Pro elektrotechnické dodavatele, výrobce rozvaděčů a správce zařízení pracující s komerčními a průmyslovými instalacemi je pochopení rozdílu mezi jističi s jmenovitým proudem 80% a 100% zásadní pro bezpečnost, dodržování předpisů a optimalizaci nákladů. Navzdory jejich rozšířenému používání zůstávají tyto jmenovité hodnoty jedním z nejvíce nepochopených aspektů návrhu elektrických rozvaděčů. Tato komplexní příručka objasňuje technické rozdíly, regulační požadavky a praktické aplikace obou typů jističů.

Co jsou jističe s jmenovitým proudem 80% a 100%?

Základ: Testovací normy UL 489

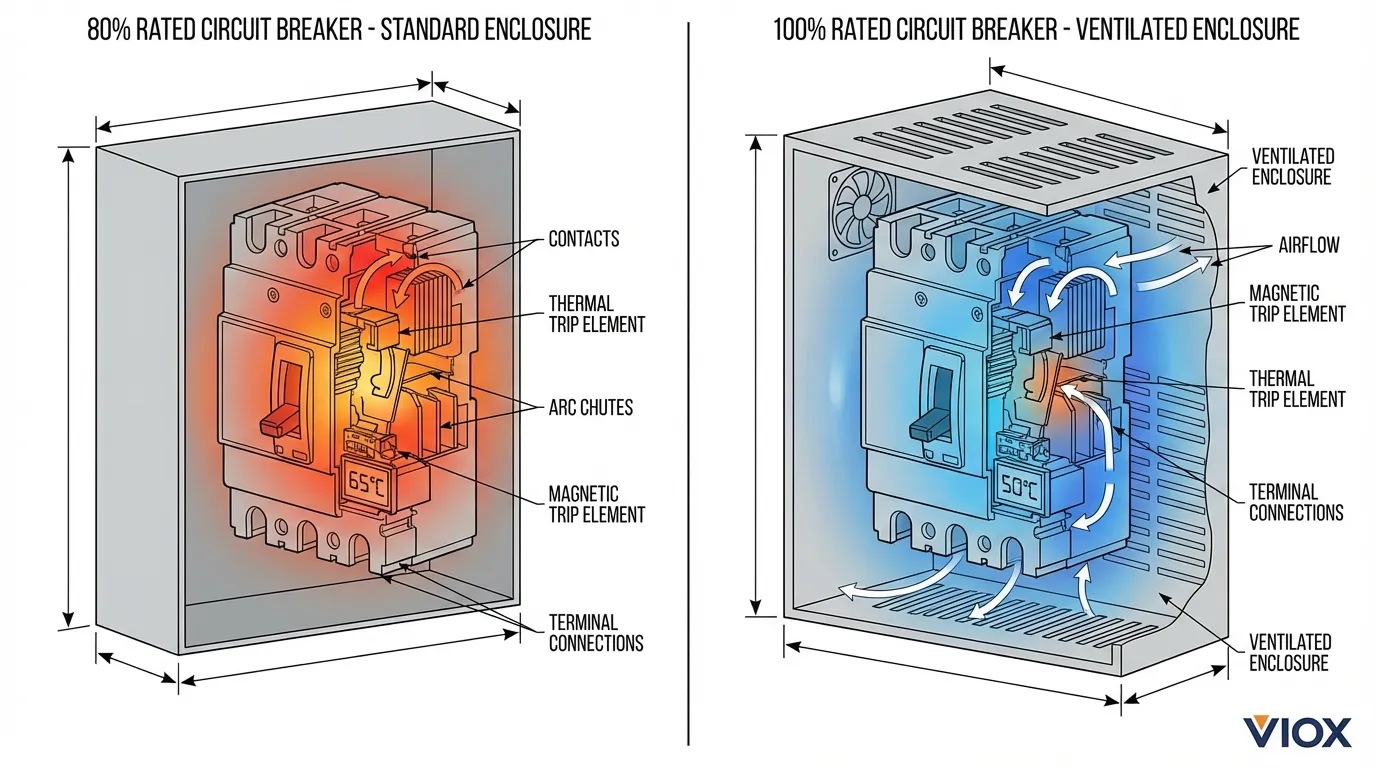

Všechny jističe v lisovaném pouzdře (MCCB) vyráběné v Severní Americe musí splňovat normu UL 489, Standard pro bezpečnost lisovaných jističů a skříní jističů. Podle této normy je každý jistič – bez ohledu na to, zda je označen 80% nebo 100% – navržen a testován tak, aby trvale vedl 100% svého jmenovitého proudu za kontrolovaných laboratorních podmínek: volný vzduch při okolní teplotě 40 °C (104 °F).

