Když uvnitř rozvodných skříní nebo ovládacích panelů vypuknou elektrické požáry, počítá se každá sekunda – a také každý centimetr krychlový prostoru. Správci budov a bezpečnostní inženýři čelí kritickému dilematu: tradiční hasicí přístroje nabízejí osvědčenou spolehlivost, ale často za cenu vedlejších škod, nákladů na údržbu a složitosti instalace. Aerosolová hasicí zařízení slibují kompaktní, automatizovanou alternativu, která chrání citlivé zařízení bez zbytků nebo tlakových nádob.

Která technologie však skutečně poskytuje lepší ochranu pro vaše zařízení? Tato příručka porovnává aerosolové a tradiční hasicí systémy napříč technickými specifikacemi, reálným výkonem, souladem s předpisy a náklady životního cyklu – a poskytuje vám data pro informované rozhodnutí.

Jak fungují aerosolová hasicí zařízení

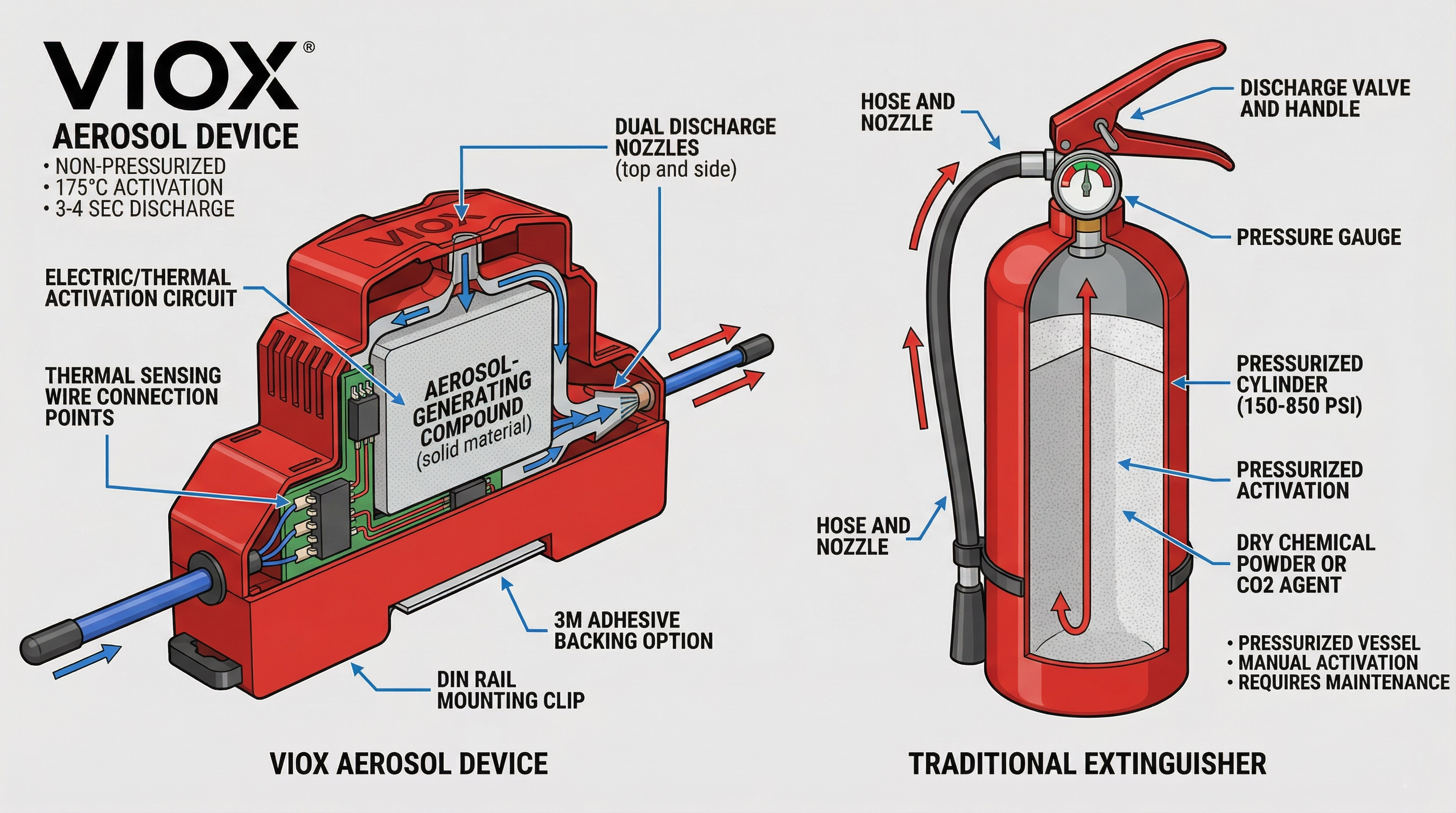

Aerosolová hasicí zařízení fungují na zásadně odlišném principu než tradiční hasicí přístroje. Po aktivaci teplem (typicky při 175 °C ± 5 °C) tyto jednotky generují a uvolňují kondenzované aerosolové částice – mikroskopické pevné a kapalné sloučeniny, obvykle na bázi draslíku – které přerušují chemickou řetězovou reakci ohně na molekulární úrovni. Částice zůstávají suspendovány ve vzduchu, interagují s volnými radikály spalování a zastavují oxidaci, aniž by významně snižovaly obsah kyslíku.

