ໃນແຕ່ລະປີ, ເຫດການໄຟຟ້າເຮັດໃຫ້ເກີດການບາດເຈັບໃນບ່ອນເຮັດວຽກຫຼາຍພັນຄົນ ແລະຄວາມລົ້ມເຫຼວຂອງອຸປະກອນ - ຫຼາຍໆຢ່າງສາມາດປ້ອງກັນໄດ້ດ້ວຍການເລືອກສະວິດການເຊື່ອມຕໍ່ທີ່ຖືກຕ້ອງ. ບໍ່ວ່າທ່ານກໍາລັງຕິດຕັ້ງລະບົບຄວບຄຸມມໍເຕີໃຫມ່ຫຼືການຍົກລະດັບອຸປະກອນຄວາມປອດໄພຂອງສະຖານທີ່, ຄວາມເຂົ້າໃຈຄວາມແຕກຕ່າງລະຫວ່າງປຸ່ມຕັດການເຊື່ອມຕໍ່ແບບຟິວກັບ fused ແລະບໍ່ fused ສາມາດຫມາຍຄວາມວ່າຄວາມແຕກຕ່າງລະຫວ່າງການດໍາເນີນງານທີ່ປອດໄພ, ສອດຄ່ອງແລະການຢຸດງານທີ່ມີຄ່າໃຊ້ຈ່າຍ.

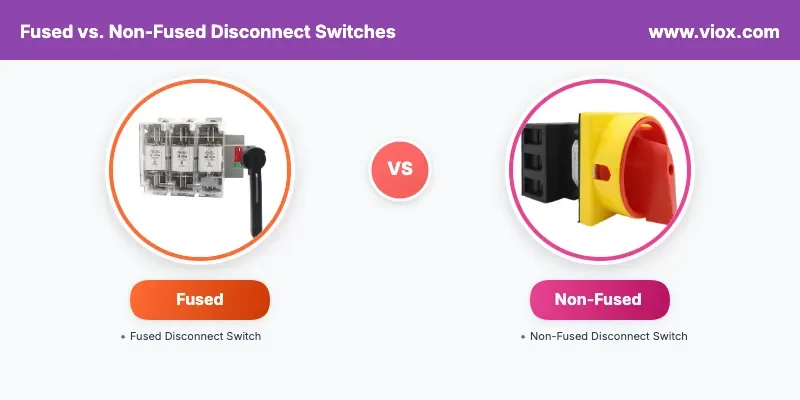

ແຖວລຸ່ມຂຶ້ນດ້ານໜ້າ: ສະຫວິດຕັດການເຊື່ອມຕໍ່ fused ສະຫນອງການປ້ອງກັນ overcurrent ໃນຕົວໂດຍຜ່ານ fuses ປະສົມປະສານ, ໃນຂະນະທີ່ສະຫຼັບຕັດການເຊື່ອມຕໍ່ທີ່ບໍ່ແມ່ນ fused ພຽງແຕ່ isolate circuits ໂດຍບໍ່ມີການສະຫນອງການປົກປ້ອງເພີ່ມເຕີມ. ການເລືອກຂອງທ່ານແມ່ນຂຶ້ນກັບລະບົບປ້ອງກັນທີ່ມີຢູ່ແລ້ວ, ຄວາມອ່ອນໄຫວຂອງອຸປະກອນ, ແລະຄວາມຕ້ອງການສະເພາະຂອງຄໍາຮ້ອງສະຫມັກ.

Disconnect Switches ແມ່ນຫຍັງ? (ເຂົ້າໃຈພື້ນຖານ)

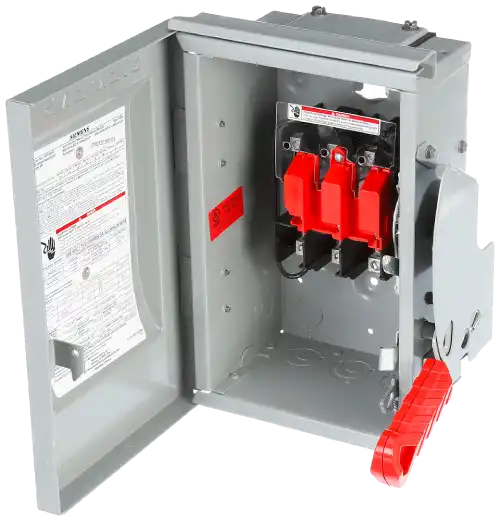

ສະຫຼັບຕັດການເຊື່ອມຕໍ່, ເຊິ່ງເອີ້ນກັນວ່າສະວິດຄວາມປອດໄພ ຫຼື ສະວິດໂດດດ່ຽວ, ແມ່ນອຸປະກອນຄູ່ມືທີ່ອອກແບບມາເພື່ອຕັດໄຟຟ້າອອກຈາກວົງຈອນ ຫຼື ຊິ້ນສ່ວນຂອງອຸປະກອນ. ສະວິດເຫຼົ່ານີ້ເຮັດຫນ້າທີ່ເປັນກົນໄກຄວາມປອດໄພຕົ້ນຕໍທີ່ອະນຸຍາດໃຫ້ພະນັກງານບໍາລຸງຮັກສາໃຫ້ບໍລິການອຸປະກອນໄຟຟ້າໂດຍບໍ່ມີຄວາມສ່ຽງຕໍ່ການໄຟຟ້າຫຼືຄວາມເສຍຫາຍອຸປະກອນ.

ຈຸດປະສົງພື້ນຖານຂອງສະຫຼັບຕັດການເຊື່ອມຕໍ່ໃດຫນຶ່ງແມ່ນເພື່ອສ້າງຊ່ອງຫວ່າງທາງດ້ານຮ່າງກາຍໃນວົງຈອນໄຟຟ້າ, ການຮັບປະກັນວ່າບໍ່ມີກະແສໄຫລໄປຫາອຸປະກອນລຸ່ມນ້ໍາ. ການໂດດດ່ຽວນີ້ແມ່ນສໍາຄັນຕໍ່ຂັ້ນຕອນການປິດ/ tagout (LOTO) ແລະການປະຕິບັດຕາມກົດລະບຽບຄວາມປອດໄພໃນບ່ອນເຮັດວຽກ.

ສະພາບລວມຄວາມຕ້ອງການ NEC

ອີງຕາມ NEC ມາດຕາ 430.102B, disconnect switches ຕ້ອງຕັ້ງຢູ່ "ໃນ sight" ຈາກ motors ແລະອຸປະກອນການຜະລິດທັງຫມົດ. ລະຫັດໄຟຟ້າແຫ່ງຊາດກໍານົດ "ໃນສາຍຕາ" ເປັນທີ່ເຫັນໄດ້ແລະບໍ່ເກີນ 50 ຟຸດຈາກອຸປະກອນຄວບຄຸມ. ຄວາມຕ້ອງການນີ້ຮັບປະກັນວ່າພະນັກງານບໍາລຸງຮັກສາສາມາດຕັດສາຍໄຟໄດ້ໄວແລະປອດໄພໃນເວລາທີ່ຈໍາເປັນ.

