Почему ваша распределительная коробка ощущается как духовка после шести месяцев эксплуатации?

Вы правильно подобрали автоматические выключатели. Вы в точности следовали расчетам нагрузки NEC. Ваша установка прошла проверку без единого замечания. И все же, шесть месяцев спустя, ваша команда технического обслуживания сообщает, что панель работает на 15°C выше номинальной температуры, вы регистрируете ложные срабатывания во время пиковой нагрузки, а пластиковые компоненты внутри демонстрируют ранние признаки термического напряжения.

Вот что упускают из виду большинство инженеров: У вас была проблема не с автоматическим выключателем. У вас была проблема с панельной сборкой.

Тепловая ловушка, о которой никто не говорит

Традиционные электрические панели - это, по сути, металлические коробки с монтажными рейками. Инженеры одержимы выбором идеального автоматического выключателя - подбором характеристик срабатывания, расчетом селективной координации, проверкой номинальных токов короткого замыкания. Но они относятся к монтажной конструкции как к второстепенной задаче, полагая, что любая металлическая пластина подойдет.

Такое мышление приводит к "тихому убийце" в электрических системах: неадекватное управление теплом на уровне монтажа компонентов.

Когда несколько автоматических выключателей работают одновременно, они выделяют тепло. В обычной панели этому теплу некуда деваться, кроме как накапливаться вокруг самих устройств. выключатели могут быть индивидуально рассчитаны на температуру окружающей среды 40°C, но когда они упакованы в плохо спроектированный корпус без спроектированного воздушного потока, локальная температура окружающей среды может подняться до 60°C или выше. Теперь ваш автоматический выключатель на 100 А фактически работает как автоматический выключатель на 85 А - и ваши тщательно рассчитанные запасы по нагрузке просто исчезли.

⚡ Ключевой вывод: Разница между распределительным щитом, который служит 10 лет, и тем, который служит 30 лет, обычно заключается не в качестве автоматических выключателей, а в качестве того, на чем эти автоматические выключатели установлены.

Что такое панельная сборка в электроснабжении?

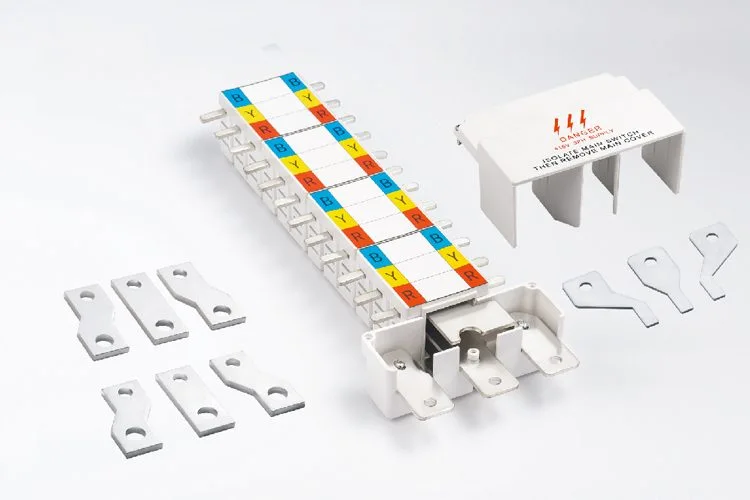

A панельная сборка в электроснабжении - это предварительно спроектированная монтажная конструкция, которая служит интегрированной основой для автоматических выключателей и устройств защиты в распределительных щитах. В отличие от простых монтажных пластин, настоящая панельная сборка объединяет три критические функции в одной стандартизированной системе:

- Механическая поддержка с точными, стандартизированными точками крепления

- Электрическое соединение через интегрированные системы шин

- Управление тепловым режимом посредством спроектированных каналов воздушного потока и путей рассеивания тепла

Представьте себе это так: если ваш распределительный щит - это город, то панельная сборка - это инфраструктура - дороги, коммунальные услуги и система зонирования, все встроенное. Ваши автоматические выключатели - это просто здания, которые подключаются к этой инфраструктуре.

