Segunda-feira de manhã, 7h15. O inspetor de saúde entra na sua fábrica de processamento de alimentos, aponta para o invólucro de controle do motor na área de embalagem e diz quatro palavras que paralisam a produção: “Isto reprova na inspeção.”

O invólucro é NEMA 3R — resistente às intempéries, classificado para uso externo, perfeito para chuva e granizo. Exceto que este não é um ambiente externo ameno. Duas vezes por turno, sua equipe atinge todas as superfícies naquela sala com mangueiras de alta pressão e solução de limpeza cáustica, e os invólucros NEMA 3R são testados para chuva caindo, não para spray de 1.000 PSI a um metro de distância. A água encontrou seu caminho pelas juntas durante a lavagem das 6h. Quando o inspetor chegou, a umidade estava visível dentro do invólucro, a condensação estava se formando nas bobinas do contator e toda a sua linha de produção — programada para rodar 2.400 caixas naquele dia — estava parada.

A solução: Retire o NEMA 3R, encomende um invólucro de aço inoxidável NEMA 4X (US$ 1.850 contra os US$ 680 que você pagou pelo 3R), espere quatro dias pela entrega, reconfigure tudo e reapresente para inspeção. Custo total: US$ 47.000 em perda de produção, mão de obra e frete premium. A causa raiz? Cair em A Armadilha da Lavagem— assumir que qualquer invólucro classificado para uso externo funciona em ambientes úmidos.

Então, como você combina NEMA as classificações de invólucro com seu ambiente real sem subproteger (inspeções reprovadas, danos ao equipamento) ou superdimensionar (prêmios de custo de 30-60% para recursos que você não precisa)?

Resposta Rápida: Classificações NEMA em Resumo

A maioria dos engenheiros perde isso: A Mentira do Número Mais Alto. NEMA 12 não é “melhor” que NEMA 4. Eles são projetados para ambientes completamente diferentes — NEMA 12 para poeira e gotejamentos internos, NEMA 4 para lavagem com mangueira externa. Os números não representam uma escala progressiva de proteção; eles representam perfis de teste ambiental distintos.

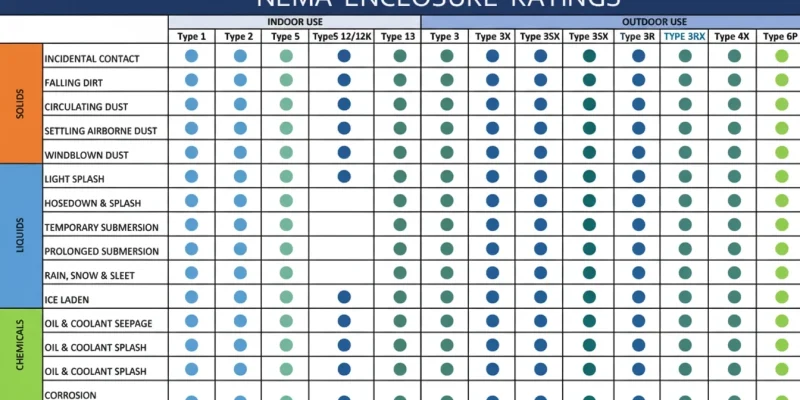

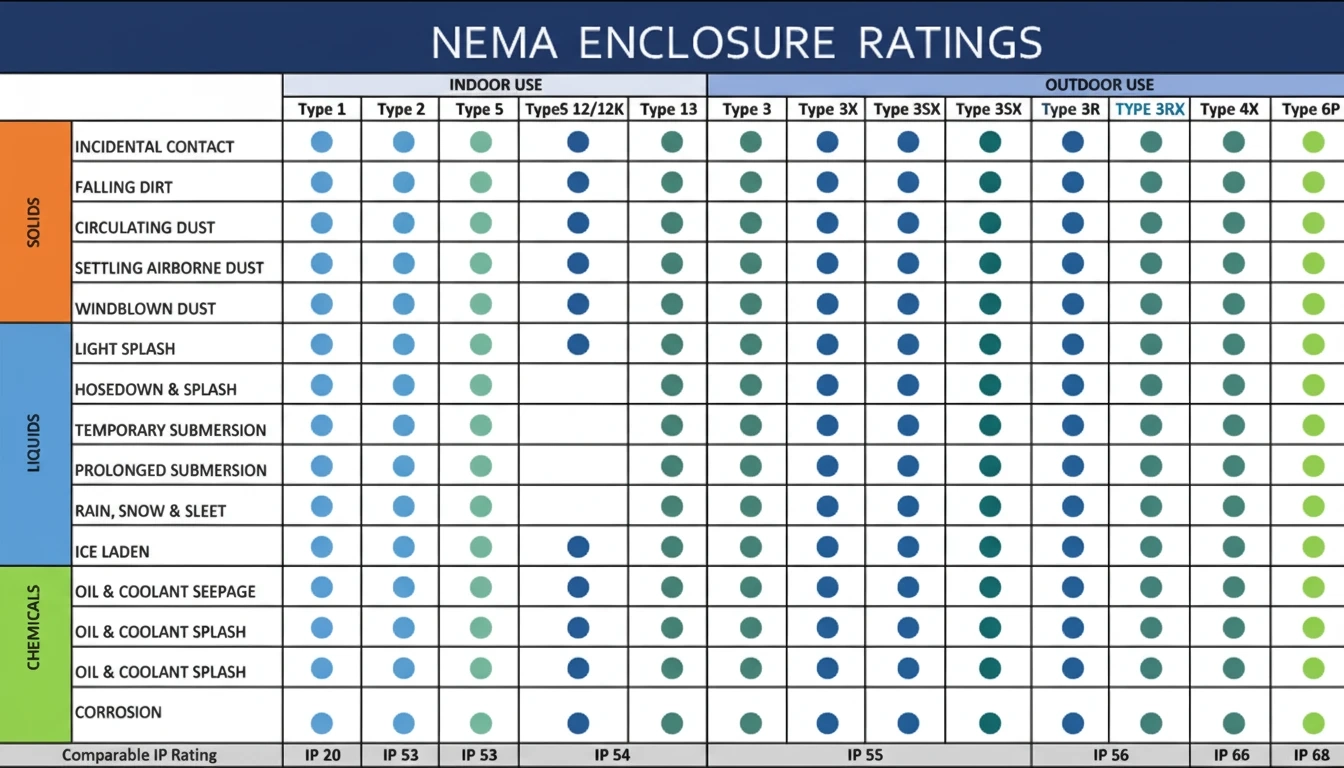

As classificações NEMA, definidas por ANSI/NEMA 250-2020, classificam os invólucros com base nos testes ambientais que eles passam. Os tipos internos (1, 2, 5, 12, 12K, 13) protegem contra poeira, gotejamentos e líquidos não corrosivos. Os tipos externos (3, 3R, 3S, 4, 4X, 6, 6P) adicionam proteção contra chuva, neve, poeira impulsionada pelo vento e, em alguns casos, água direcionada por mangueira ou submersão. O sufixo “X” (3X, 4X) indica resistência à corrosão adicional — normalmente construção em aço inoxidável ou fibra de vidro.

