Egy engedéllyel rendelkező villanyszerelő beszerelte a főelosztóba, közvetlenül a megszakítók mellé. Hat hónappal később egy villám belecsap egy 200 méterre lévő transzformátorba – még csak nem is az Ön létesítménye közelében. Másnap reggel 40 000 dollárnyi sérült PLC-t bámul, VFD-ket, és vezérlőrendszereket.

A panelre szerelt túlfeszültség-védő? Még mindig ott ül a panelben, tökéletesen jól néz ki.

Mint egy drága panelékszer.

Hogyan működnek valójában a panelre szerelt túlfeszültség-védők (és miért nem a legtöbb)?

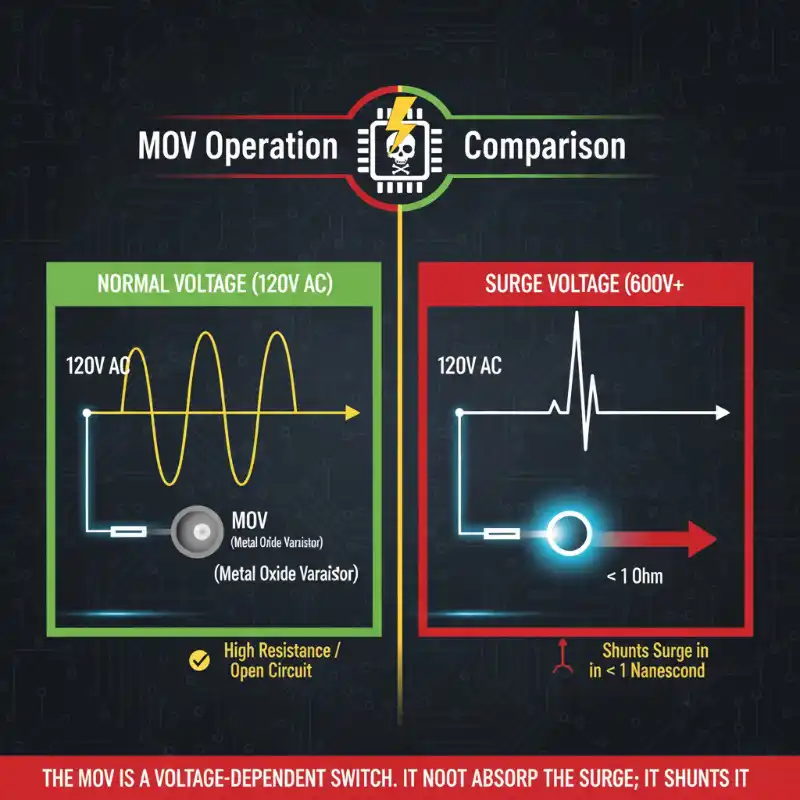

Íme, mi történik valójában a panelre szerelt túlfeszültség-védelmi eszköz (SPD) belsejében. A fő technológia egy fém-oxid varisztor – röviden MOV. Tekintse úgy, mint egy feszültségérzékeny kapcsolót, amely egy érdekes kvantumállapotban él.

Normál üzemi feszültségen (120 V vagy 240 V) a MOV rendkívül nagy ellenállással rendelkezik – lényegében egy nyitott áramkör. Az áram a megszakítókon keresztül jut el a berendezéséhez, mintha ott sem lenne semmi. De amikor a feszültség egy bizonyos küszöbérték fölé emelkedik – lakossági rendszereknél általában 400-600 V körül –, a MOV dielektromos áttörést szenved. Az ellenállása millió ohmtól közel nullára csökken körülbelül egy nanoszekundum alatt.

Ez gyorsabb, mint egy szempillantás. Gyorsabb, mint kimondani, hogy “villám”. A MOV éppen most vált egy 10 000 amperes kapcsolóvá, és éppen most zárt be.

Most itt a kérdés, amit senki sem tesz fel, amíg túl késő nem lesz: hová megy az a túlfeszültség-energia?

