What You Need to Know About Electrical Control Panels

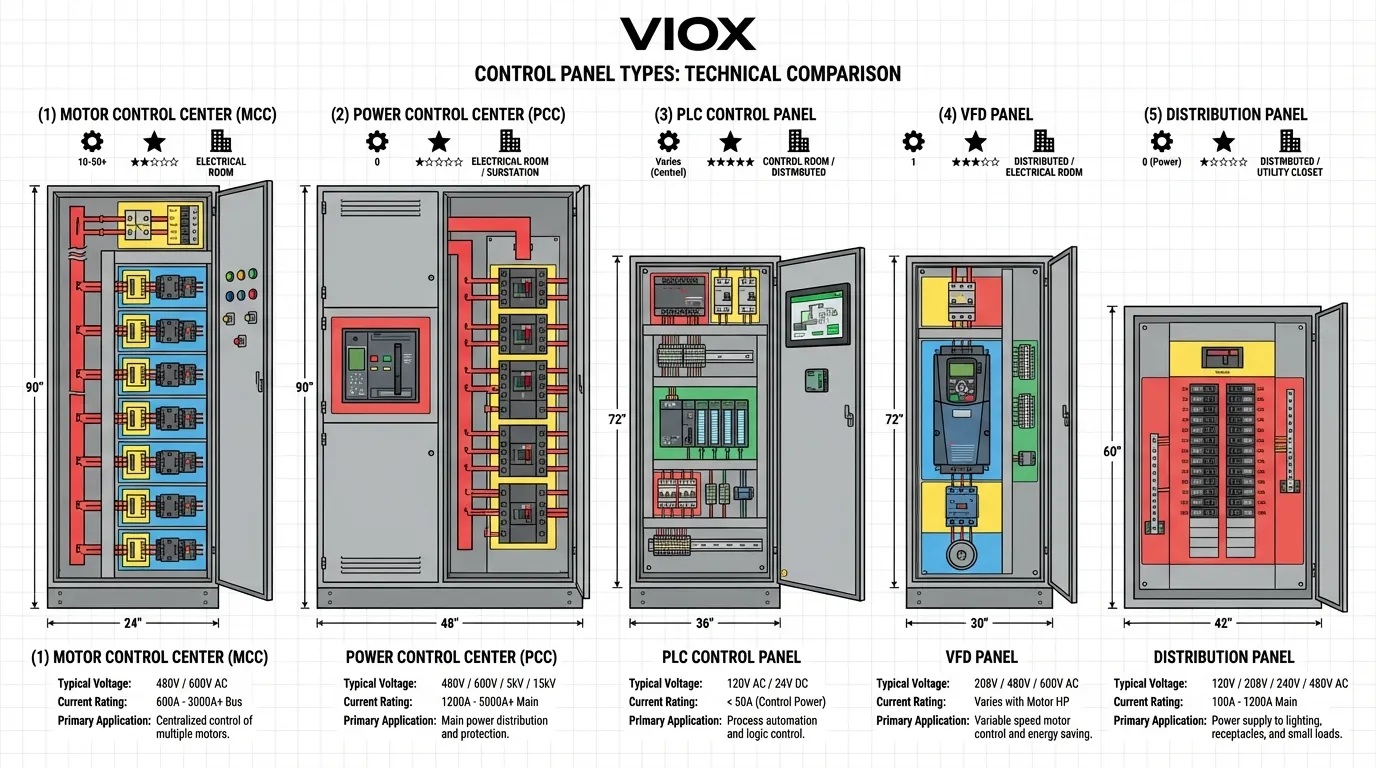

Electrical control panels are the central nervous system of industrial operations, housing the critical components that distribute power, protect equipment, and automate processes. From Motor Control Centers (MCCs) managing dozens of motors to sophisticated PLC enclosures orchestrating complex automation sequences, selecting the right panel type directly impacts operational efficiency, safety compliance, and long-term maintenance costs. This guide examines seven essential control panel types—MCC, PCC, PLC, VFD, distribution panels, custom control panels, and smart integrated systems—with technical specifications, application criteria, and selection frameworks based on IEC 60947, UL 508A, and NEC Article 409 standards.