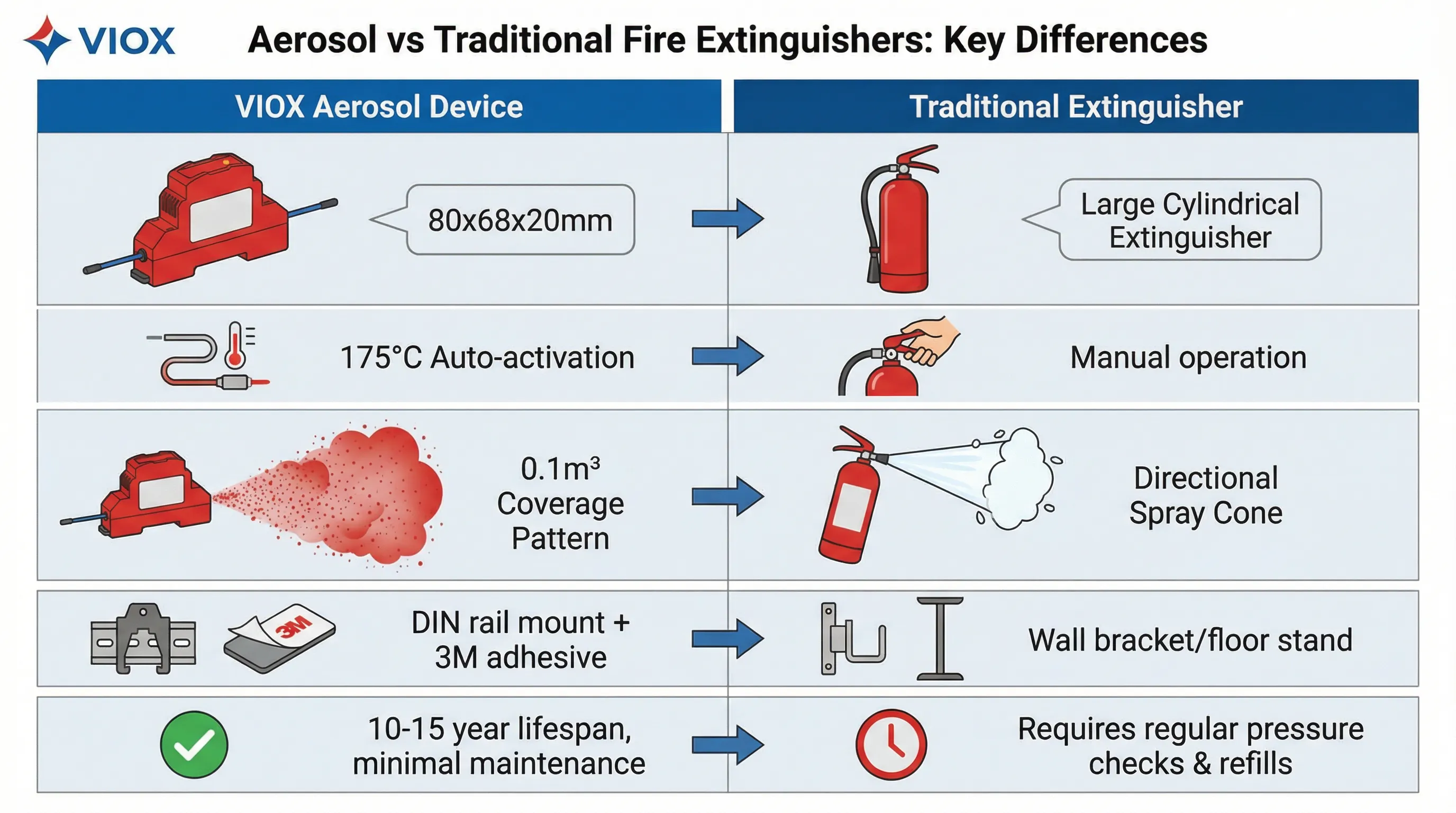

Moderní kondenzované aerosolové systémy, jako jsou jednotky VIOX montované na DIN lištu, mají rozměry pouhých 80 × 68 × 20 mm, přesto poskytují pokrytí hašení požáru až do 0,1 metru krychlového. Prostředek se vypouští za 3–4 sekundy strategicky umístěnými tryskami a zaplavuje chráněný prostor částicemi potlačujícími oheň. Na rozdíl od plynných systémů nevyžadují aerosolové generátory žádné tlakové skladovací válce, externí potrubí ani složitou instalační infrastrukturu.