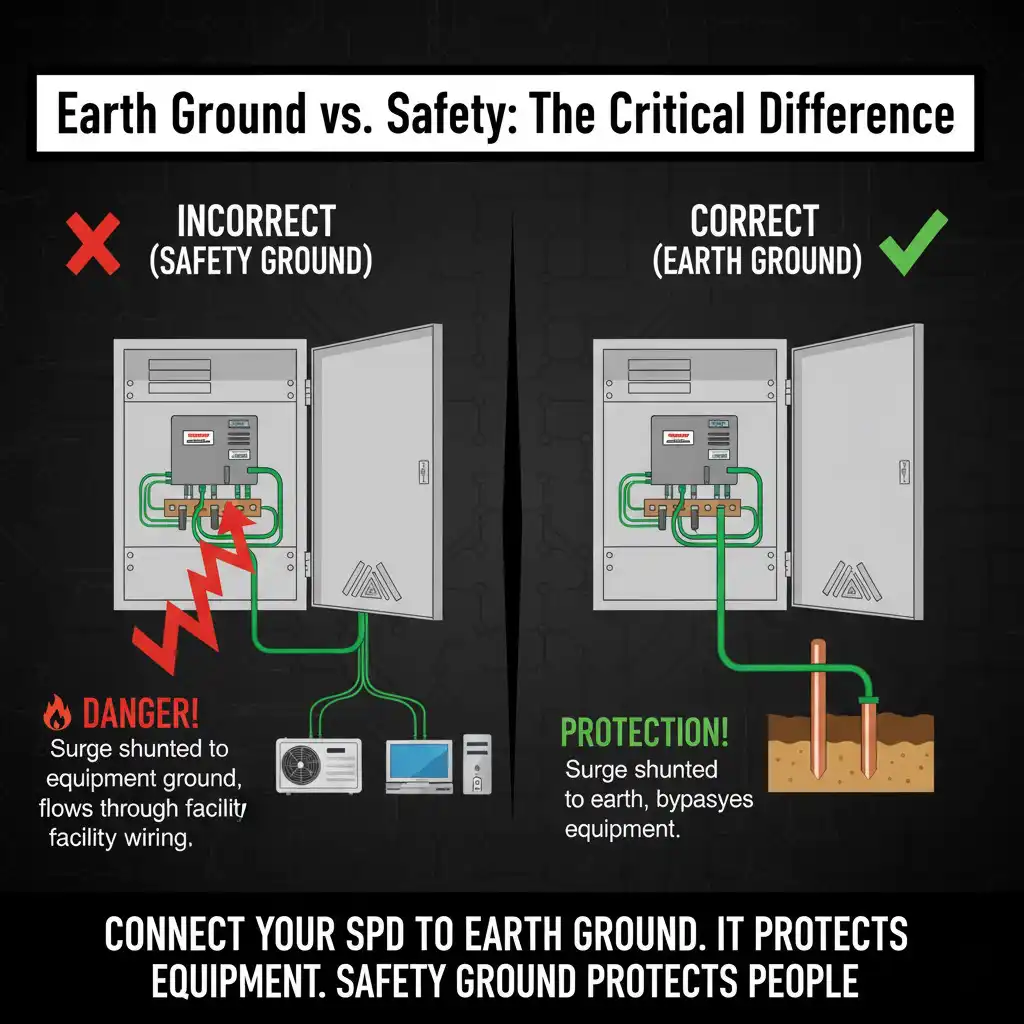

A MOV létrehoz egy útvonalat. De egy útvonalat hová? Ez A Földelés Kérdése– és ez a különbség a tényleges védelem és a drága panelékszer között.

A legtöbb panelre szerelt SPD három ponthoz csatlakozik: fázis-nulla, fázis-föld és nulla-föld. Amikor a MOV bekapcsol, megpróbálja valahová söntölni ezt a túlfeszültség-energiát. Ha a “valahová” csak a berendezés földelő sínje – ugyanaz a sín, amelyre a konnektorok földelése és a berendezések keretei vannak kötve –, akkor problémát okozott, nem pedig megoldott egyet.

Ennek a túlfeszültség-energiának el kell oszlania a földben. Nem a földelő rendszer berendezésbiztonsági földelésében. Nem a vízvezetékekben. A tényleges földben – amiről Benjamin Franklin beszélt, amikor 250 évvel ezelőtt felengedte azt a sárkányt.

Egy villámcsapás 300 000 joule energiát hordozhat. Az Ön panelre szerelt SPD-je a “20 000 joule névleges értékével”? Ez nem abszorpciós kapacitás – ez marketing színház. A MOV nem nyeli el a túlfeszültséget. Söntöli azt. És ha nincs hová mennie a 300 000 joule-nak, kivéve a létesítmény vezetékein, a PLC rackeken és a változó frekvenciájú meghajtókon keresztül? Nos, ez megmagyarázza a 40 000 dolláros javítási számlát.

Pro-Tipp: A joule értékek megmondják, mikor fog meghibásodni a MOV, nem pedig azt, hogy mennyi védelme van. Egy 50 000 amperes áramerősség sokkal fontosabb, mint egy 20 000 joule-os energiaérték. Az SPD-nek a földbe kell söntölnie a túlfeszültséget, nem pedig megpróbálnia elnyelni azt.

Miért csak drága panelékszer a “földelés” “föld” nélkül?

A villanyszerelők és a mérnökök úgy dobálóznak a “földelés” szóval, mintha mindenki tudná, mit jelent. Nem tudják. És ez a nyelvi hanyagság létesítmények tízezreibe kerül évente a sérült berendezésekben.

Két teljesen különböző földelés létezik az elektromos rendszerében:

Biztonsági földelés (berendezés földelés): Ez a földelő sín a panelben, ahol az összes berendezés földelő vezetője végződik. A feladata, hogy zárlat esetén hibaáram útvonalat biztosítson vissza a forráshoz, kioldva a megszakítót, mielőtt valakit áramütés érne. Összeköti a berendezések kereteit, a konnektorok földelését és a fémházakat. Elengedhetetlen az elektromos biztonsághoz. Teljesen helytelen a túlfeszültség-védelemhez.

Földelés: Ez egy kapcsolat a tényleges földdel – földelő rudak, Ufer földelések, a talajba vert földelő elektródák. A feladata, hogy végtelen nyelőt biztosítson a túlfeszültség-energiához, több százezer joule-t ártalmatlanul eloszlatva a bolygó tömegében. Ezt mutatta be Franklin. Ez az, ami valójában megállítja a villámkárokat.