Основные выводы

- Центры управления двигателями (ЦУД) centralize control of multiple motors through modular bucket designs, ideal for facilities with 10+ motors requiring coordinated operation

- Power Control Centers (PCCs) handle high-current distribution (800A-6300A) and serve as the primary power interface between utility supply and facility loads

- Панели управления ПЛК house programmable logic controllers and I/O modules for process automation, requiring careful consideration of environmental ratings and communication protocols

- VFD Panels provide energy-efficient motor speed control with potential energy savings of 20-50% in variable-torque applications

- Критерии выбора must balance electrical specifications (voltage, current, SCCR), environmental factors (IP ratings, temperature), automation requirements, and compliance with UL 508A or IEC 61439 standards

- Smart control panels integrate IoT connectivity and predictive maintenance capabilities, representing the evolution toward Industry 4.0 manufacturing environments

Understanding Electrical Control Panel Fundamentals

An electrical control panel is an engineered assembly that houses electrical components—автоматические выключатели, контакторы, реле, PLCs, and monitoring devices—within a protective enclosure. These panels serve three primary functions: power distribution to connected loads, equipment protection through overcurrent and fault detection, and process control through manual or automated switching logic.

Modern industrial facilities typically deploy multiple panel types in a hierarchical architecture. A Power Control Center receives utility power and distributes it to downstream Motor Control Centers, which in turn feed individual machines or process areas. PLC panels interface with these power systems to provide supervisory control and data acquisition (SCADA) capabilities. цитата

The distinction between panel types often blurs in practice. A single enclosure might combine MCC functionality with integrated VFDs and PLC control, creating a hybrid system optimized for specific applications. Understanding the core characteristics of each panel type enables engineers to specify systems that balance functionality, cost, and future expandability.

Motor Control Centers (MCC): Centralized Motor Management

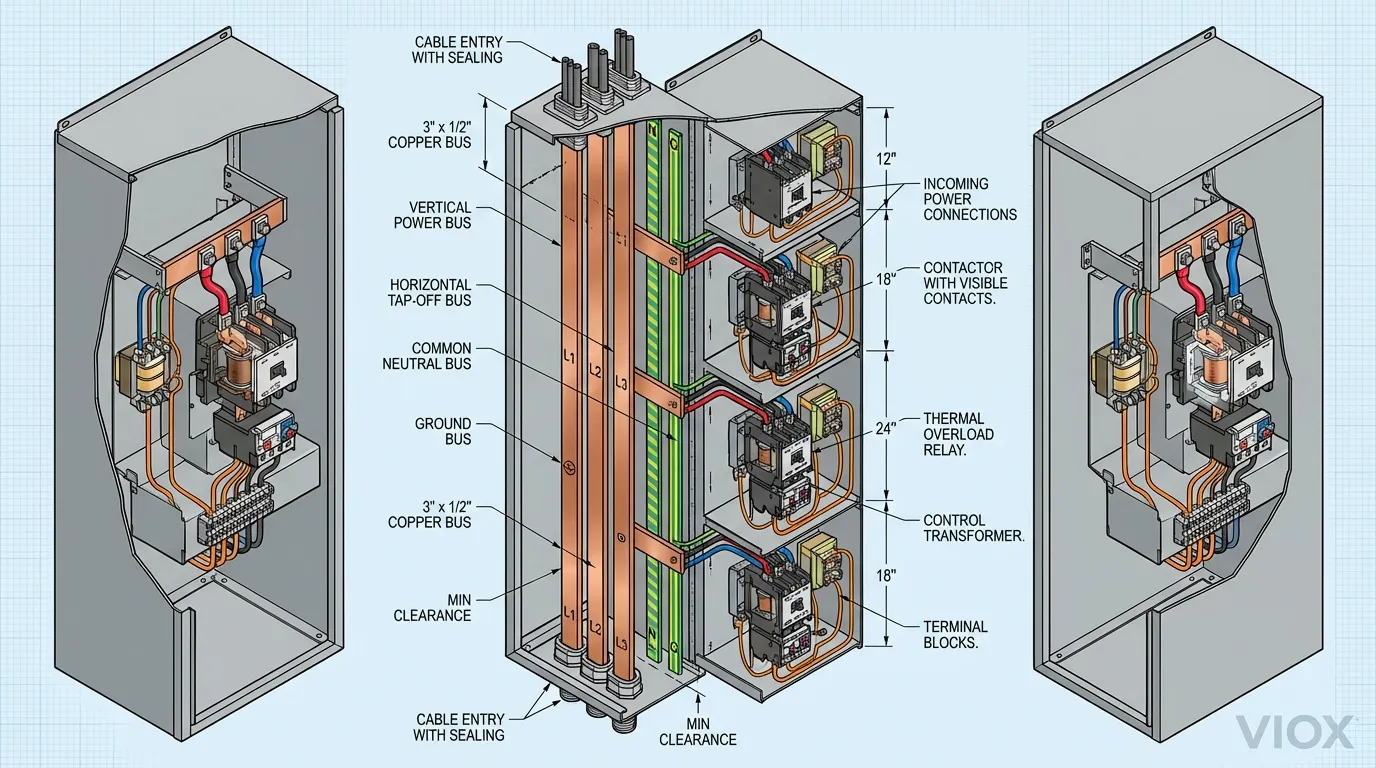

Motor Control Centers represent the most common solution for facilities operating multiple electric motors. An MCC consists of a vertical assembly with a common horizontal power bus feeding individual motor control units housed in removable “buckets” or fixed compartments. This modular architecture allows independent control, protection, and isolation of each motor circuit while maintaining centralized power distribution.