Fused Disconnect Switches ອະທິບາຍ

ວິທີການປິດການເຊື່ອມຕໍ່ Fused Disconnect ເຮັດວຽກ

ປຸ່ມຕັດການເຊື່ອມຕໍ່ Fused ສົມທົບສອງຫນ້າທີ່ທີ່ສໍາຄັນໃນ enclosure ດຽວ: ການແຍກວົງຈອນແລະການປ້ອງກັນ overcurrent. ອຸປະກອນເຫຼົ່ານີ້ປະກອບດ້ວຍຟິວທີ່ຈະລະເບີດ (ເປີດ) ເມື່ອກະແສໄຟຟ້າເກີນລະດັບທີ່ປອດໄພ, ປົກປ້ອງທັງວົງຈອນແລະອຸປະກອນທີ່ເຊື່ອມຕໍ່ຈາກຄວາມເສຍຫາຍ.

ໃນເວລາທີ່ການ overload ຫຼືວົງຈອນສັ້ນເກີດຂຶ້ນ, ອົງປະກອບຂອງຟິວ melts, ສ້າງວົງຈອນເປີດທີ່ຢຸດເຊົາການໄຫຼຂອງປະຈຸບັນ. ການທໍາງານສອງອັນນີ້ເຮັດໃຫ້ສະວິດການເຊື່ອມຕໍ່ fused disconnect ທີ່ມີຄຸນຄ່າໂດຍສະເພາະໃນຄໍາຮ້ອງສະຫມັກທີ່ມີຄວາມຈໍາເປັນການປົກປ້ອງວົງຈອນເພີ່ມເຕີມເກີນສິ່ງທີ່ສະຫນອງໃຫ້ຢູ່ໃນແຜງຕົ້ນຕໍ.

ຄຸນນະສົມບັດທີ່ສໍາຄັນຂອງສະວິດການຕັດການເຊື່ອມຕໍ່ Fused

- ການປົກປ້ອງກະແສໄຟຟ້າໃນຕົວ: ຟິວທີ່ປະສົມປະສານໃຫ້ການປົກປ້ອງທັນທີຕໍ່ກັບຄວາມຜິດທາງໄຟຟ້າ, ມັກຈະປະຕິກິລິຍາໄວກວ່າຕົວຕັດວົງຈອນຫ່າງໄກ.

- ຕົວຊີ້ວັດຄວາມຜິດທາງສາຍຕາ: ເມື່ອຟິວໄຟແຕກ, ມັນຈະແຈ້ງທັນທີທີ່ວົງຈອນປະສົບຄວາມຜິດ, ເຮັດໃຫ້ການແກ້ໄຂບັນຫາແລະການບໍາລຸງຮັກສາງ່າຍຂຶ້ນ.

- ຄວາມປອດໄພອຸປະກອນທີ່ປັບປຸງ: ອຸປະກອນທີ່ລະອຽດອ່ອນຫຼືລາຄາແພງໄດ້ຮັບຜົນປະໂຫຍດຈາກການປົກປ້ອງທ້ອງຖິ່ນທີ່ປ້ອງກັນຄວາມເສຍຫາຍຈາກການເກີດໄຟຟ້າຫຼືຄວາມຜິດ.

- ການອອກແບບແບ່ງປັນ: ສະຫຼັບຕັດເຊື່ອມຕໍ່ fused ຫຼາຍມີຊ່ອງແຍກສໍາລັບການສະຫຼັບແລະຟິວ, ອະນຸຍາດໃຫ້ປ່ຽນຟິວທີ່ປອດໄພກວ່າໂດຍບໍ່ມີການສໍາຜັດກັບແຮງດັນຂອງສາຍ.

ຄໍາຮ້ອງສະຫມັກທົ່ວໄປສໍາລັບ Switches Disconnect Fused

- ເຄື່ອງຈັກອຸດສາຫະກໍາຫນັກ: ອຸປະກອນການຜະລິດທີ່ມີການໂຫຼດທີ່ປ່ຽນແປງໄດ້ຜົນປະໂຫຍດຈາກຊັ້ນປ້ອງກັນເພີ່ມເຕີມ.

- ສູນຄວບຄຸມມໍເຕີ: ມໍເຕີຂະຫນາດໃຫຍ່ທີ່ບໍ່ມີການປົກປ້ອງທາງເທິງທີ່ພຽງພໍຮຽກຮ້ອງໃຫ້ມີການຕັດການເຊື່ອມຕໍ່ fused ສໍາລັບການດໍາເນີນງານທີ່ປອດໄພ.

- ລະບົບ HVAC ການຄ້າ: ໜ່ວຍເຄື່ອງປັບອາກາດ ແລະປ້ຳຄວາມຮ້ອນມັກຈະລະບຸການຕັດການເຊື່ອມຕໍ່ແບບຟິວຊັນເພື່ອປ້ອງກັນທີ່ດີທີ່ສຸດ.

- ອຸປະກອນປຸງແຕ່ງ: ການປຸງແຕ່ງສະບຽງອາຫານ, ສານເຄມີ, ແລະອຸປະກອນການຢາທີ່ downtime ແມ່ນຄ່າໃຊ້ຈ່າຍ.

ການອະທິບາຍສະວິດການຕັດຕໍ່ບໍ່ແມ່ນ Fused

ວິທີການທີ່ສະຫຼັບຕັດການເຊື່ອມຕໍ່ທີ່ບໍ່ແມ່ນ Fused ເຮັດວຽກ

ປຸ່ມຕັດການເຊື່ອມຕໍ່ທີ່ບໍ່ຕິດຟິວສິກສຸມໃສ່ການແຍກວົງຈອນໂດຍບໍ່ໄດ້ໃຫ້ການປົກປ້ອງກະແສໄຟຟ້າເພີ່ມເຕີມ. ພວກເຂົາເຈົ້າອີງໃສ່ອຸປະກອນພາຍນອກເຊັ່ນ: breakers ຫຼື fuses ໃນແຜງຕົ້ນຕໍເພື່ອຈັດການກັບຄວາມຜິດ.

ສະວິດເຫຼົ່ານີ້ດໍາເນີນການໂດຍການແຍກອອກທາງກາຍະພາບຕິດຕໍ່ພົວພັນໄຟຟ້າໃນເວລາທີ່ເປີດ, ສ້າງຊ່ອງຫວ່າງອາກາດທີ່ປ້ອງກັນການໄຫຼຂອງປະຈຸບັນ. ຄວາມງ່າຍດາຍຂອງການອອກແບບນີ້ເຮັດໃຫ້ການສະຫຼັບຕັດການເຊື່ອມຕໍ່ທີ່ບໍ່ແມ່ນ fused ທີ່ເຊື່ອຖືໄດ້, ປະຫຍັດຄ່າໃຊ້ຈ່າຍ, ແລະງ່າຍຕໍ່ການຮັກສາ.