Современные модульные системы панельных сборок (обычно рассчитанные на ток до 250 А для коммерческих применений) развивают эту концепцию, позволяя вам строить вашу систему распределения как конструктор LEGO - каждый компонент предварительно спроектирован для работы с другими, устраняя догадки о совместимости и значительно сокращая время установки.

⚡ Профессиональный совет: Если вы указываете “распределительный щит”, но на ваших чертежах показаны только модели автоматических выключателей без упоминания системы панельной сборки, вы на самом деле не указываете систему - вы просто перечисляете компоненты и надеетесь, что установщик разберется, как заставить их работать вместе.

Понимание модульных систем распределительных щитов с панельной сборкой до 250 А

Здесь технология распределения электроэнергии совершила квантовый скачок, который многие инженеры до сих пор не осознали.

A модульная система распределительного щита с панельной сборкой до 250 А это не просто панель со стандартизированным монтажом - это полная архитектура распределения электроэнергии, разработанная с нуля для:

- Скорости установки: Компоненты, которые защелкиваются за секунды, а не за минуты

- Тепловых характеристик: Спроектированное рассеивание тепла, которое позволяет на 15-20% более высокую плотность цепей, чем в обычных конструкциях

- Гибкости в будущем: Добавляйте цепи без перепрокладки проводов или перепроектирования

- Координация защиты: Предварительно рассчитанные номиналы шин, которые упрощают расчеты селективной координации

Недавно я работал с производственным предприятием, которое заменило три обычные распределительные панели двумя модульными системами панельной сборки. Они не только сэкономили ценную площадь, но и их подрядчик по установке выполнил работу на 40% быстрее, чем было первоначально оговорено. Что еще более важно, тепловизионное обследование через шесть месяцев после установки показало, что рабочие температуры на 12°C ниже, чем у их старых панелей при идентичных нагрузках.

3-шаговый метод выбора правильной системы панельной сборки

Позвольте мне поделиться систематическим подходом, который я использую при спецификации панельных сборок для распределительных щитов. Этот метод спас моих клиентов от дорогостоящего завышения и опасного занижения размеров.

Шаг 1: Сопоставьте вашу нагрузку с архитектурой системы (а не только с токовой нагрузкой)

Большинство инженеров начинают с общего тока и выбирают панель, рассчитанную на значение выше этого числа. Неправильный подход.

Вместо этого начните с отображения вашего профиля нагрузки:

- Сколько ответвлений цепей вам действительно нужно? (Это определяет количество необходимых позиций на панели)

- Какова ваша самая большая одиночная нагрузка? (Это определяет выбор вашей главной вводной панели)

- Каков ваш состав цепей? (Нагрузки с преобладанием освещения и нагрузки с преобладанием двигателей имеют разные тепловые профили)

Для модульной системы панельной сборки вы покупаете не просто токовую нагрузку - вы покупаете позиции, возможности подключения и тепловую мощность как полный пакет.

Пример: Рассчитанная нагрузка в 200 А может идеально вписаться в модульную систему на 250 А с 24 позициями, если у вас в основном освещение и небольшие двигатели. Но та же нагрузка в 200 А с шестью большими частотно-регулируемыми приводами может потребовать систему на 250 А с улучшенными тепловыми характеристиками или принудительной вентиляцией, даже если математика токовой нагрузки говорит, что у вас есть запас в 50 А.

⚡ Ключевой вывод: Общая токовая нагрузка - это только одна треть истории. Количество цепей и плотность тепловой нагрузки имеют такое же значение для надежной работы.

Шаг 2: Проектируйте с учетом тепловой реальности, а не только электрической теории

Здесь качество панельной сборки отделяет профессиональные установки от проблемных.

Вот что вы должны проверить:

- Аудит температуры окружающей среды: Не используйте просто “40°C”, потому что это указано в спецификациях. Пройдитесь по фактическому месту установки. В механических помещениях, на крышах и в зонах рядом с технологическим оборудованием часто бывает жарче. Современные панельные сборки со спроектированным воздушным потоком могут выдерживать более высокие температуры окружающей среды - но только если вы их укажете.