Tato technologie získala na významu v 90. letech jako ekologicky bezpečnější alternativa k halonovým systémům. EPA schválila kondenzované aerosoly jako přijatelné náhrady halonu 1301 pro aplikace s úplným zaplavením, přičemž uznala jejich nulový potenciál poškozování ozonové vrstvy (ODP) a minimální potenciál globálního oteplování (GWP).

Tradiční technologie hasicích přístrojů: Stručný přehled

Tradiční přenosné a pevné hasicí přístroje zahrnují několik odlišných technologií, z nichž každá má specifické aplikace pro třídy požáru:

Hasicí přístroje ABC se suchou chemikálií používají prášek monoamoniumfosfátu k udušení ohně vytvořením bariéry mezi palivem a kyslíkem a zároveň přerušením chemické reakce. Účinné pro požáry třídy A (hořlavé látky), B (hořlavé kapaliny) a C (elektrické), představují nejběžnější víceúčelový typ hasicího přístroje. Jemný práškový zbytek však může být korozivní pro elektroniku a obtížně se čistí.

Hasicí přístroje CO2 (oxid uhličitý) vytlačují kyslík a ochlazují oheň pomocí stlačeného oxidu uhličitého. Ideální pro požáry třídy B a C, CO2 nezanechává žádné zbytky, takže je vhodný pro serverovny a laboratoře. Mezi omezení patří neúčinnost u požárů třídy A, riziko udušení v uzavřených prostorách a potenciál omrzlin z výtlačné hubice.

Hasicí přístroje na bázi vody (včetně vodní mlhy a pěny) ochlazují hořící materiály absorpcí tepla. Vodní hasicí přístroje jsou vysoce účinné u požárů třídy A, jsou nákladově efektivní a šetrné k životnímu prostředí. Mezi hlavní nevýhody patří nevhodnost pro elektrické požáry nebo požáry hořlavých kapalin, potenciální poškození zařízení vodou a riziko zamrznutí v chladném prostředí.

Každá technologie se spoléhá na tlakové nádoby, ruční nebo automatické aktivační systémy a pravidelnou údržbu, včetně kontroly tlaku a výměny hasiva.

Porovnání technických specifikací

Pochopení základních technických rozdílů pomáhá určit, která technologie vyhovuje specifickým požadavkům na ochranu.

| Specifikace | Aerosolové hasicí zařízení | Tradiční hasicí přístroje |

|---|---|---|

| Typ hasiva | Kondenzované aerosolové částice (sloučeniny draslíku) | Suchý chemický prášek, plyn CO2, kapalina voda/pěna |

| Velikost částic/hasiva | Submikron až 10 mikronů | 5–75 mikronů (suchý prášek), plynné (CO2), kapalné kapky (voda) |

| Aktivační metoda | Automatická tepelná aktivace (175 °C) nebo elektrický spouštěč | Ruční ovládání nebo automatické (sprinkler, detektor tepla) |

| Doba výboje | 3–4 sekundy | 8–60 sekund (liší se podle typu a velikosti) |

| Tlakování | Netlakové; chemická reakce generuje aerosol | Tlakové válce (150–850 psi) vyžadující pravidelné kontroly |

| Pokrytí na jednotku | 0,1–1,0 m³ (kompaktní jednotky) | 0,5–10 m³ (závisí na velikosti a hasivu) |

| Složitost instalace | Montáž na DIN lištu nebo lepidlo; není nutné žádné potrubí | Nástěnné držáky, podlahové stojany nebo potrubní distribuční systémy |

| Frekvence údržby | Minimální; vizuální kontrola ročně | Čtvrtletní až roční kontroly tlaku; výměna hasiva každé 3–5 roky |

| Životnost | 10-15 let | 5–12 let (liší se podle typu) |

| Provozní teplota | -40 °C až +95 °C | Různé: Voda (+4 °C až +65 °C), Suchý prášek (-20 °C až +60 °C) |

Srovnání výkonu: Účinnost v reálném světě

Metriky výkonu odhalují, jak se každá technologie chová za skutečných požárních podmínek.

| Faktor výkonu | Aerosolová zařízení | Suchá chemikálie ABC | CO2 | Na bázi vody |

|---|---|---|---|---|

| Doba odezvy | <1 sekunda od detekce k aktivaci | Ruční: závislé na obsluze; Automatické: 3–5 sekund | Ruční: závislé na obsluze; Automatické: 3–5 sekund | Ruční: závislé na obsluze; Automatické: 5–10 sekund |

| Účinnost pro třídu požáru | Třída A, B, C, E (elektrické) | Třída A, B, C | Třída B, C | Pouze třída A (mlha: A, B, C) |

| Rychlost hašení | 3–4 sekundy plné vypuštění | 10-30 sekund | 10–20 sekund | 30–60 sekund |

| Úroveň zbytků | Minimální jemné částice, nekorozivní | Silné zbytky prášku, korozivní pro elektroniku | Žádné (plyn) | Poškození zařízení vodou |

