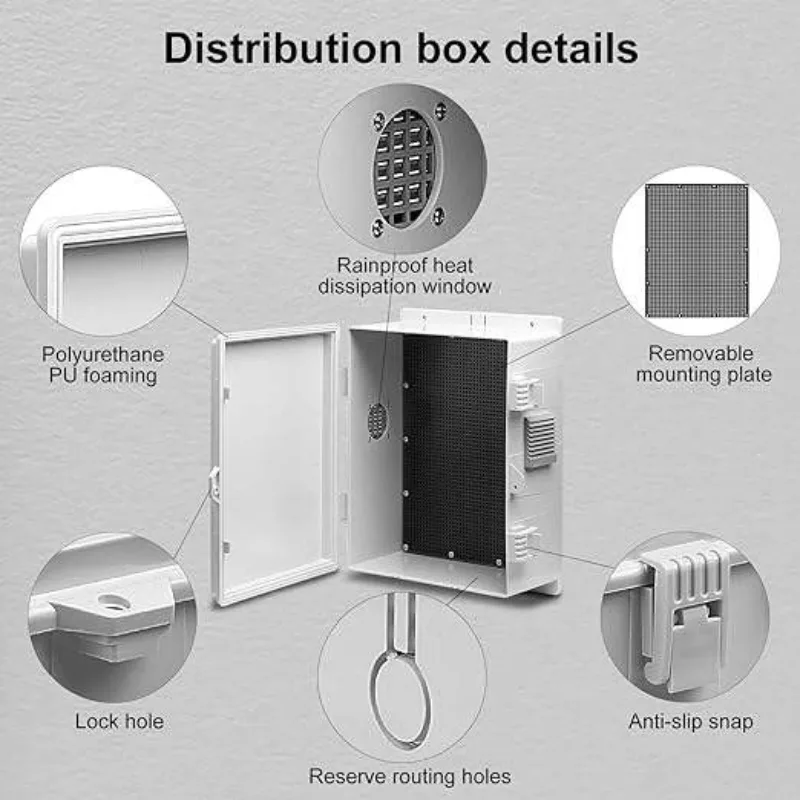

Belüftete Schaltschränke sind spezielle Gehäuse, die elektrische Komponenten schützen und gleichzeitig eine angemessene Luftzirkulation ermöglichen, die für den Umgang mit Hitze und Feuchtigkeit in verschiedenen industriellen und kommerziellen Anwendungen entscheidend ist. Diese Gehäuse verfügen über Belüftungsmechanismen wie passive Belüftungsöffnungen, Lüftungsschlitze oder Zwangsluftsysteme, um optimale Betriebstemperaturen aufrechtzuerhalten und Kondensation zu verhindern, was die Langlebigkeit und Zuverlässigkeit der eingeschlossenen elektrischen Geräte gewährleistet.

VIOX belüftetes elektrisches Gehäuse

Belüftungsmechanismen

Bei belüfteten Schaltschränken kommen verschiedene Belüftungsmechanismen zum Einsatz, um optimale interne Bedingungen zu schaffen. Diese Mechanismen reichen von passiven Systemen bis hin zu komplexeren aktiven Lösungen, die jeweils für bestimmte Anforderungen an die Kühlung und Feuchtigkeitskontrolle entwickelt wurden. Hier sind die wichtigsten Belüftungsmechanismen, die in Schaltschränken eingesetzt werden:

- Passive Belüftung: Einfache Öffnungen oder Lamellenpaneele, die eine natürliche Luftzirkulation durch Konvektion ermöglichen. Sie sind in der Regel am unteren und oberen Ende des Gehäuses angebracht, um einen Kamineffekt zu erzeugen.

- Gefilterte Entlüftung: Integrieren Sie Luftfilter, um das Eindringen von Staub und Schmutz in das Gehäuse zu verhindern und gleichzeitig den Luftstrom zu ermöglichen. Diese sind entscheidend für die Aufrechterhaltung einer sauberen internen Umgebung.

- Druckausgleichsventile: Spezielle Entlüftungsöffnungen, die einen Druckausgleich zwischen dem Inneren und dem Äußeren des Gehäuses ermöglichen, um das Eindringen von Feuchtigkeit zu verhindern und die Integrität der Dichtungen zu erhalten.

- Systeme mit Zwangsbelüftung: Aktive Kühllösungen, die mit Hilfe von Lüftern oder Gebläsen die Luft durch das Gehäuse zirkulieren lassen und so eine effizientere Wärmeableitung für Anwendungen mit hoher Wärmeentwicklung ermöglichen.

- Jalousie-Türen: Türen mit eingebauten Lüftungsschlitzen oder gepressten Lüftungsschlitzen, die oft strategisch platziert sind, um die Luftzirkulation zu optimieren.

