នៅក្នុងពិភពនៃស្វ័យប្រវត្តិកម្មឧស្សាហកម្ម និងការដំឡើងអគ្គិសនី ផ្លូវដែក DIN ដើរតួនាទីជាឆ្អឹងខ្នងសម្រាប់ដំឡើងសមាសភាគ និងឧបករណ៍បញ្ជា។ ត្រូវបានបង្កើតឡើងដោយវិទ្យាស្ថាន Deutsches Institut für Normung (វិទ្យាស្ថានអាល្លឺម៉ង់សម្រាប់ស្តង់ដារនីយកម្ម) ផ្លូវដែក DIN បានវិវត្តន៍ពីស្តង់ដារជាតិអាឡឺម៉ង់ទៅជាដំណោះស្រាយម៉ោនដែលត្រូវបានទទួលស្គាល់ជាអន្តរជាតិដែលគ្រប់គ្រងដោយស្តង់ដារ IEC និង EN ។ ប៉ុន្តែមិនមែនផ្លូវដែក DIN ទាំងអស់ត្រូវបានបង្កើតស្មើៗគ្នានោះទេ។ ការកំណត់គុណភាពនៃផ្លូវដែក DIN គឺមានសារៈសំខាន់សម្រាប់ការធានានូវភាពជឿជាក់ អាយុកាលវែង និងសុវត្ថិភាពនៅក្នុងការដំឡើងអគ្គិសនីរបស់អ្នក។ មគ្គុទ្ទេសក៍ដ៏ទូលំទូលាយនេះនឹងនាំអ្នកឆ្លងកាត់អ្វីគ្រប់យ៉ាងដែលអ្នកត្រូវដឹងអំពីការវាយតម្លៃគុណភាពផ្លូវដែក DIN ចាប់ពីសមាសភាពសម្ភារៈរហូតដល់វិធីសាស្ត្រសាកល្បង។

តើអ្វីជាផ្លូវដែក DIN និងហេតុអ្វីបានជាគុណភាពសំខាន់

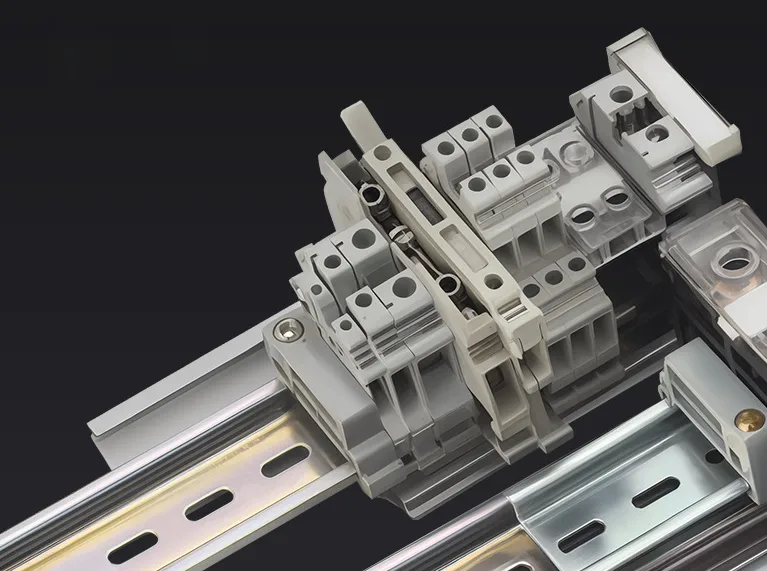

ផ្លូវដែក DIN គឺជាផ្លូវដែកដែកស្ដង់ដារដែលប្រើនៅក្នុងបន្ទះត្រួតពិនិត្យឧស្សាហកម្ម ប្រព័ន្ធស្វ័យប្រវត្តិកម្ម និងឯករភជប់អគ្គិសនីដើម្បីភ្ជាប់ឧបករណ៍ផ្សេងៗដូចជា ឧបករណ៍បំលែងសៀគ្វី ស្ថានីយ និងឧបករណ៍បញ្ជា។ ជាធម្មតាផលិតពីដែកថែបកាបូនដែលរមូរត្រជាក់ជាមួយនឹងផ្ទៃការពារ—ឬជាជម្រើសពីដែកអ៊ីណុក ឬអាលុយមីញ៉ូម—ផ្លូវរថភ្លើងទាំងនេះត្រូវបានរចនាឡើងដើម្បីផ្តល់ការគាំទ្រផ្នែកមេកានិចដ៏រឹងមាំសម្រាប់សមាសធាតុដែលបានម៉ោន។ ខណៈពេលដែលផ្លូវដែក DIN គឺជាលោហធាតុ ជាទូទៅពួកវាមិនមានបំណងធ្វើចរន្តអគ្គិសនីទេ ទោះបីជាពេលខ្លះពួកគេអាចផ្តល់នូវការភ្ជាប់ខ្សែដីក្រោមលក្ខខណ្ឌនៃការរចនាសមរម្យក៏ដោយ។

កម្មវិធីទូទៅនៃផ្លូវដែក DIN

- ផ្ទាំងបញ្ជាស្វ័យប្រវត្តិកម្មឧស្សាហកម្ម

- ការកសាងប្រព័ន្ធស្វ័យប្រវត្តិកម្ម

- បន្ទះចែកចាយថាមពល

- ទូដាក់ឧបករណ៍ទូរគមនាគមន៍

- ប្រព័ន្ធសញ្ញាផ្លូវដែក

- ប្រព័ន្ធគ្រប់គ្រង HVAC

- ការដំឡើងថាមពលកកើតឡើងវិញ។

ផលវិបាកនៃផ្លូវដែក DIN ដែលមានគុណភាពទាប

ការប្រើប្រាស់ផ្លូវដែក DIN ដែលមិនស្តង់ដារអាចនាំឱ្យមានបញ្ហាជាច្រើនពេញមួយវដ្តជីវិតរបស់ប្រព័ន្ធ។ នេះជារឿង៖ ខណៈពេលដែលការកាត់ថ្លៃដើមហាក់ដូចជាគួរឲ្យទាក់ទាញ ផលវិបាកអាចថ្លៃជាង៖

- ការបរាជ័យនៃសមាសធាតុមុនអាយុដោយសារតែការម៉ោនមិនត្រឹមត្រូវឬការខូចទ្រង់ទ្រាយផ្លូវដែក

- បង្កើនភាពញឹកញាប់នៃការថែទាំ និងការចំណាយ

- ការផ្អាកប្រព័ន្ធប៉ះពាល់ដល់ផលិតកម្ម

- គ្រោះថ្នាក់សុវត្ថិភាពពីសមាសធាតុរលុង ឬគែមមុតស្រួច

- កាត់បន្ថយភាពជឿជាក់នៃប្រព័ន្ធទាំងមូល

- បញ្ហាភាពឆបគ្នាជាមួយឧបករណ៍ដែលបានម៉ោន

- ការ corrosion និងការបរាជ័យរចនាសម្ព័ន្ធនៅក្នុងបរិស្ថានអាក្រក់

- ការតភ្ជាប់អគ្គិសនីបណ្តោះអាសន្នដែលបណ្តាលឱ្យមានបញ្ហាប្រតិបត្តិការ

- ភាពលំបាកកំឡុងពេលដំឡើងដំបូង ការបង្កើនថ្លៃពលកម្ម

- ការខូចខាតអ៊ីសូឡង់ខ្សែពី burrs ឬគែមមុតស្រួចបង្កើតសៀគ្វីខ្លីសក្តានុពល

- ការបរាជ័យនៃការផ្ទុកបន្ទុកដែលបណ្តាលឱ្យយារធ្លាក់ឬការដួលរលំផ្លូវដែកទាំងស្រុង

ស្តង់ដារផ្លូវដែក DIN សំខាន់ៗ និងការបញ្ជាក់

ការយល់ដឹងអំពីស្តង់ដារដែលគ្រប់គ្រងផ្លូវដែក DIN គឺជាជំហានដំបូងក្នុងការវាយតម្លៃគុណភាព។ លក្ខណៈបច្ចេកទេសទាំងនេះផ្តល់នូវស្តង់ដារដែលប្រឆាំងនឹងផ្លូវដែក DIN ទាំងអស់គួរតែត្រូវបានវាស់។

ស្តង់ដារអន្តរជាតិ និងតំបន់

ស្តង់ដារដែលទទួលយកយ៉ាងទូលំទូលាយបំផុតសម្រាប់ផ្លូវដែក DIN រួមមាន:

- IEC 60715៖ មូលដ្ឋានគ្រឹះនៃស្តង់ដារអន្តរជាតិដែលកំណត់វិមាត្រ និងតម្រូវការមុខងារសម្រាប់ទម្រង់ផ្លូវដែក DIN ទូទៅ ដែលធានានូវអន្តរប្រតិបត្តិការជាសកល។

- EN 60715: ការអនុម័តរបស់អ៊ឺរ៉ុបនៃ IEC 60715 ជាមួយនឹងលក្ខណៈបច្ចេកទេសដូចគ្នាបេះបិទ

- EN 50022៖ ស្តង់ដារអឺរ៉ុបជាប្រវត្តិសាស្ត្រសម្រាប់ផ្លូវដែកមួកកំពូល 35mm (ជំនួសដោយ EN 60715)

- EN 50035: ស្តង់ដារអ៊ឺរ៉ុបគ្របដណ្តប់ផ្លូវដែកប្រភេទ G-DIN

- EN 50045: ស្តង់ដារអ៊ឺរ៉ុបសម្រាប់ផ្លូវរថភ្លើងកំពូលខ្នាតតូច 15mm

- EN 50023/50024: ស្តង់ដារប្រវត្តិសាស្ត្រសម្រាប់ផ្លូវដែកផ្នែក C

- DIN 46277៖ ស្តង់ដារជាតិអាល្លឺម៉ង់ដើមដែលបម្រើជាមូលដ្ឋានគ្រឹះសម្រាប់ស្តង់ដារ EN និង IEC នៅពេលក្រោយ

ការអនុលោមតាមស្តង់ដារទាំងនេះគឺជាមូលដ្ឋានគ្រឹះសម្រាប់ការធានានូវអន្តរប្រតិបត្តិការនៃសមាសភាគ គុណភាពមូលដ្ឋាន និងការអនុវត្តសុវត្ថិភាព។

ទម្រង់ផ្លូវដែក DIN ស្តង់ដារ

ប្រភេទទម្រង់ផ្សេងៗគ្នាបម្រើកម្មវិធីផ្សេងៗដោយផ្អែកលើការរចនា និងសមត្ថភាពផ្ទុករបស់វា៖

- TS 35/7.5 – ទទឹង 35mm ជាមួយនឹងកម្ពស់ 7.5mm (ទូទៅបំផុត)

- កំណត់ជាផ្លូវការ IEC/EN 60715 – 35 × 7.5

- ស័ក្តិសមសម្រាប់កម្មវិធីដែលមានគោលបំណងទូទៅបំផុត។

- TS 35/15 - ទទឹង 35mm ជាមួយនឹងកម្ពស់ 15mm (សម្រាប់សមាសធាតុធ្ងន់ជាង)

- កំណត់ជាផ្លូវការ IEC/EN 60715 – 35 × 15

- ផ្តល់នូវភាពរឹងមាំ និងកម្លាំងកាន់តែខ្លាំងសម្រាប់សមាសធាតុដែលធ្ងន់ជាង

- TS 15 – ទទឹង 15mm ជាមួយនឹងកម្ពស់ 5.5mm (ទម្រង់តូច)

- សម្រាប់សមាសធាតុបង្រួមក្នុងកម្មវិធីដែលមានការរឹតបន្តឹងក្នុងលំហ

- TS 32 (G-Section) – ទម្រង់ G-shape asymmetrical 32mm

- ជាធម្មតាប្រើសម្រាប់សមាសធាតុធ្ងន់ជាង

- ការរចនា asymmetrical ការពារការដំឡើងមិនត្រឹមត្រូវ

- ផ្នែក C - ទម្រង់ស៊ីមេទ្រីរាង C

- មាននៅក្នុងបំរែបំរួលដូចជា C20, C30, C40 និង C50

- ការគាំទ្រជញ្ជាំងដ៏ល្អសម្រាប់សមាសធាតុធ្ងន់ដូចជាម៉ាស៊ីនបំលែង

ស្ដង់ដារនីមួយៗបញ្ជាក់ពីតម្រូវការវិមាត្រច្បាស់លាស់ រួមទាំង៖

- ទទឹងផ្លូវដែកនិងកម្ពស់

- គម្លាតរន្ធនិងវិមាត្រ

- ទម្រង់គែម និងការអត់ធ្មត់

- លក្ខណៈបច្ចេកទេសនៃកម្រាស់សម្ភារៈ

ការបញ្ជាក់សម្ភារៈសម្រាប់បរិស្ថានផ្សេងៗគ្នា

អាស្រ័យលើបរិយាកាសនៃការដំឡើង សម្ភារៈ និងការបញ្ចប់ផ្សេងៗត្រូវបានទាមទារ៖

| បរិស្ថាន | សម្ភារៈដែលបានណែនាំ | ការបញ្ចប់ធម្មតា។ | កំណត់ចំណាំកម្មវិធី |

|---|---|---|---|

| ស្តង់ដារក្នុងផ្ទះ | ដែកថែបកាបូនរមៀលត្រជាក់ | ស័ង្កសី-plated ជាមួយ chromate passivation | បន្ទះត្រួតពិនិត្យឧស្សាហកម្មទូទៅ, ស្រោម NEMA 1/12 |

| សំណើមខ្ពស់។ | ដែកអ៊ីណុក 304 (V2A) | ធម្មជាតិឬអកម្ម | ការកែច្នៃម្ហូបអាហារ តំបន់លាងសម្អាត បរិស្ថាន NEMA 4 |

| បរិស្ថាន corrosive | ដែកអ៊ីណុក ៣១៦ | ធម្មជាតិឬអកម្ម | រុក្ខជាតិគីមី ការដំឡើងសមុទ្រ ឯករភជប់ក្រៅ |

| ឧស្សាហកម្មធុនធ្ងន់ | ដែក | ស័ង្កសីក្តៅ | តំបន់ដែលមានសមាសធាតុធ្ងន់ឬរំញ័រ |

| កង្វល់អេឡិចត្រូម៉ាញ៉េទិច | អាលុយមីញ៉ូម | ធម្មជាតិ ឬ anodized | ទូរគមនាគមន៍ គ្រឿងអេឡិចត្រូនិចដែលងាយរងគ្រោះ |

| កម្មវិធីងាយនឹងទម្ងន់ | យ៉ាន់ស្ព័រអាលុយមីញ៉ូម (6000 ស៊េរី) | អុកស៊ីដធម្មជាតិឬអាណូឌីស | ការដឹកជញ្ជូន យានអវកាស ឧបករណ៍ចល័ត |

ការធានាបាននូវការជ្រើសរើសសម្ភារៈសមស្របដោយផ្អែកលើបរិយាកាសជាក់លាក់គឺមានសារៈសំខាន់សម្រាប់ការអនុវត្តយូរអង្វែង និងភាពជឿជាក់។ ខណៈពេលដែលដែកស័ង្កសីដែលធ្វើពីស័ង្កសីផ្តល់នូវការអនុវត្តប្រកបដោយប្រសិទ្ធភាពសម្រាប់កម្មវិធីស្តង់ដារ បរិស្ថានដែលមានតម្រូវការកាន់តែច្រើនត្រូវការសម្ភារៈឯកទេសដែលអាចទប់ទល់នឹងការ corrosion ទប់ទល់នឹងបន្ទុកធ្ងន់ ឬបំពេញតាមកម្រិតទម្ងន់។

កត្តាសំខាន់ៗចំនួន 7 ដែលកំណត់គុណភាពផ្លូវដែក DIN

1. សមាសភាពសម្ភារៈនិងភាពធន់

សម្ភារៈមូលដ្ឋាននៃផ្លូវដែក DIN ប៉ះពាល់យ៉ាងខ្លាំងដល់ដំណើរការ និងអាយុកាលរបស់វា។ ផ្លូវដែក DIN ដែលមានគុណភាពខ្ពស់ជាធម្មតាមានលក្ខណៈពិសេស៖