Skutečné instalace se však dramaticky liší od laboratorních podmínek. Jističe jsou obvykle instalovány v uzavřených rozvaděčích s omezeným větráním, často vedle dalších komponent generujících teplo a v prostředích, kde okolní teploty mohou překročit testovací podmínky. Tato akumulace tepla ovlivňuje tepelný spouštěcí mechanismus jističe, a proto National Electrical Code (NEC) ukládá další požadavky na dimenzování.

Jističe s jmenovitým proudem 80%: Standard

Jistič s jmenovitým proudem 80% je průmyslový standard a představuje většinu jističů v rezidenčních a komerčních aplikacích. Označení “80%” neznamená, že jistič může vést pouze 80% svého jmenovitého proudu – spíše naznačuje, že při instalaci v typickém uzavřeném rozvaděči může jistič bezpečně zvládnout trvalé zatížení při 80% svého jmenovitého proudu.

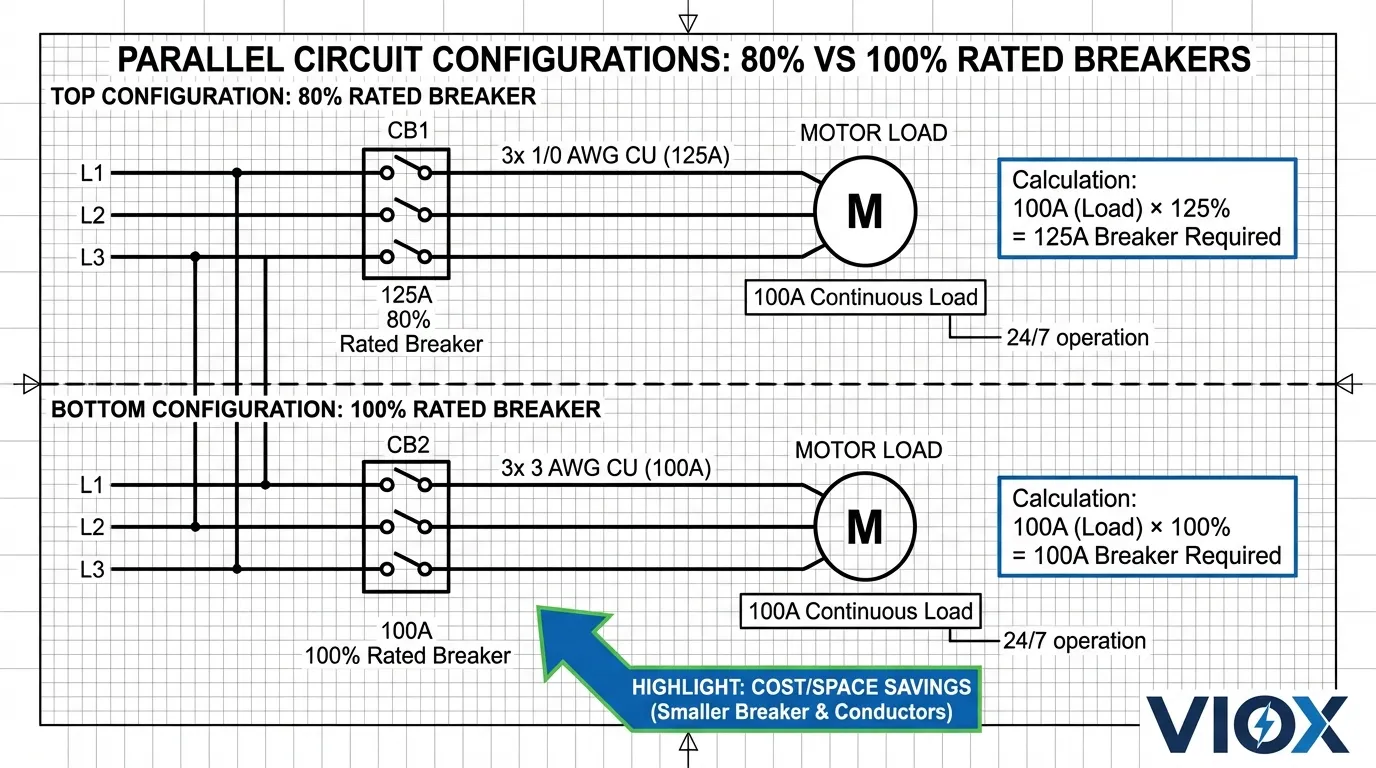

Toto omezení vyplývá z článku 210.20(A) normy NEC, který vyžaduje, aby ochranná zařízení proti nadproudu byla dimenzována minimálně na 125% trvalého zatížení plus 100% netrvalého zatížení. Protože 80% je matematická inverze 125%, jsou tyto jističe běžně označovány jako “jističe s jmenovitým proudem 80%”.”

Příklad: Pro ochranu trvalého zatížení 100 A standardním jističem musíte jistič dimenzovat na 125 A (100 A × 1,25 = 125 A). Jistič 125 A pak bude pracovat na 80% své kapacity (100 A ÷ 125 A = 80%).

