E) | Nepřetržité cyklické zapínání/vypínání | Výstražná světla, signály upozornění |

| Kumulativní (H) | Akumuluje dobu běhu | Plánování údržby, sledování využití |

| Hvězda-trojúhelník (Y-Δ) | Sekvence spouštění motoru | Aplikace měkkého startu velkých motorů |

Pokročilé funkce: Kde vyniká montáž do panelu

Časovače pro montáž do panelu často zahrnují další funkce, které ospravedlňují jejich vyšší cenu a prostorové nároky:

Vícekanálový provoz: Některé 48mm panelové časovače poskytují 2-4 nezávislé časovací kanály se samostatnými reléovými výstupy, čímž efektivně nahrazují více časovačů pro DIN lištu ve složitých sekvenčních aplikacích.

Integrace hodin reálného času: Panelové časovače často obsahují funkce RTC pro astronomické časování, týdenní plány a programování svátků – funkce, které se u kompaktních jednotek pro DIN lištu vyskytují jen zřídka.

Možnost analogového vstupu: Pokročilé panelové modely akceptují analogové vstupy 4-20 mA nebo 0-10 V pro variabilní časování na základě procesních parametrů, jako je teplota, tlak nebo průtok.

Záznam dat: Špičkové panelové časovače mohou zaznamenávat události časování, počty cyklů a statistiky doby běhu – cenné pro prediktivní údržbu a optimalizaci procesů.

Doporučení specifická pro danou aplikaci

Kdy zvolit časovače pro montáž na DIN lištu (17,5 mm)

Ideální aplikace:

- Systémy automatizace budov: Ovládání osvětlení, plánování HVAC a řízení přístupu, kde může být v jednom panelu vyžadováno desítky časovačů

- Průmyslové řídicí panely: Automatizace strojů vyžadující více funkcí časování v prostorově omezených skříních

- Projekty modernizace: Přidání funkcí časování do stávajících panelů bez úpravy skříně

- OEM zařízení: Výrobci hledající cenově efektivní řešení časování pro sériově vyráběné zařízení

- Konstrukce nenáročné na údržbu: Aplikace vyžadující častou výměnu nebo rekonfiguraci časovače

Real-World Example: Panel automatizace komerční budovy, který řídí 15 zón osvětlení a HVAC, by vyžadoval 30 funkcí časování. Při použití 17,5mm časovačů pro DIN lištu se všechny jednotky vejdou na dvě 300mm lišty (celková šířka 525 mm). Ekvivalentní řešení pro montáž do panelu by vyžadovalo 1 440 mm šířky panelu – 2,7násobné zvětšení velikosti skříně.

Kdy zvolit časovače pro montáž do panelu (48 mm)

Ideální aplikace:

- Ovládací panely rozhraní operátora: Řídicí stanice, kde operátoři často upravují parametry časování

- Zkušební zařízení: Laboratorní nebo výrobní testovací systémy vyžadující přesnou viditelnost časování

- Řízení procesu: Chemické zpracování, úprava vody nebo výroba potravin, kde je časování kritické pro kvalitu produktu

- Venkovní/drsné prostředí: Aplikace vyžadující ochranu čelního panelu IP65

- Bezpečnostně kritické systémy: Tam, kde musí být stav časování jasně viditelný z důvodů shody nebo bezpečnosti

Real-World Example: Systém chemického dávkování v úpravně vody používá časovač pro montáž do panelu o velikosti 48 mm s velkým LCD displejem zobrazujícím zbývající čas v minutách a sekundách. Operátoři mohou snadno ověřit správnou dobu dávkování ze vzdálenosti 5 metrů a čelní panel s krytím IP65 chrání před vlhkostí ve vlhkém prostředí.

Analýza nákladů: Celkové náklady na vlastnictví

Srovnání počátečních nákupních nákladů

Montáž na DIN lištu (17,5 mm):

- Základní jednoúčelové: $15-$25

- Multifunkční (8-10 režimů): $25-$35

- Pokročilé (18+ funkcí, LCD): $35-$45

Montáž do panelu (48 mm):

- Základní jednoúčelové: $35-$50

- Multifunkční (10-15 režimů): $50-$65

- Pokročilé (vícekanálové, RTC): $65-$85+

Rozdíl v nákladech: Časovače pro montáž do panelu obvykle stojí 1,5-2,5x více než ekvivalentní modely pro DIN lištu.