- សមាសភាពដែក: កម្រាស់ 1.5mm ទៅ 2.3mm ជាមួយនឹងរចនាសម្ព័ន្ធឯកសណ្ឋាន

- ដែកថែបកាបូនរមូរត្រជាក់ដែលមានកម្លាំង tensile ច្រើនតែលើសពី 690 MPa

- ធន់នឹងរំញ័រ និងរំញ័រដ៏អស្ចារ្យ

- ភាពរឹងខ្ពស់បំផុត និងសមត្ថភាពផ្ទុកបន្ទុកសម្រាប់វិមាត្រទម្រង់ដូចគ្នា។

- ថ្នាក់ដែកអ៊ីណុក៖

- 304/V2A (18-20% Chromium, 8-10.5% Nickel) សម្រាប់បរិស្ថានសើម

- ថ្នាក់ទី 316 សម្រាប់បរិស្ថានដែលមានការច្រេះខ្លាំង

- ភាពធន់នឹងការ corrosion inherent ដ៏អស្ចារ្យដោយមិនពឹងផ្អែកលើការព្យាបាលលើផ្ទៃ

- ជាទូទៅតម្រូវឱ្យមានការថែទាំតិចតួចបំផុតដោយសារតែធម្មជាតិដ៏រឹងមាំរបស់វា។

- សមាសធាតុអាលុយមីញ៉ូម៖

- យ៉ាន់ស្ព័រស៊េរី 6000 ដែលមានលក្ខណៈសម្បត្តិជាប់លាប់

- កម្លាំងជាក់លាក់ប្រហែល 260 MPa/m³ (ទាបជាងដែក)

- ប្រហែល 1/3 នៃទំងន់ដែកដោយដង់ស៊ីតេ

- បង្កើតជាស្រទាប់អុកស៊ីតការពារធម្មជាតិ

- វិញ្ញាបនប័ត្រសម្ភារៈ៖ រកមើលសម្ភារៈដែលមានវិញ្ញាបនប័ត្រម៉ាស៊ីនកិនដែលអាចតាមដានបាន និងសមាសធាតុផ្សំដែលបានបញ្ជាក់

ការធ្វើតេស្តរហ័ស៖ ផ្លូវដែក DIN គុណភាពនឹងមិនពត់ស្រួលទេ នៅពេលដែលសម្ពាធមធ្យមត្រូវបានអនុវត្តដោយដៃ។ ផ្លូវដែកដែក និងដែកអ៊ីណុកគួរមានអារម្មណ៍រឹងខ្លាំងបើប្រៀបធៀបទៅនឹងអាលុយមីញ៉ូមដែលមានទម្រង់ដូចគ្នា។

2. ភាពត្រឹមត្រូវនៃវិមាត្រនិងភាពអត់ធ្មត់

ភាពជាក់លាក់ក្នុងការផលិតធានានូវសមត្រឹមត្រូវ និងការដំឡើងសមាសធាតុ។ ផ្លូវដែក DIN ដែលមានគុណភាពខ្ពស់រក្សាការអត់ធ្មត់យ៉ាងតឹងរ៉ឹងដើម្បីធានាឱ្យមានអន្តរប្រតិបត្តិការជាមួយសមាសធាតុពីក្រុមហ៊ុនផលិតពិភពលោក៖

- ទទឹងអត់ធ្មត់៖ ± 0.2mm ទៅ ±0.5mm (ផ្អែកលើលក្ខណៈបច្ចេកទេសទំនាក់ទំនង Phoenix)

- ភាពធន់នឹងកម្ពស់: ± 0.1mm ទៅ ± 0.5mm

- ភាពត្រង់៖ គម្លាតអតិបរមា 0.5mm ក្នុងមួយម៉ែត្រ

- ភាពត្រឹមត្រូវនៃគម្លាតរន្ធ: ± 0.5mm សម្រាប់រន្ធម៉ោន

- ភាពអត់ធ្មត់នៃទម្រង់៖ ± 0.5mm (សំខាន់សម្រាប់ការភ្ជាប់សមាសធាតុត្រឹមត្រូវ)

- ភាពស៊ីសង្វាក់គ្នានៃកម្រាស់សម្ភារៈ៖ ឯកសណ្ឋានឆ្លងកាត់ផ្លូវដែកទាំងមូល

អាថ៌កំបាំងគឺ៖ ក្រុមហ៊ុនផលិតដែលធ្វើការត្រួតពិនិត្យវិមាត្រ 100% ជាធម្មតាផលិតផ្លូវរថភ្លើងដែលមានភាពស៊ីសង្វាក់គ្នាកាន់តែច្រើនជាមួយនឹងការអត់ធ្មត់កាន់តែតឹងរ៉ឹង។ ក្រុមហ៊ុនផលិតល្បីឈ្មោះដូចជា Phoenix Contact និង Eaton បញ្ជាក់យ៉ាងច្បាស់អំពី "ភាពត្រឹមត្រូវនៃវិមាត្រខ្ពស់" និង "ការអត់ធ្មត់ដែលបានដាក់កម្រិត" ជាលក្ខណៈគុណភាពសំខាន់ៗ។

វិមាត្រច្បាស់លាស់ធានាថា សមាសធាតុស្រូបទាញភ្ជាប់យ៉ាងត្រឹមត្រូវជាមួយនឹងទម្រង់ផ្លូវដែក ការពារការរញ្ជួយ ការរលុង ឬតម្រូវការសម្រាប់កម្លាំងខ្លាំងពេកកំឡុងពេលដំឡើង។ ពួកគេក៏ជួយសម្រួលដល់ការរអិលដោយរលូននៃសមាសធាតុដែលអាចលៃតម្រូវបាន និងធានាបាននូវការតម្រឹមត្រឹមត្រូវនៅក្នុងប្រព័ន្ធម៉ូឌុល។

3. ការបញ្ចប់ផ្ទៃនិងគុណភាពថ្នាំកូត

ការព្យាបាលលើផ្ទៃប៉ះពាល់ដោយផ្ទាល់ទៅលើភាពធន់នឹងការ corrosion និងចរន្តអគ្គិសនី៖

- ការដាក់ស័ង្កសី៖

- គួរតែជាឯកសណ្ឋានដែលមានកម្រាស់ 5-12 microns (ជាធម្មតា 8 microns)

- ដើរតួនាទីជា anode បូជា, corroding និយមដើម្បីការពារដែកពីក្រោម

- ផ្លាស្ទិចមានគុណភាព មានភាពស្អិតល្អ ដោយមិនរបក ឬរបក

- ថ្នាំកូតបំប្លែងក្រូម៉ូសូម៖

- អនុវត្តជាការព្យាបាលក្រោយការលាបស័ង្កសី

- បង្កើតជាស្រទាប់ការពារនៃសមាសធាតុក្រូមីញ៉ូមនៅលើផ្ទៃស័ង្កសី

- ពណ៌ផ្សេងគ្នា (ច្បាស់ លឿង ខៀវ) លទ្ធផលពីគីមីវិទ្យាក្រូម៉ាតខុសៗគ្នា

- trivalent chromium (Cr³⁺) passivation ត្រូវបានគេពេញចិត្តជាង chromium hexavalent (Cr⁶⁺) សម្រាប់ការអនុលោមតាមបរិស្ថាន

- "ស្រទាប់ passivated ក្រាស់" របស់ Phoenix Contact ផ្តល់នូវការការពារការច្រេះដ៏ល្អប្រសើរ

- រូបរាងពណ៌លឿងនៅលើផ្លូវដែកអកម្មមួយចំនួនគឺធម្មតា ហើយបង្ហាញពីវត្តមានស្រទាប់ការពារ

- ការដាក់ស័ង្កសីក្តៅ៖

- មិនគួរបង្ហាញស្នាមប្រេះ ផ្ទៃដែលមិនស្រោប ឬក្រាស់ពេក

- ជាធម្មតាក្រាស់ និងប្រើប្រាស់បានយូរជាងស័ង្កសីដែលធ្វើពីដែក

- ថ្នាំកូតម្សៅ៖

- មិនគួរបង្ហាញពពុះ ស្នាមប្រេះ ឬកម្មវិធីមិនស្មើគ្នា

- ត្រូវតែត្រូវគ្នាជាមួយស្រទាប់ការពារក្រោម

សូចនាករគុណភាពថ្នាំកូតសំខាន់ៗ៖

- ឯកសណ្ឋាន៖ សូម្បីតែលាបលើផ្ទៃទាំងអស់ រួមទាំងគែម និងផ្នែកខាងក្នុង

- ភាពស្អិតជាប់៖ ភាពស្អិតជាប់រឹងមាំទៅនឹងលោហៈធាតុ ដោយមិនមានការរបក ឬរបក

- អវត្ដមាននៃពិការភាព៖ គ្មានការកោស រន្ធម្ជុល ពងបែក ឬរន្ធដែលអាចសម្របសម្រួលការការពារ