MCC Architecture and Components

The typical MCC structure includes a vertical power bus rated from 600A to 6000A, with horizontal tap-off buses feeding individual motor starters. Each motor control unit contains a combination starter assembly: a контактор for switching, thermal overload relay for motor protection, disconnect means for isolation, and control circuitry for local or remote operation. Modern MCCs commonly integrate variable frequency drives, soft starters, and solid-state motor protection relays within the same bucket structure.

MCC designs follow either IEC 61439 or UL 845 standards depending on regional requirements. The choice between fixed-mounted and drawout bucket designs impacts maintenance accessibility and replacement costs. Drawout designs allow hot-swapping of motor control units without de-energizing adjacent circuits, but command a 30-40% price premium over fixed installations.

MCC Application Criteria

MCCs excel in applications requiring centralized control of 10 or more motors, particularly when motors operate independently rather than as coordinated machine sequences. Typical installations include water treatment plants with multiple pump motors, HVAC systems serving large commercial buildings, material handling systems with distributed conveyor drives, and manufacturing facilities with numerous process machines.

The decision to specify an MCC versus individual motor control panels hinges on several factors. MCCs offer superior space efficiency—a single 90-inch tall section can house 6-12 motor starters compared to equivalent wall-mounted individual panels. Centralized installation simplifies power distribution and reduces installation labor by 40-60% compared to distributed panels. However, MCCs require dedicated electrical rooms with appropriate clearances per NEC 110.26, making them less suitable for facilities with distributed equipment layouts.

MCC Selection Specifications

| Спецификация | Типичный диапазон | Критерии отбора |

|---|---|---|

| Bus Rating | 600A – 6000A | Size based on sum of motor FLAs plus 25% growth margin |

| Номинальное напряжение | 208V – 690V AC | Match facility distribution voltage |

| Short Circuit Rating | 35kA – 100kA | Должна превышать доступный ток короткого замыкания в точке установки |

| Bucket Size | NEMA Size 1-5 | Determined by largest motor starter required |

| Enclosure Type | NEMA 1, 3R, 12 | Based on environmental conditions |

| Напряжение управления | 120V AC, 24V DC | Standardize across facility for maintenance efficiency |

When specifying MCCs, engineers must calculate the Short Circuit Current Rating (SCCR) using series-rated or fully-rated methodologies. The SCCR represents the maximum fault current the MCC can safely interrupt without catastrophic failure. Underestimating SCCR creates life-safety hazards and violates NEC Article 409 requirements. цитата

Power Control Centers (PCC): High-Current Distribution Hubs

Power Control Centers function as the primary power distribution interface between utility supply and facility electrical systems. While MCCs focus on motor control, PCCs emphasize power distribution, metering, and main circuit protection. A typical PCC receives power from a utility transformer or on-site generation source and distributes it to multiple downstream panels—MCCs, distribution boards, and large individual loads.

PCC Design Characteristics

PCCs typically feature bus ratings from 800A to 6300A with main circuit breakers or fused disconnect switches providing overcurrent protection. The internal architecture includes metering sections with current transformers and potential transformers for power monitoring, main distribution sections with high-capacity breakers, and feeder sections distributing power to downstream panels.

Modern PCCs increasingly incorporate power quality monitoring, harmonic filtering, and power factor correction equipment. These integrated systems address power quality issues at the source rather than requiring distributed correction equipment throughout the facility. Advanced PCCs may include automatic transfer switch (ATS) functionality for facilities with backup generation, seamlessly transferring loads between utility and generator power sources. цитата

PCC vs MCC: Functional Distinction

The primary distinction between PCCs and MCCs lies in their functional purpose and internal components. PCCs distribute bulk power and provide main circuit protection but typically don’t include individual motor control devices. MCCs receive power from PCCs and provide dedicated motor starting and protection for multiple motors. A facility might have one or two PCCs feeding five to ten MCCs distributed throughout the plant.

| Характеристика | Power Control Center (PCC) | Центр управления двигателем (MCC) |

|---|---|---|

| Основная функция | Power distribution and metering | Управление и защита двигателя |

| Bus Rating | MCCB в сравнении с другими автоматическими выключателями: Полное сравнение | 600A – 6000A |

| Main Components | Main breakers, feeders, metering | Motor starters, contactors, overloads |

| Typical Sections | 2-6 vertical sections | 4-20 vertical sections |

| Downstream Loads | MCCs, distribution panels, large equipment | Individual motors (0.5-500 HP) |

| Сложность управления | Minimal (switching only) | Moderate to high (start/stop logic) |

PLC Control Panels: The Brain of Automated Systems

Programmable Logic Controller (PLC) panels house the industrial computers that execute automation logic, process sensor inputs, and command output devices. Unlike MCCs that provide power switching for motors, PLC panels focus on control logic, data processing, and communication with field devices and supervisory systems.