Úvahy o nákladech na instalaci

Instalace na DIN lištu:

- Doba práce: 30-60 sekund na jednotku

- Není nutná žádná úprava panelu

- Nejsou potřeba žádné specializované nástroje

- Odhadované náklady na práci: $2-$5 na časovač

Instalace do panelu:

- Doba práce: 5-10 minut na jednotku (kromě výřezu)

- Vyžadován výřez panelu ($5-$15 v práci/materiálech)

- Potřebné specializované nástroje (děrovač panelu: $50-$200)

- Odhadované náklady na práci: $15-$30 na časovač

Rozdíl v nákladech na instalaci: Instalace do panelu stojí 3-6x více než montáž na DIN lištu, především kvůli požadavkům na úpravu panelu.

Dlouhodobé náklady na údržbu a výměnu

Výhody lišty DIN:

- Demontáž a výměna bez použití nářadí (30 sekund)

- Pro výměnu není nutný přístup k panelu

- Snadná rekonfigurace během upgradů systému

- Nižší náklady na skladové zásoby díky standardizované montáži

Výhody montáže do panelu:

- Snížená frekvence výměny díky chráněným ovládacím prvkům

- Nižší riziko náhodného nastavení nebo poškození

- Vhodnější pro prostředí s vibracemi nebo otřesy

- Delší životnost v náročných podmínkách (ochrana IP65)

Příklad TCO za 10 let (10 časovačů):

- Lišta DIN: Počáteční náklady ($350) + Instalace ($50) + 2 výměny ($700) = $1,100

- Montáž do panelu: Počáteční náklady ($650) + Instalace ($300) + 1 výměna ($650) = $1,600

Zatímco časovače pro DIN lištu vykazují v tomto příkladu nižší TCO, výpočet se posouvá ve prospěch montáže do panelu pro náročná prostředí, kde se frekvence výměny výrazně zvyšuje.

Elektrické specifikace a kompatibilita

Požadavky na napájení

Oba formáty obvykle nabízejí univerzální napájecí vstupy akceptující 24-240V AC/DC, čímž eliminují potřebu samostatných řídicích transformátorů ve většině aplikací. Existují však některé klíčové rozdíly:

Montáž na DIN lištu:

- Typická spotřeba energie: 0,5-2W

- Zapínací proud: <5A po dobu <1ms

- Vhodné pro sdílené napájecí zdroje

- Lze napájet ze stávajících 24V DC řídicích obvodů

Montáž do panelu:

- Typická spotřeba energie: 2-5W (kvůli větším displejům)

- Zapínací proud: <10A po dobu <1ms

- Může vyžadovat vyhrazený napájecí zdroj pro více jednotek

- Vyšší proudový odběr pro podsvícené LCD displeje

Specifikace výstupních kontaktů

| Parametr | DIN lišta (17,5 mm) | Montáž do panelu (48 mm) |

|---|---|---|

| Typ kontaktu | SPDT (nejběžnější) | SPDT nebo DPDT |

| Odporová zátěž | 5-8A @ 250V AC | 5-10A @ 250V AC |

| Induktivní zátěž (AC-15) | 3A @ 250V AC | 5A @ 250V AC |

| DC zátěž | 5A @ 30V DC | 5A @ 30V DC |

| Mechanická životnost | 10 milionů operací | 10-20 milionů operací |

| Elektrická životnost | 100 000 operací při jmenovitém zatížení | 100 000-200 000 operací |

| Kontaktní materiál | AgNi nebo AgSnO2 | AgNi nebo AgCdO |

Důležitá poznámka: Pro zátěže překračující jmenovité hodnoty kontaktů časovače by měly být oba formáty použity k ovládání mezilehlého stykače nebo relé, namísto přímého spínání zátěže. Tím se prodlužuje životnost časovače a zajišťuje spolehlivý provoz. Další informace o správném výběru stykače naleznete v naší příručce o jak vybrat modulární stykače.