Amikor a panelre szerelt SPD a berendezés földelő sínjéhez csatlakozik ahelyett, hogy egy dedikált földelő útvonalhoz, akkor éppen egy autópályát adott a túlfeszültségnek közvetlenül az elektromos rendszerén keresztül. A MOV bekapcsol. A túlfeszültség eltérül a fázisvezetőről. És aztán minden egyes vezetőn keresztülhalad, amely ehhez a berendezés földelő sínjéhez van kötve, és utat keres a föld felé – a számítógép házán, a VFD bemeneti fokozatán, a PLC tápegységén keresztül.

Ha ezt a hosszabbító kábelt megtalálják a poggyászában, a tengerjáró hajók elkobozzák. Komolyan veszik a tűzveszélyt. Miért? Mert a túl kicsi MOV-ok, amelyek megpróbálnak kezelni a túlfeszültség-energiát, amelyet nem tudnak söntölni, hőt termelnek. Elegendő hőt a műanyag ház meggyulladásához. Egy 25 dolláros hosszabbító kábel, amelyben 0,50 dollár értékű MOV alkatrész van, nem rendelkezik hőtehetetlenséggel ahhoz, hogy még a mérsékelt túlfeszültség-energiát is kezelje.

Most skálázza fel ezt. Egy panelre szerelt SPD, amely helytelenül van földelve, és megpróbál egy közeli villámcsapást a létesítmény vezetékein keresztül a föld helyett söntölni? Ez nem túlfeszültség-védelem. Ez egy elosztott tűzveszély.

Pro-Tipp: Tegyen fel egy egyszerű kérdést a villanyszerelőjének: “Hová megy ennek az SPD-nek a földelő vezetéke – a berendezés földelő sínjéhez vagy közvetlenül a földelő elektródákhoz?” Ha azt mondják, hogy “a földelő sínhez”, akkor drága panelékszere van, nem pedig túlfeszültség-védelme.

1. típus, 2. típus, 3. típus: Miért fontosabb a hely és a földelés, mint a joule értékek?

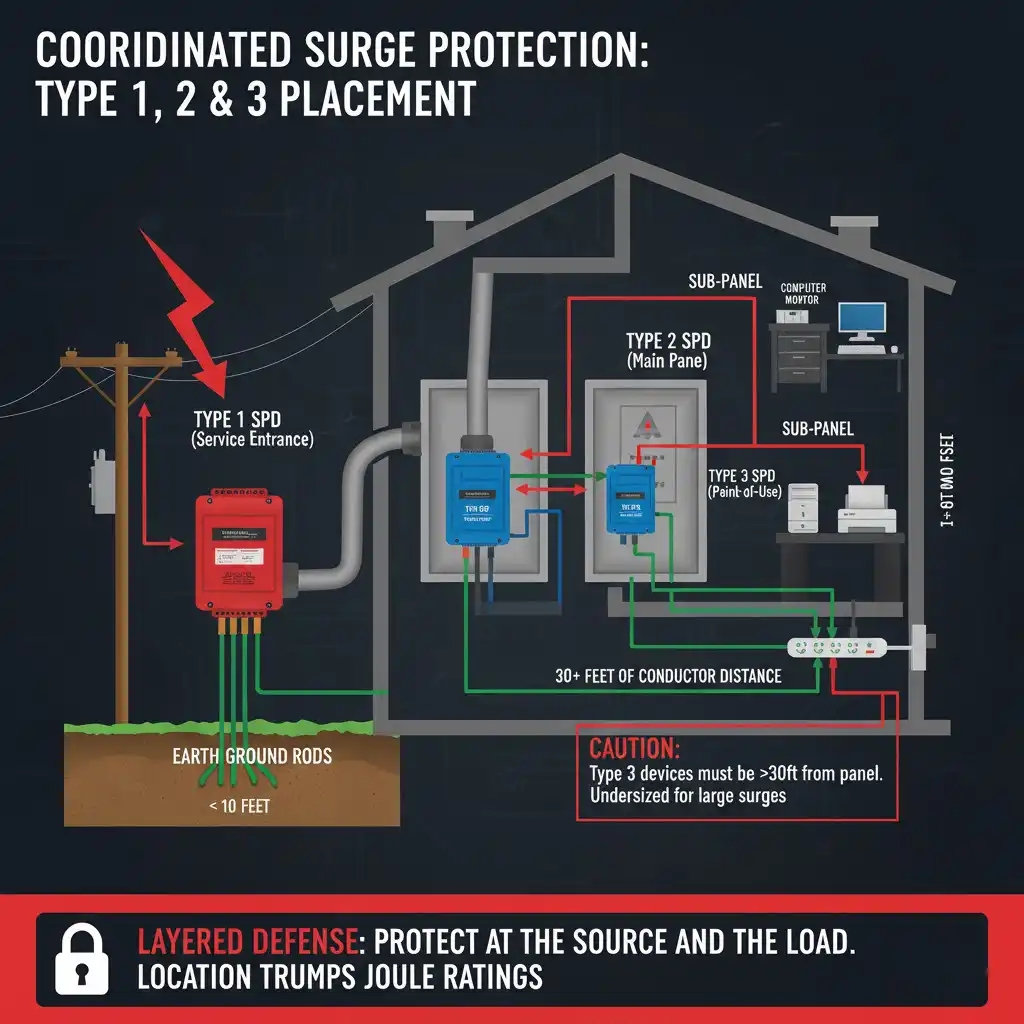

Az ipar a túlfeszültség-védelmi eszközöket aszerint osztályozza, hogy hová vannak telepítve, nem pedig aszerint, hogy hány joule-t állítanak magukról. Ennek az osztályozásnak a megértése megmagyarázza, hogy a legtöbb létesítmény miért rontja el a túlfeszültség-védelmet.