- ការអនុលោមតាម RoHS: ថ្នាំកូតទំនើបគួរតែគោរពតាមបទប្បញ្ញត្តិបរិស្ថាន

សាកល្បងថ្នាំកូតដោយពិនិត្យមើលភាពស្អិតជាប់ - ថ្នាំកូតដែលមានគុណភាពនឹងមិនរលាយឬបន្ទះសៀគ្វីងាយស្រួលទេនៅពេលកោសស្រាល។

4. សមត្ថភាពផ្ទុក

ផ្លូវដែក DIN ដែលមានគុណភាពខ្ពស់ត្រូវតែទ្រទ្រង់ទម្ងន់នៃសមាសធាតុដែលបានម៉ោនដោយគ្មានការខូចទ្រង់ទ្រាយ។ សមត្ថភាពនេះត្រូវបានរងឥទ្ធិពលដោយសម្ភារៈ ទម្រង់ កម្រាស់ និងវិធីសាស្ត្រម៉ោន៖

- ផ្លូវដែកស្ដង់ដារ TS35x7.5: គួរទ្រទ្រង់យ៉ាងហោចណាស់ 40-60 គីឡូក្រាម/m នៅពេលដំឡើងត្រឹមត្រូវ

- ផ្លូវរថភ្លើង TS35x15 ធន់ធ្ងន់៖ គួរទ្រទ្រង់ 80-100 គីឡូក្រាម/m

- ផ្លូវដែកផ្នែក G និងផ្នែក C: ត្រូវបានរចនាឡើងជាពិសេសសម្រាប់សមត្ថភាពផ្ទុកបន្ទុកខ្ពស់។

- ប្លង់រឹងទល់នឹងរន្ធដោត៖ ផ្លូវដែករឹងផ្តល់កម្លាំងអតិបរមា។ ផ្លូវដែក perforated ជួញដូរភាពរឹងមួយចំនួនសម្រាប់ការកាត់បន្ថយទម្ងន់និងភាពបត់បែននៃខ្សែ

ការពិចារណាសំខាន់ៗ៖

- គ្មានការយារធ្លាក់ដែលអាចមើលឃើញគួរកើតឡើងនៅពេលផ្ទុកពេញ

- ការខូចទ្រង់ទ្រាយអចិន្រ្តៃយ៍មិនគួរកើតឡើងក្រោមការផ្ទុកដែលបានវាយតម្លៃទេ។

- សមត្ថភាពផ្ទុកដ៏មានប្រសិទ្ធិភាពអាស្រ័យលើវិធីសាស្រ្តម៉ោននិងវិសាលភាពរវាងចំណុចគាំទ្រ

- សមាសធាតុធ្ងន់តែមួយដាក់នៅចំកណ្តាលនៃវិសាលភាពដែលមិនគាំទ្របង្កើតភាពតានតឹងច្រើនជាងទម្ងន់ដូចគ្នាដែលចែកចាយស្មើៗគ្នា។

- បន្ទុកថាមវន្តពីការរំញ័រអាចបង្កើតភាពតានតឹងភ្លាមៗខ្ពស់ជាងការផ្ទុកឋិតិវន្ត

សម្រាប់កម្មវិធីសំខាន់ៗ រកមើលលក្ខណៈបច្ចេកទេសរបស់ក្រុមហ៊ុនផលិតដែលបញ្ជាក់យ៉ាងច្បាស់ថាសមត្ថភាពផ្ទុកបន្ទុកគិតជាគីឡូក្រាម/មម។ អវត្ដមាននៃទិន្នន័យបែបនេះគួរតែជាការព្រួយបារម្ភនៅពេលជ្រើសរើសផ្លូវដែកសម្រាប់កម្មវិធីដែលពាក់ព័ន្ធនឹងសមាសធាតុធ្ងន់។

5. លក្ខណៈសម្បត្តិធន់ទ្រាំនឹងការ corrosion

មានសារៈសំខាន់ជាពិសេសសម្រាប់ការដំឡើងនៅក្នុងបរិយាកាសអាក្រក់៖

- ការធ្វើតេស្តបាញ់អំបិល៖ ផ្លូវដែកស័ង្កសីដែលមានគុណភាពគួរទប់ទល់ 96+ ម៉ោងក្នុងការធ្វើតេស្តបាញ់អំបិលតាមស្តង់ដារ

- ការអនុវត្តបរិស្ថាន៖

- ផ្លូវដែកដែកអ៊ីណុកគួរទប់ទល់នឹងស្នាមប្រេះ និងការច្រេះនៅក្នុងបរិយាកាសដែលមានជាតិអាស៊ីត ឬក្លរួ

- ផ្លូវដែកអាលុយមីញ៉ូមគួរតែទប់ទល់នឹងការ corrosion ពណ៌សក្នុងលក្ខខណ្ឌសើមល្មម

- ដែកស័ង្កសីដែលមានជាតិក្រូមេអកម្មផ្តល់នូវការការពារច្រេះទូទៅដ៏ល្អសម្រាប់កម្មវិធីក្នុងផ្ទះ

- ភាពសុចរិតនៃថ្នាំកូត៖

- រាល់ការរំលោភលើថ្នាំកូតការពារបង្កើតចំណុចដែលបានធ្វើមូលដ្ឋានីយកម្មដែលការច្រេះអាចចាប់ផ្តើម

- សូម្បីតែការកោស ឬការខូចខាតតិចតួចអាចនាំឱ្យមានការច្រេះបន្តពូជនៅក្រោមការស្រោបនៅដដែល (កាត់ក្រោម)

- ការការពារមានប្រសិទ្ធភាពដូចចំណុចខ្សោយបំផុតរបស់វា។

- ឥរិយាបថសម្ភារៈ៖

- ថ្នាំកូតការពារគួរតែរក្សាភាពសុចរិតបន្ទាប់ពីការធ្វើតេស្តបរិស្ថាន

- សមា្ភារៈគួររក្សាភាពសុចរិតនៃរចនាសម្ព័ន្ធនៅក្នុងបរិយាកាសដែលបានវាយតម្លៃរបស់ពួកគេ។

- ជៀសវាងការប្រើដែកស័ង្កសីនៅក្នុងបរិយាកាសខាងក្រៅ ឬបរិស្ថានដែលច្រេះដោយមិនមានការការពារបន្ថែម

សម្រាប់កម្មវិធីនៅក្នុងផ្នែកកែច្នៃម្ហូបអាហារ ឱសថ សមុទ្រ ឬបរិស្ថានគីមី ភាពធន់នឹងការច្រេះនៃដែកអ៊ីណុក (ជាពិសេសថ្នាក់ទី 316) ជាធម្មតាមានតម្លៃថ្លៃជាងសម្ភារៈដោយសារអាយុកាលសេវាកម្មបានពង្រីកយ៉ាងខ្លាំង។

6. ភាពស៊ីសង្វាក់គ្នានៃផលិតកម្ម

ភាពស៊ីសង្វាក់គ្នាជាបាច់បង្ហាញពីការគ្រប់គ្រងគុណភាពដែលអាចទុកចិត្តបាន៖

- ស្ថេរភាពវិមាត្រ៖ វិមាត្រស្របគ្នានៅទូទាំងដំណើរការផលិតកម្មច្រើន។

- ភាពស្មើគ្នានៃផ្ទៃ៖ រូបរាងដែលអាចទស្សន៍ទាយបាន និងការការពារច្រេះ

- ភាពជាប់លាប់នៃទ្រព្យសម្បត្តិសម្ភារៈ៖ លក្ខណៈមេកានិចឯកសណ្ឋាន

- ការត្រួតពិនិត្យដំណើរការផលិត៖

- ម៉ាស៊ីន និងឧបករណ៍ដែលបានក្រិតតាមខ្នាតយ៉ាងល្អ

- គុណភាពវត្ថុធាតុដើមដែលជាប់លាប់

- ប្រតិបត្តិការជំនាញ និងការត្រួតពិនិត្យ

- បច្ចេកទេសកម្រិតខ្ពស់ដូចជាការបោះត្រាលើបរិវេណសម្រាប់ការធ្វើឱ្យភាពត្រឹមត្រូវនៃវិមាត្រប្រសើរឡើង

- ប្រតិបត្តិការកាត់ច្បាស់លាស់សម្រាប់ទម្រង់ច្បាស់លាស់ និងច្បាស់លាស់

ភាពល្អឥតខ្ចោះនៃផលិតកម្មទាមទារឱ្យមានការត្រួតពិនិត្យដំណើរការតឹងតែងនៅទូទាំងផលិតកម្ម។ ក្រុមហ៊ុនផលិតដែលមានគុណភាពខ្ពស់ជាធម្មតាអនុវត្ត៖