ຄຸນນະສົມບັດທີ່ສໍາຄັນຂອງສະຫຼັບຕັດການເຊື່ອມຕໍ່ທີ່ບໍ່ແມ່ນ Fused

- ການດໍາເນີນງານງ່າຍດາຍ: ດ້ວຍອົງປະກອບທີ່ໜ້ອຍລົງ, ສະຫຼັບທີ່ບໍ່ແມ່ນຟິວຊັນ ສະເໜີການເປີດ/ປິດແບບກົງໄປກົງມາ ໂດຍມີຄວາມຕ້ອງການການບຳລຸງຮັກສາໜ້ອຍທີ່ສຸດ.

- ການແກ້ໄຂຄ່າໃຊ້ຈ່າຍທີ່ມີປະສິດທິພາບ: ຄ່າໃຊ້ຈ່າຍເບື້ອງຕົ້ນຕ່ໍາແລະຈໍານວນອົງປະກອບທີ່ຫຼຸດລົງເຮັດໃຫ້ສະຫຼັບເຫຼົ່ານີ້ເປັນທີ່ດຶງດູດສໍາລັບຄໍາຮ້ອງສະຫມັກທີ່ມີງົບປະມານ.

- ການຟື້ນຟູພະລັງງານດ່ວນ: ຫຼັງຈາກການແກ້ໄຂບັນຫາ, ພະລັງງານສາມາດໄດ້ຮັບການຟື້ນຟູທັນທີທັນໃດໂດຍບໍ່ມີການທົດແທນການ blown fuses.

- ການອອກແບບກະທັດຮັດ: ໂດຍບໍ່ມີຊ່ອງໃສ່ຟິວ, ສະວິດເຫຼົ່ານີ້ຕ້ອງການພື້ນທີ່ຫນ້ອຍແລະມັກຈະງ່າຍຕໍ່ການຕິດຕັ້ງໃນສະຖານທີ່ໃກ້ຊິດ.

ຄໍາຮ້ອງສະຫມັກທົ່ວໄປສໍາລັບ Switches Disconnect ທີ່ບໍ່ແມ່ນ Fused

- ຄໍາຮ້ອງສະຫມັກການຄ້າແສງສະຫວ່າງ: ອາຄານຫ້ອງການ, ສະຖານທີ່ຂາຍຍ່ອຍ, ແລະສິ່ງອໍານວຍຄວາມສະດວກດ້ານການຄ້າຂະຫນາດນ້ອຍ.

- ລະບົບ HVAC ທີ່ຢູ່ອາໄສ: ເຄື່ອງປັບອາກາດໃນເຮືອນແລະອຸປະກອນເຮັດຄວາມຮ້ອນທີ່ມີການປົກປ້ອງກະດານທີ່ພຽງພໍ.

- ຄໍາຮ້ອງສະຫມັກການຄວບຄຸມມໍເຕີ: ໃນເວລາທີ່ motor starters ປະກອບມີການກໍ່ສ້າງໃນການປ້ອງກັນ overload.

- ການແຍກໄຟຟ້າທົ່ວໄປ: ການຕັດການເຊື່ອມຕໍ່ອຸປະກອນສໍາລັບການບໍາລຸງຮັກສາເມື່ອມີການປ້ອງກັນ overcurrent ຢູ່ບ່ອນອື່ນ.

ການປຽບທຽບດ້ານຂ້າງ: Fused ທຽບກັບສະວິດການເຊື່ອມຕໍ່ທີ່ບໍ່ແມ່ນ Fused

| ຄຸນສົມບັດ | Fused ຕັດການເຊື່ອມຕໍ່ | ຕັດການເຊື່ອມຕໍ່ທີ່ບໍ່ແມ່ນ Fused |

|---|---|---|

| ຟັງຊັນປະຖົມ | ການໂດດດ່ຽວ + ການປົກປ້ອງ | ໂດດດ່ຽວເທົ່ານັ້ນ |

| ການປົກປ້ອງກະແສໄຟຟ້າເກີນ | Built-in ຜ່ານ fuses | ຕ້ອງການອຸປະກອນພາຍນອກ |

| ຕົວຊີ້ບອກຄວາມຜິດ | ສາຍຕາ (ຟິວທີ່ເປົ່າ) | ບໍ່ມີ |

| ການຟື້ນຟູພະລັງງານ | ຕ້ອງການປ່ຽນຟິວ | ຣີເຊັດສະວິດທັນທີ |

| ຄ່າໃຊ້ຈ່າຍເບື້ອງຕົ້ນ | ສູງກວ່າ | ຕ່ໍາກວ່າ |

| ສະລັບສັບຊ້ອນການບໍາລຸງຮັກສາ | ປານກາງ (ປ່ຽນຟິວ) | ຕໍ່າ |

| ຂະໜາດບັນຈຸ | ໃຫຍ່ກວ່າ | ນ້ອຍກວ່າ |

| ຄວາມສັບສົນໃນການຕິດຕັ້ງ | ສູງກວ່າ | ຕ່ໍາກວ່າ |

| ດີທີ່ສຸດສໍາລັບ | ອຸປະກອນທີ່ລະອຽດອ່ອນ, ການໂຫຼດສູງໃນປະຈຸບັນ | ຄ່າໃຊ້ຈ່າຍສະຕິ, ວົງຈອນປ້ອງກັນ |

ຄວາມສາມາດໃນການປົກປ້ອງ

ຄວາມແຕກຕ່າງທີ່ ສຳ ຄັນທີ່ສຸດແມ່ນຢູ່ໃນຄວາມສາມາດໃນການປົກປ້ອງ. ປຸ່ມຕັດການເຊື່ອມຕໍ່ແບບ Fused ສະຫນອງການປົກປ້ອງ overcurrent ທ້ອງຖິ່ນທີ່ສາມາດຕອບສະຫນອງໄວກວ່າຕົວຕັດວົງຈອນຫ່າງໄກ. ການປົກປ້ອງທັນທີນີ້ແມ່ນມີຄຸນຄ່າໂດຍສະເພາະສໍາລັບ:

- ອຸປະກອນທີ່ມີອົງປະກອບທີ່ລະອຽດອ່ອນກະຕຸ້ນ

- ແອັບພລິເຄຊັ່ນທີ່ການປ້ອງກັນຕົ້ນນໍ້າອາດຈະຖືກຂະໜາດໃຫຍ່

- ລະບົບທີ່ຮຽກຮ້ອງໃຫ້ມີການປະສານງານຄວາມຜິດໃນປະຈຸບັນທີ່ຊັດເຈນ

ປຸ່ມຕັດການເຊື່ອມຕໍ່ທີ່ບໍ່ແມ່ນຟິວສິກແມ່ນຂຶ້ນກັບອຸປະກອນປ້ອງກັນທາງເທິງທັງໝົດ. ໃນຂະນະທີ່ວິທີການນີ້ເຮັດວຽກໄດ້ດີໃນຫຼາຍໆຄໍາຮ້ອງສະຫມັກ, ມັນອາດຈະເຮັດໃຫ້ອຸປະກອນມີຄວາມສ່ຽງຖ້າການປ້ອງກັນນ້ໍາບໍ່ພຽງພໍຫຼືຂະຫນາດທີ່ບໍ່ຖືກຕ້ອງ.

