The Monday Morning Catastrophe

It’s 6:47 AM on Monday, and your phone is already ringing. The plant manager’s voice is tight with panic: “The main production line is down. The VFD is completely fried—circuit boards are black, and there’s a burnt smell throughout the electrical room.”

You rush to the site. Weekend thunderstorms rolled through, and a nearby lightning strike sent a massive surge through the facility’s power system. As you stare at the charred remains of a $52,000 variable frequency drive, you notice something that makes your stomach drop: there’s a surge protector installed right there in the panel—a $300 device that was supposed to prevent exactly this disaster.

But it didn’t work. The equipment died anyway.

The plant manager asks the question you’re dreading: “I thought we installed surge protection last year. Why didn’t it work? And how do we make sure this never happens again?”

Why “Installing a Surge Protector” Isn’t Enough

Here’s the brutal truth that most engineers learn the expensive way: Not all surge protective devices (SPDs) are created equal, and installation alone doesn’t guarantee protection.

The SPD that failed to protect your VFD? After investigation, you discover three critical mistakes:

- Wrong voltage rating – The SPD’s maximum continuous working voltage (Uc) was 385V, but transient overvoltages in your system regularly spike to 420V during motor starting, causing the SPD to degrade prematurely

- Insufficient discharge capacity – The SPD was rated for 40 kA (Imax), but the installation location—near the service entrance in an industrial facility with overhead lines—needed 100 kA to handle lightning-induced surges

- Poor protection distance – The SPD was mounted at the main distribution panel 150 feet away from the VFD, allowing induced voltages to develop along the cable run and bypass the protection entirely

Each mistake alone could compromise protection. Together, they guaranteed failure.

The core problem? SPD selection isn’t about buying “a surge protector”—it’s about engineering a protection system that matches your specific application parameters. Miss even one parameter, and you’re gambling with six-figure equipment.

Principais conclusões: An SPD can only protect what it’s properly rated and positioned to protect. Wrong ratings or installation location = zero protection, regardless of brand name or price tag. The selection process matters more than the product itself.

The Solution: Master the 6-Parameter Selection Method

The answer isn’t complicated, but it requires a systematic approach. Professional electrical engineers use a 6-step method based on IEC and GB/T standards that considers voltage ratings, discharge capacity, protection levels, and system coordination. This isn’t guesswork—it’s engineering.

Here’s what this method delivers:

- Match SPD ratings to actual system conditions – not generic “industrial” specs

- Prevent nuisance tripping that shuts down production

- Coordinate multiple protection stages without complex spacing calculations

- Extend SPD lifespan by selecting appropriate discharge ratings

- Pass inspection with properly documented protection engineering

Let’s break down the six-step process that ensures your SPD actually protects equipment instead of giving you false confidence.

Step 1: Calculate the Four Critical Voltage and Current Parameters

Most engineers start SPD selection by asking “what kA rating do I need?” Wrong starting point. You must first establish the voltage environment, then determine discharge capacity.

Parameter 1: Maximum Continuous Working Voltage (Uc) – Your First Line of Defense

What it is: The highest RMS voltage the SPD can withstand continuously without degrading or failing.

Why it matters: If your system voltage exceeds Uc—even momentarily during normal operations—the SPD begins to fail. This isn’t a surge event; this is regular system voltage killing your protection.

How to calculate it correctly:

For a 400V three-phase system (phase-to-neutral = 230V):

- Minimum Uc required: System voltage × 1.1 = 230V × 1.1 = 253V minimum

- Recommended Uc: System voltage × 1.15 to 1.2 = 230V × 1.2 = 276V recommended

The mistake engineers make: Selecting an SPD with Uc = 255V for a 230V system seems adequate on paper, but transient overvoltages (TOVs) during capacitor switching or ground faults can push system voltage to 250V for several seconds. Your SPD is now operating at its absolute limit during what should be routine operations.