- ការត្រួតពិនិត្យដំណើរការស្ថិតិ (SPC) ដើម្បីតាមដាន និងរក្សាភាពជាប់លាប់

- ការក្រិតតាមខ្នាតទៀងទាត់នៃឧបករណ៍វាស់

- ប្រព័ន្ធតាមដានសម្ភារៈ

- ឯកសារនៃប៉ារ៉ាម៉ែត្រផលិតកម្ម

ភាពស៊ីសង្វាក់គ្នានៃផលិតកម្មមិនល្អនាំឱ្យដំណើរការដែលមិនអាចទាយទុកជាមុនបាន ភាពមិនស៊ីគ្នានៃសមាសធាតុ និងការកើនឡើងលទ្ធភាពនៃការបរាជ័យ ឬបញ្ហាការដំឡើង។ ភាពប្រែប្រួលនៃសមាសធាតុមួយទៅសមាសធាតុគឺជាសូចនាករសំខាន់នៃបញ្ហាគុណភាពផលិតកម្ម។

7. ការបញ្ជាក់ និងការអនុលោមតាមច្បាប់

ក្រុមហ៊ុនផលិតគុណភាពផ្តល់ជូន៖

- ឯកសារតាមដានសម្ភារៈ៖ ឯកសារតាមដានឯកសារត្រឡប់ទៅប្រភពរបស់វា។

- វិញ្ញាបនបត្រសាកល្បង៖ ឯកសារបញ្ជាក់ពីលក្ខណៈសម្បត្តិសំខាន់ៗ ដូចជាធន់នឹងច្រេះ

- សេចក្តីប្រកាសអំពីការអនុលោមតាមស្តង់ដារ៖ សេចក្តីថ្លែងការណ៍បញ្ជាក់ពីការប្រកាន់ខ្ជាប់នូវ IEC 60715 ឬស្តង់ដារតំបន់

- វិញ្ញាបនប័ត្រគ្រប់គ្រងគុណភាព៖

- វិញ្ញាបនប័ត្រ ISO 9001 បង្ហាញពីប្រព័ន្ធគ្រប់គ្រងគុណភាពដែលមានរចនាសម្ព័ន្ធ

- បង្ហាញពីដំណើរការស្របគ្នាដើម្បីបំពេញតម្រូវការអតិថិជន និងបទប្បញ្ញត្តិ

- ឧទាហរណ៍រួមមានក្រុមហ៊ុនផលិតដូចជា Schaltbau (ISO បញ្ជាក់តាំងពីឆ្នាំ 1994) និង Kowa Kasei

- ការអនុលោមតាមបរិស្ថាន៖

- ការអនុលោមតាម RoHS (ការដាក់កម្រិតនៃសារធាតុគ្រោះថ្នាក់)

- ការអនុលោមតាម REACH (ការចុះឈ្មោះ ការវាយតម្លៃ ការអនុញ្ញាត និងការរឹតត្បិតសារធាតុគីមី)

- ដំណើរការផលិតកម្មដែលមិនប៉ះពាល់ដល់បរិស្ថាន

- វិញ្ញាបនប័ត្រឧស្សាហកម្មជាក់លាក់៖

- ការចុះបញ្ជី/ការទទួលស្គាល់ UL សម្រាប់ទីផ្សារអាមេរិកខាងជើង

- សញ្ញាសម្គាល់ CE សម្រាប់ទីផ្សារអឺរ៉ុប

- វិញ្ញាបនប័ត្របន្ថែមសម្រាប់កម្មវិធីឯកទេស (ផ្លូវដែក យានយន្ត។ល។)

ឆន្ទៈរបស់អ្នកផលិតក្នុងការផ្តល់នូវឯកសារលម្អិត ជារឿយៗជាសូចនាករដ៏ល្អនៃការប្តេជ្ញាចិត្តរបស់ពួកគេចំពោះគុណភាព និងតម្លាភាព។ អវត្ដមាននៃឯកសារបែបនេះគួរតែជាសញ្ញាព្រមាននៅពេលជ្រើសរើសផ្លូវដែក DIN សម្រាប់កម្មវិធីសំខាន់ៗ។

របៀបពិនិត្យផ្លូវដែក DIN ដើម្បីទទួលបានគុណភាព

បច្ចេកទេសត្រួតពិនិត្យមើលឃើញ

មុនពេលដំឡើង សូមធ្វើការពិនិត្យមើលទាំងនេះ៖

- ការពិនិត្យផ្ទៃ៖

- រកមើលស្នាមប្រេះ ស្នាមប្រេះ ឬការបញ្ចប់មិនទៀងទាត់

- ពិនិត្យមើលពណ៌ និងវាយនភាពឯកសណ្ឋាននៅក្នុងថ្នាំកូតការពារ

- ពណ៌លឿង ឬពណ៌ខៀវបន្តិចនៅលើផ្លូវដែកស័ង្កសីគឺធម្មតា ហើយបង្ហាញពីភាពអសកម្ម

- ពិនិត្យមើលភាពខុសប្រក្រតីនៃការលាបពណ៌ដូចជាការរបកចេញ ពងបែក ឬការរលាត់

- ការត្រួតពិនិត្យគែម៖

- គែមគួរតែស្អាត មិនរដិបរដុប ឬរលួយ

- រត់ម្រាមដៃ ឬកណាត់ដោយប្រុងប្រយ័ត្នតាមគែម ដើម្បីរកមើលស្នាមប្រេះ ឬចំណុចមុតស្រួច

- ផ្លូវដែកមានគុណភាពមានគែមរលោង បញ្ចប់យ៉ាងល្អ ដោយគ្មានគ្រោះថ្នាក់កាត់

- ការបញ្ចប់គែមមិនល្អអាចធ្វើឱ្យខូចអ៊ីសូឡង់ខ្សែ និងបង្កហានិភ័យសុវត្ថិភាព

- ការត្រួតពិនិត្យរន្ធ / ប្រហោង:

- ផ្ទៀងផ្ទាត់រន្ធស្អាត មានគម្លាតត្រឹមត្រូវ និងឯកសណ្ឋាន

- លំនាំ perforation ស្តង់ដាររួមមាន 15mm x 6.2mm oblong slots

- រន្ធសម្រាប់ម៉ោនជាធម្មតាត្រូវបានកំណត់ស្តង់ដារនៅអង្កត់ផ្ចិតដូចជា 5.2mm ឬ 5.3mm

- ពិនិត្យមើលថាស្នាមប្រេះត្រូវបានបង្កើតឡើងយ៉ាងស្អាតដោយគ្មានបំណែកដែក

- ពិនិត្យភាពត្រង់៖

- ដាក់លើផ្ទៃរាបស្មើដើម្បីពិនិត្យមើលការរហែក

- ក្រឡេកមើលប្រវែង (វិធីសាស្ត្រ "Mk1 eyeball") ដើម្បីរកមើលធ្នូ ឬបង្វិល

- ផ្លូវដែកគួរលេចឡើងត្រង់ និងពិតតាមបណ្តោយប្រវែងទាំងមូលរបស់វា។

- ប្រៀបធៀបជាមួយគែមត្រង់ដែលគេស្គាល់សម្រាប់ភាពត្រឹមត្រូវកាន់តែច្រើន

- ការត្រួតពិនិត្យភាពស៊ីសង្វាក់គ្នានៃកម្រងព័ត៌មាន៖

- ពិនិត្យទម្រង់ផ្នែកឆ្លងកាត់សម្រាប់ភាពស៊ីសង្វាក់គ្នា។

- រកមើលការប្រែប្រួលនៃរូបរាង ឬមុំដែលអាចប៉ះពាល់ដល់ការភ្ជាប់សមាសភាគ

- ពិនិត្យមើលភាពស៊ីសង្វាក់នៃសម្ភារៈនៅទូទាំង

- ផ្ទៀងផ្ទាត់ការអនុលោមតាមវិមាត្រទម្រង់ស្តង់ដារ (TS35, TS32 ។ល។)