Veja como os tipos NEMA mais comuns se comparam:

| Tipo NEMA | Localização | Proteção Contra | Faixa de custo típica | Melhores casos de utilização |

| 1 | Interior | Sujeira caindo, contato acidental | \$50-\$200 | Painéis internos limpos, ambientes de escritório |

| 3R | Ar livre | Chuva, granizo, neve, sujeira caindo | \$150-\$400 | Utilidade externa, medição, serviço geral |

| 4 | Ar livre | Chuva, lavagem com mangueira, poeira impulsionada pelo vento | \$300-\$800 | Áreas de lavagem (não corrosivas), industrial externo |

| 4X | Ar livre | Todo Tipo 4 + resistência à corrosão | \$600-\$1,850 | Costeiro, marítimo, químico, processamento de alimentos |

| 12 | Interior | Poeira, fiapos, gotejamentos, líquidos não corrosivos | \$120-\$350 | Fabricação, fábricas, industrial sem lavagem |

| 13 | Interior | Tipo 12 + infiltração de óleo/refrigerante | \$180-\$450 | Ambientes de máquinas-ferramentas, invólucros CNC |

Observe a divisão funcional: os tipos externos resistem ao clima e à lavagem com mangueira, enquanto os tipos internos lidam com poeira e respingos. Quando você cai em A Armadilha da Lavagem— escolher 3R para um ambiente de lavagem com mangueira porque “é classificado para uso externo” — você está selecionando um invólucro testado para chuva para uma aplicação de pulverização sob pressão. Esse é o erro de US$ 47 mil da abertura.

Figura 1: Matriz de comparação de classificação NEMA mostrando os recursos de proteção para os Tipos 1 a 6P. Este gráfico fornece uma referência rápida para combinar os tipos de invólucro com os riscos ambientais — proteção contra poeira, níveis de exposição à água e resistência à corrosão.

A Fundação de Padrões: ANSI/NEMA 250-2020

A NEMA não apenas atribui números às caixas e considera o assunto encerrado. O sistema de classificação é apoiado por ANSI/NEMA 250-2020, Invólucros para Equipamentos Elétricos (1.000 Volts Máximo), aprovado em 8 de dezembro de 2020. Este padrão define os requisitos de construção, métodos de teste ambiental e especificações de marcação para cada tipo NEMA.

O que ANSI/NEMA 250 realmente testa:

Cada tipo NEMA deve passar por testes de design específicos definidos na Seção 5 do padrão. Estas não são classificações abstratas — são simulações ambientais mensuráveis:

- Teste de chuva (Seção 5.4): Invólucro exposto à água caindo a 5 polegadas por hora durante 30 minutos. A água não deve entrar e afetar a operação. Os tipos 3, 3R, 3S, 4, 4X, 6, 6P passam neste teste.

- Teste de lavagem com mangueira (Seção 5.7): Invólucro pulverizado com fluxo de água de 65 GPM de um bocal de 1 polegada a 65 PSI de todos os ângulos. Nenhuma entrada de água permitida. Apenas os Tipos 4 e 4X passam neste teste — não o Tipo 3R.

- Testes de poeira (Seção 5.5): Testes de poeira impulsionada pelo vento, poeira circulante e poeira depositada. O Tipo 3/4 resiste à poeira impulsionada pelo vento. O Tipo 12 resiste à poeira circulante e aos fiapos. O Tipo 5 é à prova de poeira (exclusão completa).

- Testes de corrosão (Seção 5.10): Névoa salina (600 horas para variantes X externas) e exposição a CO2/SO2/ar. Os Tipos 3X, 3RX, 3SX, 4X e 6P exigem proteção adicional contra corrosão e devem passar nesses testes estendidos.

- Testes de submersão (Seções 5.11-5.12): O Tipo 6 resiste à submersão temporária (ocasional, profundidade limitada). O Tipo 6P lida com submersão prolongada.

A NEMA não certifica invólucros. Os fabricantes autodeclaram conformidade com a NEMA, e laboratórios de testes de terceiros (NRTLs como a UL) listam produtos de acordo com os padrões UL 50 (construção) e UL 50E (ambiental), que se alinham com a NEMA 250. Ao especificar um invólucro, procure a marca de listagem da UL — essa é a sua verificação de que ele passou nos testes.

Dica #1: Os tipos NEMA definem a proteção ambiental, mas não abordam o gerenciamento térmico. Um invólucro NEMA 4X selado não pode usar um ventilador simples que aspire ar externo — isso comprometeria a vedação. Você precisará de resfriamento de circuito fechado (condicionadores de ar, trocadores de calor), o que adiciona US$ 800 - US$ 3.500 ao custo do seu sistema. Se sua aplicação não precisar de proteção contra lavagem com mangueira, escolher NEMA 12 com ventilação filtrada economiza custos significativos de resfriamento.

Tipos NEMA Internos: Quando Ambientes Limpos Precisam de Proteção

Os tipos NEMA internos (1, 2, 5, 12, 12K, 13) são projetados para ambientes controlados onde a chuva e o clima externo não são preocupações. Mas “interno” não significa “nenhuma proteção necessária” — essas classificações abordam poeira, gotejamentos, respingos e, em ambientes industriais, exposição a óleo e refrigerante.

NEMA Tipo 1: Propósito Geral Interno

Proteção: Proteção básica contra contato acidental com partes energizadas e sujeira caindo limitada. Não é à prova de poeira. Proteção mínima contra água (apenas gotejamento/respingo leve).

Aplicações: Ambientes de escritório limpos, painéis residenciais, salas de equipamentos com condições controladas. Pense em quadros de distribuição em edifícios comerciais, gabinetes de CLP em salas de servidores com controle climático e invólucros de interruptores internos onde poeira e umidade não são preocupações.

Custo: US$ 50 - US$ 200 para tamanhos típicos (30x30x15 cm a 60x60x25 cm).

Quando falha: Coloque um invólucro Tipo 1 em uma fábrica empoeirada, e a poeira circulante entrará pelas aberturas de ventilação e se depositará nos componentes. Coloque-o onde a condensação se forma (perto de equipamentos de HVAC, lavanderias), e a entrada de umidade pode causar corrosão ou curtos-circuitos.

NEMA Tipo 2: Interno com Proteção contra Gotejamento

Proteção: Semelhante ao Tipo 1 com proteção aprimorada contra gotejamento e respingos leves de água. Ainda não é à prova de poeira.

Aplicações: Lavanderias, salas de equipamentos de resfriamento, áreas com condensação, mas sem respingos pesados. Menos comum do que os Tipos 1 ou 12 em ambientes industriais.

Custo: US$ 80 - US$ 250 para tamanhos típicos.

NEMA Tipo 5: Interno à Prova de Poeira

Proteção: Completamente à prova de poeira (sem entrada de poeira), além de proteção contra gotejamento e respingos leves de água. Esta é a classificação de proteção contra poeira mais alta para invólucros internos.

Aplicações: Siderúrgicas, fábricas de cimento, instalações de manuseio de pó — em qualquer lugar onde a poeira no ar seja uma grande preocupação. Também adequado para ambientes com fiapos ou fibras (fábricas têxteis).

Custo: \$200-\$500 para tamanhos típicos. A construção e a vedação da junta aumentam o custo em comparação com o Tipo 1.

Distinção fundamental do Tipo 12: O Tipo 5 é completamente à prova de poeira (entrada zero). O Tipo 12 resiste à poeira, mas não é hermeticamente vedado. Para ambientes com muita poeira, o Tipo 5 é a escolha certa.