| Dopad na viditelnost | Mírný dočasný opar | Silný oblak prášku | Mírná mlha | Minimální |

| Riziko vedlejších škod | Velmi nízké; bezpečné pro elektroniku | Vysoké; poškození elektroniky práškem | Velmi nízké | Vysoké; poškození zařízení vodou |

| Prevence opětovného vznícení | Vynikající; částice zůstávají suspendované | Dobrý | Špatné pro požáry třídy A | Dobré pro třídu A |

| Bezpečnost v uzavřeném prostoru | Bezpečné; minimální vytěsnění kyslíku | Riziko podráždění dýchacích cest | Riziko udušení | Bezpečné |

| Dopad na životní prostředí | Nulový ODP, minimální GWP | Nízké obavy o životní prostředí | Skleníkový plyn (GWP: 1) | Šetrné k životnímu prostředí |

Data odhalují výhodu aerosolové technologie při ochraně citlivých elektronických zařízení v uzavřených prostorech, kde provoz bez zbytků a rychlá automatizovaná reakce poskytují kritickou ochranu bez sekundárních škod.

Soulad s předpisy a certifikace

Obě technologie fungují v rámci odlišných regulačních rámců, které upravují návrh, instalaci a údržbu.

Normy pro aerosolové hasicí systémy:

- NFPA 2010: Standard pro pevné aerosolové hasicí systémy. Zahrnuje požadavky na návrh, instalaci, testování a údržbu pevných aerosolových systémů chránících stacionární nebezpečí, jako jsou elektrické skříně a rozvodny.

- UL 2775: Standard pro pevné kondenzované aerosolové hasicí jednotky. Certifikuje komponenty pro shodu s NFPA 2010.

- Mezinárodní standardy: EN 15276, ISO 15779, IMO MSC.1/Circ.1270 (námořní aplikace)

- Schválení EPA: Uvedeno jako přijatelná náhrada Halonu 1301 pro systémy úplného zaplavení

Normy pro tradiční hasicí přístroje:

- NFPA 10: Standard pro přenosné hasicí přístroje. Stanovuje požadavky na výběr, instalaci, kontrolu a údržbu.

- UL 299: Standard pro hasicí přístroje na suché chemikálie

- UL 154: Standard pro hasicí přístroje na oxid uhličitý

- NFPA 13: Standard pro instalaci sprinklerových systémů (pevné systémy na bázi vody)

Jak aerosolová zařízení VIOX, tak kvalitní tradiční hasicí přístroje mají příslušné certifikace (shoda s CE, UL, NFPA), které zajišťují regulační přijetí ve všech jurisdikcích.

Vhodnost aplikace: Kde každá technologie vyniká

Výběr správné technologie hašení závisí do značné míry na chráněném prostředí, profilu požárního rizika a provozních omezeních.

| Aplikační scénář | Aerosolová zařízení | Tradiční hasicí přístroje | Doporučená volba |