វិធីសាស្ត្រវាស់វែង និងតេស្ត

សម្រាប់ការវាយតម្លៃគុណភាពកាន់តែច្បាស់៖

- ការផ្ទៀងផ្ទាត់វិមាត្រ៖

- ប្រើ calipers ដើម្បីវាស់ទទឹង កម្ពស់ និងកម្រាស់

- ពិនិត្យមើលការបញ្ជាក់ស្តង់ដារ (ទទឹង 35mm សម្រាប់ TS35 ។ល។)

- ផ្ទៀងផ្ទាត់គម្លាតរន្ធដោយប្រើបន្ទាត់ច្បាស់លាស់

- ធ្វើការវាស់វែងនៅចំណុចច្រើន ដើម្បីពិនិត្យមើលភាពស៊ីសង្វាក់គ្នា។

- ការអត់ធ្មត់ធម្មតាគួរតែស្ថិតនៅក្នុង± 0.5mm សម្រាប់វិមាត្រសំខាន់

- ការវាស់វែងកម្រាស់ថ្នាំកូត៖

- ប្រើរង្វាស់កម្រាស់ថ្នាំកូតសម្រាប់ផ្លូវដែកដែលបានដាក់

- បន្ទះស័ង្កសីធម្មតាគួរវាស់ 5-12 មីក្រូន (ជាញឹកញាប់ 8 មីក្រូ)

- ផ្ទៀងផ្ទាត់កម្រាស់ស្របគ្នាតាមប្រវែងផ្លូវដែក

- យកចិត្តទុកដាក់ជាពិសេសចំពោះគែមនិងជ្រុងដែលថ្នាំកូតអាចស្តើងជាង

- ការធ្វើតេស្តសមទៅនឹងសមាសធាតុ៖

- ម៉ោនសមាសធាតុគំរូពីក្រុមហ៊ុនផលិតល្បីឈ្មោះ

- សមាសធាតុគួរតែចាប់យកដោយសុវត្ថិភាពជាមួយនឹងកម្លាំងសមហេតុផល

- ពិនិត្យរកមើលការលេងហួសហេតុ ញ័រ ឬរលុង

- ត្រូវប្រាកដថាយន្តការចាក់សោភ្ជាប់បានត្រឹមត្រូវ។

- សមាសធាតុរអិលគួរផ្លាស់ទីដោយរលូនដោយគ្មានការចង

- ការធ្វើតេស្ត Flex ដោយដៃ៖

- សម្រាប់ផ្លូវរថភ្លើងខ្លីជាង (រហូតដល់ 1 ម៉ែត្រ) សូមព្យាយាមបត់ដោយដៃទន់ភ្លន់

- ប្រៀបធៀបភាពរឹងរវាងគំរូផ្សេងៗ

- ផ្លូវដែកដែលមានគុណភាពខ្ពស់គួរតែទប់ទល់នឹងការពត់កោងក្រោមកម្លាំងមធ្យម

- ផ្លូវដែកគួរមានអារម្មណ៍រឹងមាំជាងអាលុយមីញ៉ូម

- ការធ្វើតេស្តភាពរឹង៖

- ប្រើឧបករណ៍សាកល្បងភាពរឹងចល័តប្រសិនបើមាន

- ប្រៀបធៀបការអានទៅនឹងលក្ខណៈបច្ចេកទេសរបស់ក្រុមហ៊ុនផលិត

- ការអានជាប់លាប់បង្ហាញពីលក្ខណៈសម្បត្តិសម្ភារៈឯកសណ្ឋាន

នីតិវិធីធ្វើតេស្តគំរូ

សម្រាប់ការដំឡើងសំខាន់ៗ សូមពិចារណាការធ្វើតេស្តកម្រិតខ្ពស់បន្ថែមទៀតទាំងនេះ៖

- ការធ្វើតេស្តផ្ទុក៖

- ដំឡើងផ្លូវដែកគំរូតាមលក្ខណៈបច្ចេកទេសរបស់ក្រុមហ៊ុនផលិត

- អនុវត្តបន្ទុកបន្ថែមដើម្បីផ្ទៀងផ្ទាត់សមត្ថភាពដែលបានវាយតម្លៃ

- ផ្លូវដែកស្ដង់ដារ TS35x7.5 គួរតែគាំទ្រ 40-60 គីឡូក្រាមក្នុងមួយម៉ែត

- ផ្លូវរថភ្លើង TS35x15 ធុនធ្ងន់គួរគាំទ្រ 80-100 គីឡូក្រាមក្នុងមួយម៉ែត

- ពិនិត្យមើលការខូចទ្រង់ទ្រាយបន្ទាប់ពីការដកបន្ទុកចេញ

- ចំណាំថាសមត្ថភាពផ្ទុកដែលមានប្រសិទ្ធភាពអាស្រ័យលើវិធីសាស្ត្រម៉ោននិងវិសាលភាព

- ការធ្វើតេស្ត corrosion:

- បញ្ចោញសំណាកសំណាកទៅនឹងការបាញ់អំបិល ដើម្បីធ្វើតេស្តពន្លឿន

- ផ្លូវដែកស័ង្កសីដែលមានគុណភាពគួរទប់ទល់ 96+ ម៉ោង។

- ប្រៀបធៀបលទ្ធផលជាមួយនឹងការអះអាងរបស់អ្នកផលិត

- ពិនិត្យមើលគំរូច្រេះឯកសណ្ឋានដោយគ្មានការធ្វើមូលដ្ឋានីយកម្ម

- ផ្លូវដែកដែកអ៊ីណុកគួរបង្ហាញតិចតួចបំផុតដើម្បីមិនច្រេះ

- ភាពធន់នឹងរំញ័រ៖

- ម៉ោនសមាសធាតុនិងជាកម្មវត្ថុនៃការធ្វើតេស្តរំញ័រ

- ផ្ទៀងផ្ទាត់ការរក្សាទុកសមាសធាតុនៅក្រោមរំញ័រដែលបានបញ្ជាក់

- ផ្លូវដែកដែលមានទម្រង់កាន់តែជ្រៅ ជាធម្មតាផ្តល់នូវភាពធន់នឹងរំញ័រប្រសើរជាងមុន។

- សំខាន់សម្រាប់កម្មវិធីនៅជិតម៉ាស៊ីនធុនធ្ងន់ ឬនៅក្នុងប្រព័ន្ធដឹកជញ្ជូន

- ការវាយតម្លៃគុណភាពកាត់៖

- ប្រើឧបករណ៍កាត់ដែលសមស្រប (hacksaw ដែលមានធ្មេញល្អ ឧបករណ៍កាត់ផ្លូវដែក)

- ពិនិត្យគែមកាត់សម្រាប់ burrs ឬខូចទ្រង់ទ្រាយ

- ផ្លូវដែកដែលមានគុណភាពគួរកាត់ឱ្យស្អាតដោយមិនមានការបង្កើត burr ច្រើនពេក

- ការធ្វើតេស្តនេះក៏វាយតម្លៃភាពស៊ីសង្វាក់គ្នា និងរឹងរបស់សម្ភារៈផងដែរ។

- ជិះកង់បរិស្ថាន៖

- ប្រធានបទគំរូទៅនឹងវដ្តសីតុណ្ហភាព និងសំណើម

- ពិនិត្យមើលស្ថេរភាពវិមាត្រ និងភាពត្រឹមត្រូវនៃថ្នាំកូត

- ផ្លូវដែកគុណភាពរក្សាលក្ខណៈសម្បត្តិរបស់ពួកគេនៅទូទាំងបរិយាកាសប្រតិបត្តិការធម្មតា។

ក្រុមហ៊ុនផលិតកំពូលដែលស្គាល់សម្រាប់ផ្លូវដែក DIN គុណភាពខ្ពស់

ខណៈពេលដែលការណែនាំម៉ាកជាក់លាក់អាចផ្លាស់ប្តូរតាមពេលវេលា ក្រុមហ៊ុនផលិតទាំងនេះបានបង្កើតកេរ្តិ៍ឈ្មោះសម្រាប់ផ្លូវដែក DIN ដែលមានគុណភាព៖

ម៉ាកអន្តរជាតិសំខាន់ៗ

- Phoenix Contact: ស្គាល់សម្រាប់ភាពត្រឹមត្រូវនៃវិមាត្រខ្ពស់ (ភាពអត់ធ្មត់ ± 0.5mm) និង "ស្រទាប់ passivated ក្រាស់" សម្រាប់ការការពារការច្រេះដ៏ប្រសើរ។

- VIOX៖ ត្រូវបានទទួលស្គាល់សម្រាប់ការត្រួតពិនិត្យគុណភាពដ៏តឹងរ៉ឹង និងនីតិវិធីធ្វើតេស្តយ៉ាងទូលំទូលាយ