NEMA Tipo 12 e 12K: Cavalo de batalha industrial para interiores

Proteção: Construção com junta não ventilada. Protege contra queda de sujeira, poeira circulante, fiapos, fibras, gotejamento de água e respingos leves de líquidos não corrosivos. Não é resistente a óleo.

Aplicações: Ambientes industriais de uso geral — pisos de fábrica, linhas de montagem, armazéns, centros de distribuição. Esta é a classificação de invólucro industrial interno mais comum. O Tipo 12K inclui knockouts para entrada de conduíte; o Tipo 12 padrão pode não incluir.

Custo: \$120-\$350 para tamanhos típicos (16×16×8 a 30×24×10 polegadas).

Quando funciona: Um painel de controle de motor em uma instalação de fabricação limpa, onde a poeira está presente, mas não é extrema, e não há lavagem com mangueira ou exposição a óleo. Gotejamento de água de tubulações suspensas ou respingos leves durante a limpeza (esfregão e balde, não spray de pressão) são aceitáveis.

Quando falha: Coloque um Tipo 12 em um ambiente de máquina-ferramenta CNC com névoa de óleo e spray de refrigerante, e as juntas acabarão se degradando devido à exposição ao óleo. É quando você precisa do Tipo 13.

NEMA Tipo 13: Resistência a óleo e refrigerante

Proteção: Todas as proteções do Tipo 12, além de resistência a pulverização, respingos e infiltração de óleo e refrigerantes não corrosivos. As juntas e vedações são de elastômeros resistentes a óleo.

Aplicações: Máquinas-ferramentas CNC, ambientes de metalurgia, sistemas hidráulicos — em qualquer lugar onde névoa de óleo, fluidos de corte ou spray de fluido hidráulico estejam presentes.

Custo: \$180-\$450 para tamanhos típicos. Juntas e vedações resistentes a óleo adicionam 20-30% em comparação com o Tipo 12.

Dica #2: Ao especificar invólucros internos, considere a exposição aos raios UV de claraboias ou janelas. Os invólucros de aço pintado padrão Tipo 12 podem sofrer degradação por UV (desbotamento, esfarelamento) ao longo de 5 a 10 anos sob luz solar direta. Se o seu ambiente “interno” tiver luz solar significativa, especifique revestimento em pó resistente a UV ou considere invólucros de policarbonato com estabilizadores de UV.

Figura 2: Diferenças de construção entre NEMA 12 (com junta interna), NEMA 4 (vedado para lavagem com mangueira externa) e NEMA 4X (aço inoxidável resistente à corrosão). Observe a vedação da junta, as especificações do material e os ambientes de aplicação pretendidos para cada tipo.

Tipos NEMA para exteriores: Chuva, lavagem com mangueira e a armadilha da lavagem

Os tipos NEMA para exteriores (3, 3R, 3S, 3X, 3RX, 3SX, 4, 4X, 6, 6P) adicionam resistência às intempéries e, criticamente, diferentes níveis de proteção contra água. É aqui que A Armadilha da Lavagem pega os engenheiros: assumindo que todas as classificações externas lidam com água de alta pressão.

NEMA Tipo 3 e 3R: À prova de intempéries para exteriores

Proteção Tipo 3: Chuva, granizo, neve, poeira soprada pelo vento e formação de gelo. O invólucro deve permanecer operável quando o gelo se formar no exterior.

Proteção Tipo 3R: Chuva, granizo, neve e queda de sujeira — mas sem proteção contra poeira soprada pelo vento. O “R” significa “à prova de chuva”. As disposições de drenagem evitam o acúmulo de água. Custo mais baixo do que o Tipo 3 devido aos requisitos simplificados de junta.

Aplicações:

- Tipo 3: Canteiros de obras, docas de navios, equipamentos industriais externos em ambientes empoeirados.

- Tipo 3R: Invólucro de utilidade externa mais comum — medição, chaves de desconexão, controles de iluminação externa, equipamentos de serviço residencial. Se a poeira soprada pelo vento não for uma preocupação, o 3R é mais econômico do que o 3.

Custo: O Tipo 3R custa \$150-\$400 para tamanhos típicos. O Tipo 3 adiciona 20-30% para vedação de junta aprimorada.

Limitação crítica: Os Tipos 3 e 3R passam no teste de chuva (5 polegadas/hora de água caindo), mas não passam no teste de lavagem com mangueira. Se o seu ambiente incluir lavagem sob pressão, você acabou de entrar em A Armadilha da Lavagem.

NEMA Tipo 3S: Operável com gelo para exteriores

Proteção: Todas as proteções do Tipo 3, além de que o invólucro deve permanecer operável quando coberto de gelo. Os mecanismos de operação externos (alças, travas) não podem congelar.

Aplicações: Serviços públicos em climas do norte, subestações externas, qualquer equipamento que deva permanecer acessível durante tempestades de gelo.

Custo: \$250-\$600 para tamanhos típicos. Mecanismos resistentes ao gelo e opções aquecidas aumentam o custo.

NEMA Tipo 4 e 4X: Proteção contra lavagem com mangueira

Proteção Tipo 4: Todas as proteções do Tipo 3, além de água direcionada por mangueira (teste da Seção 5.7: 65 GPM a 65 PSI de todos os ângulos). Esta é a distinção crítica — as vedações do Tipo 4 devem resistir ao spray direto, não apenas à chuva caindo.

Proteção Tipo 4X: Todas as proteções do Tipo 4, além de resistência à corrosão (teste de névoa salina de 600 horas, exposição a CO2/SO2). Requer aço inoxidável, fibra de vidro ou materiais resistentes à corrosão.

Aplicações:

- Tipo 4: Áreas de lavagem com aço macio aceitável — processamento de alimentos (zonas não corrosivas), fábricas de bebidas, salas limpas farmacêuticas, equipamentos industriais externos com manutenção periódica com mangueira.

- Tipo 4X: Ambientes corrosivos — instalações costeiras/marinhas, processamento químico, tratamento de águas residuais, plataformas de petróleo e gás, qualquer ambiente externo ou de lavagem com sal, produtos químicos ou atmosferas corrosivas.

Custo:

- Tipo 4 (aço macio): \$300-\$800 para tamanhos típicos

- Tipo 4X (aço inoxidável 304): \$600-\$1.850 para tamanhos típicos — geralmente o dobro do custo do Tipo 4

Este é o cruzamento 3R vs 4X: A decisão de invólucro externo mais comum. Pergunte a si mesmo: “Este invólucro será lavado com mangueira ou apenas exposto à chuva?” Se a lavagem com mangueira for possível (limpeza de manutenção, operações de lavagem próximas), você precisa do Tipo 4 ou 4X. Se for realmente apenas chuva, o Tipo 3R economiza 50-60% em comparação com o 4X.

Dica #3: A orientação da instalação é importante para a drenagem. Os invólucros NEMA 3R e 4 têm orifícios de drenagem ou dispositivos de escape na parte inferior. Monte o invólucro nivelado e orientado de acordo com as instruções do fabricante — inclinar ou inverter pode prender água dentro. Verifique as instruções de montagem; alguns invólucros são aprovados apenas para montagem vertical na parede, não para montagem horizontal na superfície.