1. típusú EPD-k a szervizbejáratnál kell telepíteni – ahol a közművi áram belép a létesítménybe, a fő leválasztó előtt. Ezeket a földelő elektródákhoz kell csatlakoztatni kevesebb, mint 10 lábnyi vezetővel (hamarosan eljutunk oda, hogy ez a szám miért számít). Ezek a nehézsúlyúak: jellemzően 50 000 és 200 000 amper közöttiek. A feladatuk, hogy lefogják a külső forrásokból származó hatalmas túlfeszültséget – villámcsapások, közművi kapcsolások, transzformátorhibák –, mielőtt az elérné a létesítmény vezetékeit.

2. típusú EPD-k a főelosztóban vagy az al-elosztókban kell telepíteni. Második védelmi réteget biztosítanak azoknak a túlfeszültségeknek, amelyek átjutnak az 1. típuson, és kezelik a létesítményen belül keletkező túlfeszültségeket is (motor kapcsolás, VFD harmonikusok, kondenzátor bank kapcsolás). A legtöbb panelre szerelt SPD 2. típusú eszköz.

3. típusú egységes programozási dokumentumok pontszerű használatú védők – a hosszabbító kábelek, az egyedi berendezések túlfeszültség-védői, a koaxiális vonali védők. Itt van a kritikus követelmény, amelyet szinte senki sem tud: a 3. típusú eszközöket több mint 30 lábnyi vezetőhosszal kell telepíteni a főelosztótól.

Várjunk csak, több mint 30 láb? Ez fordítva tűnik. Nem kellene a védelemnek a lehető legközelebb lennie?

Nem. És itt van, hogy miért:

A 3. típusú SPD-k szándékosan alul vannak méretezve. Kisebb, helyi túlfeszültségek kezelésére tervezték őket – a statikus kisülés, a kisebb kapcsolási tranziens. Kis MOV-okat használnak korlátozott hőtehetetlenséggel. Ha egy 3. típusú SPD-t közel telepít a panelhez – mondjuk 5 lábnyira –, és egy nagyobb túlfeszültség érkezik a közműtől, akkor az a 3. típusú eszköz a teljes ütést látja, mielőtt a vezető impedanciája korlátozni tudná az áramot.

Azok a kis MOV-ok elpárolognak. Néha erőszakosan. A tűzvizsgálók ezt “hőfutasnak” nevezik. A létesítményvezetők ezt “az égő szagnak a falból” nevezik. Akárhogy is, nem berendezéseket véd, hanem tűzveszélyt teremt.

A 30 lábas minimum elektromos impedanciát biztosít, amely természetesen korlátozza, hogy mennyi túlfeszültség-áram éri el a 3. típusú eszközt. Ez egy biztonsági tartalék. Az 1. vagy 2. típusú SPD a szervizbejáratnál vagy a panelen kezeli a nagy ütéseket. A 3. típusú eszköz kezeli a helyi zajt.

De itt van, ami megfogja az embereket: egy 3 dolláros hosszabbító kábel, amelyben öt cent értékű MOV alkatrész van, 25-80 dollárért kel el. A marketing azt kiabálja, hogy “20 000 joule!” vagy “4000 joule!”. Ezek a számok arra szolgálnak, hogy védettnek érezze magát. Amit nem mondanak el: ezek a joule-ok azt a pontot mérik, ahol a MOV meghibásodik, nem pedig azt, amit valójában biztonságosan kezelni tud.

Egy megfelelő 1. típusú SPD 150-300 dollárba kerül, és védi az egész létesítményt – a mosogatógépet, a HVAC-t, a PLC-ket, a számítógépeket, a csengőket, mindent. Ez körülbelül 1 dollár védett készülékenként egy tipikus létesítményben. A 80 dolláros hosszabbító kábel semmit sem véd, ha rosszul van telepítve, kigyullad, ha túlterhelik, és valakinek nagyon egészséges haszonkulcsot biztosít.

Ez az A Joule Csapda– egy olyan specifikációra összpontosít, amely nem számít, miközben figyelmen kívül hagyja a telepítési követelményeket, amelyek igen.

Pro-Tipp: Egy 50 000 amperes 1. vagy 2. típusú SPD több tucat villámcsapást is túlél, és évtizedekig működőképes marad. Egy 3. típusú “20 000 joule-os” hosszabbító kábel talán nem éli túl az első igazi túlfeszültséget. Az áramerősség minden alkalommal felülmúlja a joule értéket.