- Schneider Electric: ផ្តល់ជូននូវឯកសារបច្ចេកទេសដ៏ទូលំទូលាយ និងស្តង់ដារសកល

- ABB៖ ស្គាល់សម្រាប់ការផលិតភាពជាក់លាក់ និងភាពឆបគ្នានៃសមាសធាតុ

- Rittal: មានជំនាញក្នុងប្រព័ន្ធឯករភជប់ជាមួយនឹងដំណោះស្រាយផ្លូវដែករួមបញ្ចូលគ្នា

- អ៊ីតុន៖ រំលេច "ភាពត្រឹមត្រូវនៃវិមាត្រខ្ពស់" និង "ការអត់ធ្មត់ដែលបានដាក់កម្រិត" ជាលក្ខណៈសំខាន់ៗ

- Siemens: ម៉ាកយីហោដែលបានបង្កើតឡើងជាយូរមកហើយជាមួយនឹងបទពិសោធន៍ផ្នែកឧស្សាហកម្មយ៉ាងទូលំទូលាយ

ក្រុមហ៊ុនផលិតគួរឱ្យកត់សម្គាល់ផ្សេងទៀត។

- ក្រុមហ៊ុន Altech Corp

- Wieland Electric Inc. (បង្កើតឡើងឆ្នាំ 1910)

- ស្វ័យប្រវត្តិកម្មផ្ទាល់

- Kowa Kasei Co., Ltd. (ប្រទេសជប៉ុន បង្កើតឡើងឆ្នាំ ១៩៦៩)

- OBO Bettermann

- c3controls

រកមើលក្រុមហ៊ុនផលិតដែល:

- បញ្ជាក់យ៉ាងច្បាស់ពីការអនុលោមតាម IEC 60715 ឬស្តង់ដារពាក់ព័ន្ធ

- កាន់វិញ្ញាបនប័ត្រប្រព័ន្ធគ្រប់គ្រងគុណភាព ISO 9001

- ផ្តល់ឯកសារបច្ចេកទេសលម្អិត និងលក្ខណៈបច្ចេកទេស

- ផ្តល់ជូននូវវិញ្ញាបនប័ត្រអនុលោមភាពបរិស្ថាន (RoHS, REACH)

- រក្សាការត្រួតពិនិត្យគុណភាពជាប់លាប់នៅទូទាំងផលិតកម្ម

- មានកំណត់ត្រាបទបង្ហាញឱ្យឃើញនៅក្នុងសមាសធាតុឧស្សាហកម្ម

- ផ្តល់ការធានា និងការគាំទ្រផលិតផលឆ្លើយតប

VIOX DIN RIN ដំណើរការផលិត

តម្លៃធៀបនឹងគុណភាព៖ ការវិនិយោគត្រឹមត្រូវនៅក្នុងផ្លូវដែក DIN

នៅពេលវាយតម្លៃជម្រើសផ្លូវដែក DIN សូមពិចារណាតម្លៃសរុបនៃភាពជាម្ចាស់៖

ថ្លៃដើម៖

- តម្លៃសម្ភារៈ (ដែកស័ង្កសីទល់នឹងដែកអ៊ីណុកទល់នឹងអាលុយមីញ៉ូម)

- ការចំណាយលើការបញ្ចប់ (បន្ទះស័ង្កសីស្តង់ដារធៀបនឹងការជ្រលក់ទឹកក្តៅ)

- ការចំណាយលើការផលិតភាពជាក់លាក់ (ការអត់ធ្មត់កាន់តែតឹងតែងបញ្ជាឱ្យតម្លៃកាន់តែខ្ពស់)

- ការពិចារណាលើប្រវែង និងបរិមាណ (ការទិញច្រើនជាធម្មតាកាត់បន្ថយតម្លៃឯកតា)

ការពិចារណារយៈពេលវែង៖

- ភាពញឹកញាប់នៃការជំនួសនៅក្នុងបរិយាកាសផ្សេងៗគ្នា

- ការចំណាយលើការផ្អាកប្រព័ន្ធពីការបរាជ័យផ្លូវដែក ឬផ្នែក

- ថែទាំថ្លៃពលកម្មសម្រាប់ជួសជុលគ្រឿងបន្លាស់ដែលខូច

- ផលប៉ះពាល់សុវត្ថិភាព និងភាពជឿជាក់លើប្រតិបត្តិការទាំងមូល

- ភាពឆបគ្នាជាមួយនឹងការពង្រីកប្រព័ន្ធនាពេលអនាគត

- ភាពស៊ីសង្វាក់គ្នានៃការដំឡើងសម្រាប់ស្តង់ដារ

ប៉ុន្តែរង់ចាំ - មានច្រើនទៀត៖ ផ្លូវដែក DIN គុណភាពជាធម្មតាតំណាងឱ្យតិចជាង 1% នៃតម្លៃដំឡើងសរុប ប៉ុន្តែអាចប៉ះពាល់ដល់ភាពជឿជាក់នៃប្រព័ន្ធទាំងមូល។ ផ្លូវដែក DIN ដែលផលិតមិនសូវល្អដែលបរាជ័យមុនអាយុអាចសន្សំបានពីរបីដុល្លារខាងមុខ ប៉ុន្តែអាចចំណាយអស់រាប់ពាន់ក្នុងពេលវេលារងចាំ ការជួសជុល និងការជំនួសគ្រឿងបន្លាស់។

ឧទាហរណ៍ការវិភាគតម្លៃ-អត្ថប្រយោជន៍

| ប្រភេទផ្លូវដែក DIN | ថ្លៃដើម | អាយុកាលរំពឹងទុក | តម្រូវការថែទាំ | កម្មវិធីល្អបំផុត |

|---|---|---|---|---|

| ដែកស័ង្កសីស្តង់ដារ | $ | 10-15 ឆ្នាំ (ក្នុងផ្ទះ) | ការត្រួតពិនិត្យតាមកាលកំណត់ | ការដំឡើងក្នុងផ្ទះទូទៅ |

| ដែកអ៊ីណុក ៣០៤ | $$ | 20+ ឆ្នាំ។ | តិចតួចបំផុត។ | ការកែច្នៃចំណីអាហារ បរិយាកាសសើម |

| ដែកថែបស័ង្កសីក្តៅ | $ | ១៥-២០ ឆ្នាំ។ | ការត្រួតពិនិត្យតាមកាលកំណត់ | ការប្រើប្រាស់ខាងក្រៅ និងឧស្សាហកម្ម |

| អាលុយមីញ៉ូម | $ | 10-15 ឆ្នាំ។ | ការត្រួតពិនិត្យតាមកាលកំណត់ | កម្មវិធីងាយនឹងទម្ងន់ |

នៅពេលជ្រើសរើសរវាងជម្រើស វាយតម្លៃបរិយាកាសប្រតិបត្តិការ អាយុកាលសេវាកម្មដែលរំពឹងទុក ការរិះគន់នៃកម្មវិធី និងផលវិបាកនៃការបរាជ័យ។ សម្រាប់ប្រព័ន្ធសំខាន់ៗ ឬបរិស្ថានអាក្រក់ បុព្វលាភសម្រាប់សម្ភារៈដែលមានគុណភាពខ្ពស់គឺស្ទើរតែតែងតែត្រូវបានរាប់ជាសុចរិតដោយការពន្យារអាយុសេវាកម្ម និងកាត់បន្ថយការចំណាយលើការថែទាំ។

ការដោះស្រាយបញ្ហាគុណភាពផ្លូវដែក DIN ទូទៅ

ការកំណត់អត្តសញ្ញាណពិការភាពផលិតកម្ម

សូមមើលសញ្ញាព្រមានទាំងនេះនៃការផលិតមិនស្តង់ដារ៖

- គម្លាតរន្ធមិនស្មើគ្នា៖

- មូលហេតុ៖ ឧបករណ៍ខ្សោយ ការគ្រប់គ្រងគុណភាពមិនគ្រប់គ្រាន់

- ផលប៉ះពាល់៖ ការម៉ោនពិបាក ការតម្រឹមសមាសធាតុមិនត្រឹមត្រូវ

- ការរកឃើញ៖ វាស់ចម្ងាយរវាងរន្ធជាមួយនឹងបន្ទាត់ច្បាស់លាស់

- គម្លាតស្តង់ដារជាញឹកញាប់គឺ 25mm សម្រាប់រន្ធដោត

- ផ្លូវដែករមួលឬរហែក៖

- មូលហេតុ៖ ការគ្រប់គ្រងសម្ភារៈមិនត្រឹមត្រូវ បញ្ហាព្យាបាលកំដៅ

- ផលប៉ះពាល់៖ សមាសធាតុមិនសមស្រប ភាពតានតឹងលើឧបករណ៍ដែលបានម៉ោន

- ការរកឃើញ៖ ដាក់លើផ្ទៃរាបស្មើ ហើយពិនិត្យមើលចន្លោះប្រហោង មើលឃើញតាមបណ្តោយប្រវែង

- ហានិភ័យ៖ អាចបណ្តាលឱ្យមានការភ្ជាប់ចរន្តអគ្គិសនីមិនទៀងទាត់

- Burrs និងគែមមុតស្រួច:

- មូលហេតុ៖ ឧបករណ៍កាត់មិនគ្រប់គ្រាន់

- ផលប៉ះពាល់៖ គ្រោះថ្នាក់សុវត្ថិភាព អ៊ីសូឡង់ខ្សែដែលខូច

- ការរកឃើញ៖ ការត្រួតពិនិត្យមើលឃើញដោយប្រុងប្រយ័ត្ន និងការធ្វើតេស្តប៉ះ (ជាមួយស្រោមដៃ)

- ផ្លូវដែកមានគុណភាពមានគែមរលោង និងបញ្ចប់យ៉ាងល្អ

- ការដាក់ចានមិនស្មើគ្នា៖

- មូលហេតុ៖ ការគ្រប់គ្រងដំណើរការមិនល្អ ការសម្អាតមិនគ្រប់គ្រាន់

- ផលប៉ះពាល់៖ ការច្រេះមុនអាយុ កាត់បន្ថយអាយុកាលសេវាកម្ម

- ការរកឃើញ៖ រកមើលពណ៌មិនស្មើគ្នា ការប្រែប្រួលកម្រាស់ ចំណុចរិល

- ចានគុណភាពមានរូបរាងឯកសណ្ឋាននិងកម្រាស់

សញ្ញានៃគុណភាពសម្ភារៈមិនល្អ

ប្រុងប្រយ័ត្នចំពោះសូចនាករទាំងនេះនៃសម្ភារៈដែលមិនមានស្តង់ដារ៖

- ភាពបត់បែនហួសហេតុ៖

- មូលហេតុ៖ កម្រាស់សម្ភារៈមិនគ្រប់គ្រាន់ (ក្រោម 1mm) ការជ្រើសរើសយ៉ាន់ស្ព័រមិនល្អ

- ផលប៉ះពាល់៖ ការយារធ្លាក់នៅក្រោមបន្ទុក ការតម្រឹមសមាសធាតុមិនត្រឹមត្រូវ

- ការរកឃើញ៖ ការធ្វើតេស្តបត់បែនដោយដៃទន់ភ្លន់ បើប្រៀបធៀបទៅនឹងគំរូល្អដែលគេស្គាល់

- ផ្លូវដែកដែលមានគុណភាពគួរមានភាពរឹងមាំខ្ពស់។

- រណ្តៅឬរន្ធផ្ទៃ:

- មូលហេតុ៖ សម្ភារៈមូលដ្ឋានទាប ការរៀបចំផ្ទៃមិនគ្រប់គ្រាន់

- ផលប៉ះពាល់៖ ចំណុចចាប់ផ្តើមនៃការច្រេះ ការបរាជ័យនៃថ្នាំកូត

- ការរកឃើញ៖ បិទការត្រួតពិនិត្យដោយមើលឃើញ ជាពិសេសនៅពត់ និងគែម

- លោហៈធាតុមានគុណភាព មានផ្ទៃរលោង និងជាប់លាប់

- ពណ៌ឬពណ៌មិនស្មើគ្នា៖

- មូលហេតុ៖ ការគ្រប់គ្រងគុណភាពមិនល្អ ការចម្លងរោគអំឡុងពេលបញ្ចប់

- ផលប៉ះពាល់៖ បង្ហាញពីបញ្ហាគុណភាពមូលដ្ឋានដែលមានសក្តានុពល

- ការរកឃើញ៖ ពិនិត្យនៅក្រោមពន្លឺល្អ ដើម្បីភាពស៊ីសង្វាក់គ្នា។

- ចំណាំ៖ ពណ៌លឿងបន្តិចពីភាពអសកម្មគឺធម្មតា ហើយមិនបង្ហាញពីបញ្ហាគុណភាពទេ។

- ការចាប់ផ្តើម corrosion យ៉ាងឆាប់រហ័ស:

- មូលហេតុ៖ កម្រាស់ថ្នាំកូតមិនគ្រប់គ្រាន់ ការជ្រើសរើសសម្ភារៈមិនល្អ

- ផលប៉ះពាល់៖ អាយុកាលសេវាកម្មខ្លី ការបរាជ័យប្រព័ន្ធសក្តានុពល

- ការរកឃើញ៖ ចំណុចច្រែះដំបូង ឬការ corrosion ពណ៌សនៅលើអាលុយមីញ៉ូម

- ផ្លូវដែកមានគុណភាពរក្សាភាពធន់នឹងច្រេះដែលសមស្របទៅនឹងបរិស្ថានរបស់វា។

- ការលំបាកក្នុងការដំឡើងសមាសធាតុ៖

- មូលហេតុ៖ គម្លាតទម្រង់ពីទំហំស្តង់ដារ

- ផលប៉ះពាល់៖ សមាសធាតុមិនសមត្រឹមត្រូវ ឬត្រូវការកម្លាំងខ្លាំងពេក

- ការរកឃើញ៖ សាកល្បងដំឡើងប្រភេទសមាសធាតុជាច្រើនពីក្រុមហ៊ុនផលិតល្បីឈ្មោះ

- ផ្លូវដែកមានគុណភាពអនុញ្ញាតឱ្យសមាសធាតុចាប់យកដោយកម្លាំងសមហេតុផល និងជាប់លាប់

- ឥរិយាបថកាត់មិនស្មើគ្នា៖

- មូលហេតុ៖ ការប្រែប្រួលនៃភាពរឹងរបស់សម្ភារៈ ឬសមាសភាព

- ផលប៉ះពាល់៖ ការប្រឌិតពិបាក ប្រេះខ្លាំងពេក

- ការរកឃើញ៖ សាកល្បងកាត់ផ្នែកតូចៗដោយប្រើឧបករណ៍សមស្រប

- ផ្លូវដែកដែលមានគុណភាពកាត់យ៉ាងស្អាតជាមួយនឹងការបង្កើតស្នាមប្រេះតិចតួច

សេចក្តីសន្និដ្ឋាន៖ ការធានានូវការអនុវត្តរយៈពេលវែង តាមរយៈការជ្រើសរើសគុណភាព

ការកំណត់គុណភាពនៃផ្លូវដែក DIN គឺជាដំណើរការចម្រុះដែលពាក់ព័ន្ធនឹងការយល់ដឹងអំពីស្តង់ដារ លក្ខណៈសម្បត្តិសម្ភារៈ ភាពជាក់លាក់នៃការផលិត និងតម្រូវការកម្មវិធីសមស្រប។ ដោយការវាយតម្លៃដោយប្រុងប្រយ័ត្ននូវកត្តាគុណភាពសំខាន់ៗទាំងប្រាំពីរ និងការអនុវត្តបច្ចេកទេសត្រួតពិនិត្យត្រឹមត្រូវ អ្នកអាចធានាថាផ្លូវដែក DIN របស់អ្នកផ្តល់នូវភាពជឿជាក់ និងអាយុកាលយូរដែលត្រូវការសម្រាប់កម្មវិធីឧស្សាហកម្មសំខាន់ៗ។

ពាក់ព័ន្ធ

របៀបជ្រើសរើសផ្លូវដែក DIN ត្រឹមត្រូវ៖ ការណែនាំពេញលេញ

ផ្លូវដែក DIN ទល់នឹងការដំឡើងតាមបែបប្រពៃណី

8 ភាពខុសគ្នា: អាលុយមីញ៉ូមទល់នឹងដែក DIN Rails

ក្រុមហ៊ុនផលិតផ្លូវដែក Din ផ្ទាល់ខ្លួន

កត្តាសំខាន់ៗដែលជះឥទ្ធិពលលើតម្លៃផ្លូវដែក DIN៖ ការវិភាគដ៏ទូលំទូលាយ