Jističe s jmenovitým proudem 100%: Výjimka

Jistič s jmenovitým proudem 100% prošel dalším testováním podle oddílu 7.1.4 normy UL 489, aby se ověřilo, že může trvale vést svůj plný jmenovitý proud, když je instalován ve specifické konfiguraci skříně. Tyto jističe jsou vyráběny s vylepšenými funkcemi tepelného managementu a musí být instalovány podle přísných specifikací výrobce týkajících se:

- Minimální velikosti a rozměrů skříně

- Požadovaných větracích otvorů (obvykle 7 čtverečních palců nad a pod)

- Specifikací vodičů (izolace 90 °C jmenovitá na 75 °C proudové zatížitelnosti)

- Specifikací utahovacího momentu svorek

- Správné vzdálenosti od sousedních komponent

Pokud jsou tyto podmínky splněny a sestava je uvedena pro provoz 100%, výjimka článku 210.20(A) normy NEC umožňuje dimenzovat jistič přesně na 100% trvalého zatížení plus 100% netrvalého zatížení – čímž se eliminuje multiplikátor 125%.

Klíčové rozdíly mezi jističi s jmenovitým proudem 80% a 100%

| Funkce | Jistič s jmenovitým proudem 80% | Jistič se 100% jmenovitým proudem |

|---|---|---|

| Kapacita trvalého zatížení | 80% jmenovitého proudu | 100% jmenovitého proudu |

| Požadavek na dimenzování podle NEC | 125% trvalého zatížení + 100% netrvalého | 100% trvalého zatížení + 100% netrvalého |

| Příklad pro trvalé zatížení 100 A | Vyžaduje jistič 125 A | Vyžaduje jistič 100 A |

| Požadavky na skříň | Standardní instalace do rozvaděče | Uvedená sestava se specifickým větráním |

| Požadavky na vodiče | Standardní jmenovitá hodnota 75 °C | Izolace 90 °C při proudové zatížitelnosti 75 °C |

| Testovací norma | Základní testování UL 489 | UL 489 + další testy jmenovité hodnoty 100% |

| Typické aplikace | Rezidenční, lehké komerční | Průmysl, datová centra, nepřetržitý provoz |

| Náklady | Nižší počáteční náklady | O 10-30% vyšší cena |

| Dostupnost | Široce dostupné všechny jmenovité hodnoty | Typicky rám 400 A a výše |

| Úspora místa v rozvaděči | Může vyžadovat větší rám | Umožňuje menší velikost rámu |

Pochopení trvalého vs. netrvalého zatížení

Rozlišení mezi trvalým a netrvalým zatížením je zásadní pro správný výběr jističe. Podle článku 100 normy NEC a nepřetržité zatížení je definováno jako zatížení, u kterého se očekává, že maximální proud bude trvat tři hodiny nebo déle. To zahrnuje:

- Systémy HVAC běžící během špičkových sezón

- Průmyslové stroje v nepřetržitých výrobních zařízeních

- Serverové racky a chladicí systémy datových center

- Komerční osvětlení v maloobchodních nebo kancelářských prostorech

- Chladicí zařízení v závodech na zpracování potravin

- Nabíjecí stanice EV během prodloužených nabíjecích relací

Netrvalé zatížení pracují méně než tři hodiny při maximálním proudu, například:

- Domácí spotřebiče s pracovními cykly

- Přerušovaný provoz motorů

- Dočasné stavební vybavení

- Záložní systémy, které se aktivují jen zřídka

Kdy použít jističe s jmenovitým proudem 80%

Standardní jističe s jmenovitým proudem 80% zůstávají nejekonomičtější volbou pro mnoho aplikací:

Ideální aplikace:

- Převážně netrvalé zatížení: Pokud zátěže pracují méně než tři hodiny, požadavek na dimenzování 125% se neuplatňuje, díky čemuž jsou jističe 80% nákladově efektivní.

- Rezidenční instalace: Většina domácích obvodů slouží přerušovaným zátěžím (spotřebiče, osvětlení s proměnlivou obsazeností), kde dodatečné náklady na jističe s jmenovitým proudem 100% nepřinášejí žádný užitek.

- Obvody se smíšenou zátěží: Pokud můžete oddělit trvalé a netrvalé zátěže do samostatných obvodů, jističe s jmenovitým proudem 80% na netrvalých obvodech nabízejí úspory.

- Nižší požadavky na proud: Pod 400 A jsou jističe s jmenovitým proudem 100% méně běžně dostupné a dražší ve srovnání s potenciálními úsporami.

- Standardní konfigurace panelů: Při použití předem navržených rozvaděčů nebo zátěžových center, které nejsou uvedeny pro sestavy s jmenovitým proudem 100%.

Nákladové úvahy:

Pro přípojku 200 A se 160 A netrvalé zátěže stojí jistič 200 A s jmenovitým proudem 80% výrazně méně než jistič 200 A s jmenovitým proudem 100%, přičemž poskytuje identickou ochranu.