NEMA Tipo 6 e 6P: Invólucros submersíveis

Proteção Tipo 6: Todas as proteções do Tipo 4, além de submersão temporária em água (submersão ocasional em profundidade limitada por tempo limitado, de acordo com as especificações do fabricante — normalmente 6 pés por 30 minutos).

Proteção Tipo 6P: Submersão prolongada em maior profundidade (de acordo com a classificação do fabricante). Não se destina à operação subaquática contínua, mas pode lidar com inundações prolongadas ou instalação subaquática temporária.

Aplicações:

- Tipo 6: Bueiros, poços de utilidade, túneis, estações de bombeamento — em qualquer lugar onde inundações temporárias sejam possíveis.

- Tipo 6P: Estações elevatórias de águas residuais, controles de bombas de cárter, instalações em planícies de inundação.

Custo: \$800-\$2.500 para tamanhos típicos. Juntas, prensa-cabos e vedação com classificação de submersão adicionam um custo significativo.

Raro na maioria das aplicações industriais: A menos que você esteja em serviços públicos de água/águas residuais ou áreas propensas a inundações, você não precisará do Tipo 6/6P. O Tipo 4X lida com a maioria dos ambientes externos agressivos sem o prêmio de submersão.

Figura 3: Instalação de invólucro NEMA externo no mundo real em poste de utilidade. Este tipo de implantação normalmente requer NEMA 3R (apenas chuva) ou NEMA 4X (se a manutenção com mangueira ou a corrosão costeira for uma preocupação). A orientação de montagem adequada garante a drenagem de acordo com as especificações do fabricante.

As variantes “X” de corrosão: quando o aço inoxidável vale a pena

O sufixo “X” nas classificações NEMA (3X, 3RX, 3SX, 4X, 6P) sinaliza resistência à corrosão. Esta não é uma atualização menor — é uma mudança fundamental de material que aciona testes de corrosão estendidos e normalmente um prêmio de custo de 40-150%. Bem-vindo ao O imposto sobre corrosão.

O que “X” realmente exige (ANSI/NEMA 250-2020 Seção 5.10):

- Teste de névoa salina de 600 horas (variantes X para exterior): Invólucro exposto a névoa salina de NaCl 5% por 600 horas contínuas. Nenhuma corrosão ou degradação da função permitida.

- Teste de corrosão CO2/SO2/ar: Exposição de 1.200 horas a mistura de gases corrosivos simulando atmosferas industriais.

- Requisitos de material (Seção 3.5.7): Aço inoxidável (grau 304 ou 316), poliéster reforçado com fibra de vidro, policarbonato ou outros materiais resistentes à corrosão com proteção de superfície apropriada.

Detalhamento de custos para Tipo 4 vs 4X (invólucro de montagem na parede de 18×16×8 polegadas):

- Tipo 4 (aço macio, revestido a pó): \$450-\$650

- Tipo 4X (aço inoxidável 304): \$850-\$1,200 (+89-85% premium)

- Tipo 4X (aço inoxidável 316): \$1,200-\$1,850 (+167-185% premium)

- Tipo 4X (fibra de vidro): \$700-\$1,100 (+56-69% premium)

Quando vale a pena pagar o Imposto de Corrosão:

- Ambientes costeiros e marinhos: Dentro de 1 milha de água salgada, a névoa salina acelera a corrosão drasticamente. O Tipo 4 de aço macio pode apresentar ferrugem em 6-18 meses. O 4X inoxidável dura 15-25+ anos.

- Processamento químico: Exposição a ácidos, bases, solventes ou vapores corrosivos. Mesmo a exposição leve ao longo de 5-10 anos degrada os revestimentos e causa ferrugem.

- Alimentos e bebidas (limpeza corrosiva): Produtos químicos de limpeza cáusticos (hidróxido de sódio, ácido fosfórico) atacam o aço macio. O 4X inoxidável é padrão em ambientes regulamentados pela FDA.

- Tratamento de águas residuais e água: A liberação de gás sulfeto de hidrogênio (H2S), cloro e alta umidade aceleram a corrosão. 4X ou fibra de vidro é padrão.

- Climas tropicais ao ar livre: Alto calor + alta umidade + ar carregado de sal (mesmo no interior) cria condições agressivas de corrosão.

Quando você pode pular a variante X e economizar 40-150%:

- Climas secos ao ar livre (deserto, regiões áridas) sem exposição a sal ou produtos químicos - o aço macio Tipo 3R ou 4 funciona bem por 10-20 anos com bom revestimento em pó.

- Exterior temperado não costeiro, não industrial - instalações de serviços públicos suburbanos, exteriores de edifícios comerciais sem exposição a produtos químicos.

- Ambientes internos, mesmo com lavagem, se os produtos químicos não forem corrosivos (apenas água e detergentes suaves) - o aço macio Tipo 4 pode ser suficiente.

Seleção de material dentro de 4X:

- Aço inoxidável 304: Resistência à corrosão de uso geral. Bom para costeiro (não zona de respingo direto), processamento de alimentos, exposição química geral.

- Aço inoxidável 316: Resistência à corrosão aprimorada, especialmente cloretos e ambientes marinhos. Especifique 316 para exposição direta à água do mar, plataformas offshore, plantas químicas com compostos clorados.

- Fibra de vidro: Não condutor, excelente resistência química, resistente a UV, 30-50% mais leve que o aço. Ideal para ambientes químicos altamente corrosivos ou onde o isolamento elétrico é necessário. Desvantagem: menor resistência ao impacto do que o aço.

Dica #4: Verifique a placa de listagem UL e a marcação NEMA dentro do invólucro. O rótulo deve indicar o(s) tipo(s) NEMA e listar o número do arquivo UL. Se você estiver pagando o Imposto de Corrosão para 4X, verifique a listagem - invólucros “equivalentes a 4X” não listados podem não atender ao teste de névoa salina de 600 horas. Durante as inspeções, as AHJs (Autoridades com Jurisdição) procurarão essa marca UL.

Tipos de Localização Perigosa: Ambientes Classe I e Classe II

Se sua instalação estiver em um local perigoso (classificado) de acordo com o Artigo 500 do NEC, os tipos NEMA padrão não são suficientes. Você precisa de invólucros que impeçam a ignição de gases inflamáveis, vapores ou poeiras combustíveis.

Tipo NEMA 7: Classe I, Divisão 1 À Prova de Explosão

Proteção: Atende aos requisitos para locais perigosos Classe I, Divisão 1 (gases ou vapores inflamáveis presentes em condições normais de operação). Invólucro projetado para conter uma explosão interna e evitar a ignição da atmosfera circundante. Testado de acordo com UL 1203 (Equipamento Elétrico À Prova de Explosão e À Prova de Ignição de Poeira).

Aplicações: Refinarias petroquímicas, plantas químicas, cabines de pintura, áreas de distribuição de combustível - em qualquer lugar onde vapores inflamáveis (gasolina, solventes, hidrogênio) estejam presentes.

Custo: \$1,500-\$8,000+ dependendo do tamanho e da classificação de Classe/Divisão/Grupo. A construção à prova de explosão (fundição de parede grossa, juntas de retenção de chama) é cara.

Instalação: Requer conexões de conduíte rosqueadas com profundidade de engate especificada, acessórios de vedação a 18 polegadas da entrada do invólucro e adesão estrita aos requisitos do NEC 501.