|---|---|---|---|

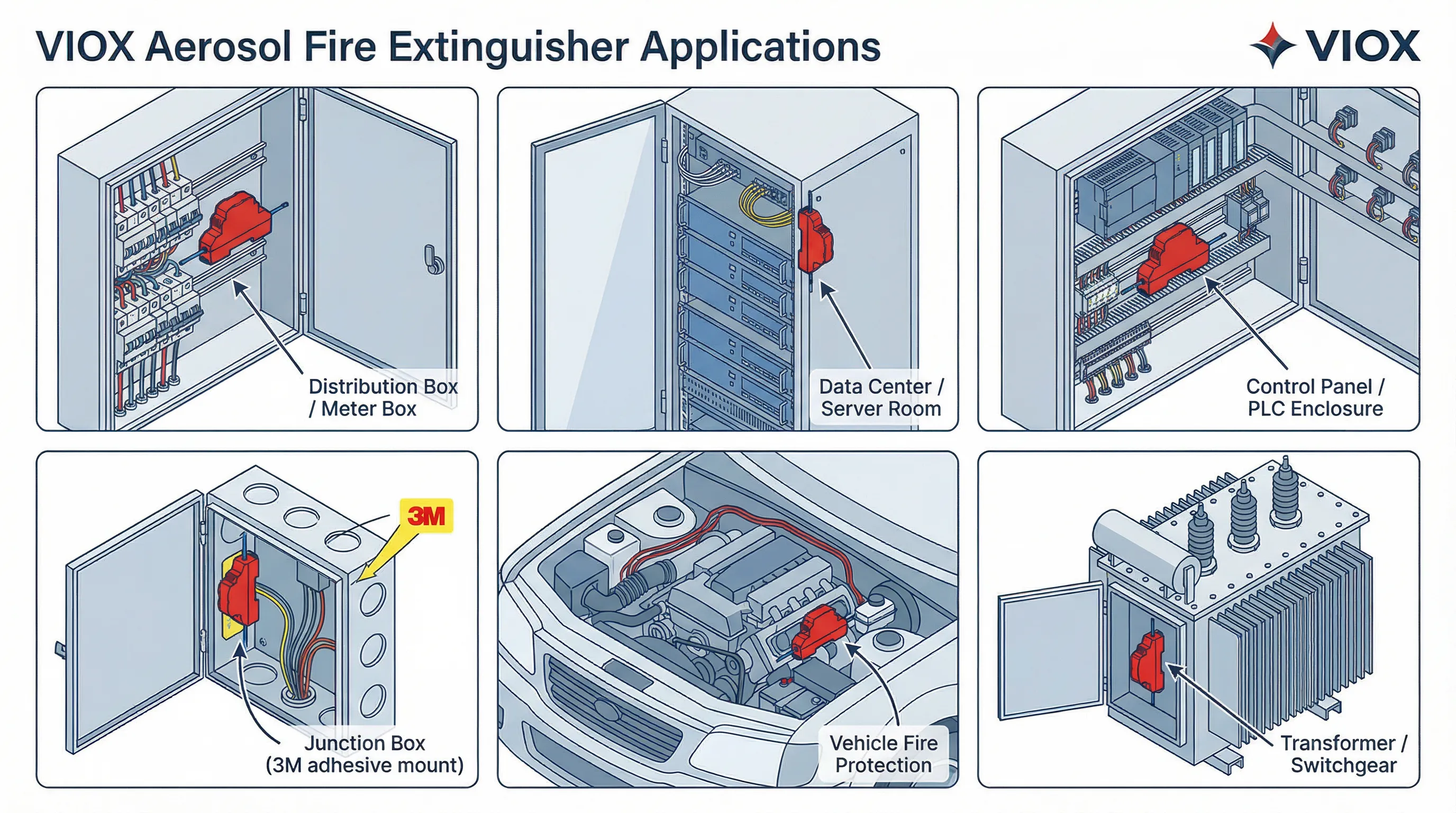

| Elektrické skříně | ✓ Vynikající (kompaktní, automatizované, beze zbytků) | Omezené (prostorová omezení, obavy ze zbytků) | Aerosol |

| Rozvodné skříně/Skříně elektroměrů | ✓ Ideální (montáž na DIN lištu, pokrytí 0,1 m³) | Špatné (prostorová omezení) | Aerosol |

| Serverovny/Datová centra | ✓ Dobré (bezpečné pro elektroniku, automatizované) | ✓ Dobré (CO2: beze zbytků; Suchá chemie: poškozující) | Aerosol nebo CO2 (v závislosti na velikosti místnosti) |

| Ovládací panely/Skříně PLC | ✓ Vynikající (flexibilita instalace, automatizovaná ochrana) | Omezené (zpoždění ručního ovládání, velikost) | Aerosol |

| Motorové prostory vozidel | ✓ Vynikající (odolné proti vibracím, automatizované) | Omezené (přístupnost, ruční ovládání) | Aerosol |

| Průmyslové sklady | Omezené (rozptyl v otevřeném prostoru) | ✓ Vynikající (pokrytí, víceúčelové) | Tradiční |

| Kancelářské prostory | Omezené (nákladová efektivita ve velkém měřítku) | ✓ Vynikající (víceúčelové, manuální ovládání) | Tradiční |

| Komerční kuchyně | Nedoporučeno | ✓ Vynikající (mokrá chemikálie třídy K) | Tradiční (třída K) |

| Strojovny lodí/člunů | ✓ Vynikající (odolné proti korozi, automatizované) | ✓ Dobré (běžné systémy CO2) | Aerosol nebo CO2 |

| Skříně transformátorů | ✓ Vynikající (odolné proti venkovním vlivům, automatizované) | Omezené (přístup pro údržbu) | Aerosol |

| Akumulace energie z baterií (BESS) | ✓ Dobré (reakce na tepelný únik) | ✓ Dobré (záleží na konstrukci systému) | Aerosol (počáteční stadia požárů) |