Pro-Tip: Always select Uc at least 15-20% above your nominal system voltage. For 230V systems, choose Uc ≥ 275V. For 480V systems (277V phase-to-neutral), choose Uc ≥ 320V. This margin accounts for TOVs and extends SPD lifespan dramatically.

Parameter 2: Temporary Overvoltage Withstand (UT) – Surviving System Faults

What it is: The SPD’s ability to withstand temporary overvoltages that occur during ground faults or neutral loss in the low-voltage system.

Real-world scenario: A phase-to-ground fault upstream causes the healthy phases to rise to phase-to-phase voltage (400V instead of 230V) for 1-5 seconds until protective devices clear the fault. Your SPD must survive this without conducting or failing.

Specification requirement: UT value must exceed the expected TOV magnitude and duration in your system. For TN-S systems, this is typically 1.45 × Un for 5 seconds. For TN-C systems or systems with uncertain grounding, use 1.55 × Un.

Parameter 3 & 4: Discharge Currents (In, Iimp, Imax) – Matching Threat Level

These three parameters define the SPD’s ability to handle surge energy:

- In (nominal discharge current): Used for classification testing; 20 kA for Class II SPDs

- Iimp (impulse current): Required for Class I SPDs near service entrance; 12.5 kA, 25 kA, or 50 kA

- Imax (maximum discharge current): The absolute maximum the SPD can survive; determines lifespan

How to select the right values:

| Local de instalação | Exposure Level | Minimum Imax Required |

|---|---|---|

| Service entrance, overhead lines, lightning-prone area | Alta | 100 kA (Class I with Iimp) |

| Main distribution panel, industrial facility | Médio | 60-80 kA (Class I or II) |

| Sub-distribution, near sensitive equipment | Baixa | 40 kA (Class II) |

| Final protection at equipment | Muito baixo | 20 kA (Class III) |

Critical insight: Higher Imax = longer SPD life expectancy under repeated surge stress. An SPD rated 100 kA will outlast a 40 kA SPD by 3-5× in the same application, even if actual surges never exceed 30 kA. The margin matters.

Step 2: Determine Protection Distance (The 10-Meter Rule That Everyone Ignores)

Here’s where most installations fail: An SPD at the main panel cannot protect equipment 50 meters away.

Understanding Protection Distance

When a surge hits your system, it travels as a wave. If the SPD is far from the protected equipment, reflections and inductive coupling along the cable create voltage “overshoot” at the equipment terminals that exceeds what the SPD limited.

The physics: For every 10 meters of cable between SPD and equipment, add approximately 1 kV of additional voltage stress during fast transients.

Exemplo de cálculo:

SPD voltage protection level (Up): 1.5 kV

Cable distance to equipment: 40 meters

Additional induced voltage: 40m ÷ 10m × 1 kV = 4 kV

Actual voltage at equipment terminals: 1.5 kV + 4 kV = 5.5 kV

If your VFD’s impulse withstand is 4 kV (typical for industrial equipment), it fails despite the SPD.

The Three-Zone Protection Strategy

For sensitive equipment, use cascaded protection:

Zone 1 – Service Entrance SPD (Class I):

- Location: Main distribution board

- Rating: Iimp = 25-50 kA, Up = 2.5 kV

- Purpose: Absorb massive external surges (lightning)

Zone 2 – Distribution Board SPD (Class II):

- Location: Sub-distribution feeding sensitive loads

- Rating: Imax = 40-60 kA, Up = 1.5 kV

- Distance from Zone 1: >10 meters (or use auto-coordinating SPDs)

- Purpose: Reduce voltage stress further

Zone 3 – Equipment SPD (Class III):

- Location: Mounted at equipment terminals

- Rating: Imax = 20 kA, Up = 1.0 kV

- Distance from equipment: <5 meters

- Purpose: Final protection to equipment withstand level

Pro-Tip: Modern SPDs with automatic energy coordination functions eliminate the “10-meter rule” spacing requirement between stages. These use built-in decoupling to coordinate energy sharing without relying on cable impedance. For retrofit applications where you can’t maintain spacing, specify auto-coordinating SPDs—it’s worth the 20-30% premium.