Tipo NEMA 9: Classe II, Divisão 1 À Prova de Ignição de Poeira

Proteção: Atende aos requisitos para locais Classe II, Divisão 1 (poeira combustível presente em condições normais - poeira de metal, poeira de carvão, poeira de grãos). O invólucro impede a entrada de poeira e não permitirá que faíscas internas ou calor ignitem camadas de poeira externas.

Aplicações: Elevadores de grãos, moinhos de farinha, manuseio de carvão, processamento de pó de metal, serrarias.

Custo: \$1,200-\$6,000+ dependendo do tamanho e da classificação do grupo de poeira.

Tipo NEMA 10: Segurança de Minas (MSHA)

Proteção: Atende aos requisitos da Administração de Segurança e Saúde de Minas (MSHA) para uso em minas de carvão com riscos de metano.

Aplicações: Mineração subterrânea de carvão apenas.

Raramente especificado fora da mineração: A menos que você esteja projetando para minas de carvão subterrâneas, você não encontrará o Tipo 10.

Ponto Chave: Os invólucros de localização perigosa exigem conformidade com o Artigo 500-506 do NEC e normalmente a listagem UL 1203 ou UL 698. Nunca substitua um NEMA 4X ou 12 padrão em uma área classificada - o risco de ignição cria riscos à segurança da vida e violações massivas do código. Trabalhe com um projetista ou engenheiro certificado de localização perigosa se seu projeto envolver áreas Classe I ou Classe II.

Classificações NEMA vs IP: Por que a Conversão Direta Falha

Projetos globais geralmente exigem equipamentos com classificações NEMA (América do Norte) e IP (Comissão Eletrotécnica Internacional IEC 60529). Os engenheiros frequentemente perguntam: “Qual é o equivalente IP de NEMA 4X?” A resposta: não há um perfeito.

A diferença fundamental:

- Classificações NEMA (ANSI/NEMA 250): Categorias holísticas de proteção ambiental que incluem requisitos de construção, múltiplos riscos (poeira, água, corrosão, óleo) e métodos de teste específicos para os padrões norte-americanos.

- Classificações IP (IEC 60529): Código de proteção de entrada de dois dígitos focado exclusivamente na entrada de partículas sólidas (primeiro dígito, 0-6) e líquidas (segundo dígito, 0-9). Sem requisitos explícitos de corrosão, resistência a óleo ou construção.

Estrutura do código IP: IPXY

- Primeiro dígito (sólidos): 0 = sem proteção, 1 = objetos >50mm, 2 = >12,5mm, 3 = >2,5mm, 4 = >1mm, 5 = protegido contra poeira, 6 = à prova de poeira.

- Segundo dígito (líquidos): 0 = sem proteção, 1 = gotejamento de água (vertical), 2 = gotejamento de água (inclinação de 15°), 3 = pulverização de água (60° da vertical), 4 = respingos, 5 = jatos de água, 6 = jatos de água potentes, 7 = imersão temporária, 8 = imersão contínua, 9 = jatos de alta pressão/alta temperatura.

Mapeamento aproximado (ANSI/NEMA 250-2020 Anexo A e NEMA BI 50014-2024):

| Tipo NEMA | Equivalente IP aproximado | Advertências |

| 1 | IP10 | NEMA 1 inclui proteção limitada contra gotejamento; IP10 é o mínimo |

| 3, 3R | IP24 (às vezes IP54) | NEMA 3R não possui poeira soprada pelo vento (IP5X); teste de chuva ≠ teste de jato de água IP |

| 4, 4X | IP65 ou IP66 | A mangueira NEMA ≈ jatos IP65/66, mas os métodos de teste são diferentes |

| 12, 13 | IP54 ou IP52 | NEMA 12/13 se concentra em poeira/gotejamento interno; IP54 é mais amplo |

| 6, 6P | IP67 ou IP68 | Submersão temporária vs prolongada NEMA ≈ IP67 vs IP68 |

Por que você não pode confiar na conversão direta:

- Os métodos de teste são diferentes: A mangueira NEMA usa 65 GPM a 65 PSI. IP66 usa 100 litros/min a 100 kPa de 3 metros. Semelhante, mas não idêntico.

- NEMA inclui requisitos adicionais: A resistência à corrosão (sufixo X) não faz parte da classificação IP. A exclusão de óleo (NEMA 13) não tem equivalente IP.

- IP não aborda a construção: NEMA especifica materiais de vedação, montagem, marcação. IP testa apenas a entrada.

- Aceitação regulatória: NEC e UL exigem classificações NEMA na América do Norte. A marcação CE na Europa exige classificações IP de acordo com a IEC 60529.

Orientação prática para projetos globais:

- Invólucros com classificação dupla: Especifique equipamentos listados nos padrões NEMA e IP (por exemplo, “NEMA 4X / IP66”). Muitos fabricantes oferecem produtos com classificação dupla.

- Verifique os relatórios de teste: Se um fornecedor alegar que “NEMA 4X equivalente a IP65”, solicite relatórios de teste que mostrem conformidade com ANSI/NEMA 250 e IEC 60529.

- Não presuma equivalência: Um invólucro europeu com classificação IP54 pode não atender aos requisitos NEMA 12 se os materiais de vedação, a construção ou a marcação não estiverem alinhados.

Para uma comparação detalhada, verifique NEMA BI 50014-2024, Graus de Proteção Fornecidos por Invólucros (Código IP): Uma Breve Comparação, publicado pela NEMA para esclarecer essas distinções.

Estrutura de Decisão de 5 Perguntas: Correspondência do Ambiente ao Tipo NEMA

Você viu os tipos, os métodos de teste e as implicações de custo. Agora, aqui está a estrutura prática: responda a estas cinco perguntas e você saberá qual classificação NEMA sua aplicação precisa.

Pergunta 1: Instalação Interna ou Externa?

Interior (ambiente controlado, sem chuva ou exposição ao clima):

→ Comece com NEMA 1, 2, 5, 12 ou 13. Vá para a Pergunta 2.

Ar livre (exposto ao clima):

→ Comece com NEMA 3, 3R, 3S, 4, 4X, 6 ou 6P. Vá para a Pergunta 3.

Pergunta 2 (Interna): Quais são seus riscos ambientais?

Poeira/fiapos/fibras presentes?

- Poeira mínima, ambiente limpo → NEMA 1

- Poeira moderada, ambiente industrial → NEMA 12

- Poeira pesada, necessidade de exclusão completa → NEMA 5

Óleo, refrigerante ou fluidos de corte presentes?

- Sem exposição ao óleo → NEMA 1 ou 12

- Névoa de óleo, spray de refrigerante → NEMA 13

Gotejamento de água ou condensação?

- Ambiente seco → NEMA 1

- Pingos ou respingos leves → NEMA 2 ou 12

Necessidades de gerenciamento térmico?

- Se você precisar de ventilação para resfriamento, NEMA 1 ou 12 com venezianas/ventiladores é viável. Se você precisar de um ambiente selado para poeira, NEMA 5 ou 12 requer resfriamento de circuito fechado (Pro-Tip #1).

→ Vá para a Pergunta 5 (considerações de custo/material).

Pergunta 3 (Externa): Exposição Apenas à Chuva ou à Mangueira?

This is A Armadilha da Lavagem ponto de decisão.