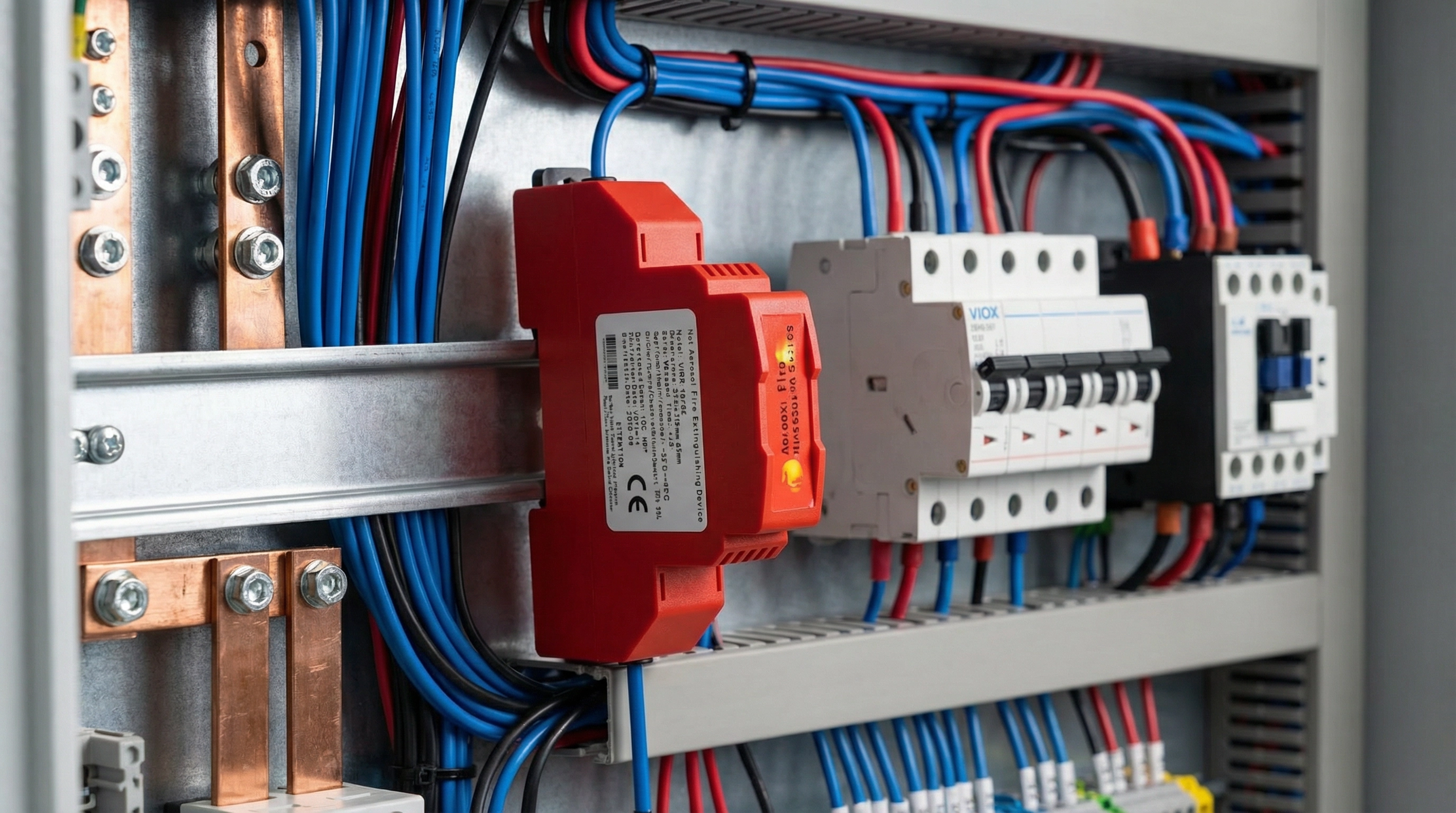

Hasicí přístroj VIOX DIN Rail Aerosol: Vyrobeno na míru pro elektrickou ochranu

Konkrétně pro systémy elektrické distribuce nabízí VIOX 10gramový aerosolový hasicí přístroj montovaný na DIN lištu zkonstruovaný tak, aby odpovídal tvarovému faktoru a způsobu instalace standardních vzduchových jističů. Tato inovativní konstrukce umožňuje instalaci hasicí jednotky vedle elektrických komponent v rozvodných skříních, elektroměrových skříních a ovládacích panelech pomocí stejného systému montáže na lištu.

S rozměry 80 × 68 × 20 mm a kapacitou pokrytí 0,1 m³ poskytuje jednotka komplexní ochranu pro typické elektrické skříně. Aktivace tepelnou šňůrou (175 °C ± 5 °C) zajišťuje automatickou reakci na požár bez externích detekčních systémů, zatímco pouzdro ABS zpomalující hoření odolává provozním teplotám od -40 °C do +95 °C. Umístění trysek na obou stranách umožňuje rychlou a rovnoměrnou distribuci aerosolu v chráněném prostoru.

Pokyny pro výběr: Výběr správné technologie

Optimální volba hasicího zařízení vyžaduje vyhodnocení několika rozhodovacích faktorů:

Vyberte aerosolové hasicí přístroje, když:

- Chráníte elektrické zařízení, kde by zbytky prášku nebo vody způsobily značné škody

- Prostorové omezení brání instalaci tradičního hasicího přístroje

- Je vyžadována automatizovaná ochrana proti selhání bez lidského zásahu

- Chráněná oblast je uzavřená nebo polo-uzavřená (0,1-10 m³)

- Prioritou je dlouhá životnost (10-15 let) a minimální údržba

- Záleží na jednoduchosti instalace (žádné potrubí, žádné externí napájení pro tepelnou aktivaci)