Integrace s řídicími systémy

Samostatný provoz vs. Integrace do systému

Časovače na DIN lištu:

- Primárně určeny pro samostatnou pevnou logiku

- Omezené komunikační schopnosti (některé modely nabízejí beznapěťové kontakty pro stav)

- Ideální pro jednoduché časovací aplikace bez integrace PLC

- Lze je použít společně s PLC pro vyhrazené časovací funkce

- Nižší cena než časovací řešení založená na PLC

Časovače pro montáž do panelu:

- Často zahrnují komunikační rozhraní (RS-485, Modbus RTU)

- Lze je integrovat do systémů SCADA pro vzdálené monitorování

- Některé modely nabízejí ethernetové připojení pro IoT aplikace

- Vhodnější pro záznam dat a historické trendy

- Vyšší počáteční náklady, ale poskytuje viditelnost na úrovni systému

Zapojení a konfigurace svorek

Montáž na DIN lištu:

- Šroubové svorky: kapacita pro lanko 2,5 mm² / plný vodič 4 mm²

- Rozteč svorek: typicky 5-7 mm

- Odnímatelné svorkovnice u některých modelů

- Svorky přístupné zepředu pro snadnou údržbu

- Vhodné pro bodové zapojení v ovládacích panelech

Montáž do panelu:

- Zadní šroubové svorky nebo konektory

- Kapacita vodiče: typicky 2,5 mm²

- Rozteč svorek: 7-10 mm

- Mohou zahrnovat odnímatelné svorkovnice

- Vyžaduje přístup k zadnímu panelu pro změny zapojení

- Vhodnější pro trvalé instalace

Pro správné postupy zapojení a výběr svorek se podívejte do naší komplexní příručky o výběr svorkovnic.

Úvahy o životním prostředí

Specifikace provozního prostředí

| Parametr | Montáž na DIN lištu | Montáž na panel |

|---|---|---|

| Provozní teplota | -25 °C až +70 °C | -10°C až +60°C |

| Teplota skladování | -40 °C až +85 °C | -30°C až +80°C |

| Vlhkost | 5-95% RH (nekondenzující) | 5-95% RH (nekondenzující) |

| Krytí IP (nainstalováno) | IP20 (zadní strana panelu) | IP65 (přední strana), IP20 (zadní strana) |

| Odolnost proti vibracím | 2g @ 10-55Hz | 3g @ 10-55Hz |

| Odolnost proti nárazům | 15g, trvání 11ms | 30g, trvání 11ms |

| Nadmořská výška | Až 2 000 m bez snížení výkonu | Až 2 000 m bez snížení výkonu |

| Stupeň znečištění | 2 (IEC 60664-1) | 2 (IEC 60664-1) |

Aplikace v náročném prostředí

Kdy je montáž do panelu lepší:

- Venkovní kryty: Krytí IP65 předního panelu zabraňuje vniknutí vlhkosti přes ovládací rozhraní

- Zpracování potravin: Prostředí s oplachováním, kde přední panel musí odolat čisticím chemikáliím

- Mořské aplikace: Prostředí se solným postřikem a vysokou vlhkostí těží z utěsněného předního panelu

- Prašné prostředí: Aplikace v hornictví, cementárnách nebo dřevozpracujících provozech, kde je infiltrace prachu problémem

Kdy je DIN lišta vhodná:

- Vnitřní kontrolní místnosti: Klimatizované prostředí s minimální kontaminací

- Uzavřené skříně: Skříně NEMA 4X nebo IP65, kde je vnitřní prostředí chráněno

- Čistá výroba: Montáž elektroniky, farmaceutická nebo polovodičová zařízení

- Komerční budovy: Místnosti HVAC, elektrické rozvodny a panely automatizace budov

Normy a certifikace

Požadavky na shodu

Časovače pro montáž na DIN lištu i na panel musí splňovat příslušné mezinárodní normy pro bezpečnost a elektromagnetickou kompatibilitu:

Klíčové standardy:

- IEC 61812-1 / EN 61812-1: Časová relé pro průmyslové použití

- IEC 60664-1: Koordinace izolace zařízení v nízkonapěťových systémech

- IEC 60947-5-1: Spínací prvky a řídicí obvody (stykače a relé)

- UL 508: Průmyslové řídicí zařízení (severoamerické trhy)

- Označení CE: Evropská shoda pro EMC a směrnice o nízkém napětí

Shoda s EMC:

- Emise: EN 55011 třída A nebo B

- Odolnost: EN 61000-6-2 (průmyslové) nebo EN 61000-6-1 (rezidenční)

Bezpečnostní certifikace:

- UL/cUL (Severní Amerika)

- CE (Evropa)

- CCC (Čína)

- EAC (Euroasijská hospodářská unie)

Při výběru časovačů pro mezinárodní projekty ověřte, zda zvolený tvarový faktor zahrnuje všechny požadované certifikace pro vaše cílové trhy. Časovače VIOX mají komplexní mezinárodní certifikace pro globální nasazení.