ການພິຈາລະນາຄ່າໃຊ້ຈ່າຍ

ລາຄາຊື້ເບື້ອງຕົ້ນ: ສະຫຼັບຕັດການເຊື່ອມຕໍ່ທີ່ບໍ່ມີຟິວ ປົກກະຕິມີລາຄາ 20-40% ໜ້ອຍກວ່າຕົວແບບຟິວທີ່ທຽບເທົ່າ. ຄວາມແຕກຕ່າງຂອງຄ່າໃຊ້ຈ່າຍນີ້ເພີ່ມຂຶ້ນດ້ວຍອັດຕາ amperage ທີ່ສູງຂຶ້ນ.

ຄ່າໃຊ້ຈ່າຍໃນການຕິດຕັ້ງ: ສະຫວິດ fused ຕ້ອງການ enclosures ຂະຫນາດໃຫຍ່ແລະສາຍໄຟສະລັບສັບຊ້ອນຫຼາຍ, ອາດຈະເພີ່ມແຮງງານການຕິດຕັ້ງໂດຍ 15-25%.

ການບໍາລຸງຮັກສາໄລຍະຍາວ: ໃນຂະນະທີ່ສະວິດ fused ຕ້ອງການການປ່ຽນ fuse ເປັນໄລຍະ, ສະວິດທີ່ບໍ່ແມ່ນ fused ອາດຈະມີປະສົບການການບໍາລຸງຮັກສາການຕິດຕໍ່ເລື້ອຍໆເນື່ອງຈາກຄວາມຜິດທີ່ສູງຂຶ້ນໃນປະຈຸບັນ.

ຄ່າໃຊ້ຈ່າຍໃນການທົດແທນ Fuse: fuses ອຸດສາຫະກໍາສາມາດຕັ້ງແຕ່ $20-200+ ຂຶ້ນກັບ amperage ແລະປະເພດ, ເປັນຕົວແທນຂອງຄ່າໃຊ້ຈ່າຍໃນການດໍາເນີນງານຢ່າງຕໍ່ເນື່ອງ.

ເມື່ອໃດທີ່ຈະເລືອກປຸ່ມປິດການເຊື່ອມຕໍ່ Fused

ຄໍາຮ້ອງສະຫມັກທີ່ເຫມາະສົມ

ເລືອກປຸ່ມຕັດການເຊື່ອມຕໍ່ແບບຟິວເມື່ອ:

- ຜູ້ຜະລິດອຸປະກອນລະບຸ Fuses: ຜູ້ຜະລິດມໍເຕີແລະອຸປະກອນຈໍານວນຫຼາຍຮຽກຮ້ອງໃຫ້ມີການຕັດການເຊື່ອມຕໍ່ fused ສໍາລັບການປະຕິບັດຕາມການຮັບປະກັນແລະການປົກປ້ອງທີ່ດີທີ່ສຸດ.

- ການປົກປ້ອງຕົ້ນນໍ້າບໍ່ພຽງພໍ: ເມື່ອ breaker ກະດານຕົ້ນຕໍແມ່ນ oversized ສໍາລັບອຸປະກອນສະເພາະ, ການປ້ອງກັນ fuse ທ້ອງຖິ່ນຮັບປະກັນການປະສານງານທີ່ເຫມາະສົມ.

- ອຸປະກອນເອເລັກໂຕຣນິກທີ່ລະອຽດອ່ອນ: ຂັບຄວາມຖີ່ທີ່ປ່ຽນແປງໄດ້, ມໍເຕີ servo, ແລະອຸປະກອນຄອມພິວເຕີໄດ້ຮັບຜົນປະໂຫຍດຈາກການປ້ອງກັນຟິວທີ່ເຮັດວຽກໄວ.

- ຄໍາຮ້ອງສະຫມັກໃນປະຈຸບັນທີ່ມີຄວາມຜິດສູງ: ໃນລະບົບໄຟຟ້າທີ່ມີກະແສໄຟຟ້າທີ່ມີຄວາມຜິດສູງ, ຟິວສາມາດສະຫນອງການຈໍາກັດພະລັງງານ Arc ທີ່ດີກວ່າເຄື່ອງຕັດວົງຈອນບາງອັນ.

ຂໍ້ກໍານົດກົດລະບຽບ

ລະຫັດແລະມາດຕະຖານຈໍານວນຫນຶ່ງມັກຫຼືຮຽກຮ້ອງໃຫ້ມີການປ່ຽນການຕັດການເຊື່ອມຕໍ່ fused:

- NEC ມາດຕາ 430: ຄວາມຕ້ອງການດ້ານການປ້ອງກັນມໍເຕີມັກຈະຈໍາເປັນຕ້ອງມີການຕັດການເຊື່ອມຕໍ່ fused.

- ມາດຕະຖານອຸປະກອນ: ອຸປະກອນທີ່ມີລາຍຊື່ UL ອາດຈະລະບຸການຕັດການເຊື່ອມຕໍ່ fused ສໍາລັບການປະສານງານການປົກປ້ອງທີ່ເຫມາະສົມ.

- ຄວາມຕ້ອງການປະກັນໄພ: ຜູ້ໃຫ້ບໍລິການປະກັນໄພບາງຄົນມັກການຕັດການເຊື່ອມຕໍ່ແບບປະສົມປະສານເພື່ອການປົກປ້ອງອຸປະກອນທີ່ມີຄ່າສູງ.

ເມື່ອໃດທີ່ຈະເລືອກປຸ່ມຕັດການເຊື່ອມຕໍ່ທີ່ບໍ່ແມ່ນ Fused

ກໍລະນີການນໍາໃຊ້ທີ່ດີທີ່ສຸດ

ເລືອກສະວິດການຕັດການເຊື່ອມຕໍ່ທີ່ບໍ່ໄດ້fused ເມື່ອ:

- ການປົກປ້ອງຕົ້ນນ້ຳທີ່ພຽງພໍມີຢູ່: ເມື່ອເຄື່ອງຕັດວົງຈອນທີ່ມີຂະໜາດເໝາະສົມໃຫ້ການປົກປ້ອງພຽງພໍ, ຟິວເພີ່ມເຕີມອາດຈະຊໍ້າຊ້ອນ.

- ຂໍ້ຈຳກັດດ້ານງົບປະມານ: ສໍາລັບໂຄງການທີ່ລະອຽດອ່ອນຄ່າໃຊ້ຈ່າຍທີ່ການໂດດດ່ຽວພື້ນຖານຕອບສະຫນອງຄວາມຕ້ອງການຄວາມປອດໄພ.

- ການບໍາລຸງຮັກສາແບບງ່າຍດາຍທີ່ຕ້ອງການ: ແອັບພລິເຄຊັ່ນທີ່ຫຼຸດການນັບອົງປະກອບຫຼຸດຄວາມຊັບຊ້ອນໃນການບຳລຸງຮັກສາ.

- ແອັບພລິເຄຊັນທີ່ມີຄວາມສ່ຽງຕໍ່າ: ອຸປະກອນທີ່ມີການປົກປັກຮັກສາໃນຕົວຫຼືຄໍາຮ້ອງສະຫມັກທີ່ຄວາມສ່ຽງຄວາມຜິດພາດແມ່ນຫນ້ອຍ.