- Оценка вентиляции: Панельные сборки работают за счет создания конвекционных потоков. Если ваш корпус не пропускает воздух снизу и не выпускает его сверху, вы только что превратили свой распределительный щит в герметичную духовку. Я видел установки, где панель была идеальной, но установщик загерметизировал все вентиляционные отверстия, “чтобы не попадала пыль”, создав тепловую катастрофу.

- Планирование плотности цепей: Здесь панельные сборки проявляют себя во всей красе. Спроектированное расстояние и интегрированные пути рассеивания тепла означают, что вы можете безопасно разместить больше цепей, чем предполагает общепринятое мнение - но только если вы учтете это должным образом.

Современные модульные панельные системы обычно имеют:

- Вертикальное расстояние между шинами, которое создает естественные каналы воздушного потока

- Оптимизированные поперечные сечения проводников, которые снижают нагрев I²R

- Тепловые барьеры между сильноточными и чувствительными устройствами

⚡ Профессиональный совет: Запросите исследования тепловизионной съемки у производителя панельной сборки для конфигураций, аналогичных вашей. 5-минутный просмотр тепловых данных стоит часов пересчета - и может показать, что вы можете безопасно увеличить размер своей системы на 15-20% без тепловых проблем.

Шаг 3: Устанавливайте как систему, а не как набор деталей

Самая распространенная причина отказов в распределительных щитах — это не выход из строя компонентов, а отказ соединения. И отказ соединения почти всегда сводится к практике установки.

Три обязательных условия для установки панельной сборки:

- Соблюдение спецификаций по крутящему моменту: Каждая система панельной сборки имеет спецификации по крутящему моменту для соединений шин. Это не просто предложения — это разница между соединением, которое прослужит 20 лет, и соединением, которое выйдет из строя через 18 месяцев. Используйте калиброванный динамометрический ключ. Отмечайте завершенные соединения краской для контроля крутящего момента. Документируйте свою работу.

- Проверка выравнивания шин: Панельные сборки разработаны с точными допусками. Если ваши шины не выровнены в пределах спецификации (обычно ±2 мм), вы создаете точки напряжения, которые в конечном итоге выйдут из строя. Это особенно важно в модульных системах, где панели устанавливаются вертикально.

- Учет теплового расширения: Металл расширяется при нагревании. Качественные панельные сборки разработаны с прорезями для монтажных отверстий и гибкими соединителями шин для учета этого. Если ваша установка препятствует тепловому расширению (слишком затянутые монтажные винты, зажатые шины), вы создаете будущие отказы.

Один промышленный клиент вызвал меня после того, как столкнулся с повторными отказами соединений шин. Проблема была не в панельной сборке, а в установке. Подрядчик использовал ударный гайковерт вместо динамометрического ключа, создавая соединения, которые были либо слишком ослаблены (искрение), либо слишком затянуты (образование трещин). Мы повторно подключили все должным образом, и у них не было ни одной проблемы с соединением в течение трех лет.

⚡ Ключевой вывод: Панельная сборка предоставляет вам платформу для надежности, но качество установки определяет, получите ли вы эту надежность на самом деле. Нельзя пренебрегать спецификациями по крутящему моменту и выравниванию.

Электрическая панель против распределительного щита: понимание критической разницы

Эта путаница стоит инженерам времени и денег на каждом проекте. Давайте проясним это раз и навсегда.

An электрическая панель — это, по сути, защитный корпус — металлический ящик с некоторыми основными приспособлениями для монтажа электрических компонентов. Он может иметь DIN-рейку, монтажные пластины или даже простые шины, но они часто собираются ad-hoc во время установки.

A распределительный щит с панельной сборкой — это полная система распределения электроэнергии, в которой монтажная конструкция, электрическое соединение и управление температурным режимом предварительно спроектированы для работы как единое целое.