PLC Panel Architecture

A typical PLC panel contains the PLC processor module, input/output (I/O) modules for interfacing with field devices, power supplies providing 24V DC control power, communication modules for networking, and a human-machine interface (HMI) for operator interaction. The panel also includes circuit protection for the PLC system, typically миниатюрных автоматических выключателей rated 2-10A, and устройства защиты от перенапряжения to guard against transient overvoltages.

Modern PLC panels increasingly incorporate distributed I/O architectures using industrial Ethernet protocols—EtherNet/IP, PROFINET, or Modbus TCP. This approach reduces panel wiring complexity by locating I/O modules near field devices rather than centralizing all I/O in the main control panel. The PLC panel then serves primarily as the processor and communication hub rather than a wiring termination point.

PLC Panel vs MCC Integration

PLC panels and MCCs serve complementary functions in industrial automation. The PLC panel contains the intelligence—executing ladder logic programs that determine when motors should start or stop based on process conditions. The MCC provides the power switching capability—the contactors and motor starters that actually energize motors. The two systems interconnect through control wiring, with the PLC providing start/stop commands to MCC motor starters and receiving status feedback (running, tripped, fault conditions).

Many modern installations integrate PLC functionality directly into MCC structures, creating “smart MCCs” that combine power distribution and control logic in a single assembly. This integration reduces installation costs and improves response times by eliminating control wiring between separate panels. However, it also increases complexity and may complicate troubleshooting when electrical and control issues occur simultaneously.

PLC Panel Design Standards

PLC panels must comply with UL 508A (North America) or IEC 61439-1 (international) standards for industrial control panels. These standards specify requirements for conductor sizing, overcurrent protection, grounding, and environmental ratings. Additionally, PLC panels often must meet functional safety standards—IEC 61508 or ISO 13849—when controlling safety-critical processes.

The environmental rating significantly impacts PLC panel design. Standard NEMA 1 or IP20 enclosures suffice for climate-controlled electrical rooms. Harsh environments require NEMA 4X or IP66 rated enclosures with sealed cable entries, internal climate control, and corrosion-resistant materials. PLC components themselves typically operate within 0-55°C ambient temperatures, necessitating active cooling in hot environments or heated enclosures in cold climates.

Variable Frequency Drive (VFD) Panels: Energy-Efficient Motor Control

Variable Frequency Drive panels house the power electronics that control AC motor speed by varying the frequency and voltage supplied to the motor. VFDs enable precise speed control, soft starting to reduce mechanical stress, and significant energy savings in variable-torque applications like pumps and fans.

VFD Panel Components and Considerations

A VFD panel contains the VFD itself (rectifier, DC bus, and inverter sections), input circuit protection (автоматические выключатели or fuses), output contactors for motor isolation, and EMI/RFI filtering to reduce electromagnetic interference. VFDs generate substantial heat—typically 3-5% of rated power dissipates as heat within the drive—requiring careful thermal management through ventilation, heat sinks, or active cooling.

VFD installations must address harmonic distortion introduced into the electrical system. Six-pulse VFDs (the most common type) generate significant 5th and 7th harmonic currents that can cause transformer overheating, neutral conductor overloading, and interference with sensitive electronic equipment. Solutions include line reactors, DC bus choke coils, or active harmonic filters. Facilities with multiple VFDs should conduct harmonic analysis to ensure total harmonic distortion remains below 5% per IEEE 519 recommendations.

VFD Panel Application Benefits

VFDs deliver compelling benefits in appropriate applications. Centrifugal pumps and fans exhibit cubic relationship between speed and power consumption—reducing speed by 20% cuts power consumption by approximately 50%. This characteristic enables dramatic energy savings in variable-flow applications. Additionally, VFDs eliminate mechanical starting stress, extending motor and driven equipment life by 30-50% compared to across-the-line starting.