Kdy používat jističe s jmenovitým proudem 100%

Dodatečné náklady na jističe s jmenovitým proudem 100% lze ospravedlnit ve specifických scénářích, kde poskytují hmatatelné výhody:

Ideální aplikace:

- Vysoké trvalé zátěže: Průmyslové provozy s motory, HVAC nebo technologickým zařízením běžícím 24 hodin denně, 7 dní v týdnu, těží z eliminace penalizace za dimenzování 125%.

- Panely s omezeným prostorem: Pokud je prostor v panelu omezený, použití jističe s jmenovitým proudem 100% zabrání přechodu na další větší velikost rámu. Například jistič 250 A s jmenovitým proudem 100% může nahradit jistič 300 A s jmenovitým proudem 80% (který vyžaduje rám 400 A), což ušetří značný prostor v panelu.

- Datová centra a serverovny: Tam, kde nepřetržité chlazení a serverové zátěže vyžadují spolehlivou kapacitu 100% bez předimenzování.

- Optimalizace nákladů při vyšších proudech: Při 400 A a výše může rozdíl v nákladech mezi velikostmi rámů učinit jističe s jmenovitým proudem 100% ekonomičtějšími než předimenzování na další rám.

- Instalace v horkém prostředí: Venkovní skříně, střešní zařízení nebo místa s vysokou okolní teplotou těží z vylepšeného tepelného výkonu sestav s jmenovitým proudem 100%.

Příklad analýzy nákladů v reálném světě:

Scénář: Trvalá zátěž 250 A pro výrobní závod

Varianta 1 – Jistič s jmenovitým proudem 80%:

- Požadovaná velikost jističe: 250 A × 125% = 312,5 A → jistič 350 A

- Požadovaná velikost rámu: rám 400 A

- Velikost vodiče: měď 350 kcmil

- Odhadované náklady: $1 200 (jistič) + $2 800 (vodiče) = $4 000

Varianta 2 – Jistič s jmenovitým proudem 100%:

- Požadovaná velikost jističe: 250 A × 100% = jistič 250 A

- Požadovaná velikost rámu: rám 250 A

- Velikost vodiče: měď 250 kcmil

- Odhadované náklady: $1 400 (jistič) + $2 200 (vodiče) = $3 600

Úspory: $400 (snížení o 10%) plus menší půdorys panelu

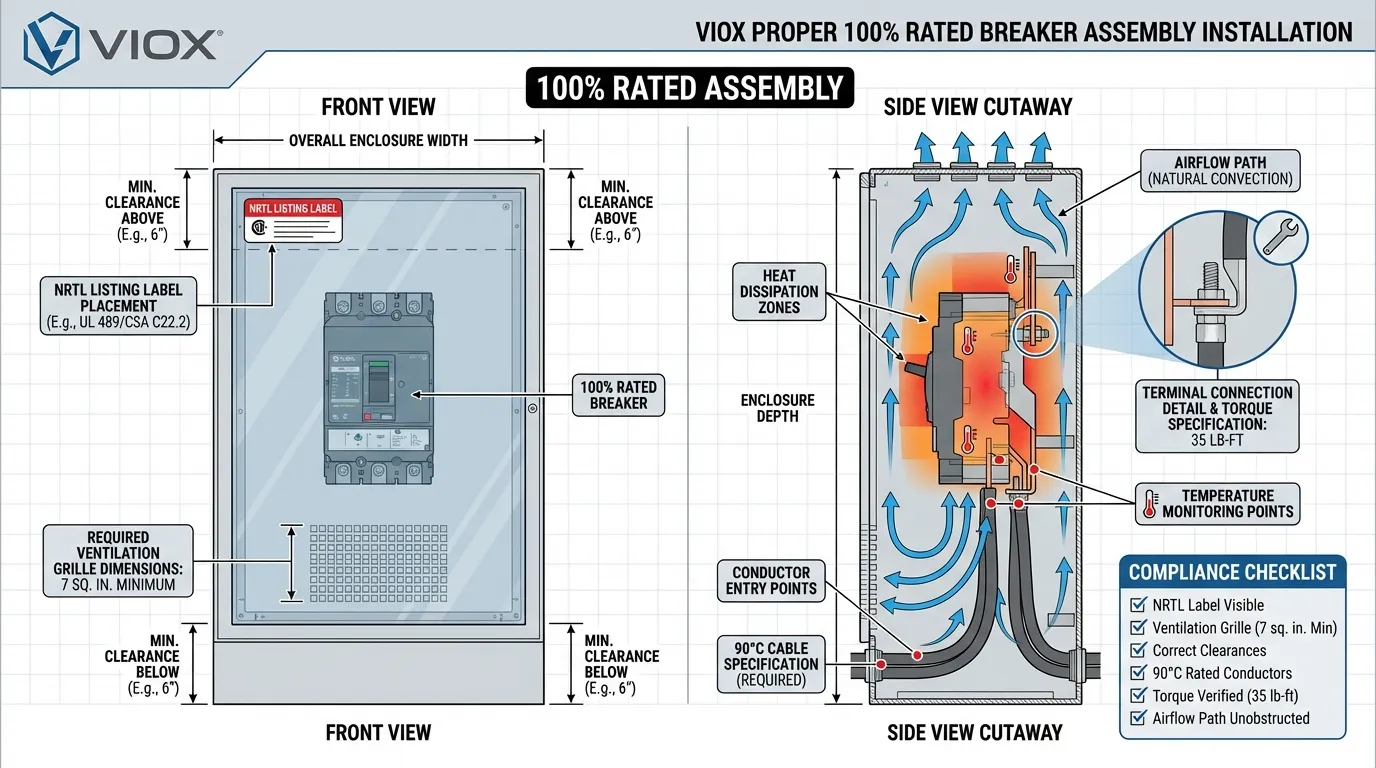

Požadavky na instalaci jističů s jmenovitým proudem 100%

Dosažení jmenovitého proudu 100% vyžaduje přísné dodržování specifikací výrobce. Pouhá instalace jističe s jmenovitým proudem 100% do standardního panelu nezaručuje výkon 100% – celá sestava musí být uvedena.

Kritické požadavky:

- Uvedená sestava: Kompletní instalace (jistič + skříň + vodiče) musí být uvedena Národně uznávanou zkušební laboratoří (NRTL) pro provoz 100%.

- Specifikace krytu:

- Minimální rozměry skříně podle výrobce

- Požadované větrací otvory (obvykle minimálně 7 čtverečních palců nahoře a dole)

- Správné rozestupy mezi jističi a stěnami skříně

- Jasně označené teplotní limity

- Požadavky na vodiče:

- Povinné jmenovité izolační napětí 90 °C

- Ampacita vypočítaná ve sloupci 75 °C tabulky 310.16 NEC

- Správný utahovací moment svorek podle specifikací výrobce

- Ověřené jmenovité teploty svorek

- Dokumentace:

- Je nutné přesně dodržovat pokyny výrobce k instalaci

- Štítek s uvedením musí být připevněn ke skříni

- Inspekční orgán musí ověřit shodu

Běžné mylné představy a chyby

Mylná představa 1: “Jističe s jmenovitým proudem 100% jsou silnější”

Běžné mylné představy o zatahovacím proudu MCB Jističe s jmenovitým proudem 80% i 100% se stejným proudem mají identické zkratové proudy a vypínací schopnost. Rozdíl spočívá pouze v trvalé proudové zatížitelnosti v uzavřených podmínkách.

Mylná představa 2: “Mohu vyměnit jistič 80% za jistič 100%”

Běžné mylné představy o zatahovacím proudu MCB Jmenovitý proud 100% se vztahuje na kompletní sestavu, nejen na jistič. Instalace jističe s jmenovitým proudem 100% do neuvedené skříně jej vrátí do provozu 80%.

Mylná představa 3: “Jističe s jmenovitým proudem 80% nemohou přenášet plné zatížení”

Běžné mylné představy o zatahovacím proudu MCB Jističe s jmenovitým proudem 80% mohou přenášet 100% svého jmenovitého proudu pro netrvalé zátěže (pod 3 hodiny). Omezení 80% platí pouze pro trvalý provoz.

Mylná představa 4: “Všechny zátěže jsou trvalé”

Běžné mylné představy o zatahovacím proudu MCB Mnoho zátěží má pracovní cykly nebo přerušovaný provoz. Správné kategorizování zátěží může zabránit zbytečnému předimenzování.

Mylná představa 5: “Jističe s jmenovitým proudem 100% nepotřebují dimenzování vodičů”

Běžné mylné představy o zatahovacím proudu MCB Vodiče musí být stále dimenzovány podle článku 310 NEC, s použitím izolace 90 °C při ampacitě 75 °C. Jmenovitý proud jističe nepřepisuje požadavky na ampacitu vodiče.

Soulad s předpisy a regulační rámec

Shrnutí požadavků NEC:

Článek 210.20(A) – Nadproudová ochrana odbočkového obvodu:

“Pokud odbočkový obvod napájí trvalé zátěže nebo jakoukoli kombinaci trvalých a netrvalých zátěží, jmenovitá hodnota nadproudového zařízení nesmí být menší než netrvalá zátěž plus 125 procent trvalé zátěže.”

Výjimka:

“Pokud je sestava, včetně nadproudových zařízení chránících odbočkový obvod(y), uvedena pro provoz při 100 procentech svého jmenovitého výkonu, smí být jmenovitá hodnota nadproudového zařízení nejméně součtem trvalé zátěže plus netrvalé zátěže.”