Думайте об этом так: электрическая панель — это ящик с инструментами. Распределительный щит с панельной сборкой — это рабочая станция: в ней есть инструменты, но также организация, рабочий процесс и эргономика.

| Характеристика | Базовая электрическая панель | Распределительный щит с панельной сборкой |

|---|---|---|

| Внутренняя структура | Собирается на заказ во время установки | Стандартизированная, предварительно спроектированная панельная система |

| Система шин | Часто базовая или устанавливается на месте | Интегрированная, рассчитанная система шин с определенной пропускной способностью по току |

| Терморегулирование | Пассивная (основана на вентиляции корпуса) | Активная конструкция с каналами воздушного потока и путями отвода тепла |

| Плотность цепей | Ограничена накоплением тепла | На 15-20% выше благодаря терморегулированию |

| Время установки | Зависит от квалификации установщика | Снижается на 30-40% благодаря стандартизации |

| Будущее расширение | Часто требует значительной переделки | Модульное расширение с минимальными нарушениями |

| Координация защиты | Рассчитывается вручную для каждого проекта | Часто поддерживается предварительно разработанными схемами производителя |

На практике я обнаружил, что объекты, использующие надлежащие распределительные щиты с качественными панельными сборками, испытывают примерно на 30% меньше проблем с электричеством в течение срока эксплуатации по сравнению с объектами, использующими базовые панели. Стандартизация снижает человеческий фактор во время установки, а разработанное управление температурным режимом предотвращает медленную деградацию, которая вызывает проблемы спустя годы.

Как рассчитать нагрузку распределительного щита с системами панельной сборки

Здесь большинство расчетов нагрузки упускают возможность.

Традиционные методы расчета нагрузки были разработаны, когда распределительные щиты были простыми ящиками. Они предполагают консервативные тепловые условия, потому что должны — нет инженерных данных, подтверждающих что-либо другое. Но современные системы панельной сборки были термически протестированы и охарактеризованы. Это означает, что вы можете быть более точными в обоих направлениях: обеспечивая достаточную мощность там, где она вам нужна, и не переоценивая там, где она вам не нужна.

Метод расчета нагрузки с 4 факторами для современных систем

Фактор 1: Оценка подключенной нагрузки

- Перечислите каждую цепь с ее максимальным потреблением

- Используйте фактические таблички с данными оборудования, а не общие значения

- Для моторных нагрузок используйте 125% от самого большого двигателя плюс 100% от всех остальных

Фактор 2: Применение коэффициента спроса

- Освещение: обычно 100% для первых 3000 ВА, уменьшаясь для более крупных установок

- Общие розетки: 50-70% в зависимости от характера использования (офис против промышленности)

- Стационарное оборудование: 100%, если мониторинг использования не доказывает обратное

Фактор 3: Интеграция коэффициента разнообразия

- Не все цепи достигают максимума одновременно

- Офисные здания: обычно коэффициент разнообразия 0,6-0,7

- Промышленные объекты: коэффициент разнообразия 0,7-0,8

- Критическая инфраструктура: коэффициент разнообразия 0,9-1,0 (минимальный учет разнообразия)

Фактор 4: Кредит тепловой эффективности панельной сборки

Это то, что упускают большинство инженеров. Качественные системы панельной сборки с документально подтвержденными тепловыми характеристиками могут позволить на 10-20% более высокую эффективную мощность по сравнению с обычными панелями с тем же номиналом.

Почему? Три причины:

- Лучшее рассеивание тепла = более низкие рабочие температуры = устройства работают ближе к своей номинальной мощности

- Разработанное расстояние = уменьшенное тепловое взаимодействие между соседними устройствами

- Оптимизированные пути проводников = более низкие потери I²R = меньше тепловыделения изначально

⚡ Важный совет от профессионала: Не просто добавьте 20% к своим расчетам и считайте, что все готово. Запросите данные о тепловых характеристиках у производителя панельной сборки. Попросите отчеты об испытаниях, показывающие фактический рост температуры под нагрузкой. Используйте эти значения для проверки расчетов мощности. Именно так профессиональные инженеры избегают как недостаточного, так и дорогостоящего избыточного запаса.