Údržba a řešení problémů

Požadavky na preventivní údržbu

Časovače pro montáž na DIN lištu:

- Frekvence kontrol: Ročně nebo podle plánu zařízení

- Klíčové kontroly: Dotažení svorek, funkce LED indikátoru, přesnost časování

- Čištění: Stlačený vzduch k odstranění prachu z ventilačních otvorů

- Indikátory výměny: Nepravidelné časování, nefunkční LED indikátory, svařování kontaktů

- Průměrná životnost: 10-15 let v typickém průmyslovém prostředí

Časovače pro montáž do panelu:

- Frekvence kontrol: Ročně nebo podle plánu zařízení

- Klíčové kontroly: Čitelnost displeje, funkce klávesnice, stav těsnění, přesnost časování

- Čištění: Jemný čisticí prostředek na přední panel, vyhněte se rozpouštědlům, která poškozují těsnění

- Indikátory výměny: Selhání displeje, nereagující ovládací prvky, zhoršení stavu těsnění

- Průměrná životnost: 12-18 let v typickém průmyslovém prostředí

Běžné problémy a jejich řešení

| Problém | Řešení pro DIN lištu | Řešení pro montáž na panel |

|---|---|---|

| Nepřesné načasování | Zkontrolujte stabilitu napájecího napětí; vyměňte, pokud drift překročí ±5% | Zkontrolujte baterii RTC (je-li vybavena); rekalibrujte nebo vyměňte |

| Žádný výstup | Ověřte vstupní signál; zkontrolujte výstupní zátěž; otestujte se známou dobrou zátěží | Zkontrolujte režim programování; ověřte, zda není výstup zakázán; otestujte relé |

| Přerušovaný provoz | Utáhněte šrouby svorek; zkontrolujte uvolněnou sponu DIN lišty | Zkontrolujte zadní svorky; ověřte, zda není skřípnuté těsnění předního panelu |

| Problémy s displejem | Vyměňte jednotku (LED indikátory obvykle nejsou opravitelné) | Zkontrolujte nastavení kontrastu displeje; vyměňte, pokud LCD selhal |

| Mechanické poškození | Vyměňte jednotku; zkontrolujte zdroj vibrací | Vyměňte přední rámeček nebo celou jednotku v závislosti na poškození |

Pro komplexní řešení problémů s časovými relé si přečtěte našeho podrobného průvodce o jak číst datové listy časových relé.

Budoucí trendy a technologie chytrých časovačů

Vývoj tvarových faktorů časovačů

Průmysl automatizace je svědkem konvergence tradiční technologie časových relé s chytrými, připojenými zařízeními:

Chytré časovače pro DIN lištu:

- Konfigurace Bluetooth prostřednictvím aplikací pro chytré telefony

- Programování NFC pro nastavení bez použití nástrojů

- Monitorování energie a analýza kvality napájení

- Prediktivní upozornění na údržbu na základě počítání cyklů

- Kompaktní provedení blížící se šířce 12 mm (ultra tenké moduly)

Časovače pro montáž do panelu:

- Barevné dotykové displeje s intuitivním rozhraním

- Víceprotokolová komunikace (Modbus, BACnet, MQTT)

- Cloudové připojení pro vzdálené monitorování a ovládání

- Algoritmy strojového učení pro adaptivní časování

- Integrace se systémy správy budov (BMS)

Průmysl 4.0 a integrace IoT

Vzhledem k tomu, že výrobní závody přijímají principy Průmyslu 4.0, výběr časovačů stále více zohledňuje konektivitu a datové možnosti:

Připojené časovače na DIN lištu:

- Nižší náklady na uzel pro distribuované aplikace časování

- Vhodné pro architektury edge computingu

- Lze je propojit do sítě pomocí průmyslových ethernetových switchů

- Ideální pro modernizace přidávající konektivitu ke stávajícím zařízením

Připojené časovače pro montáž do panelu:

- Vyšší schopnosti zpracování dat

- Lépe se hodí pro funkce brány

- Mohou agregovat data z více senzorů

- Preferované pro aplikace vyžadující lokální HMI funkcionalitu

Pro více informací o moderních principech návrhu ovládacích panelů si přečtěte náš článek o co je DIN lišta.