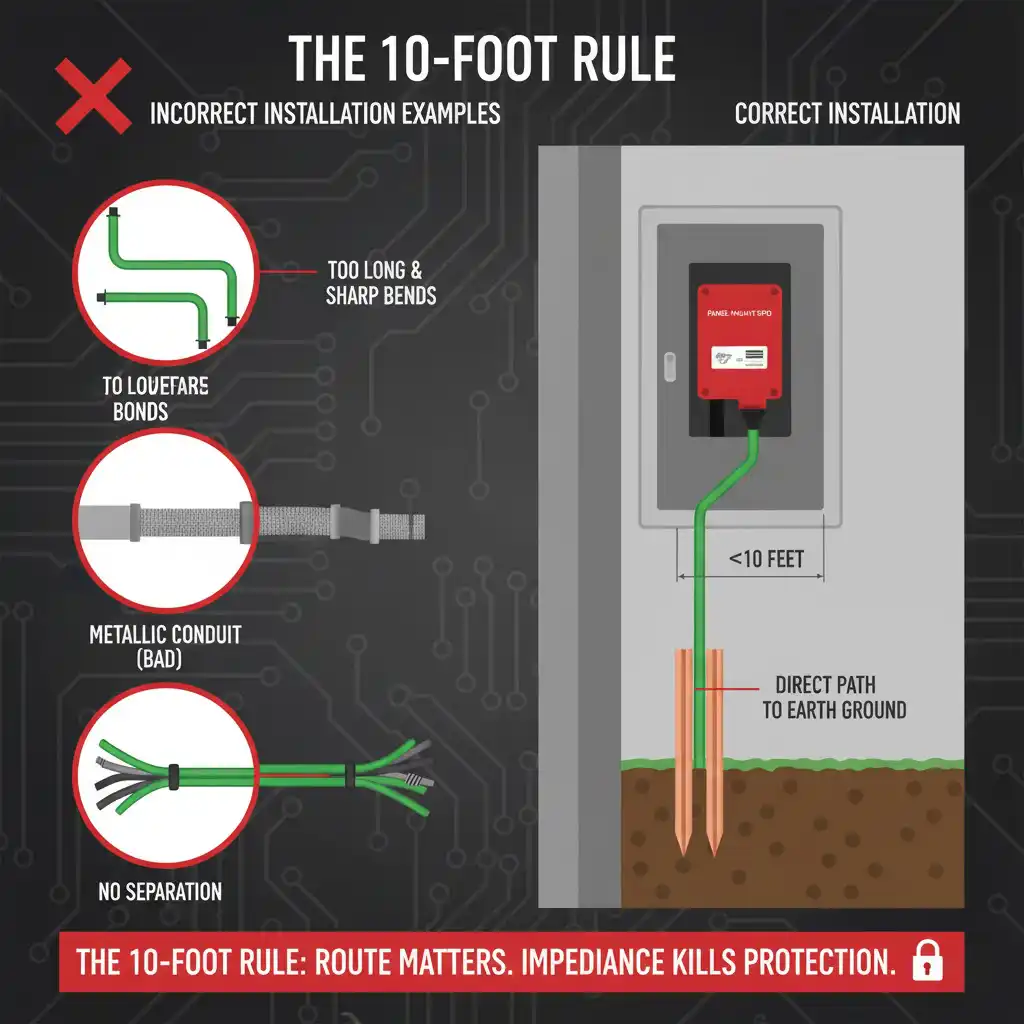

A 10 lábas szabály: Miért fontosabb a földelő vezeték hossza, mint a vezeték vastagsága?

Valószínűleg látta már a telepítési útmutatót: “Csatlakoztassa az SPD-t a földelő rendszerhez.” Egyszerű, igaz? Húzzon egy 6 AWG-s rézvezetéket az SPD-től a legközelebbi földelő sínhez. Jelölje be a dobozt, lépjen tovább.

Rosszul. Ez a telepítés éppen most változtatta az Ön 200 dolláros SPD-jét panelékszerré.

A probléma az impedancia. Nem az ellenállás – az impedancia. Kapcsolódnak egymáshoz, de nem ugyanazok, és a különbség óriási jelentőséggel bír, amikor megpróbálja elterelni egy villámcsapás élvonalát, amely mikroszekundumok alatt emelkedik.

Az ellenállás az, amit egy multiméterrel mér: az egyenáram áramlásának ellenállása. Egy 6 AWG-s rézvezeték körülbelül 0,4 ohm ezer lábonként. Az SPD-től a földelő sínig? Talán 8 láb? Ez 0,003 ohm. Elhanyagolható, igaz?

Az impedancia frekvenciafüggő. Ez az ellenállás plusz a reaktancia – az áramváltozás ellenállása. A villámcsapásból származó túlfeszültség nem egyenáram. Ez egy gyorsan emelkedő impulzus, amelynek frekvenciatartalma a megahertz tartományba terjed. Ezeken a frekvenciákon még egy egyenes vezeték is induktorként viselkedik. Minél hosszabb a vezeték, annál nagyobb az induktivitás. Minél nagyobb az induktivitás, annál nagyobb az impedancia.

Minden lábnyi vezető hozzávetőlegesen 300-400 nanohenry induktivitást ad hozzá. Egy gyorsan emelkedő túlfeszültség során ez az induktivitás feszültségesést okoz. Képlet: V = L × (di/dt). Amikor az áram 10 000 amperrel változik mikroszekundumonként – ami nem szokatlan a közeli villámlásnál –, minden nanohenry induktivitás feszültséget hoz létre.