Step 3: Select Voltage Protection Level (Up) Based on Equipment Immunity

The voltage protection level (Up) is the most important SPD specification, yet it’s often overlooked. This is the actual voltage your equipment sees during a surge.

Matching Up to Equipment Withstand Voltage

The fundamental rule: SPD voltage protection level (Up) must be significantly lower than the equipment’s impulse withstand voltage (Uw).

Recommended safety factor: Up ≤ 0.8 × Uw

Common equipment impulse withstand voltages:

| Equipment Type | Category per IEC 60364-4-44 | Impulse Withstand (Uw) |

|---|---|---|

| Sensitive electronics, PLCs, instruments | Category I | 1,5 kV |

| Distribution boards, industrial appliances | Category II | 2.5 kV |

| Fixed industrial equipment | Categoria III | 4.0 kV |

| Equipamento de entrada de serviço | Category IV | 6.0 kV |

Selection example for VFD protection:

VFD impulse withstand: 4.0 kV (Category III)

Required Up: ≤ 0.8 × 4.0 kV = 3.2 kV maximum

But here’s the sophisticated part: Lower Up values provide better protection but require higher-quality SPD components and cost more.

SPD Up comparison:

- Standard SPD: Up = 2.5 kV, cost baseline

- Enhanced SPD: Up = 1.5 kV, cost +30%

- Premium SPD: Up = 1.0 kV, cost +60%

Decision framework:

- For equipment <$5,000: Up ≤ 2.5 kV acceptable

- For equipment $5,000-$50,000: Up ≤ 1.5 kV recommended

- For critical equipment >$50,000: Up ≤ 1.0 kV strongly recommended

Principais conclusões: The lower the Up value, the better the protection—but diminishing returns set in. Going from Up = 2.5 kV to 1.5 kV is worth it for expensive equipment. Going from 1.5 kV to 1.0 kV provides marginal additional benefit unless equipment is exceptionally sensitive (Category I).

Step 4: Eliminate Nuisance Tripping with Zero-Leakage SPDs

You’ve selected an SPD with perfect ratings. You install it per code. Then, mysteriously, your RCDs (residual current devices) start tripping randomly, shutting down production.

The Leakage Current Problem

Traditional SPDs using metal oxide varistors (MOVs) or gas discharge tubes (GDTs) have inherent leakage current—small amounts of current (typically 0.5-2 mA) that continuously flow to ground even when no surge is present.

Why this causes problems:

- RCD nuisance tripping: If you have 5-10 SPDs in a system, total leakage current can reach 10-20 mA, approaching RCD trip thresholds (typically 30 mA for personnel protection)

- Continuous power consumption: 2 mA × 230V × 24 hours × 365 days = 4 kWh/year per SPD. In a large facility with 50 SPDs, that’s 200 kWh wasted annually

- Premature SPD aging: Continuous leakage causes gradual degradation of MOV elements

The Solution: Composite SPD Technology

Composite SPDs with zero continuous current use a combination of technologies:

- GDT (gas discharge tube) as primary element: Zero leakage until breakdown

- MOV (metal oxide varistor) as clamping element: Limits voltage after GDT fires

- Thermal disconnect: Isolates failed components

Technical advantage: The GDT has virtually infinite resistance until the surge voltage reaches its breakdown level (typically 600-900V). Below this threshold, zero current flows—solving the leakage problem.

Pro-Tip: When specifying SPDs for systems with RCDs or in applications where nuisance tripping is unacceptable (hospitals, data centers, continuous processes), require “zero leakage current” or “composite SPD with GDT primary element” in your specification. The 15-25% cost premium is recovered in the first avoided shutdown.

Step 5: Plan SPD Failure Mode and Backup Protection

Here’s an uncomfortable truth: All SPDs eventually fail. The question isn’t “if,” it’s “when”—and more importantly, “what happens when they do?”