ສະຖານະການຄ່າໃຊ້ຈ່າຍ-ຜົນປະໂຫຍດ

ສະວິດທີ່ບໍ່ແມ່ນຟິວຊັນໃຫ້ມູນຄ່າທີ່ດີທີ່ສຸດເມື່ອ:

- ການປົກປັກຮັກສາເທິງນ້ໍາແມ່ນການປະສານງານຢ່າງຖືກຕ້ອງ

- ອຸປະກອນມີການປ້ອງກັນ overload ພາຍໃນ

- ພະນັກງານບໍາລຸງຮັກສາມັກລະບົບທີ່ງ່າຍດາຍ

- ຄ່າໃຊ້ຈ່າຍເບື້ອງຕົ້ນແມ່ນຄວາມກັງວົນຕົ້ນຕໍ

ຂໍ້ກໍານົດຂອງ NEC ແລະການປະຕິບັດຕາມລະຫັດ

ມາດຕາ 430.102B ຄວາມຕ້ອງການ

ລະຫັດໄຟຟ້າແຫ່ງຊາດກໍານົດຂໍ້ກໍານົດສະເພາະສໍາລັບການຕັດການວາງສະວິດແລະການດໍາເນີນງານ:

- ຄໍານິຍາມ "ໃນສາຍຕາ": ປຸ່ມຕັດການເຊື່ອມຕໍ່ຕ້ອງເຫັນໄດ້ຊັດເຈນແລະພາຍໃນ 50 ຟຸດຂອງອຸປະກອນຄວບຄຸມ. ນີ້ຮັບປະກັນວ່າພະນັກງານບໍາລຸງຮັກສາສາມາດກວດສອບຕໍາແຫນ່ງສະຫຼັບກ່ອນທີ່ຈະເລີ່ມຕົ້ນການເຮັດວຽກ.

- ການປະຕິບັດຕາມການລັອກ/ Tagout: ປຸ່ມຕັດການເຊື່ອມຕໍ່ຈະຕ້ອງສາມາດຖືກລັອກໃນບ່ອນເປີດ. ພາກທີ 110.25 ລະບຸວ່າການໃຫ້ການລັອກຕ້ອງໄດ້ຮັບການຕິດຕັ້ງຢ່າງຖາວອນກັບສະວິດ.

- ມາດຕະຖານການເຂົ້າເຖິງ: ສະວິດຕ້ອງສາມາດເຂົ້າເຖິງໄດ້ຢ່າງສະດວກຕໍ່ກັບບຸກຄະລາກອນທີ່ມີຄຸນວຸດທິແຕ່ໄດ້ຮັບການປົກປ້ອງຈາກການເຮັດວຽກໂດຍບັງເອີນ.

ມາດຕະຖານການຕິດຕັ້ງ

- ການຈັດອັນດັບການປິດລ້ອມ: ເລືອກການຈັດອັນດັບ NEMA ທີ່ເຫມາະສົມໂດຍອີງໃສ່ເງື່ອນໄຂສິ່ງແວດລ້ອມ:

- NEMA 1: ຈຸດປະສົງທົ່ວໄປໃນການນໍາໃຊ້ພາຍໃນ

- NEMA 3R: ຄໍາຮ້ອງສະຫມັກກາງແຈ້ງທີ່ມີການປ້ອງກັນຝົນ

- NEMA 4: ການນໍາໃຊ້ພາຍໃນ / ນອກມີການປ້ອງກັນທໍ່ຫຼຸດລົງ

- NEMA 4X: ທົນທານຕໍ່ການກັດກ່ອນສໍາລັບສະພາບແວດລ້ອມທີ່ຮຸນແຮງ

- ຄວາມຕ້ອງການພື້ນຖານ: ຝາປິດໂລຫະທັງໝົດຕ້ອງມີພື້ນຖານຢ່າງຖືກຕ້ອງຕາມມາດຕາ 250 NEC.

ການປັບປຸງ NEC 2023

ການປັບປຸງລະຫັດຫຼ້າສຸດລວມມີຄວາມຕ້ອງການຕັດການເຊື່ອມຕໍ່ສຸກເສີນທີ່ປັບປຸງໃຫ້ດີຂຶ້ນສໍາລັບຄໍາຮ້ອງສະຫມັກທີ່ຢູ່ອາໄສ. ທີ່ຢູ່ອາໃສໃໝ່ຕ້ອງມີເຄື່ອງຕັດການເຊື່ອມຕໍ່ສຸກເສີນທາງນອກທີ່ສາມາດເຂົ້າເຖິງໄດ້ຢ່າງສະດວກເພື່ອຄວາມປອດໄພຂອງຜູ້ຕອບໂຕ້ຄັ້ງທຳອິດ.

ຄູ່ມືການເລືອກ: ການເລືອກປຸ່ມຕັດການເຊື່ອມຕໍ່ທີ່ຖືກຕ້ອງ

ເກນການປະເມີນ

ປະຕິບັດຕາມວິທີການລະບົບນີ້ສໍາລັບການເລືອກສະຫຼັບທີ່ດີທີ່ສຸດ:

- ປະເມີນການປົກປ້ອງທີ່ມີຢູ່ແລ້ວ:

- ກວດເບິ່ງຂະໜາດຕົວຕັດວົງຈອນທາງເທິງ

- ປະເມີນການປະສານງານດ້ານການປົກປ້ອງ

- ພິຈາລະນາລະດັບຄວາມຜິດໃນປະຈຸບັນ

- ກໍານົດຊ່ອງຫວ່າງປ້ອງກັນ

- ປະເມີນຄວາມຕ້ອງການອຸປະກອນ:

- ກວດເບິ່ງສະເພາະຜູ້ຜະລິດ

- ກວດເບິ່ງຄວາມຕ້ອງການຮັບປະກັນ

- ພິຈາລະນາຄວາມອ່ອນໄຫວຂອງອຸປະກອນ

- ປະເມີນລັກສະນະການເລີ່ມຕົ້ນ

- ພິຈາລະນາປັດໄຈການບໍາລຸງຮັກສາ:

- ປະເມີນຄວາມສາມາດຂອງພະນັກງານ

- ພິຈາລະນາການມີອາໄຫຼ່

- ປະເມີນຄວາມທົນທານຕໍ່ເວລາຢຸດເຮັດວຽກ

- ກວດເບິ່ງຕາຕະລາງການບໍາລຸງຮັກສາ

- ກວດສອບການປະຕິບັດຕາມກົດລະບຽບ:

- ກວດສອບຄວາມຕ້ອງການ NEC

- ກວດເບິ່ງການແກ້ໄຂລະຫັດທ້ອງຖິ່ນ

- ພິຈາລະນາຄວາມຕ້ອງການປະກັນໄພ

- ປະເມີນມາດຕະຖານອຸດສາຫະກໍາ

- ຄິດໄລ່ຄ່າໃຊ້ຈ່າຍທັງໝົດຂອງການເປັນເຈົ້າຂອງ:

- ປຽບທຽບຄ່າໃຊ້ຈ່າຍເບື້ອງຕົ້ນ

- ຄ່າໃຊ້ຈ່າຍໃນການບໍາລຸງຮັກສາປັດໄຈ

- ພິຈາລະນາຄ່າໃຊ້ຈ່າຍໃນການຢຸດເຮັດວຽກ

- ປະເມີນຄວາມຕ້ອງການທົດແທນ

ຄວາມຜິດພາດການເລືອກທົ່ວໄປ

ຫຼີກລ້ຽງການອຸປະສັກເລື້ອຍໆເຫຼົ່ານີ້:

- ການປົກປ້ອງເກີນກຳນົດ: ການເພີ່ມສະວິດຟິວທີ່ບໍ່ຈໍາເປັນໃສ່ວົງຈອນທີ່ມີການປ້ອງກັນແລ້ວຈະເພີ່ມຄ່າໃຊ້ຈ່າຍໂດຍບໍ່ມີຜົນປະໂຫຍດ.