Íme a matek:

8 láb 6 AWG ≈ 3000 nH induktivitás

Túlfeszültség emelkedés: 10 kA/μs = 10 000 000 000 A/s

Feszültség a vezetéken: V = 3000 × 10-9 H × 1010 A/s = 30 000 volt

Az Ön SPD-je 600 V-on fogta le a túlfeszültséget. De most 30 000 volt van a földelő vezetőn az impedanciája miatt. Hol jelenik meg ez a feszültség? A berendezésén, amely a másik végéhez van csatlakoztatva.

Ez az A 10 lábas szabály: az SPD földeléshez való csatlakozásának kevesebbnek kell lennie, mint 10 láb, és az útvonal minden részlete számít.

Mi öli meg a 10 lábas szabályt:

Éles kanyarok. A földelő vezető minden 90 fokos kanyarja növeli az induktivitást. A mágneses mező nem tudja követni a kanyart, ellentétes feszültséget hoz létre. Vezesse a földelő vezetéket enyhe ívekben, ha muszáj meghajlítani. Még jobb: vezesse egyenesen.

Fém védőcső. A földelő vezető fém védőcsőben vagy EMT csőben történő futtatása sorba köti a cső induktivitását. Olyan, mintha a földelő vezetéket egy induktív tekercsbe csavarná. Soha ne vezesse az SPD földelő vezetőit fém védőcsőben – ha védelemre van szükség, használjon műanyagot, vagy vezesse szabadon, ahol a szabványok megengedik.

Egyéb vezetőkkel való útvonalvezetés. Az SPD földelő vezetékét ne vezesse a tápvezetékekkel azonos útvonalon. A kölcsönös induktivitás azt jelenti, hogy az egyik vezetőben fellépő túlfeszültség feszültséget indukál a közeli vezetőkben. Válassza el az SPD földelését legalább 30 cm-re a többi vezetéktől.

Helytelen földelés csatlakozás. Felmegy az alapfalon, majd le a földelő rudakhoz? Ezzel 2,4 méterrel hosszabbította meg a vezetőt és két éles kanyart tett bele. Ha lehetséges, vezesse át az alapzaton, vagy egyenesen a padlón keresztül.

A legalacsonyabb impedanciájú utat szeretné a földelő elektródákhoz. Nem a berendezés földelő sínjéhez. Nem a vízvezetékekhez (ez egyébként is szabványsértés a modern telepítéseknél). Nem a legközelebbi kényelmes kötési ponthoz. A tényleges földelő rudakhoz vagy Ufer földelésekhez, ideális esetben ugyanahhoz a földelő elektróda rendszerhez, amely a betápláláshoz van kötve.

Pro-Tipp: Minden 3 méteren felüli földelő vezető, minden éles 90°-os kanyar, minden fém védőcsőben lévő 30 cm – mindegyik hozzáadja az impedanciát, ami becslések szerint 10-15%-kal csökkenti a védelem hatékonyságát. Egy 6 méteres földelő vezeték három éles kanyarral és 3 méter védőcsővel? Az SPD hatékonyságának több mint a felét elvesztette.

Van még egy kritikus pont: az egypontos földelés. Minden SPD-jének – a tápellátáson, a koaxon, a telefonon, az adatvonalakon – ugyanahhoz a földelő rendszerhez kell csatlakoznia. Ha a tápellátás SPD-je egy túlfeszültséget az A földelő rúdba vezet, és a koax SPD a 9 méterre lévő B földelő rúdra hivatkozik, akkor éppen egy 9 méteres antennát hozott létre, amely közvetlenül a berendezéséhez van csatlakoztatva. Túlfeszültség esetén ez a két földelés több ezer volttal is eltérhet.

Kössön össze mindent egyetlen egypontos földeléssel. Ezt mutatta be Franklin. Ez az, ami még mindig működik.

Hogyan védheti meg valójában a létesítményét: A 4 lépéses módszer

Nem lehet utólag védekezni a károk bekövetkezése után. Íme a módszer, amely valóban működik, és amelyet több mint 100 évnyi villámvédelmi tervezés dokumentált.

1. lépés: Szereljen be 1. vagy 2. típusú SPD-t a betáplálási ponton

Az első védelmi vonal ott kerül telepítésre, ahol a közművi áram belép – a fő megszakító előtt, vagy a fő elosztó panelben. Ez nem alku tárgya, ha van védendő berendezése.

Minimális névleges érték: 50 000 amper. Miért 50 kA, amikor a villám “csak” 20 000 amper lehet? Három okból. Először is, ez a 20 kA egy tipikus csapás – nem a legrosszabb eset. Másodszor, tartalékot szeretne; a névleges határán működő SPD gyorsabban romlik. Harmadszor, egy 50 kA-es eszköz általában nagyobb MOV-okkal rendelkezik, jobb hőtehetetlenséggel, ami azt jelenti, hogy több túlfeszültség eseményt is túlél, mielőtt cserére szorulna.

Költség valóság: Egy minőségi 50 kA-es 1. vagy 2. típusú SPD 150 és 300 dollár között mozog. Egy 200 aljzattal, 30 motorral, válogatott vezérlőrendszerekkel, HVAC-vel, világítással és elektronikával rendelkező létesítmény esetében? Ez körülbelül 1 dolláros védelmet jelent védett készülékenként. Egyetlen PLC csere többe kerül, mint az SPD.