- Provoz v extrémních teplotních prostředích (-40 °C až +95 °C)

Vyberte tradiční hasicí přístroje, když:

- Chráníte velké otevřené prostory (sklady, továrny, maloobchodní prostory)

- Je potřeba víceúčelové pokrytí pro různá rizika požáru

- Upřednostňuje se manuální ovládání a selektivní nasazení

- Počáteční náklady na zařízení jsou primárním omezením

- Jsou přítomna rizika požáru vodou nebo třídy K (kuchyně)

- Regulační požadavky specifikují konkrétní typy tradičních hasicích přístrojů

- Školení pracovníků již zahrnuje obsluhu tradičních hasicích přístrojů

Hybridní přístup:

Mnoho zařízení strategicky implementuje obě technologie – aerosolová zařízení chrání kritickou elektrickou infrastrukturu (rozvodné panely, serverové skříně, řídicí systémy), zatímco tradiční přenosné hasicí přístroje poskytují obecné pokrytí pro chodby, kanceláře a otevřené pracovní prostory. Tento vrstvený přístup optimalizuje ochranu v různých profilech požárního rizika.

Nákladové úvahy: Analýza životního cyklu

Zatímco srovnání nákupních cen zpočátku upřednostňuje tradiční hasicí přístroje, celkové náklady na vlastnictví odhalují jiný obrázek:

| Nákladový faktor | Aerosolová zařízení | Tradiční hasicí přístroje |

|---|---|---|

| Počáteční cena jednotky | 100–300 USD za jednotku | 50–200 USD (přenosné); 500–5 000 USD (pevné systémy) |

| Náklady na instalaci | Minimální (0–50 USD za práci) | Nízké (přenosné: 50–100 USD); Vysoké (pevné: 1 000–10 000+ USD) |

| Roční údržba | 0–20 USD (vizuální kontrola) | 50–150 USD (kontrola, kontrola tlaku, dokumentace) |

| Výměna hasiva | Žádná (jednorázové použití, výměna po vypuštění) | 30–150 USD každé 3–5 roky (hydrostatické testování) |

| Riziko vedlejších škod | Minimální (bezpečné pro elektroniku) | Vysoké (úklid prášku: 500–5 000+ USD; poškození vodou: 2 000–50 000+ USD) |

| Náklady na prostoje | Nízké (minimální úklid) | Střední až vysoké (úklid, obnova poškození zařízení) |

| Náklady na životní cyklus za 10 let | 100–500 USD za jednotku | 500–2 000 USD za jednotku (bez poškození/prostojů) |

Pro specifickou ochranu elektrických rozvaděčů nabízejí aerosolová zařízení vynikající ekonomiku životního cyklu, pokud se zohlední zabránění vedlejším škodám a snížení nákladů na údržbu.

Často Kladené Otázky

Otázka: Jsou aerosolová hasicí zařízení bezpečná pro prostory s lidmi?

Odpověď: Ano, pokud jsou správně specifikována. Moderní systémy s kondenzovaným aerosolem splňují požadavky NFPA 2010 pro ochranu prostor s lidmi. Aerosolové částice významně nesnižují hladinu kyslíku, i když výboj může dočasně snížit viditelnost. U malých uzavřených elektrických rozvaděčů je expozice osob minimální, protože se zařízení aktivuje uvnitř uzavřených prostor. Vždy ověřte specifické certifikace produktu a dodržujte pokyny NFPA 2010 pro objem místnosti a požadavky na ventilaci.

Otázka: Mohou aerosolová zařízení nahradit všechny tradiční hasicí přístroje v objektu?

Odpověď: Ne. Aerosolová technologie vyniká v uzavřených prostorech při ochraně elektrického zařízení, ale ztrácí účinnost ve velkých otevřených prostorech, kde dochází k rozptylu částic. Prostory by měly udržovat tradiční přenosné hasicí přístroje pro obecnou reakci na požár, zejména pro požáry třídy A v otevřených prostorech a situace vyžadující ruční ovládání obsluhou. Aerosolová zařízení doplňují, spíše než zcela nahrazují, tradiční pokrytí hasicími přístroji.

Otázka: Jak dlouho vydrží aerosolové hasicí přístroje před výměnou?

Odpověď: Kvalitní aerosolové hasicí jednotky, jako jsou produkty VIOX, obvykle poskytují 10-15 let životnosti s minimální údržbou. Na rozdíl od tlakových tradičních hasicích přístrojů, které vyžadují periodickou výměnu hasiva a tlakové zkoušky, aerosolová zařízení vyžadují pouze roční vizuální kontrolu, aby se ověřila integrita upevnění a zkontrolovalo se fyzické poškození. Po aktivaci musí být jednotka vyměněna, protože sloučenina generující aerosol se během výboje spotřebuje.

Otázka: Co se stane s citlivou elektronikou po výboji aerosolu?