Klíčové poznatky

- Efektivita využití prostoru: Časovače pro montáž na DIN lištu (17,5 mm) poskytují 3,6x lepší využití prostoru ve srovnání s alternativami pro montáž do panelu (48 mm), což je činí ideálními pro ovládací panely s vysokou hustotou a modernizační aplikace.

- Rychlost instalace: Časovače na DIN lištu se instalují za 30-60 sekund pomocí beznástrojové zacvakávací montáže, zatímco časovače pro montáž do panelu vyžadují 5-10 minut plus přípravu výřezu panelu – výsledkem je 6-10x rychlejší instalace pro řešení na DIN lištu.

- Nákladové úvahy: Počáteční pořizovací náklady upřednostňují časovače na DIN lištu ($15-$45 vs. $35-$85), ale celkové náklady na vlastnictví závisí na aplikačním prostředí, frekvenci výměny a nákladech na práci při instalaci.

- Viditelnost a rozhraní: Časovače pro montáž do panelu nabízejí 7,7x větší zobrazovací plochu (2 304 mm² vs. 300 mm²) a sofistikovanější uživatelská rozhraní, díky čemuž jsou lepší pro aplikace orientované na obsluhu vyžadující častou interakci nebo sledování z dálky.

- Ochrana životního prostředí: Časovače pro montáž do panelu poskytují ochranu předního panelu IP65 při správné instalaci, což z nich činí preferovanou volbu pro venkovní, omyvatelné nebo drsné průmyslové prostředí, zatímco časovače na DIN lištu vynikají v chráněných krytech.

- Funkční schopnosti: Oba formáty podporují standardní funkce časování (zpoždění zapnutí, zpoždění vypnutí, interval atd.), ale časovače pro montáž do panelu často zahrnují pokročilé funkce, jako je vícekanálový provoz, plánování v reálném čase a komunikační rozhraní pro integraci do systému.

- Výběr aplikace: Vyberte časovače na DIN lištu pro automatizaci budov, OEM zařízení, panely s omezeným prostorem a aplikace vyžadující častou rekonfiguraci. Vyberte časovače pro montáž do panelu pro panely operátorského rozhraní, řízení procesů, venkovní instalace a systémy kritické z hlediska bezpečnosti vyžadující vysokou viditelnost.

- Dostupnost údržby: Časovače na DIN lištu umožňují beznástrojovou výměnu bez přístupu k panelu, čímž se zkracuje doba údržby o 80-90% ve srovnání s alternativami pro montáž do panelu, které vyžadují přístup k přednímu panelu a potenciální odstavení systému.

Často Kladené Otázky

Otázka: Mohu nahradit časovač pro montáž do panelu časovačem na DIN lištu ve stávajícím panelu?

Odpověď: Ano, ale budete muset opravit stávající výřez panelu a nainstalovat DIN lištu uvnitř krytu. Tato modernizace je běžná při přechodu na ovládací panely s vyšší hustotou. Funkční schopnosti jsou pro většinu aplikací ekvivalentní, i když se můžete vzdát velikosti displeje a pohodlí operátorského rozhraní. Zvažte použití časovače s paticí na DIN lištu, pokud chcete zachovat snadnou možnost výměny podobnou konstrukcím pro montáž do panelu.

Otázka: Jaký je typický rozdíl v životnosti mezi časovači na DIN lištu a časovači pro montáž do panelu?

Odpověď: V kontrolovaném vnitřním prostředí nabízejí oba formáty podobnou životnost 10-18 let. Časovače pro montáž do panelu však obvykle vydrží o 20-30% déle v drsném prostředí díky ochraně předního panelu IP65, která zabraňuje vniknutí vlhkosti, prachu a nečistot přes operátorské rozhraní. Časovače na DIN lištu mohou vyžadovat častější výměnu ve venkovních nebo omyvatelných aplikacích, pokud nejsou instalovány ve správně utěsněných krytech.