- Wetterfeste Belüftungsöffnungen: Diese für Außenanwendungen konzipierten Belüftungsöffnungen ermöglichen einen Luftstrom und schützen gleichzeitig vor dem Eindringen von Wasser. Sie eignen sich für Gehäuse mit NEMA-Klassifizierung.

Jeder dieser Mechanismen kann auf die spezifischen Umgebungsbedingungen und Geräteanforderungen zugeschnitten werden, um eine optimale Leistung und Langlebigkeit der eingeschlossenen elektrischen Komponenten zu gewährleisten.

Vorteile von belüfteten Gehäusen

Belüftete Gehäuse bieten mehrere entscheidende Vorteile für elektrische Systeme. Sie sorgen für eine wirksame Temperaturkontrolle, indem sie die Luftzirkulation erleichtern. Dies trägt zur Aufrechterhaltung optimaler Betriebsbedingungen für elektronische Komponenten bei und verlängert so deren Lebensdauer und Zuverlässigkeit. Diese Gehäuse spielen auch eine entscheidende Rolle bei der Verhinderung von Kondensation, indem sie die Luftfeuchtigkeit im Inneren reduzieren, was vor Korrosion und Kurzschlüssen schützt. Darüber hinaus ermöglichen die Belüftungsöffnungen einen Druckausgleich, der Änderungen aufgrund von Temperaturschwankungen oder Höhenunterschieden ausgleicht, was für den Erhalt der Integrität der im Gehäuse verwendeten Dichtungen unerlässlich ist. Diese Druckausgleichsfunktion ist besonders wichtig für den Schutz gegen Staub, Wasser, Öle und Lösungsmittel in verschiedenen Branchen.

Industrieanwendungen

Belüftete Schaltschränke sind in verschiedenen Branchen weit verbreitet, da sie elektrische Komponenten schützen und gleichzeitig Wärme und Feuchtigkeit ableiten können. Hier finden Sie einen Überblick über die wichtigsten Anwendungen in der Industrie:

- Herstellung: Wird zur Unterbringung von Steuerungssystemen, Schaltanlagen und Transformatoren verwendet und sorgt für die Belüftung von wärmeerzeugenden Anlagen in Fabriken.

- Telekommunikation: Die wetterfesten, belüfteten Gehäuse eignen sich ideal für die Außeninstallation von Netzwerkgeräten und helfen dabei, die Wärme in Umgebungen mit hohen Temperaturen abzuleiten.

- Energie: Wird in Stromverteilungssystemen eingesetzt, um elektrische Komponenten zu schützen und gleichzeitig einen Druckausgleich und eine Wärmeableitung zu ermöglichen.

- Industrielle Automatisierung: Beherbergt empfindliche Steuergeräte und sorgt für optimale Betriebstemperaturen für SPS, Antriebe und andere Automatisierungskomponenten.

- Dienstprogramme im Freien: Wetterfeste, belüftete Gehäuse schützen die Geräte vor Umwelteinflüssen und ermöglichen gleichzeitig den für die Kühlung erforderlichen Luftstrom.

- Rechenzentren: Sie werden zur Unterbringung von Servern und Netzwerkgeräten verwendet, wobei die Belüftungssysteme entscheidend dafür sind, dass die Temperaturen der Komponenten innerhalb der vorgesehenen Grenzen bleiben.

- Anwendungen in der Schifffahrt: Spezielle belüftete Gehäuse schützen vor Salzwasserkorrosion und ermöglichen einen Druckausgleich in wechselnden Umgebungen.

Diese Anwendungen zeigen die Vielseitigkeit von belüfteten Elektrogehäusen, die den unterschiedlichen Anforderungen der Industrie in Bezug auf Geräteschutz und Wärmemanagement gerecht werden.

Überlegungen zur Gestaltung

Bei der Auswahl oder Konstruktion eines belüfteten Schaltschranks müssen mehrere Schlüsselfaktoren berücksichtigt werden, um optimale Leistung und Schutz zu gewährleisten. Die von den eingeschlossenen Komponenten erzeugte Wärmemenge ist von entscheidender Bedeutung, da größere oder leistungsstarke Geräte unter Umständen robustere Belüftungslösungen erfordern. Die Umgebungsbedingungen, einschließlich Temperatur, Luftfeuchtigkeit und Staubgehalt, sollten sorgfältig bewertet werden, um das erforderliche Schutzniveau und die Art der erforderlichen Belüftung zu bestimmen. Je nach Anwendung muss auch die Einhaltung einschlägiger Sicherheitsnormen wie NEMA oder IEC gewährleistet sein. Darüber hinaus sollte die Wahl der Materialien, wie z. B. Edelstahl, verzinkter Stahl oder Aluminium, auf den Anforderungen an die Haltbarkeit und die Widerstandsfähigkeit gegenüber Umweltfaktoren basieren.