However, VFDs aren’t universally beneficial. Constant-speed applications gain no energy savings from VFD control. The VFD itself consumes 2-3% of rated power even at full speed, creating a net energy loss compared to direct motor connection. VFDs also introduce motor bearing currents that can cause premature bearing failure unless mitigated through insulated bearings, shaft grounding, or filtered output reactors. цитата

| Тип приложения | VFD Benefit | Energy Savings Potential |

|---|---|---|

| Variable-torque (pumps, fans) | Высокий | 20-50% typical |

| Constant-torque (conveyors, extruders) | Умеренный | 5-15% typical |

| Constant-speed (fixed-speed processes) | Низкий | 0-5% (may be negative) |

| High-inertia loads (flywheels, crushers) | Умеренный | 10-25% typical |

Distribution Panels: Circuit-Level Power Distribution

Distribution panels—also called panelboards or load centers—provide the final level of power distribution, breaking bulk power into individual branch circuits feeding lights, receptacles, and small equipment. While MCCs and PCCs handle high-power distribution, distribution panels focus on circuit-level protection and distribution for lower-power loads.

Distribution Panel Structure

A typical distribution panel contains a main circuit breaker (or main lugs for feed-through applications), a bus bar distributing power to branch positions, and branch circuit breakers protecting individual circuits. Panel ratings range from 100A to 600A, with 120/208V or 277/480V three-phase configurations most common in commercial and industrial applications.

Modern distribution panels increasingly incorporate устройства защиты от перенапряжения to guard against transient overvoltages from lightning or switching events. Type 2 SPDs installed at distribution panels provide secondary protection for sensitive electronic loads, complementing СПД типа 1 installed at service entrance equipment.

Distribution Panel vs MCC Applications

Distribution panels and MCCs serve different load profiles. MCCs excel at motor control—starting, stopping, and protecting motors from overload and fault conditions. Distribution panels focus on lighting, receptacles, small motors (under 2 HP), and electronic equipment. A facility typically has far more distribution panels than MCCs, with distribution panels located throughout the building near the loads they serve.

The selection between a distribution panel and MCC for motor loads depends on motor size and control requirements. Motors under 2 HP typically connect to distribution panel branch circuits with manual motor starters. Motors from 2-10 HP might use either approach depending on control complexity. Motors above 10 HP almost always justify MCC installation due to the higher current requirements and need for coordinated control with other equipment. цитата

Custom Control Panels: Application-Specific Solutions

Custom control panels address unique requirements that standard MCC, PLC, or distribution panel configurations cannot efficiently accommodate. These engineered assemblies integrate power distribution, motor control, PLC logic, operator interfaces, and specialized equipment into purpose-built enclosures optimized for specific machines or processes.

Custom Panel Design Drivers

Several factors drive custom panel specifications. Machine builders often require integrated control panels combining motor control, PLC logic, safety circuits, and operator interface in a compact enclosure mounted directly on the machine. Process industries may need explosion-proof panels meeting NFPA 496 or IEC 60079 standards for hazardous locations. Retrofit applications might require custom panels matching existing equipment interfaces and footprints.

Custom panels offer maximum flexibility but require careful engineering to ensure compliance with UL 508A or IEC 61439 standards. The panel designer must calculate SCCR, verify conductor ampacity, coordinate overcurrent protection, and document the design through comprehensive electrical schematics. Many jurisdictions require third-party certification (UL, ETL, CSA) for custom control panels, adding cost and lead time compared to standard MCC or distribution panel products.

Custom Panel vs Standard MCC Economics

The economic breakpoint between custom panels and standard MCCs occurs around 6-8 motor control circuits. Below this threshold, custom panels often prove more cost-effective due to reduced footprint and elimination of unused MCC bucket positions. Above this threshold, MCC modularity and standardized components typically offer better value.

However, economics alone shouldn’t drive the decision. Custom panels excel when tight integration between control and power components is critical, when space constraints prohibit standard MCC dimensions, or when specialized environmental requirements (wash-down, corrosive atmospheres, extreme temperatures) necessitate custom enclosure designs.