Ha a létesítményében bármelyik eszköznek túlfeszültség védelemre van szüksége – és ha vannak számítógépei, vezérlői, VFD-i vagy bármi, amiben mikroprocesszor van, akkor szüksége van – akkor mindennek védelemre van szüksége. A túlfeszültség nem törődik azzal, hogy melyik áramköri útvonalon halad. A rendelkezésre álló eszközökön keresztül talál földelést. Győződjön meg arról, hogy a “rendelkezésre álló” az SPD dedikált földelése, nem a berendezése.

2. lépés: Hozzon létre dedikált földelési útvonalat (<3 méter)

Itt hibázik a telepítések 90%-a. Az SPD-hez tartozik egy földelő fül. A szerelő csatlakoztatja a… berendezés földelő sínjéhez. Kész a munka, igaz?

Nem. Éppen egy drága panel ékszert szerelt fel, amely akkor fog meghibásodni, amikor számít.

Az SPD földelő vezetőjének közvetlenül a földelő elektródákhoz kell futnia, kevesebb mint 3 méter vezetővel. Nem 4,5 méter. Nem 3,6 méter. Kevesebb mint 3. És ezek a méterek számítanak:

Vezesse a vezetőt éles kanyarok nélkül – csak enyhe ívekkel, vagy egyenesen, ha lehetséges. Minden 90 fokos derékszög induktivitást ad hozzá, amit nem engedhet meg magának egy villámcsapás felfutó élének nanoszekundumos skáláján.

Nincs fém védőcső – a cső induktivitása meghiúsítja a célt. Használjon műanyag védőcsövet, ha mechanikai védelemre van szükség, vagy vezesse a vezetőt szabadon, ahol a szabványok megengedik.

Válassza el a többi vezetéktől – tartson legalább 30 cm távolságot a tápvezetékektől. Megpróbálja minimalizálni a kölcsönös induktivitást, amely visszacsatolja a túlfeszültség energiáját a rendszerébe.

Egypontos földelés – minden SPD-nek (tápellátás, koax, telefon, adat) ugyanarra a földelő elektróda rendszerre kell hivatkoznia. Több, egymástól távol elhelyezkedő földelési pont létrehozása a létesítményét villámantennává alakítja.

A megfelelő útvonal megkövetelheti az alapfal átfúrását, a padlónyíláson keresztüli telepítést vagy az alagsori padló alatti vezetést. Ez nem kényelmes. Ez szükséges. A “kényelmes” és a “hatékony” közötti különbség berendezéskárok ezreiben mérhető.

3. lépés: Védje meg a többi bejövő szolgáltatást

A tápellátás nem az egyetlen út a túlfeszültség energiájának. Minden, a létesítményébe kívülről belépő vezető potenciális túlfeszültség belépési pont.

A koaxiális kábelnek (internet, műhold, kábel TV) koaxra méretezett SPD-re van szüksége. A túlfeszültség a pajzson keresztül léphet be, megkerülheti a berendezését, és a tápellátás földelésén keresztül távozhat – közös módusú feszültséget hozva létre, amely tönkreteszi az elektronikát.

A telefonvonalaknak távközlési minősítésű SPD-kre van szükségük. Annak ellenére, hogy a “vezetékes telefonok halottak”, sok létesítményben még mindig van analóg telefonszolgáltatás, tűzjelző tárcsázók vagy lift vészhelyzeti vonalak réz párokon. Egy villámcsapás feszültséget indukálhat ezeken a párokon.

Hálózati adatvonalak – ha kültéri Ethernet-je, biztonsági kamerái vannak az épület külső falán, vagy bármilyen épületek között futó hálózati kábele, akkor adatra méretezett SPD-kre van szüksége. A kültéri kábel közelében lévő földbe csapódó villám feszültséget indukál a csavart érpárokon.

Íme a nem alku tárgya: minden SPD-nek minden bejövő szolgáltatáson ugyanahhoz a földelési ponthoz kell csatlakoznia. Ez a 2. lépésben szereplő egypontos földelés. Ha a tápellátás SPD-je egy túlfeszültséget az A földelésbe vezet, és a koax SPD a 12 méterre lévő B földelésre hivatkozik, akkor éppen 12 méter feszültségkülönbséget hozott létre, amely közvetlenül a számítógépe tápegysége és a hálózati interfésze között van összekötve.

A túlfeszültség kiegyenlítő utakat talál. Általában a berendezés belső részein keresztül. A berendezést olcsóbb cserélni, mint azt, amit vezérelt vagy tárolt.

4. lépés: Tartsa a 3. típusú használati helyi védőket 9 méternél távolabb

Ha egyedi berendezés túlfeszültség védőket használ – a hosszabbítókat, a koax vonali védőket, az UPS egységeket – ezek 3. típusú eszközök. A használati helyen telepítik őket, és a fő paneltől több mint 9 méter vezető távolságra kell lenniük.

Miért? Mivel a 3. típusú SPD-k kis MOV-okat használnak, amelyek helyi tranziensre vannak méretezve, nem közművi méretű túlfeszültségekre. Ha egy hosszabbító 1,5 méterre van a paneltől, amikor villám csap be, akkor a teljes túlfeszültség áramot látja, mielőtt a vezető impedanciája korlátozhatná azt. A MOV-ok elpárolognak. A legjobb eset: a szalag leáll. A legrosszabb eset: a termikus szökés tüzet okoz.