Как на самом деле работает распределительный щит с панельной сборкой?

Понимание потока мощности через современный распределительный щит помогает объяснить, почему качество панельной сборки так важно для долгосрочной надежности.

Представьте поток мощности как речную систему:

- Главный ввод (Источник)

- Мощность поступает через панельную сборку главного ввода

- Главный выключатель или переключатель обеспечивает возможность изоляции

- Это ваша “плотина” — контролирующая все, что находится ниже по течению

- Вертикальные шины (Главные каналы)

- Медные или алюминиевые шины предварительно заданного размера распределяют мощность по всему щиту

- Это ваши “реки” — несущие основной поток к точкам распределения

- Размер шин определяет максимальную мощность системы

- Панельные сборки (Распределительная сеть)

- Каждая панельная сборка подключается к вертикальным шинам

- Автоматические выключатели, установленные на панелях, действуют как “контрольные затворы” для отдельных цепей

- Вот критически важная часть: Тепловая конструкция панели определяет, какое количество тепла каждая цепь может безопасно рассеивать

- Координация защиты (Система безопасности)

- Устройства расположены таким образом, что вышестоящие устройства поддерживают нижестоящую защиту

- Это селективная координация — обеспечение изоляции неисправностей на самом низком возможном уровне

- Современные системы часто включают электронные расцепители для точной координации

- Мониторинг и интеллект (Нервная система)

- Все чаще распределительные щиты включают в себя мониторинг качества электроэнергии

- Интеграция с системами управления зданием обеспечивает аналитику в реальном времени

- Это превращает пассивное распределение в активное управление электроэнергией

На одном объекте, с которым я работал, мы перешли от обычных панелей к системам панельной сборки со встроенным мониторингом. Группа технического обслуживания начала получать предупреждения о температуре до того, как компоненты достигли уровней тепловой нагрузки. Время простоя из-за проблем с электрооборудованием сократилось на 60% по сравнению с их предыдущим реактивным подходом к техническому обслуживанию.

⚡ Ключевой вывод: Современные панельные сборки — это не просто монтажные пластины, это слой теплового и электрического управления между вашим источником питания и вашими нагрузками. Сэкономите на этом слое, и пострадает все остальное.

Суть: Почему панельные сборки — ваша лучшая инвестиция в надежность распределения электроэнергии

После работы с сотнями электроустановок я четко увидел закономерность: Качество вашей панельной сборки определяет качество вашего распределения электроэнергии на следующие 20-30 лет.

Вот что обеспечивают качественные системы панельной сборки:

- ✓ 40% более быстрая установка благодаря стандартизированной, модульной конструкции

- ✓ 15-20% более высокая плотность цепей с надлежащим тепловым управлением

- ✓ 30% меньше проблем с электрооборудованием в течение срока эксплуатации

- ✓ Упрощенное будущее расширение без перепроектирования системы

- ✓ Улучшенная координация защиты благодаря предварительно разработанным решениям

- ✓ Более низкую совокупную стоимость владения если учесть время установки, надежность и гибкость

Разница в первоначальной стоимости между базовой панелью и качественной системой панельной сборки обычно составляет 15-25%. Но если учесть экономию времени установки, сокращение времени простоя, упрощение обслуживания и более длительный срок службы, система панельной сборки окупается в течение первых 2-3 лет эксплуатации.

Ваш следующий шаг: При рассмотрении спецификации вашего следующего распределительного щита задайте своему поставщику следующие три вопроса:

- “Каковы документально подтвержденные тепловые характеристики вашей панельной сборки при моем профиле нагрузки?”

- “Покажите мне спецификации крутящего момента при установке и допуски на выравнивание”.”

- “Каков ваш послужной список для установок со сроком службы более 20 лет — могу ли я поговорить с клиентом, который может дать рекомендацию?”

Если они не могут уверенно ответить на эти вопросы, вы покупаете не систему, а детали в коробке.