Smart Control Panels: Industry 4.0 Integration

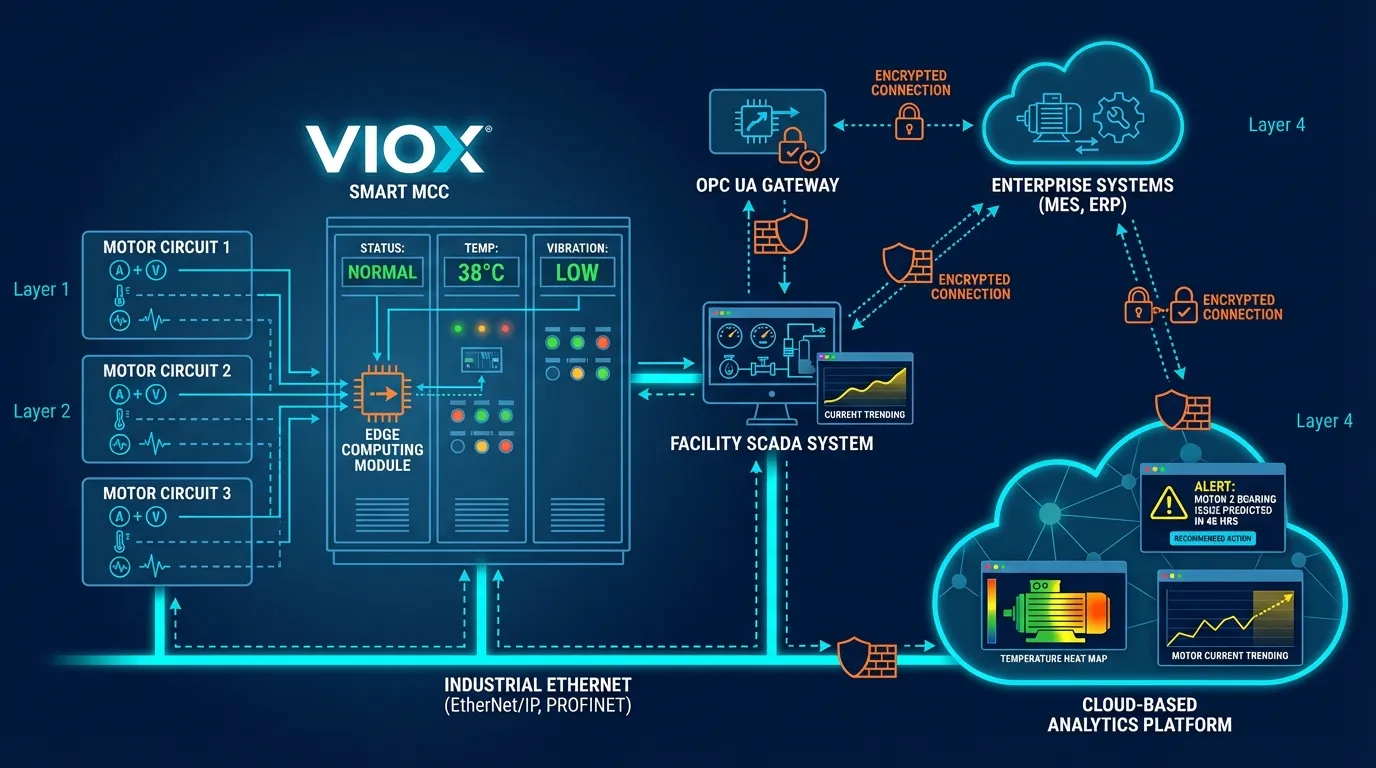

Smart control panels represent the evolution of traditional control systems toward Industry 4.0 connectivity and predictive maintenance. These advanced panels integrate IoT sensors, edge computing, and cloud connectivity to provide real-time performance monitoring, predictive failure analysis, and remote diagnostics.

Smart Panel Capabilities

Modern smart MCCs and control panels incorporate current and voltage monitoring at individual motor circuits, thermal monitoring of critical components, and vibration analysis for rotating equipment. This data feeds into analytics platforms that detect anomalies indicating impending failures—bearing wear, insulation degradation, or mechanical misalignment—enabling condition-based maintenance rather than time-based preventive maintenance schedules.

Communication protocols form the backbone of smart panel functionality. Industrial Ethernet standards (EtherNet/IP, PROFINET, Modbus TCP) provide high-speed, deterministic communication between panel components and supervisory systems. OPC UA (Open Platform Communications Unified Architecture) enables secure, standardized data exchange between control systems and enterprise IT systems, bridging the traditional operational technology (OT) and information technology (IT) divide.

Smart Panel Implementation Considerations

Implementing smart control panels requires careful cybersecurity planning. Connected panels create potential attack vectors for malicious actors seeking to disrupt operations or steal intellectual property. Defense-in-depth strategies—network segmentation, authentication, encryption, and intrusion detection—are essential for protecting industrial control systems from cyber threats.

The data volume generated by smart panels can overwhelm traditional control systems. A single smart MCC monitoring 50 motors might generate 100,000 data points per minute. Edge computing—processing data locally within the panel rather than transmitting everything to central servers—reduces network bandwidth requirements and enables real-time response to critical conditions.

Control Panel Selection Framework

Selecting the appropriate control panel type requires systematic evaluation of electrical requirements, environmental conditions, control complexity, and future expansion needs. The following framework guides this decision process.