Tato výjimka se objevuje v celém NEC v:

- Článek 215.2(A) – Napáječe

- Článek 230.42(A) – Přípojkové vodiče

- Článek 430.62 – Vodiče napáječe motoru

Požadavky na testování UL 489:

Standardní testování (všechny jističe):

- Jmenovitý proud 100% ve volném vzduchu při 40 °C

- Ověření kalibrace tepelné spouště

- Zkoušky vypínací schopnosti při zkratu

- Zkoušky životnosti (6 000 operací)

Další testy jmenovité hodnoty 100%:

- Provoz v krytu při proudu 100%

- Ověření specifické velikosti krytu a ventilace

- Měření nárůstu teploty na svorkách

- Testování kompatibility izolace vodičů

- Testování kolísání okolní teploty

Výběr správného jističe pro vaši aplikaci

Rozhodovací rámec:

Krok 1: Analýza zátěže

- Vypočítejte celkové připojené zatížení

- Identifikujte trvalé vs. netrvalé zátěže

- Určete dobu trvání zátěže (>3 hodiny = trvalá)

- Zvažte budoucí růst zatížení

Krok 2: Výpočet shody s předpisy

Pro Jistič se jmenovitou hodnotou 80%:

Velikost jističe = (Trvalá zátěž × 1,25) + Netrvalá zátěž

Pro Jistič se jmenovitou hodnotou 100%:

Velikost jističe = Trvalá zátěž + Netrvalá zátěž

Krok 3: Ekonomická analýza

- Porovnejte náklady na jističe (80% vs. 100%)

- Vypočítejte rozdíly v nákladech na vodiče

- Vyhodnoťte požadavky na prostor v rozvaděči

- Zvažte náklady na instalaci

Krok 4: Technické ověření

- Potvrďte dostupnost jističe se jmenovitou hodnotou 100% v požadované velikosti

- Ověřte kompatibilitu krytu s jmenovitou hodnotou 100%

- Zkontrolujte teplotní odolnost vodičů

- Projděte si instalační požadavky výrobce

Krok 5: Dlouhodobé úvahy

- Dostupnost údržby

- Budoucí kapacita pro rozšíření

- Dostupnost náhradních dílů

- Podmínky provozního prostředí

Praktické příklady použití

Příklad 1: Serverovna datového centra

Zátěž: 180 A trvale (servery + chlazení)

Provozní hodiny: 24/7/365

Řešení 80%:

- Jistič: 225 A (180 A × 1,25)

- Rám: 250 A

- Vodiče: měď 4/0 AWG

- Prostor v rozvaděči: 3 póly

- Cena: ~$1 800

Řešení 100%:

- Jistič: 200 A (180 A × 1,0)

- Rám: 225 A

- Vodiče: měď 3/0 AWG

- Prostor v rozvaděči: 3 póly

- Cena: ~$1 650

- Úspora: $150 + menší půdorys

Příklad 2: Komerční systém HVAC

Zátěž: 120 A trvale (provoz chladiče během léta)

Provozní hodiny: 12 hodin/den, 4 měsíce/rok

Analýza: Zatímco chladič běží >3 hodiny denně, sezónní charakter a denní cyklování z toho činí hraniční případ. Jistič se jmenovitou hodnotou 80% při 150 A poskytuje adekvátní ochranu s nižšími náklady a jednodušší instalací než sestava se jmenovitou hodnotou 100%.

Doporučení: Jistič se jmenovitou hodnotou 150 A 80%

Příklad 3: Výrobní linka

Zátěž: 400 A trvale (motory, dopravníky, technologické zařízení)

Provozní hodiny: 24/7 kromě víkendů

Řešení 80%:

- Jistič: 500 A (400 A × 1,25)

- Rám: 600 A

- Vodiče: (2) 500 kcmil na fázi

- Cena: ~$4 500

Řešení 100%:

- Jistič: 400 A (400 A × 1,0)

- Rám: 400 A

- Vodiče: (2) 350 kcmil na fázi

- Cena: ~$3 800

- Úspora: $700 + významné snížení prostoru panelu

Srovnávací tabulka: Jističe dimenzované na 80% vs. 100%

| Scénář zatížení | Řešení dimenzované na 80% | Řešení dimenzované na 100% | Doporučená volba |

|---|---|---|---|

| 100 A trvale | Jistič 125 A, vodiče 125 A | Jistič 100 A, vodiče 100 A | 100% (pokud je k dispozici) |

| 100 A netrvale | Jistič 100 A, vodiče 100 A | Nevztahuje se | 80% (standardní) |

| 50 A trvale + 50 A netrvale | Jistič 125 A [(50×1,25)+50] | Jistič 100 A [50+50] | 80% (jednodušší) |

| 400 A trvale | Jistič 500 A (rám 600 A) | Jistič 400 A (rám 400 A) | 100% (úspora nákladů) |

| Domovní přípojka | Standardní dimenzování dle výpočtu zatížení | Zřídka použitelné | 80% (standardní) |

| Průmyslový přívod | 125 % trvalé části | 100 % pokud je sestava certifikovaná | Analýza případ od případu |