Odpověď: Kondenzované aerosolové látky zanechávají minimální zbytky – jemné nekorozivní částice, které lze vyčistit standardními metodami (suchý hadřík, stlačený vzduch nebo HEPA vysavač). Na rozdíl od suchého chemického prášku (který je korozivní a vyžaduje specializované čištění) nebo vody (která způsobuje okamžité selhání zařízení) aerosolové zbytky obvykle umožňují elektronickému zařízení obnovit provoz po základním čištění. Některá zařízení mohou pokračovat v provozu i bez okamžitého čištění, i když se vždy doporučuje důkladná kontrola po výboji.

Otázka: Fungují aerosolové hasicí přístroje na požáry lithium-iontových baterií?

Odpověď: Aerosolová zařízení mohou potlačit požáry v rané fázi zahrnující lithium-iontové baterie předtím, než se plně rozvine tepelný únik. Jakmile se však tepelný únik ustálí, požáry baterií generují vlastní kyslík, což ztěžuje potlačení jakoukoli technologií. Pro systémy pro ukládání energie z baterií (BESS) fungují aerosolová zařízení nejlépe jako součást vrstveného přístupu zahrnujícího tepelné monitorování, včasnou detekci a ventilační systémy. Poskytují cennou ochranu pro požáry vznikající mimo bateriové články (elektrické spoje, součásti krytu), které by jinak mohly spustit tepelný únik.

Otázka: Jakou údržbu vyžadují aerosolová hasicí zařízení?

Odpověď: Minimální. Roční vizuální kontrola by měla ověřit: (1) bezpečné upevnění bez fyzického poškození, (2) integritu tepelné šňůry (žádné roztřepení nebo odpojení), (3) otvory trysek zůstávají neucpané a (4) environmentální podmínky zůstávají v provozním rozsahu (-40 °C až +95 °C pro jednotky VIOX). Během 10-15 let životnosti není vyžadováno žádné tlakové testování, doplňování hasiva ani recertifikace. To ostře kontrastuje s tradičními hasicími přístroji, které vyžadují čtvrtletní až roční odbornou kontrolu, ověření tlaku a periodické dobíjení.

Otázka: Jsou aerosolové systémy dražší než tradiční hasicí přístroje?

Odpověď: Počáteční pořizovací náklady jsou srovnatelné nebo mírně vyšší u aerosolových jednotek ve srovnání s přenosnými tradičními hasicími přístroji. Náklady na životní cyklus však upřednostňují aerosolovou technologii, pokud se zohlední: (1) eliminované náklady na údržbu (žádné tlakové testování nebo výměna hasiva), (2) zabránění vedlejším škodám (žádný korozivní prášek nebo poškození vodou chráněného zařízení) a (3) snížená doba prostojů po výboji. Pro specifickou ochranu elektrických rozvaděčů poskytují aerosolová zařízení obvykle nižší celkové náklady na vlastnictví během jejich 10-15 let životnosti.

Závěr: Správná volba pro váš objekt

Volba mezi aerosolovými hasicími zařízeními a tradičními hasicími přístroji není binární – je specifická pro danou aplikaci. Aerosolová technologie poskytuje bezkonkurenční výhody pro ochranu elektrické infrastruktury, řídicích systémů a citlivého zařízení v uzavřených prostorech. Kombinace automatizované reakce, provozu bez zbytků, kompaktní instalace a minimální údržby činí z aerosolových zařízení vynikající volbu pro rozvodné skříně, ovládací panely, serverové skříně a podobné aplikace, kde tradiční hasicí přístroje vytvářejí problémy s prostorem, zbytky nebo dobou odezvy.

Tradiční hasicí přístroje zůstávají nezbytné pro obecné pokrytí objektu, velké otevřené prostory a situace vyžadující ruční ovládání obsluhou. Ideální strategie protipožární ochrany často kombinuje obě technologie – aerosolová zařízení chrání kritická elektrická aktiva, zatímco tradiční přenosné jednotky poskytují všestrannou a dostupnou ochranu v celém prostoru s lidmi.

Pro správce objektů a bezpečnostní inženýry specifikující protipožární ochranu pro elektrické rozvodné systémy nabízejí aerosolové hasicí přístroje VIOX montované na DIN lištu účelově navržené řešení, které se hladce integruje se standardní infrastrukturou elektrických rozvaděčů. S životností více než 10 let, automatickou tepelnou aktivací a provozem bezpečným pro elektroniku představují tato zařízení vývoj technologie protipožární ochrany speciálně navržené pro jedinečné výzvy moderních elektrických systémů.

Otázka nezní, zda je aerosolová nebo tradiční technologie “lepší” – jde o to, která technologie nejlépe odpovídá vašim specifickým požadavkům na ochranu, uspořádání objektu a provozním omezením. Pochopení technických rozdílů, výkonnostních charakteristik a aplikačních silných stránek uvedených v této příručce vám umožní činit informovaná rozhodnutí, která optimalizují požární bezpečnost a zároveň minimalizují náklady na životní cyklus a provozní dopad.