SPD Failure Modes (The Two Extremes)

When an SPD is hit by a surge exceeding its maximum rating, it fails in one of two ways:

- Open-circuit failure (safe):

SPD disconnects from the circuit

No fire hazard

System continues operating (but without surge protection)

Disadvantage: You don’t know protection is gone until equipment fails - Short-circuit failure (dangerous):

SPD becomes a low-resistance path to ground

Massive fault current flows (potentially thousands of amps)

Without proper backup protection: Cable overheats, panel fire starts

With backup protection: Upstream breaker trips, entire system shuts down

The Solution: SPD-Specific Backup Protector (SSD)

A standard circuit breaker or fuse is not adequate backup protection for an SPD. Here’s why:

Standard circuit breaker limitations:

- Trip time: 100-500 ms at high fault current

- During this time: 10-50 kA flowing through failed SPD

- Result: SPD explodes, fire starts, or panels are damaged before breaker trips

SPD-specific backup protector (SSD):

- Resposta mais rápida: Clears fault in <10 ms

- Higher interrupt rating: Rated for 50-100 kA interrupt capacity

- SPD-coordinated: Allows normal SPD operation but trips immediately on failure

- Visual indication: Shows when SPD has failed and been disconnected

Selection criteria for SSD:

| SPD Max Discharge Current (Imax) | Minimum SSD Rating Required |

|---|---|

| 40 kA | 63A, 50 kA interrupt |

| 65 kA | 100A, 65 kA interrupt |

| 100 kA | 125A, 100 kA interrupt |

Pro-Tip: The SSD should be rated for the SPD’s maximum discharge current (Imax), not the circuit’s normal operating current. A common mistake is installing a 20A circuit breaker to protect a 65 kA SPD—this breaker will either nuisance-trip during surges or fail to protect during SPD short-circuit failure.

Step 6: Coordinate Multiple SPD Stages (Without Complex Calculations)

For multi-stage protection (service entrance + distribution + equipment), the SPDs must coordinate properly. If they don’t, one SPD absorbs all the energy while others never engage—defeating the entire protection strategy.

Traditional Coordination: The 10-15 Meter Rule

Classic approach requires physical separation between SPD stages:

- Zone 1 to Zone 2: Minimum 10 meters of cable

- Zone 2 to Zone 3: Minimum 10 meters of cable

Why separation works: Cable inductance (typically 1 μH/m) creates a “decoupling” effect that causes upstream SPDs to see higher voltage and conduct first, sharing energy burden.

The problem with this approach:

- Modern facilities have compact electrical rooms

- Cable routing may not allow 10+ meter separation

- Complex calculations required to verify coordination

- Field modifications often impossible

Modern Solution: Auto-Coordinating SPDs

Automatic energy coordination function eliminates spacing requirements through internal design:

How it works:

- Each SPD stage has built-in series impedance (inductors or resistors)

- This impedance is calibrated to create voltage division during surges

- Result: Upstream SPD always conducts first, regardless of physical separation

Selection advantage:

- Can install Zone 1 and Zone 2 SPDs in the same panel

- No field calculations needed

- Proven coordination per manufacturer testing

- Simplifies retrofit applications

Specification language: “SPD shall include automatic energy coordination function per [manufacturer standard], allowing installation at any distance from upstream protection without additional coordination calculations.”

Cost impact: Auto-coordinating SPDs cost 25-40% more than standard SPDs, but this premium is typically less than the labor cost of routing 10+ meters of additional cable to achieve spacing.

The Complete SPD Selection Checklist

Pulling it all together, here’s your specification checklist for specifying SPDs that actually protect equipment:

Electrical Parameters (Step 1):

- ☑ Uc (max continuous voltage): ≥ 1.15 × system nominal voltage

- ☑ UT (temporary overvoltage): ≥ 1.45 × Un for TN-S, ≥ 1.55 × Un for TN-C

- ☑ Imax (max discharge current): Match installation location exposure (40-100 kA)

- ☑ Iimp (impulse current): Specify for Class I SPDs at service entrance (12.5-50 kA)

Protection Performance (Steps 2-3):