Chuva, granizo, neve apenas (sem lavagem sob pressão):

- Poeira soprada pelo vento é uma preocupação → NEMA 3

- Poeira soprada pelo vento não é uma preocupação → NEMA 3R (opção exterior mais econômica)

- Deve operar quando coberto de gelo → NEMA 3S

Lavagem com mangueira, lavagem sob pressão ou jatos de água:

→ NEMA 4 ou 4X requerido. Tipo 3R falhará. Vá para a Pergunta 4 para avaliação de corrosão.

Inundação temporária ou submersão possível:

→ NEMA 6 ou 6P (raro; a maioria das aplicações externas são satisfeitas com 4/4X).

Pergunta 4 (Exterior): Avaliação de Exposição à Corrosão

This is O imposto sobre corrosão decisão.

Alto risco de corrosão (requer sufixo X):

- Localização costeira (dentro de 1 milha do oceano) → 3X, 3RX ou 4X

- Ambiente marinho (exposição direta à água do mar) → 4X com aço inoxidável 316

- Planta química ou atmosfera corrosiva → 4X (aço inoxidável ou fibra de vidro)

- Processamento de alimentos com limpeza cáustica → 4X aço inoxidável

- Tratamento de águas residuais/água → 4X ou fibra de vidro

Baixo risco de corrosão (aço macio aceitável):

- Clima seco ou temperado, sem sal/produtos químicos → 3, 3R ou 4 aço macio

- Economia de custos significativa (40-150% menor que as variantes X)

Seleção de material para variantes X:

- Corrosão geral → Aço inoxidável 304

- Exposição marinha/cloreto → Aço inoxidável 316

- Produtos químicos altamente corrosivos + preocupação com o peso → Fibra de Vidro

Pergunta 5: Classificação de Local Perigoso?

Esta é uma área classificada (perigosa) de acordo com o Artigo 500 do NEC?

Sim, Classe I, Divisão 1 (gases/vapores inflamáveis):

→ Tipo NEMA 7 (à prova de explosão, listado na UL 1203)

Sim, Classe II, Divisão 1 (poeira combustível):

→ Tipo NEMA 9 (à prova de ignição de poeira)

Sim, mina de carvão subterrânea:

→ Tipo NEMA 10 (aprovado pela MSHA)

Não, não classificado:

→ Use sua resposta das Perguntas 1-4.

Crítico: Nunca substitua NEMA 4 ou 12 padrão em uma área classificada. O risco de explosão/ignição é crítico para a segurança da vida.

Resumo da Árvore de Decisão

COMECE AQUI:

- Local perigoso?

- Sim, Classe I → Tipo 7

- Sim, Classe II → Tipo 9

- Não → Vá para 2

- Interior ou Exterior?

- Interior → Vá para 3

- Exterior → Vá para 4

- Perigos internos?

- Limpo, poeira mínima → Tipo 1

- Poeira/fiapos presentes → Tipo 12

- Poeira intensa, necessidade de vedação contra poeira → Tipo 5

- Spray de óleo/refrigerante → Tipo 13

- Exposição à água ao ar livre?

- Apenas chuva (sem lavagem com mangueira) → Tipo 3R ou 3 (se houver poeira)

- Lavagem com mangueira/lavagem sob pressão → Ir para #5

- Submersão possível → Tipo 6/6P

- Exposição à corrosão?

- Alta (costeira, marinha, química, cáustica) → Tipo 4X

- Baixa (temperada, seca, sem sal/químicos) → Tipo 4

É assim que você evita A Armadilha da Lavagem (3R em ambiente de lavagem com mangueira), A Mentira do Número Mais Alto (pensando 12 > 4), e O imposto sobre corrosão (pagando por 4X quando 3R ou 4 funcionam).

Figura 4: Fluxograma de decisão para seleção do tipo de invólucro NEMA. Siga esta estrutura de 5 etapas para corresponder aos riscos ambientais (interno/externo, exposição à água, corrosão, classificação de localização perigosa) à classificação NEMA apropriada, evitando erros de especificação comuns, como a armadilha de lavagem e o imposto de corrosão.

Implicações de custo e erros de especificação comuns

A seleção do tipo NEMA impacta diretamente os orçamentos do projeto – às vezes em 40-150%. Veja como evitar os erros dispendiosos.

Referências de custo (invólucro de montagem na parede de 18 × 16 × 8 polegadas)

| Tipo NEMA | Material | Custo típico | Premium vs NEMA 1 |

| 1 | Aço macio, revestimento em pó | \$120-\$180 | Linha de base |

| 3R | Aço macio, com junta | \$250-\$380 | +108-111% |

| 4 | Aço macio, selado | \$450-\$650 | +275-261% |

| 4X | Aço inoxidável 304 | \$850-\$1,200 | +608-567% |

| 4X | Aço inoxidável 316 | \$1,200-\$1,850 | +900-928% |

| 12 | Aço macio, com junta | \$220-\$320 | +83-78% |

Aviso O imposto sobre corrosão: A atualização de 4 para 4X (aço inoxidável 304) adiciona 89-85%. A atualização para aço inoxidável 316 adiciona 167-185%. Em um projeto de 50 invólucros, isso representa \$20.000-\$60.000 apenas em custos de material.

Erros de especificação comuns

Erro #1: Especificar 4X para todas as aplicações externas

Por que isso acontece: Os engenheiros optam pela “melhor proteção” ou os clientes exigem aço inoxidável para a qualidade percebida.

O custo: Uma instalação de utilidade suburbana com 20 invólucros em clima temperado (sem sal, sem produtos químicos) especificou aço inoxidável 4X. Custo: \$32.000. Se tivessem especificado aço macio 3R (adequado apenas para chuva), o custo teria sido de \$7.600 – \$24.400 economizados.

A correção: Pergunte: “A exposição à corrosão é alta?” Se não, o aço macio 3R ou 4 funciona. Economize O imposto sobre corrosão para ambientes que realmente precisam.

Erro #2: Usar 3R em ambientes de lavagem (a armadilha de lavagem)

Por que isso acontece: “Classificação externa” parece suficiente para “ambiente úmido”.”

O custo: O erro de \$47K da abertura – inspeção reprovada, perda de produção, substituição do invólucro, mão de obra de fiação.

A correção: Pergunte: “Este invólucro será lavado com mangueira?” Se sim, o tipo 4/4X é necessário. Teste de chuva ≠ teste de lavagem com mangueira.

Erro #3: Selecionar 12 em vez de 4 (a mentira do número maior)

Por que isso acontece: Assumindo que o número NEMA mais alto = melhor proteção.

O custo: Uma instalação de controle de motor ao ar livre especificou NEMA 12 porque “12 é maior que 4”. Após uma tempestade, a água entrou no invólucro não vedado contra intempéries. Custo de substituição: \$8.500 em mão de obra + materiais.

A correção: Entenda que os tipos NEMA são categorias ambientais, não uma escala progressiva. 12 é para poeira interna. 4 é para lavagem com mangueira ao ar livre. Riscos diferentes, tipos diferentes.

Erro #4: Ventilar demais invólucros selados

Por que isso acontece: As necessidades de gerenciamento térmico entram em conflito com a vedação ambiental.

O custo: Um invólucro NEMA 4X com VFD e PLC exigia resfriamento. O engenheiro adicionou entrada/saída de ventilador filtrada. Isso comprometeu a vedação 4X (os ventiladores atraem poeira e umidade). Seis meses depois, a umidade causou falhas no VFD. O invólucro teve que ser adaptado com ar condicionado de circuito fechado (\$2.800) em vez de ventilador de \$300.