A 9 méteres szabály nem önkényes. Ez az elektromos impedancia áramkorlátozóként működik. 300-400 nanohenry/méter mellett 9 méter körülbelül 10 mikrohenryt biztosít – elegendő soros induktivitást ahhoz, hogy jelentősen korlátozza a túlfeszültség áram felfutási sebességét, mire eléri a használati helyi eszközt.

Ez megmagyaráz valamit, amit a szerelők ösztönösen helytelennek találnak: a betáplálási ponton lévő 1. vagy 2. típusú SPD nem csak a létesítményét védi a külső túlfeszültségektől. A létesítményét a belső 3. típusú eszközöktől is védi. Ezek a túlméretezett használati helyi védők potenciális tűzveszélyt jelentenek, ha nem megfelelően vannak elhelyezve. A betáplálási SPD lefogja a túlfeszültséget, mielőtt elérhetné és tönkretehetné őket.

Nem redundáns védelmet hoz létre, amikor mindkettőt telepíti. Egy összehangolt védelmi rendszert hoz létre, ahol minden alkatrész a megfelelő helyen végzi a dolgát.

Pro-Tipp: Miután megfelelően földelte az 1. vagy 2. típusú SPD-t a földbe, a létesítmény 3. típusú dugaszolóaljzatai és berendezésvédői valójában megfelelően működnek – kezelik a helyi tranziensket, míg a betáplálási SPD kezeli a nagy túlfeszültségeket. A megfelelően földelt 1/2 típus nélkül a 3. típusú eszközei csak drága tűzveszélyek, amelyek a rossz túlfeszültségre várnak.

A lényeg: A földelés nem opcionális

A panelre szerelhető túlfeszültség védők működnek – ha megfelelően vannak csatlakoztatva. A MOV technológia megbízható. A tervezés bizonyított. Ami elromlik, az a telepítés.

Most már tudja a különbséget a panel ékszer és a tényleges védelem között: A Földelés Kérdése számít. A biztonsági földelés megvédi az embereket a hibák során. A földelés megvédi a berendezéseket a túlfeszültségek során. Csatlakoztassa az SPD-t a rosszhoz, és a rossz problémát oldotta meg.

Tudja, hogy a helymeghatározás miért határozza meg a hatékonyságot: Az 1. és 2. típusú SPD-k a betáplálási ponton vagy a fő panelen vannak telepítve, közvetlen földeléssel. A 3. típusú eszközök több mint 9 méterre vannak telepítve a használati helyen. Ha megsérti ezeket az elhelyezési szabályokat, akkor védelem helyett tűzveszélyt hoz létre.

Tudja, hogy a vezető útvonalvezetése miért hiúsítja meg a legtöbb telepítést: A 10 lábas szabály nem javaslat. Minden 30 cm-en felül, minden éles kanyar, minden hüvelyknyi fém védőcső impedanciát ad hozzá, amely a túlfeszültség feszültségét a berendezésébe küldi a föld helyett.

Mielőtt telepítene egy másik panelre szerelhető SPD-t – vagy ha már van telepítve egy –, tegye fel ezeket a kérdéseket:

Hol végződik az SPD földelő vezetője? Ha a válasz “a berendezés földelő sínje”, akkor panel ékszere van.

Milyen hosszú a földelő vezető útja a tényleges földelő elektródákhoz? Ha a válasz több mint 3 méter, akkor az SPD hatékonysága minden extra méterrel csökken.

Minden bejövő szolgáltatás (tápellátás, koax, telefon, adat) védett SPD-kkel, amelyek ugyanahhoz az egypontos földeléshez vannak kötve? Ha nem, akkor feszültségkülönbség utakat hozott létre a berendezésén keresztül.

Benjamin Franklin 250 évvel ezelőtt egy sárkánnyal, egy kulccsal és egy Leydeni palackkal rájött a földelésre. Fém-oxid varisztoraink, oszcilloszkópjaink és évtizedek óta tartó IEEE szabványaink vannak.

Nincs mentségünk arra, hogy ezt elrontsuk. Javítsa ki a földelési problémát, és a panelre szerelhető SPD-je megszűnik drága ékszer lenni, és tényleges védelemmé válik.

Műszaki pontossági megjegyzés

Hivatkozott szabványok és források:

- IEEE C62.41 (IEEE ajánlott gyakorlat a túlfeszültségekre alacsony feszültségű AC tápáramkörökben)

- IEEE C62.11 (IEEE szabvány a fém-oxid túlfeszültség levezetők számára AC tápáramkörökhöz)

- NEC 285. cikk (Túlfeszültség védő eszközök, 1000 volt vagy kevesebb)

- IEC 61643-11 (Kisfeszültségű túlfeszültség védő eszközök)

- IEEE C62.45 (IEEE ajánlott gyakorlat a berendezések túlfeszültség tesztelésére)

Aktualitási nyilatkozat: Minden műszaki specifikáció, telepítési követelmény és szabványhivatkozás 2025 novemberétől pontos. A MOV technológia, az 1/2/3 típusú besorolások és a földelési követelmények a IEEE és NEC szabványokban dokumentált bevált mérnöki gyakorlatok.