Electrical Specification Analysis

Begin by documenting all electrical loads the panel must serve: motor horsepower and voltage, lighting and receptacle loads, control power requirements, and any specialized equipment. Calculate total connected load, demand factors per NEC Article 220, and required bus ampacity with 25% growth margin. Determine available fault current at the installation point to specify appropriate SCCR ratings. цитата

Экологическая оценка

Evaluate the installation environment against NEMA or IP rating requirements. Indoor, climate-controlled electrical rooms typically require only NEMA 1 (IP20) enclosures. Outdoor installations need NEMA 3R (IP24) minimum for weather protection. Wash-down areas, corrosive atmospheres, or dusty environments may necessitate NEMA 4X (IP66) stainless steel enclosures with sealed cable entries and internal climate control. цитата

Control Complexity Evaluation

Assess control requirements along a spectrum from simple manual switching to complex automated sequences. Manual motor control with local start/stop stations suggests individual motor control panels or basic MCC installations. Coordinated multi-motor sequences with interlocking and process feedback indicates PLC control panel requirements. Safety-critical applications requiring redundant control systems and certified safety functions demand specialized safety PLC panels meeting IEC 61508 SIL ratings.

Panel Type Selection Matrix

| Load Profile | Сложность управления | Рекомендуемый тип панели | Ключевые соображения |

|---|---|---|---|

| 10+ motors, independent operation | Manual to moderate | Центр управления двигателем (MCC) | Centralized location, dedicated electrical room required |

| High-current distribution (>800A) | Минимум | Power Control Center (PCC) | Service entrance location, utility coordination |

| Process automation, multiple I/O | Высокий | PLC Control Panel | Network architecture, HMI requirements |

| Variable-speed motors | Умеренный | VFD Panel | Harmonic mitigation, thermal management |

| Lighting, receptacles, small motors | Низкий | Распределительная панель | Distributed locations, surge protection |

| Machine-specific integration | Переменная | Custom Control Panel | Space constraints, specialized requirements |

| Predictive maintenance, remote monitoring | Высокий | Smart Control Panel | Cybersecurity, data infrastructure |

Стандарты и требования соответствия

Control panel design and installation must comply with multiple overlapping standards depending on jurisdiction, application, and end-user requirements. Understanding these standards is essential for specifying compliant systems.

Североамериканские стандарты

UL 508A—Standard for Industrial Control Panels—governs control panel construction in the United States and Canada. This standard specifies requirements for conductor sizing, overcurrent protection, grounding, short circuit current rating, and enclosure integrity. Panels bearing UL 508A listing have been evaluated by Underwriters Laboratories and meet these requirements.

NEC Article 409—Industrial Control Panels—establishes installation requirements including working clearances, disconnecting means, and marking requirements. Article 430 covers motor control circuits, while Article 440 addresses air conditioning and refrigeration equipment. Compliance with NEC is enforced by local authorities having jurisdiction (AHJs) through permit and inspection processes.

Международные стандарты

IEC 61439-1 and -2 establish requirements for low-voltage switchgear and control gear assemblies in international markets. These standards define type-tested assemblies (fully tested by the original manufacturer) and partially type-tested assemblies (using tested components in new configurations). IEC 60947 series standards cover individual components—circuit breakers, contactors, and motor starters—used within control panels.

IEC 60204-1—Safety of Machinery: Electrical Equipment of Machines—applies specifically to control panels integrated with machinery. This standard addresses emergency stop circuits, control circuit design, and operator interface requirements to ensure machine safety.

Harmonization and Transition

Recent efforts have harmonized North American and international standards. UL 60947-4-1 replaces the older UL 508 standard for motor starters and contactors, aligning with IEC 60947-4-1. This harmonization simplifies global product development and reduces testing requirements for manufacturers serving both markets. However, differences remain in installation practices, with NEC and IEC standards taking different approaches to conductor sizing, overcurrent protection coordination, and enclosure ratings.

Вопросы и ответы

В чем основное различие между панелью управления MCC и ПЛК?

Центр управления двигателями (MCC) обеспечивает коммутацию и защиту питания для нескольких двигателей с помощью контакторов и пускателей двигателей, в то время как панель управления ПЛК содержит программируемый логический контроллер, который выполняет логику автоматизации и командует MCC, когда запускать или останавливать двигатели. MCC управляет распределением питания; ПЛК управляет логикой управления. Многие современные установки интегрируют обе функции в интеллектуальные MCC, объединяя питание и управление в едином узле.

Как определить правильный номинал SCCR для моей панели управления?

Номинальный ток короткого замыкания (SCCR) должен быть равен или превышать доступный ток короткого замыкания в точке установки панели. Рассчитайте доступный ток короткого замыкания, используя данные об импедансе трансформатора энергоснабжающей организации и импедансе проводника от трансформатора до панели. SCCR может быть определен с помощью последовательно соединенных комбинаций (с использованием протестированных комбинаций вышестоящих и нижестоящих защитных устройств) или методов с полной номинальной мощностью (где каждое устройство может прервать полный ток короткого замыкания). Квалифицированный инженер-электрик должен выполнять эти расчеты, поскольку ошибки создают угрозу безопасности для жизни. цитата

Когда следует выбирать панель частотно-регулируемого привода (VFD) вместо стандартного пускателя двигателя MCC?