A correção: Lembre-se de Dica profissional #1– invólucros selados (4X, 12) não podem usar ventiladores que trocam ar externo. Orçamento para resfriamento de circuito fechado desde o início se a dissipação de calor for significativa.

Erro #5: Ignorar a orientação da instalação

Por que isso acontece: A conveniência de montagem substitui os requisitos de drenagem.

O custo: Um invólucro NEMA 4 instalado horizontalmente (porta voltada para cima) em vez de verticalmente. A água da chuva acumulou-se na superfície da porta e acabou encontrando entrada. Danos causados pela água aos componentes: \$3.200.

A correção: Seguir Dica profissional #3– Os invólucros NEMA 3R, 4 e 6 têm dispositivos de drenagem que exigem orientação adequada. Verifique as instruções de instalação do fabricante e os requisitos de montagem.

Considerações sobre o custo do ciclo de vida

O custo inicial não é o único fator. Considere o ciclo de vida de 15 a 20 anos:

- Substituição por corrosão: O tipo 4 de aço macio em ambiente costeiro moderado pode precisar de substituição em 8 a 12 anos (invólucro de \$650 + mão de obra de \$1.500 para refazer a fiação). O aço inoxidável tipo 4X dura mais de 20 a 25 anos. Ao longo de 20 anos, o 4X pode ser mais barato, apesar do custo inicial 85% mais alto.

- Acesso de manutenção: Invólucros selados (4, 4X, 12) reduzem a exposição dos componentes a contaminantes, diminuindo a frequência de manutenção. O tipo 1 com ventilação aberta pode exigir limpeza mais frequente.

- Gestão térmica: O resfriamento de circuito fechado para invólucros selados adiciona custo inicial de \$800-\$3.500 mais \$200-\$600/ano em energia e manutenção. Considere isso nas decisões do tipo 4X vs tipo 1.

A classificação certa para o ambiente certo

Lembra daquele erro de lavagem de \$47.000 da abertura? Aconteceu porque alguém caiu em A Armadilha da Lavagem– escolher NEMA 3R para um ambiente que precisava de 4X. A classificação parecia suficientemente próxima. Os métodos de teste contaram uma história diferente.

Aqui está o que realmente importa:

A Mentira do Número Mais Alto é real. NEMA 12 não é melhor que NEMA 4 – eles protegem contra riscos totalmente diferentes. Os tipos NEMA são categorias ambientais, não uma escala progressiva. Combine a classificação com seus riscos específicos: poeira interna (12), chuva externa (3R), lavagem com mangueira externa (4), exposição corrosiva (4X).

A Armadilha da Lavagem pega engenheiros que assumem que “classificação externa” lida com toda a exposição à água. Não é. NEMA 3R passa em um teste de chuva (5 polegadas/hora de água caindo). NEMA 4 passa em um teste de lavagem com mangueira (65 GPM a 65 PSI de todos os ângulos). Se o seu ambiente incluir lavagem sob pressão, o 3R falhará. Gaste os \$200-\$400 extras adiantados e evite o erro de \$47K.

O imposto sobre corrosão é íngreme — prêmio de custo de 40-150% para classificações com sufixo X — mas vale a pena pagar quando o risco de corrosão é alto. Instalações costeiras, plantas químicas, ambientes marinhos e processamento de alimentos com limpeza cáustica justificam o aço inoxidável 4X. Climas temperados sem exposição a sal ou produtos químicos? Aço macio 3R ou 4 economiza milhares por invólucro.

A Encruzilhada 3R vs 4X é o seu ponto de decisão mais comum para invólucros externos. Faça duas perguntas: (1) “Isto será lavado com mangueira?” Se sim, você precisa de 4 ou 4X. (2) “A exposição à corrosão é alta?” Se sim, você precisa de 4X. Se ambas as respostas forem não, 3R economiza 60-70% em comparação com 4X.

Use a Estrutura de Decisão de 5 Perguntas: classificação de localização perigosa, interno vs externo, nível de exposição à água (chuva vs lavagem com mangueira), risco de corrosão e necessidades de gerenciamento térmico. Responda a essas cinco perguntas com suas condições ambientais reais, e o tipo NEMA correto se torna claro.

Dica Profissional: Em caso de dúvida, consulte as normas. ANSI/NEMA 250-2020 define os métodos de teste. UL 50 e UL 50E certificam a conformidade. Se um fornecedor alega uma classificação NEMA, verifique a marca de listagem UL dentro do invólucro. Sua AHJ verificará durante a inspeção — certifique-se de que esteja lá.

Escolha com base no seu ambiente, não em suposições. Métodos de teste, não marketing. Custo do ciclo de vida, não apenas preço inicial. Acerte na primeira vez e você nunca pagará por esse erro de lavagem.

Perguntas Frequentes

O que é uma classificação NEMA para invólucros?

Uma classificação NEMA é uma classificação padronizada definida por ANSI/NEMA 250-2020 que indica o nível de proteção ambiental que um invólucro elétrico fornece. As classificações especificam quais riscos ambientais o invólucro pode suportar — como poeira, chuva, água direcionada por mangueira, corrosão ou submersão — com base na aprovação em testes de design específicos. Os tipos NEMA variam do Tipo 1 (proteção interna básica) ao Tipo 4X (lavagem com mangueira externa com resistência à corrosão) ao Tipo 7/9 (à prova de explosão/à prova de ignição de poeira para locais perigosos).

Qual é a diferença entre NEMA 4 e NEMA 4X?

NEMA 4 fornece proteção contra poeira soprada pelo vento, chuva, granizo, neve e água direcionada por mangueira (65 GPM a 65 PSI). Os invólucros são normalmente de aço macio com revestimento em pó.

NEMA 4X fornece todas as proteções NEMA 4 mais resistência à corrosão. Requer materiais como aço inoxidável (grau 304 ou 316) ou fibra de vidro e deve passar por um teste de névoa salina de 600 horas e um teste de exposição à corrosão por CO2/SO2. O prêmio de custo é normalmente de 40-150% em comparação com NEMA 4.

Quando escolher 4X em vez de 4: Ambientes costeiros/marinhos, plantas químicas, instalações de tratamento de águas residuais, processamento de alimentos com limpeza cáustica ou qualquer instalação externa com sal, produtos químicos corrosivos ou atmosferas agressivas.

O NEMA 3R é adequado para uso externo?

Sim, o NEMA 3R é projetado para uso externo e fornece proteção contra chuva, granizo, neve e sujeira caindo. É a classificação NEMA externa mais econômica e é amplamente utilizada para invólucros de utilidades externas, medição, interruptores de desconexão e equipamentos elétricos externos em geral.

No entanto, o NEMA 3R não protege contra:

- Poeira soprada pelo vento (use NEMA 3 ou 4 se a poeira for uma preocupação)

- Água direcionada por mangueira ou lavagem de alta pressão (use NEMA 4 ou 4X)

- Ambientes corrosivos (use NEMA 3RX ou 4X)

Se o seu ambiente externo incluir limpeza com mangueira ou exposição corrosiva, o NEMA 3R falhará — isso é A Armadilha da Lavagem.