- ບໍ່ສົນໃຈການເຂົ້າເຖິງການບຳລຸງຮັກສາ: ການຕິດຕັ້ງສະວິດໃນສະຖານທີ່ຍາກທີ່ຈະເຂົ້າເຖິງປະນີປະນອມຄວາມປອດໄພແລະເພີ່ມເວລາການບໍາລຸງຮັກສາ.

- undersizing ສໍາລັບຄວາມຕ້ອງການໃນອະນາຄົດ: ການບໍ່ພິຈາລະນາການເຕີບໂຕຂອງການໂຫຼດອາດຈະຕ້ອງການການທົດແທນກ່ອນໄວອັນຄວນ.

- ການລະເລີຍປັດໄຈສິ່ງແວດລ້ອມ: ການຈັດອັນດັບຂອງສິ່ງຫຸ້ມຫໍ່ທີ່ບໍ່ພຽງພໍເຮັດໃຫ້ຄວາມລົ້ມເຫຼວກ່ອນໄວອັນຄວນແລະອັນຕະລາຍດ້ານຄວາມປອດໄພ.

ການຕິດຕັ້ງການປະຕິບັດທີ່ດີທີ່ສຸດ

ການວາງແຜນການຕິດຕັ້ງກ່ອນ

- ການສໍາຫຼວດສະຖານທີ່: ປະເມີນສະຖານທີ່ຕິດຕັ້ງສໍາລັບການເຂົ້າເຖິງ, ເງື່ອນໄຂສິ່ງແວດລ້ອມ, ແລະການປະຕິບັດຕາມລະຫັດ.

- ການຄິດໄລ່ການໂຫຼດ: ກວດສອບການໃຫ້ຄະແນນສະຫຼັບກົງກັບການໂຫຼດໄຟຟ້າທີ່ແທ້ຈິງແລະຄາດຄະເນ.

- ການປະສານງານດ້ານການປົກປ້ອງ: ຮັບປະກັນການປະສານງານທີ່ເຫມາະສົມລະຫວ່າງອຸປະກອນປ້ອງກັນຕົ້ນນ້ໍາແລະລຸ່ມນ້ໍາ.

- ການທົບທວນຄືນລະຫັດ: ຢືນຢັນການປະຕິບັດຕາມລະຫັດໄຟຟ້າທ້ອງຖິ່ນແລະການແກ້ໄຂ.

ຄູ່ມືການຕິດຕັ້ງແບບມືອາຊີບ

- ຄວາມຕ້ອງການຊ່າງໄຟຟ້າທີ່ມີໃບອະນຸຍາດ: ອຳນາດການປົກຄອງສ່ວນໃຫຍ່ຕ້ອງການຊ່າງໄຟຟ້າທີ່ມີໃບອະນຸຍາດເພື່ອຕັດການເຊື່ອມຕໍ່ການຕິດຕັ້ງສະວິດ.

- ອະນຸສັນຍາຄວາມປອດໄພ: ປະຕິບັດຕາມຂໍ້ກໍານົດ NFPA 70E ສໍາລັບຄວາມປອດໄພທາງໄຟຟ້າໃນລະຫວ່າງການຕິດຕັ້ງ.

- ການທົດສອບແລະກໍາມະການ: ກວດສອບການດໍາເນີນການທີ່ເຫມາະສົມ, ດິນ, ແລະການປະສານງານການປົກປ້ອງກ່ອນທີ່ຈະ energizing.

- ເອກະສານ: ຮັກສາບັນທຶກການຕິດຕັ້ງ, ຜົນການທົດສອບ, ແລະຮູບແຕ້ມທີ່ສ້າງຂຶ້ນ.

ການບໍາລຸງຮັກສາແລະການແກ້ໄຂບັນຫາ

Fused Disconnect Switch ບໍາລຸງຮັກສາ

ຕາຕະລາງການກວດກາປົກກະຕິ:

- ປະຈໍາເດືອນ: ການກວດກາສາຍຕາຂອງ enclosure ແລະອົງປະກອບພາຍນອກ

- ປະຈໍາໄຕມາດ: ການກວດສອບສະພາບການ Fuse ແລະການກວດສອບການເຊື່ອມຕໍ່

- ປະຈໍາປີ: ສໍາເລັດການທົດສອບໄຟຟ້າແລະການຢັ້ງຢືນການດໍາເນີນງານກົນຈັກ

ຂັ້ນຕອນການທົດແທນ Fuse:

- ສະເຫມີ de-energize ວົງຈອນກ່ອນທີ່ຈະປ່ຽນ fuse

- ໃຊ້ພຽງແຕ່ປະເພດຟິວທີ່ລະບຸໂດຍຜູ້ຜະລິດ ແລະການຈັດອັນດັບ

- ກວດເບິ່ງຕົວຍຶດຟິວສໍາລັບຄວາມເສຍຫາຍຫຼືຄວາມຮ້ອນເກີນ

- ທົດສອບການດໍາເນີນງານທີ່ເຫມາະສົມຫຼັງຈາກການທົດແທນ

ໂໝດຄວາມລົ້ມເຫລວທົ່ວໄປ:

- fuse degradation ຈາກ overloads ຊ້ໍາຊ້ອນ

- ຕິດຕໍ່ການຜຸພັງຈາກການສໍາຜັດກັບສິ່ງແວດລ້ອມ

- ການສວມໃສ່ກົນຈັກຈາກການດໍາເນີນງານເລື້ອຍໆ

ການຮັກສາສະວິດການເຊື່ອມຕໍ່ທີ່ບໍ່ແມ່ນ Fused Disconnect

ຂໍ້ໄດ້ປຽບຂອງການບໍາລຸງຮັກສາ:

- ອົງປະກອບຫນ້ອຍຕ້ອງການຄວາມສົນໃຈ

- ບໍ່ມີສ່ວນທີ່ບໍລິໂພກເພື່ອທົດແທນ

- ຂັ້ນຕອນການແກ້ໄຂບັນຫາງ່າຍດາຍ

ຈຸດກວດກາ:

- ເງື່ອນໄຂການຕິດຕໍ່ແລະການສອດຄ່ອງ

- ການເຮັດວຽກຂອງກົນຈັກກ້ຽງ

- ຄວາມສົມບູນຂອງການຫຸ້ມຫໍ່ແລະການຜະນຶກ

- ຄວາມໃກ້ຊິດຂອງການເຊື່ອມຕໍ່

ການແກ້ໄຂບັນຫາທົ່ວໄປ

Switch ຈະບໍ່ເຮັດວຽກ:

- ກວດເບິ່ງສິ່ງກີດຂວາງກົນຈັກ

- ຢືນຢັນການມີສ່ວນພົວພັນທີ່ເຫມາະສົມ

- ກວດສອບການເຊື່ອມໂລຫະຕິດຕໍ່

ການປະຕິບັດການລົບກວນ:

- ກວດເບິ່ງຄຸນລັກສະນະການໂຫຼດ

- ກວດສອບການປະສານງານດ້ານການປົກປ້ອງ

- ກວດສອບສະພາບແວດລ້ອມ

ຕິດຕໍ່ພົວພັນ:

- ຕິດຕາມອຸນຫະພູມການເຊື່ອມຕໍ່

- ປະເມີນລະດັບການໂຫຼດປະຈຸບັນ

- ພິຈາລະນາປັດໄຈສິ່ງແວດລ້ອມ

ການວິເຄາະຄ່າໃຊ້ຈ່າຍແລະການພິຈາລະນາ ROI

ການປຽບທຽບການລົງທຶນເບື້ອງຕົ້ນ

ຄ່າໃຊ້ຈ່າຍອຸປະກອນໂດຍການຈັດອັນດັບ:

- 30A ບໍ່ຟິວ: $85-150

- 30A Fused: $125-220

- 100A ບໍ່ຟິວ: $200-350

- 100A Fused: $280-475

ປັດໄຈການຕິດຕັ້ງ:

- ປຸ່ມຟິວຊິວຕ້ອງການຕົວຫຸ້ມໃຫຍ່ກວ່າ 25-40%

- ຄວາມສັບສົນຂອງສາຍໄຟເພີ່ມເຕີມເພີ່ມ 15-25% ກັບເວລາການຕິດຕັ້ງ

- ປະເພດຟິວພິເສດອາດຈະຕ້ອງການການຈັດການການສະຫນອງສະເພາະ

ຄ່າໃຊ້ຈ່າຍໃນການດໍາເນີນງານໄລຍະຍາວ

ຄວາມຖີ່ຂອງການບໍາລຸງຮັກສາ:

- fused switches: ການກວດກາປະຈໍາໄຕມາດ, ການກວດສອບ fuse ປະຈໍາປີ

- ສະວິດທີ່ບໍ່ແມ່ນ fused: ການກວດກາເຄິ່ງປີ, ການທົດສອບສອງປີ

ການພິຈາລະນາການທົດແທນ:

- ຄ່າໃຊ້ຈ່າຍຂອງຟິວ: $20-200+ ຕໍ່ fuse ຂຶ້ນກັບປະເພດແລະການປະເມີນ

- ການທົດແທນການຕິດຕໍ່: $50-300+ ຂຶ້ນກັບຂະຫນາດສະຫຼັບ

- ຄ່າໃຊ້ຈ່າຍແຮງງານ: 2-4 ຊົ່ວໂມງສໍາລັບການບໍາລຸງຮັກສາທີ່ສໍາຄັນ

ການວິເຄາະເວລາຢຸດ:

- fused switches: ການບົ່ງບອກຄວາມຜິດທັນທີທັນໃດ, ເວລາປ່ຽນ fuse

- ສະວິດທີ່ບໍ່ມີຟິວສິກ: ການຟື້ນຟູໄວຂຶ້ນ, ອາດຈະແກ້ໄຂບັນຫາໄດ້ດົນກວ່າ

ຄໍາຮ້ອງສະຫມັກອຸດສາຫະກໍາແລະກໍລະນີສຶກສາ

ການຜະລິດແລະອຸດສາຫະກໍາ

ຄໍາຮ້ອງສະຫມັກການຄວບຄຸມມໍເຕີ: ມໍເຕີອຸດສາຫະກໍາຂະຫນາດໃຫຍ່ໄດ້ຮັບຜົນປະໂຫຍດຈາກການຕັດການເຊື່ອມຕໍ່ທີ່ປະສົມປະສານເຊິ່ງສະຫນອງທັງການໂດດດ່ຽວແລະການປົກປ້ອງ. ຜູ້ຜະລິດແຜ່ນແພໄດ້ຫຼຸດຜ່ອນຄວາມລົ້ມເຫຼວຂອງມໍເຕີໂດຍ 40% ຫຼັງຈາກການຍົກລະດັບເປັນການຕັດເຊື່ອມຕໍ່ທີ່ມີຂະຫນາດທີ່ເຫມາະສົມ.

ອຸປະກອນຂະບວນການ: ອຸປະກອນປຸງແຕ່ງທາງເຄມີຮຽກຮ້ອງໃຫ້ມີການປິດການເຊື່ອມຕໍ່ທີ່ເຊື່ອຖືໄດ້ທີ່ສາມາດຈັດການສະພາບແວດລ້ອມ corrosive. ສະແຕນເລດສະແຕນເລດ NEMA 4X fused disconnects ໃຫ້ທັງການປົກປ້ອງແລະອາຍຸຍືນ.

ອາຄານພານິດ

ການປົກປ້ອງລະບົບ HVAC: ອາຄານຫ້ອງການທົ່ວໄປໃຊ້ການຕັດການເຊື່ອມຕໍ່ທີ່ບໍ່ແມ່ນຟິວສໍາລັບຫນ່ວຍງານເທິງຫລັງຄາເມື່ອມີການປົກປ້ອງແຜງທີ່ພຽງພໍ. ວິທີການນີ້ຫຼຸດຜ່ອນຄ່າໃຊ້ຈ່າຍເບື້ອງຕົ້ນໃນຂະນະທີ່ຮັກສາຄວາມປອດໄພ.

ລະບົບໄຟຟ້າສຸກເສີນ: ໂດຍທົ່ວໄປແລ້ວເຄື່ອງສ້າງການສໍາຮອງຮຽກຮ້ອງໃຫ້ມີການຕັດການເຊື່ອມຕໍ່ທີ່ບໍ່ແມ່ນ fused ສໍາລັບການໂດດດ່ຽວງ່າຍດາຍໃນລະຫວ່າງການບໍາລຸງຮັກສາ, ອີງໃສ່ການປົກປ້ອງຕົ້ນນ້ໍາສໍາລັບການລ້າງຄວາມຜິດ.

ພະລັງງານທົດແທນ

ລະບົບແສງຕາເວັນ: ປຸ່ມຕັດການເຊື່ອມຕໍ່ DC (ໂດຍທົ່ວໄປແລ້ວບໍ່ມີ fused) ແມ່ນຈໍາເປັນສໍາລັບການຕິດຕັ້ງແສງຕາເວັນ, ມີການປົກປ້ອງວົງຈອນສະຫນອງໃຫ້ໂດຍ breakers DC ພິເສດ.

ການນຳໃຊ້ turbine ລົມ: ສະຫຼັບຕັດການເຊື່ອມຕໍ່ແຮງດັນສູງໃນກັງຫັນລົມມັກຈະໃຊ້ການອອກແບບຟິວສໍາລັບການປ້ອງກັນທີ່ເພີ່ມຂຶ້ນໃນສະຖານທີ່ຫ່າງໄກສອກຫຼີກ.