Údržba a provozní aspekty

Pro instalace dimenzované na 80%:

- Platí standardní postupy údržby

- Termovizní snímkování během špičkového zatížení se doporučuje

- Sledovat známky přehřívání na svorkách

- Ověřit, zda se zatížení nezvýšilo nad kapacitu 80%

Pro instalace dimenzované na 100%:

- Ověřit, zda ventilační otvory zůstávají volné

- Potvrdit, že úpravy krytu neohrozily certifikaci

- Kontrolovat dotažení vodičů v intervalech stanovených výrobcem

- Uchovávat dokumentaci o certifikaci sestavy dimenzované na 100%

- Sledovat okolní teplotní podmínky

- Kontrolovat správné proudění vzduchu během provozu

Průmyslové normy a reference

Následující normy a předpisy upravují jmenovité hodnoty a aplikace jističů:

- UL 489: Norma pro bezpečnost lisovaných jističů a krytů jističů

- NFPA 70 (NEC): Národní elektrotechnický předpis, články 210, 215, 230, 430

- CSA C22.2 No. 5: Kanadská asociace pro standardy – Lisované jističe

- IEC 60947-2: Nízkonapěťové spínací a řídicí přístroje – Jističe (mezinárodní reference)

- NEMA AB 1: Lisované jističe a lisované spínače

- IEEE 1584: Průvodce prováděním výpočtů nebezpečí obloukového výboje

Budoucí trendy a vývoj

Elektrotechnický průmysl se neustále vyvíjí a existuje několik trendů, které ovlivňují jmenovité hodnoty jističů:

- Chytré jističe: Možnosti digitálního monitoringu mohou poskytovat tepelnou správu v reálném čase, což by mohlo rozšířit aplikace dimenzované na 100%.

- Vyšší účinnost zařízení: Moderní elektronická zátěž generuje méně tepla, což může snížit potřebu jističů dimenzovaných na 100% v některých aplikacích.

- Integrace obnovitelných zdrojů energie: Solární a bateriové systémy s kontinuálním nabíjením/vybíjením mohou zvýšit poptávku po řešeních dimenzovaných na 100%.

- Růst datových center: Pokračující rozšiřování výpočetních zařízení s vysokou hustotou zvyšuje poptávku po prostorově úsporných sestavách s jmenovitým proudem 100%.

- Harmonizované normy: Probíhající snahy o sladění norem NEC, IEC a dalších mezinárodních norem mohou ovlivnit budoucí metodiky hodnocení.

Klíčové poznatky

- Všechny jističe jsou navrženy tak, aby vedly 100% svého jmenovitého proudu za ideálních podmínek (volný vzduch, okolní teplota 40 °C), ale skutečné instalace v uzavřených prostorech vyžadují snížení jmenovitého proudu pro trvalé zatížení.

- Jističe s jmenovitým proudem 80% vyžadují dimenzování na 125% pro trvalé zatížení podle NEC, což je činí vhodnými pro nepřetržité nebo smíšené aplikace, kde jsou náklady primárním hlediskem.

- Jističe s jmenovitým proudem 100% eliminují penalizaci dimenzování na 125% ale vyžadují specifické konfigurace skříní, správné větrání a vodiče s teplotou 90 °C, aby si udržely svůj jmenovitý proud.

- “Jmenovitý proud 100%” se vztahuje na kompletní sestavu, nejen na samotný jistič – nemůžete jednoduše vyměnit jistič s jmenovitým proudem 80% za jistič s jmenovitým proudem 100% a očekávat výkon 100%.

- Ekonomické výhody jističů s jmenovitým proudem 100% se zvyšují s ampéráží– při 400 A a více často úspory nákladů plynoucí z vyhnutí se další větší velikosti rámu ospravedlňují vyšší náklady na jistič.

- Trvalé zatížení je definováno jako provoz po dobu 3 hodin nebo déle– správné kategorizování zatížení je zásadní pro správný výběr jističe a dodržování předpisů.

- Instalační požadavky pro sestavy s jmenovitým proudem 100% jsou přísné– větrání, specifikace vodičů a velikost skříně musí přesně odpovídat pokynům výrobce.

- Úspora místa může být značná– jističe s jmenovitým proudem 100% umožňují menší velikosti rámu, čímž se zmenšuje půdorys panelu v instalacích s omezeným prostorem.

- Oba typy jističů mají identickou ochranu proti zkratu– rozdíl v jmenovitém proudu ovlivňuje pouze trvalou proudovou zatížitelnost, nikoli vypínací schopnost.

- Dokumentace a certifikace jsou kritické– sestavy s jmenovitým proudem 100% musí být řádně certifikovány NRTL, přičemž certifikační štítky musí být připevněny ke skříni pro schválení inspekcí.