- ☑ Protection distance: <10m from equipment OR use auto-coordinating SPDs

- ☑ Up (voltage protection level): ≤ 0.8 × equipment impulse withstand voltage

- ☑ Multi-stage coordination: Define Zone 1/2/3 locations and ratings

System Integration (Steps 4-5):

- ☑ Leakage current: Specify zero-leakage or composite SPD type to prevent RCD tripping

- ☑ Backup protection: Include SPD-specific disconnect (SSD) rated for Imax

- ☑ Failure indication: Visual or remote alarm when SPD protection lost

Installation Optimization (Step 6):

- ☑ Coordination function: Specify auto-coordinating if spacing <10m between stages

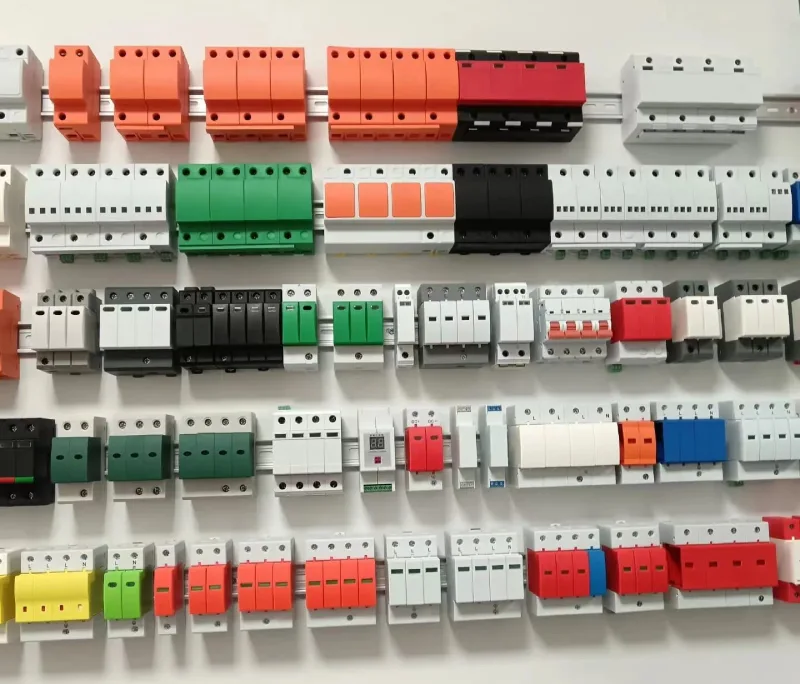

- ☑ Montagem: DIN-rail or panel-mount based on application

- ☑ Documentação: Require installation records and testing certificates

Your Surge Protection Action Plan

By following this 6-step selection and specification method, you ensure surge protection that actually works:

- ✓ Prevent six-figure equipment failures from lightning and switching transients

- ✓ Eliminate nuisance tripping that shuts down production and frustrates operators

- ✓ Extend SPD lifespan by proper voltage and discharge rating selection

- ✓ Simplify coordination with auto-matching SPDs that don’t require complex spacing

- ✓ Protect safely with proper backup protection that prevents panel fires during SPD failure

Conclusão: Installing “a surge protector” is easy. Engineering a protection system that matches your specific voltage environment, discharge capacity requirements, and equipment sensitivity—that’s what separates functioning equipment from expensive scrap metal after the next storm.

Next step: Before specifying your next SPD, calculate the four critical parameters: Uc based on system voltage with 15-20% margin, Imax based on installation exposure level, Up based on equipment withstand voltage, and verify protection distance or specify auto-coordination. These ten minutes of calculation can save you from explaining why a $50,000 VFD died despite having “surge protection installed.”

About SPD Standards:

This article references IEC 61643-11 and GB/T 18802.12 standards for SPD classification and selection. For systems in North America, also consult IEEE C62.41 for surge environment characterization and UL 1449 for SPD performance standards. Always verify local code requirements, as some jurisdictions mandate specific SPD ratings or installation practices.