ແນວໂນ້ມແລະເຕັກໂນໂລຢີໃນອະນາຄົດ

ສະຫຼັບຕັດການເຊື່ອມຕໍ່ອັດສະລິຍະ

ປຸ່ມຕັດເຊື່ອມຕໍ່ແບບທັນສະ ໄໝ ປະກອບມີຄຸນສົມບັດອັດສະລິຍະຫຼາຍຂຶ້ນ:

- ການເຊື່ອມໂຍງ IoT: ຄວາມສາມາດຕິດຕາມທາງໄກອະນຸຍາດໃຫ້ຜູ້ຈັດການສະຖານທີ່ເພື່ອຕິດຕາມສະຖານະການສະຫຼັບແລະໄດ້ຮັບການແຈ້ງການບໍາລຸງຮັກສາ.

- ການຮັກສາການຄາດເດົາ: ສະຫວິດຂັ້ນສູງສາມາດຕິດຕາມສະພາບຕິດຕໍ່ແລະຄາດຄະເນຄວາມຕ້ອງການບໍາລຸງຮັກສາກ່ອນທີ່ຄວາມລົ້ມເຫຼວຈະເກີດຂື້ນ.

- ການປະຕິບັດທາງໄກ: ແອັບພລິເຄຊັນບາງອັນໄດ້ຮັບຜົນປະໂຫຍດຈາກປຸ່ມຕັດການເຊື່ອມຕໍ່ທີ່ເຮັດວຽກຈາກໄລຍະໄກທີ່ຊ່ວຍເພີ່ມຄວາມປອດໄພໃນລະຫວ່າງສະຖານະການສຸກເສີນ.

ປັບປຸງຄຸນສົມບັດຄວາມປອດໄພ

- Arc Flash Mitigation: ການອອກແບບໃຫມ່ລວມເອົາຄຸນສົມບັດທີ່ຫຼຸດຜ່ອນພະລັງງານ arc flash ໃນລະຫວ່າງການດໍາເນີນການສະຫຼັບ.

- ປັບປຸງກົນໄກການລັອກ: ອຸປະກອນ lockout ປັບປຸງໃຫ້ຄວາມປອດໄພທີ່ດີກວ່າແລະສະແດງເຖິງສະຖານະການລັອກ.

- ຄວາມຕ້ານທານຕໍ່ສິ່ງແວດລ້ອມ: ວັດສະດຸຂັ້ນສູງ ແລະເຕັກນິກການປະທັບຕາຂະຫຍາຍຊີວິດການສະຫຼັບໃນສະພາບແວດລ້ອມທີ່ຮຸນແຮງ.

ສະຫລຸບ

ທາງເລືອກລະຫວ່າງປຸ່ມຕັດການເຊື່ອມຕໍ່ແບບຟິວໆ ແລະບໍ່ຟິວແມ່ນຂຶ້ນກັບຄວາມຕ້ອງການຂອງແອັບພລິເຄຊັນສະເພາະຂອງທ່ານ, ລະບົບປ້ອງກັນທີ່ມີຢູ່ແລ້ວ ແລະບູລິມະສິດໃນການປະຕິບັດງານ. ສະຫວິດຕັດເຊື່ອມຕໍ່ fused ສະຫນອງການປົກປ້ອງທ້ອງຖິ່ນທີ່ມີຄຸນຄ່າສໍາລັບອຸປະກອນທີ່ລະອຽດອ່ອນຫຼືທີ່ສໍາຄັນ, ໃນຂະນະທີ່ສະວິດທີ່ບໍ່ແມ່ນ fused ສະຫນອງການແຍກຄ່າໃຊ້ຈ່າຍທີ່ມີປະສິດທິພາບສໍາລັບວົງຈອນທີ່ມີການປ້ອງກັນຢ່າງພຽງພໍ.

ປັດໄຈການຄັດເລືອກທີ່ສໍາຄັນ:

- ຄວາມຕ້ອງການການປົກປ້ອງ: ເລືອກ fused ເມື່ອມີການປ້ອງກັນ overcurrent ເພີ່ມເຕີມ.

- ຂໍ້ຈໍາກັດຄ່າໃຊ້ຈ່າຍ: ເລືອກທີ່ບໍ່ມີການເຊື່ອມຕໍ່ສໍາລັບຄໍາຮ້ອງສະຫມັກງົບປະມານທີ່ມີການປົກປັກຮັກສາຕົ້ນສະບັບທີ່ພຽງພໍ.

- ການຕັ້ງຄ່າການບຳລຸງຮັກສາ: ພິຈາລະນາຄວາມສາມາດຂອງພະນັກງານແລະຄວາມພ້ອມຂອງອາໄຫຼ່.

- ການປະຕິບັດຕາມລະຫັດ: ຮັບປະກັນວ່າການຄັດເລືອກກົງກັບທຸກລະຫັດ ແລະມາດຕະຖານໄຟຟ້າທີ່ໃຊ້ໄດ້.

ການໃຫ້ຄໍາປຶກສາແບບມືອາຊີບແນະນໍາ: ເນື່ອງຈາກຄວາມຊັບຊ້ອນຂອງການປະສານງານການປົກປ້ອງໄຟຟ້າແລະຄວາມຕ້ອງການດ້ານຄວາມປອດໄພ, ປຶກສາຫາລືກັບຜູ້ຊ່ຽວຊານດ້ານໄຟຟ້າທີ່ມີໃບອະນຸຍາດສໍາລັບການຄັດເລືອກແລະການຕິດຕັ້ງສະຫຼັບຕັດການເຊື່ອມຕໍ່ທີ່ເຫມາະສົມ. ຄວາມຊ່ຽວຊານຂອງພວກເຂົາຮັບປະກັນຄວາມປອດໄພທີ່ດີທີ່ສຸດ, ການປະຕິບັດຕາມລະຫັດ, ແລະການປະຕິບັດໃນໄລຍະຍາວ.

ບໍ່ວ່າທ່ານຈະເລືອກປຸ່ມຕັດເຊື່ອມຕໍ່ແບບຟິວ ຫຼື ບໍ່ຟິວ, ການເລືອກທີ່ເໝາະສົມ, ການຕິດຕັ້ງ ແລະ ການບຳລຸງຮັກສາແມ່ນມີຄວາມຈຳເປັນຕໍ່ຄວາມປອດໄພທາງໄຟຟ້າ ແລະ ຄວາມໜ້າເຊື່ອຖືຂອງລະບົບ. ການກວດກາເປັນປົກກະຕິແລະການປະຕິບັດຕາມຄໍາແນະນໍາຂອງຜູ້ຜະລິດຈະຮັບປະກັນການດໍາເນີນງານຫຼາຍປີທີ່ປອດໄພ, ເຊື່ອຖືໄດ້.

ທີ່ກ່ຽວຂ້ອງ

Changeover Switch ແມ່ນຫຍັງ: ຄູ່ມືຄົບຖ້ວນສົມບູນ