Často Kladené Otázky

Otázka: Mohu použít jistič s jmenovitým proudem 100% ve standardním panelu?

Odpověď: Ne. Jmenovitý proud 100% platí pouze tehdy, když je jistič instalován ve skříni, která byla testována a certifikována jako sestava s jmenovitým proudem 100%. Instalace jističe s jmenovitým proudem 100% v necertifikované skříni znamená, že musí být použit s 80% jmenovitého proudu pro trvalé zatížení.

Otázka: Jsou jističe s jmenovitým proudem 100% spolehlivější než jističe s jmenovitým proudem 80%?

Odpověď: Ne nutně. Oba typy procházejí přísným testováním UL 489 a mají stejnou spolehlivost, pokud jsou správně použity v rámci svých jmenovitých hodnot. Rozdíl je v trvalé proudové zatížitelnosti v uzavřených podmínkách, nikoli v celkové spolehlivosti nebo kvalitě.

Otázka: Potřebuji speciální vodiče pro jističe s jmenovitým proudem 100%?

Odpověď: Ano. NEC vyžaduje vodiče s izolací 90 °C, i když proudová zatížitelnost se vypočítává pomocí sloupce 75 °C v tabulce 310.16 NEC. To zajišťuje, že vodiče zvládnou teplo generované trvalým zatížením 100%.

Otázka: Jak poznám, zda je můj panel certifikován pro provoz s jmenovitým proudem 100%?

Odpověď: Zkontrolujte certifikační štítek NRTL na skříni, který konkrétně uvádí “Certifikováno pro provoz s jmenovitým proudem 100%” nebo podobnou formulaci. Instalační pokyny výrobce také specifikují požadavky na jmenovitý proud 100%. Pokud máte jakékoli pochybnosti, kontaktujte výrobce panelu.

Otázka: Mohu kombinovat jističe s jmenovitým proudem 80% a 100% ve stejném panelu?

Odpověď: Ano, ale každý jistič musí být použit podle svého jmenovitého proudu. Jističe s jmenovitým proudem 100% musí splňovat všechny požadavky na sestavu (větrání, rozestupy atd.), zatímco jističe s jmenovitým proudem 80% se řídí standardními instalačními postupy. Každý obvod musí být dimenzován odpovídajícím způsobem pro svůj typ jističe.

Otázka: Jsou jističe s jmenovitým proudem 100% k dispozici v rezidenčních velikostech (15A-50A)?

Odpověď: Zřídka. Jmenovitý proud 100% je nejběžnější u průmyslových a komerčních jističů 400A a výše. Pod 400A obvykle náklady a složitost sestav s jmenovitým proudem 100% převáží výhody pro typické aplikace. Většina rezidenčních a lehkých komerčních instalací používá standardní jističe s jmenovitým proudem 80%.

Otázka: Co se stane, když trvale přetížím jistič s jmenovitým proudem 80% nad 80%?

Odpověď: Tepelný spouštěcí prvek se nakonec aktivuje a způsobí vypnutí jističe. Časování závisí na stupni přetížení – při trvalém zatížení 100% může jističi s jmenovitým proudem 80% trvat 30–60 minut, než vypne, v závislosti na okolní teplotě a podmínkách skříně. Proto je správné dimenzování kritické pro bezpečnost i provozní spolehlivost.

Otázka: Jsou jističe s jmenovitým proudem 100% nákladnější na údržbu?

Odpověď: Náklady na údržbu jsou obecně podobné, ale instalace s jmenovitým proudem 100% vyžadují dodatečné ověření, že větrání zůstává neomezené a že sestava stále splňuje požadavky na certifikaci. Jakékoli úpravy skříně by mohly zrušit platnost jmenovitého proudu 100%.

Související zdroje

Pro více informací o ochraně obvodů a elektrické distribuci prozkoumejte tyto zdroje VIOX:

- Typy jističů

- Co je to jistič v lisovaném pouzdře (MCCB)

- Jak vybrat MCCB pro panel

- MCB vs MCCB: Pochopení klíčových rozdílů

- Jmenovité hodnoty jističe: ICU, ICS, ICW, ICM

- Pochopení jmenovitého zkratového proudu kA u jističů

- Jak číst štítky MCCB pro elektrickou bezpečnost

O společnosti VIOX Electric

VIOX Electric je přední B2B výrobce elektrických zařízení, specializující se na vysoce kvalitní zařízení pro ochranu obvodů, distribuční zařízení a elektrické komponenty pro průmyslové, komerční a rezidenční aplikace. S desetiletími inženýrských zkušeností a závazkem k bezpečnostním normám poskytuje VIOX spolehlivá řešení pro elektroprofesionály po celém světě.

Pro technickou podporu nebo dotazy k produktům kontaktujte náš inženýrský tým nebo navštivte viox.com.