Contra o que o NEMA 12 protege?

O NEMA 12 protege contra:

- Sujeira caindo

- Poeira, fiapos e fibras circulantes

- Gotejamento de água e respingos leves de líquidos não corrosivos

Não não protege contra:

- Infiltração de óleo ou refrigerante (use NEMA 13)

- Chuva externa ou lavagem com mangueira (use NEMA 3R ou 4)

- Ambientes corrosivos

Melhores aplicações: Ambientes industriais internos de uso geral — pisos de fabricação, armazéns, linhas de montagem, fábricas sem lavagem.

Você pode usar um invólucro NEMA 4 em ambientes internos?

Sim, o NEMA 4 pode ser usado em ambientes internos e fornece proteção que excede a maioria dos requisitos internos (à prova de poeira, à prova de gotejamento, resistente a respingos). No entanto, muitas vezes é superespecificado para ambientes internos típicos:

- O NEMA 4 é selado: Sem aberturas de ventilação, o que limita as opções de resfriamento. Você precisará de resfriamento de circuito fechado (ar condicionado, trocador de calor) se a dissipação de calor for significativa — adicionando US$ 800 a US$ 3.500 ao custo do sistema.

- O NEMA 12 geralmente é suficiente para uso industrial interno (poeira, gotejamentos, respingos leves) e custa 30-50% menos que o NEMA 4.

- Use NEMA 4 em ambientes internos quando: Você precisa de capacidade de limpeza com mangueira (processamento de alimentos, farmacêutico, salas de lavagem) ou vedação à prova de poeira além do NEMA 12.

Qual é a diferença entre as classificações NEMA e IP?

As classificações NEMA (ANSI/NEMA 250) são normas norte-americanas que classificam os invólucros com base na proteção ambiental holística — incluindo requisitos de construção, materiais, resistência à corrosão e múltiplos riscos (poeira, água, óleo).

As classificações IP (IEC 60529) são normas internacionais que usam um código de dois dígitos (IPXY) para indicar a proteção contra entrada: primeiro dígito = proteção contra partículas sólidas (0-6), segundo dígito = proteção contra líquidos (0-9). As classificações IP se concentram apenas na entrada; elas não abordam corrosão, resistência a óleo ou normas de construção.

Equivalentes aproximados (por NEMA BI 50014-2024):

- NEMA 1 ≈ IP10

- NEMA 3R ≈ IP24 (às vezes IP54)

- NEMA 4/4X ≈ IP65 ou IP66

- NEMA 12 ≈ IP54

- NEMA 6/6P ≈ IP67 ou IP68

Ponto chave: Estes são aproximados mapeamentos. Os métodos de teste diferem e o NEMA inclui requisitos (resistência à corrosão, exclusão de óleo) que o IP não aborda. Para projetos globais, especifique invólucros com classificação dupla (por exemplo, “NEMA 4X / IP66”) e verifique a conformidade com ambas as normas.

Qual classificação NEMA eu preciso para uma planta de processamento de alimentos?

As plantas de processamento de alimentos normalmente exigem Aço inoxidável NEMA 4X por vários motivos:

- Requisitos de lavagem: As regulamentações do USDA e da FDA exigem lavagem regular de alta pressão com água quente e produtos químicos de limpeza cáusticos (hidróxido de sódio, ácido fosfórico). O NEMA 4X passa no teste de lavagem com mangueira; o 3R não.

- Resistência à corrosão: Os produtos de limpeza cáusticos atacam o aço macio. O aço inoxidável (grau 304 ou 316) é necessário para durabilidade a longo prazo.

- Design sanitário: Superfícies lisas de aço inoxidável são mais fáceis de limpar e higienizar do que aço macio pintado.

Escolha do material: Aço inoxidável 304 é o padrão. Use aço inoxidável 316 se os produtos químicos de limpeza incluírem compostos clorados ou se a planta for costeira.

Custo: Aço inoxidável NEMA 4X custa de \$600 a \$1.850 para tamanhos típicos (vs \$150 a \$400 para aço macio NEMA 3R). O custo adicional é justificado pela conformidade regulatória, maior vida útil e evitar inspeções reprovadas.

As classificações NEMA são exigidas por lei?

As classificações NEMA em si não são requisitos de código—o Código Elétrico Nacional (NEC) não exige tipos NEMA específicos. No entanto:

- NEC 110.3(B) exige que o equipamento seja instalado de acordo com as instruções do fabricante e a listagem, que inclui adequação ambiental.

- Artigo 500-506 do NEC exige invólucros à prova de explosão ou à prova de ignição de poeira (NEMA 7, 9) em locais perigosos (classificados).

- Códigos locais e AHJs (Autoridades com Jurisdição) frequentemente exigem invólucros adequados para o ambiente de instalação. Se um inspetor determinar que o invólucro não está adequadamente protegido para o ambiente (por exemplo, NEMA 3R em uma área de lavagem com mangueira), ele pode reprovar a instalação.

Melhor prática: Especifique as classificações NEMA que correspondam aos riscos ambientais e garanta que os invólucros tenham as marcas de listagem UL 50/50E. Os inspetores procuram marcas UL como verificação de conformidade.

Quanto tempo duram os invólucros NEMA?

A vida útil depende do tipo NEMA, material, ambiente e manutenção:

- NEMA 1 interno (aço macio, ambiente seco): 15-25+ anos com manutenção mínima.

- NEMA 3R externo (aço macio, clima temperado): 10-15 anos; pode apresentar ferrugem/degradação em 5-10 anos em áreas úmidas ou costeiras.

- NEMA 4 externo (aço macio, exposição moderada): 8-12 anos antes da degradação do revestimento e ferrugem em climas úmidos/costeiros.

- Aço inoxidável NEMA 4X (304 ou 316): 20-30+ anos na maioria dos ambientes. O aço inoxidável 316 costeiro pode durar 30+ anos com corrosão mínima.

- Fibra de vidro NEMA 4X: 20-25+ anos em ambientes quimicamente agressivos; resistente a UV e produtos químicos.

Consideração do custo do ciclo de vida: Um invólucro de aço inoxidável NEMA 4X custa 85% mais inicialmente do que o aço macio NEMA 4, mas dura 2-3× mais em ambientes corrosivos. Ao longo de 20 anos, o 4X pode ser mais econômico quando o trabalho de substituição é levado em consideração.

Normas Técnicas Referenciadas

- ANSI/NEMA 250-2020 – Invólucros para Equipamentos Elétricos (1.000 Volts Máximo)

- UL 50 – Invólucros para Equipamentos Elétricos, Considerações Não Ambientais (construção)

- UL 50E – Invólucros para Equipamentos Elétricos, Considerações Ambientais

- IEC 60529 – Graus de proteção fornecidos por invólucros (Código IP)

- NEMA BI 50014-2024 – Graus de Proteção Fornecidos por Invólucros (Código IP): Uma Breve Comparação

- UL 1203 – Equipamentos Elétricos à Prova de Explosão e à Prova de Ignição de Poeira para Uso em Locais Perigosos (Classificados)

- Artigo 500-506 do NEC – Locais Perigosos (Classificados)

- NEC 110.3(B) – Instalação e Uso (instruções do fabricante e conformidade com a listagem)

Em novembro de 2025, todas as normas e especificações neste guia refletem as edições publicadas mais recentes e as práticas da indústria.