Выбирайте панели с частотно-регулируемым приводом (VFD) для применений, требующих регулирования скорости или когда двигатели работают на пониженных скоростях в течение длительного времени. Нагрузки с переменным крутящим моментом (насосы, вентиляторы) обеспечивают наибольшую экономию энергии — обычно 20-50% в приложениях с переменным расходом. Приложения с постоянной скоростью не получают никакой выгоды от VFD с точки зрения экономии энергии и могут испытывать чистые потери энергии из-за потерь при преобразовании в VFD. Также рассмотрите VFD для плавного пуска нагрузок с высокой инерцией, чтобы снизить механическое напряжение и продлить срок службы оборудования.

Какой класс защиты (NEMA/IP) необходим для моей панели управления?

Внутренние электрощитовые с контролируемым климатом обычно требуют панели NEMA 1 (IP20). Для наружных установок требуется минимум NEMA 3R (IP24) для защиты от атмосферных воздействий. Зоны промывки требуют NEMA 4X (IP66) с герметичными кабельными вводами. Для опасных зон требуются взрывозащищенные (Class I Division 1) или продуваемые/герметизированные корпуса в соответствии с NFPA 496. В коррозионных средах может потребоваться конструкция из нержавеющей стали независимо от рейтинга NEMA. Проконсультируйтесь с эксплуатационным персоналом объекта, чтобы понять процедуры очистки, условия окружающей среды и любое воздействие химических веществ.

Допустимо ли смешивать компоненты IEC и NEMA в одной и той же панели управления?

Да, но с тщательным вниманием к номинальным характеристикам и координации. Компоненты IEC и NEMA используют разные методологии определения номинальных характеристик — категории использования IEC (AC-3, AC-4) против размеров NEMA (1, 2, 3). Убедитесь, что все компоненты соответствуют требуемым электрическим характеристикам для вашего применения. Для панелей, сертифицированных по UL 508A, все компоненты должны быть признаны или сертифицированы UL. Разработчик панели должен проверить надлежащую координацию между защитными устройствами независимо от стандарта номинальных характеристик. Многие производители теперь предлагают продукты, соответствующие стандартам IEC и NEMA, что упрощает спецификацию.

Сколько места мне следует выделить для центра управления двигателями?

Физические размеры MCC (центра управления двигателями) варьируются в зависимости от производителя, но обычно составляют 50-75 см в глубину, 230 см в высоту и 50-60 см в ширину на вертикальную секцию. Типовая установка может потребовать 4-8 секций (200-480 см в ширину). Добавьте необходимые рабочие зазоры NEC (Национального электротехнического кодекса): минимум 90 см перед MCC, 75 см ширины по центру оборудования и 200 см высоты. Для MCC с напряжением свыше 600 В зазоры увеличиваются в зависимости от напряжения и доступного тока короткого замыкания согласно таблице 110.26(A)(1) NEC.

What’s the difference between a PCC and a distribution panel?

Power Control Centers (PCCs) handle high-current distribution (800A-6300A) at the facility level, receiving power from utility transformers and distributing to multiple downstream panels. Distribution panels provide circuit-level distribution (100A-600A) for lighting, receptacles, and small equipment. PCCs typically include extensive metering and main circuit protection; distribution panels focus on branch circuit protection. Think of PCCs as primary distribution and distribution panels as secondary distribution in the electrical hierarchy.

Do I need a custom control panel or will a standard MCC work?

Standard MCCs work well for facilities with multiple motors requiring independent control, where centralized installation in an electrical room is feasible. Choose custom panels when: (1) space constraints prohibit standard MCC dimensions, (2) tight integration between power and control components is critical, (3) specialized environmental requirements exceed standard NEMA ratings, or (4) the application requires fewer than 6-8 motor control circuits where custom panels prove more economical than partially-filled MCCs.

What maintenance do control panels require?

Annual maintenance should include: visual inspection for loose connections and signs of overheating, thermal imaging to detect hot spots indicating high resistance connections, verification of proper ventilation and cooling system operation, testing of emergency stop circuits and safety interlocks, and cleaning of dust and debris. Quarterly inspections suffice for critical systems. Document all maintenance activities and trending data to enable predictive maintenance. Replace components showing signs of degradation before failure occurs.

How do smart control panels improve operations?

Smart panels provide real-time monitoring of current, voltage, power, and equipment health parameters. This data enables predictive maintenance—detecting bearing wear, insulation degradation, or mechanical issues before catastrophic failure occurs. Remote diagnostics reduce troubleshooting time by 40-60% compared to traditional panels. Energy monitoring identifies inefficient equipment and validates energy savings initiatives. However, smart panels require robust cybersecurity measures and data infrastructure to realize these benefits without creating operational vulnerabilities.