Otázka: Mohou časovače na DIN lištu zvládnout stejné elektrické zatížení jako časovače pro montáž do panelu?

Odpověď: Ano, oba formáty obvykle nabízejí podobné jmenovité hodnoty kontaktů (5-10A @ 250V AC). Klíčový rozdíl není v zatížitelnosti, ale spíše v konfiguraci kontaktů – časovače pro montáž do panelu častěji nabízejí kontakty DPDT (double pole double throw), zatímco časovače na DIN lištu obvykle poskytují SPDT (single pole double throw). Pro zatížení překračující jmenovité hodnoty časovače by oba měly ovládat mezilehlý stykač spíše než spínat zátěž přímo.

Otázka: Jsou časovače na DIN lištu méně přesné než časovače pro montáž do panelu?

Odpověď: Ne, přesnost časování je mezi formáty srovnatelná, přičemž oba obvykle dosahují přesnosti ±1-2% pro elektronické časovače a ±5-10% pro elektromechanické modely. Časovače pro montáž do panelu s funkcí reálného času (RTC) mohou nabízet lepší dlouhodobou přesnost pro plánování na základě kalendáře díky časování krystalového oscilátoru, ale pro základní zpoždění a intervalové časování fungují oba formáty ekvivalentně. Pro kritické aplikace časování ověřte specifikace přesnosti výrobce bez ohledu na formát.

Otázka: Který formát je lepší pro integraci s PLC a automatizačními systémy?

Odpověď: Časovače pro montáž do panelu obecně nabízejí lepší možnosti integrace, přičemž mnoho modelů zahrnuje komunikační rozhraní RS-485, Modbus RTU nebo Ethernet. Pro jednoduché aplikace s pevně zapojenou logikou jsou však časovače na DIN lištu často preferovány, protože jsou nákladově efektivnější a nevyžadují programování. Pokud potřebujete rozsáhlou integraci systému, protokolování dat nebo vzdálené monitorování, investujte do časovačů pro montáž do panelu s komunikačními schopnostmi. Pro samostatné funkce časování vedle řízení PLC poskytují časovače na DIN lištu vyhrazené časování bez spotřeby prostředků PLC.

Otázka: Mohu použít automobilové nebo spotřebitelské časovače namísto průmyslových časovačů na DIN lištu nebo pro montáž do panelu?

Odpověď: Toto se pro průmyslové aplikace nedoporučuje. Průmyslové časovače jsou navrženy tak, aby splňovaly normy IEC 61812-1 pro spolehlivost, elektromagnetickou kompatibilitu (EMC) a bezpečnost v průmyslovém prostředí. Vyznačují se: (1) širším rozsahem provozních teplot (-25 °C až +70 °C vs. 0 °C až +40 °C), (2) vyšší odolností proti vibracím a nárazům, (3) lepší odolností proti EMC, která zabraňuje falešnému spouštění od motorových pohonů a stykačů, a (4) bezpečnostními certifikacemi (UL 508, CE) vyžadovanými pro průmyslové zařízení. Použití neprůmyslových časovačů může vést k předčasnému selhání, bezpečnostním rizikům a problémům s pojištěním/souladem.

Související

- Seznamte se se základy modulárních ovládacích panelů: Co je DIN lišta

- Pochopte různé typy časovačů a aplikace: Kompletní průvodce časovými relé

- Porovnejte funkce časování časovačů: Zpoždění zapnutí vs. časovače zpoždění vypnutí

- Vyberte správný časovač pro vaši aplikaci: Jak vybrat správné časové relé

- Prozkoumejte výrobce časovačů: Top 10 Výrobců Časových Relé

- Pochopte specifikace časovačů: Jak číst Datové listy Časových Relé

- Seznamte se s doplňkovými řídicími komponentami: Co je to stykač

- Objevte výběr stykačů: Jak vybrat modulární stykač AC DC

- Prozkoumejte terminálové připojení: Průvodce výběrem svorkovnic

- Pochopte ochranu obvodů: Typy jističů