Modular contactors are electrically controlled switching devices that play a crucial role in managing the flow of current within electrical installations. These devices function as actuators, enabling both economical and safe control of electricity in a wide array of applications. Their significance has grown in modern electrical systems due to the increasing demand for automation and efficient power management across residential, commercial, and industrial environments. In industrial settings, modular contactors are indispensable for the remote switching of loads and the automated control of electrical circuits within diverse building structures. Moreover, they are vital in controlling electrical circuits across various environments, ensuring operational efficiency, reliability, and safety. As building technology becomes increasingly reliant on automated processes, high-quality components like modular contactors are essential for ensuring seamless automation in both homes and industries.

A defining characteristic of modular contactors is their standardized size and form factor, which allows for straightforward integration into modular electrical panels and onto DIN rails. The term “modular” itself refers to this standardized design, which facilitates easy incorporation into electrical panels. In the broader electrical industry, “modular” often denotes any low-voltage device designed for installation on a DIN rail within a switchboard or enclosure. Notably, the width of a single module is typically standardized at 17.5 mm. This emphasis on standardization highlights a design philosophy centered on interoperability and ease of assembly within standard electrical panels, suggesting that scalability and the efficient use of space are key drivers for their widespread adoption. Furthermore, the early mention of a wide range of applications, including heating, lighting, ventilation, and motors, indicates the versatility of these devices as central control elements in various building systems. The consistent reference to diverse applications right from their definition implies that modular contactors are not limited to niche uses but are broadly applicable components in building automation and electrical control.

What are Modular Contactors? Definition and Working Principle

Definition:

Modular contactors are fundamentally electromagnetic devices designed to establish or interrupt the connection between a power supply and a load. They represent a category of actuators that provide an economical and safe means of managing current flow in electrical installations. Their primary function lies in the remote switching of loads, thereby enabling automated control of electrical circuits. The term “modular” specifically refers to their design, which allows them to be mounted on a DIN rail within control cabinets, and their standardized width, typically a multiple of 17.5 mm. These devices are engineered to handle significant electrical currents, making them suitable for a wide variety of applications.

Working Principle:

A typical modular contactor comprises several key components, including working contacts (which can be one or more pairs), a coil, and an electromagnet. The operational principle revolves around electromagnetism. When a control voltage, which is usually lower than the voltage of the circuit being controlled, is applied to the coil, it generates a magnetic field. This magnetic field then exerts a force on an armature, causing the main contacts within the contactor to change their state. Specifically, normally open (NO) contacts will close, allowing current to flow, while normally closed (NC) contacts will open, interrupting the current. This change in contact position enables the electric current to be transmitted to the connected load. Conversely, when the control voltage is removed and the coil is de-energized, the magnetic force ceases, and the contacts automatically return to their original, default states.

Key Components:

Coil: This is the electromagnetic component that, upon receiving an electrical signal (the control voltage), becomes energized and initiates the mechanical switching action of the contactor.

Contacts: These are the conductive elements within the contactor that physically make or break the electrical circuit. They are categorized as either normally open (NO), meaning the circuit is open when the coil is not energized, or normally closed (NC), meaning the circuit is closed when the coil is not energized. Modular contactors can have varying numbers of poles, ranging from one to four, which corresponds to the number of power contacts they possess.

Enclosure: This outer casing provides physical protection to the internal components of the modular contactor, shielding them from environmental factors and potential damage.

The fundamental working principle of modular contactors relies on electromagnetism, a concept similar to that of relays, but these devices are specifically designed to handle higher power applications. The consistent description of the coil and electromagnet as the core mechanism across multiple sources underscores the well-established technology behind their operation. Furthermore, the distinction between the control voltage and the load voltage is a significant safety feature. It allows for the control of high-power circuits using low-power signals, which is essential for automation and enhances the safety of electrical systems.

Function and Purpose in Electrical Systems

The primary function of a modular contactor in electrical systems is to control the flow of electricity within circuits. They serve as remote-controlled switches that can be activated either manually or through an external control system. This capability enables the switching of the power supply to electrical circuits, effectively turning them on or off as needed. A key purpose of modular contactors is to facilitate the automation of various processes within buildings and facilities. They are commonly used to control a wide range of electrical circuits, including those for lighting, heating, ventilation, pumps, and motors.

In high-power applications, such as sophisticated lighting control systems, modular contactors can be configured in latching arrangements. This setup, often involving two coils working in tandem, allows the contactor to maintain an on or off state even after the control signal is removed, similar to the function of a latching relay. It is important to note that while modular contactors are essential for switching circuits, they are not primarily designed for providing circuit protection. Although some models may incorporate overload protection features, their main role is to open and close electrical circuits.

The emphasis on “remote switching” and “automation” clearly highlights the crucial role of modular contactors in modern intelligent building systems and industrial processes. Their ability to be controlled remotely and integrated into automated systems makes them indispensable for efficient and responsive electrical management. Moreover, the explicit clarification that their primary function is switching, rather than protection, is vital for understanding their correct application and the necessity of using supplementary protective devices like circuit breakers to ensure the safety and integrity of electrical installations.

Applications Across Different Settings

Modular contactors find extensive use across a diverse range of settings, including residential, commercial, and industrial environments.

Residential Applications:

In homes, modular contactors are commonly employed for automating lighting systems to achieve energy savings and enhance convenience. They are also used in managing electric heating systems, such as underfloor heating, providing efficient control over home comfort. Furthermore, their compatibility with smart home systems allows for seamless integration and enhanced automation of various household functions. This includes controlling household appliances like water heaters and pumps, contributing to overall energy efficiency. Additionally, they are often used as day/night contactors to take advantage of peak and off-peak electricity tariffs, optimizing energy consumption and costs.

Commercial Applications:

In commercial buildings, modular contactors are essential for controlling large-scale lighting systems in offices, retail spaces, and public areas, enabling efficient management of energy use. They play a vital role in optimizing HVAC systems for improved energy management and occupant comfort. Their ability to enable remote circuit switching enhances safety and operational efficiency in commercial settings. Often, modular contactors used in commercial applications need to handle higher currents and voltages to effectively control commercial equipment and extensive lighting systems. They are also integral to building automation systems, providing centralized control over various electrical loads and contributing to overall system efficiency.

Industrial Applications:

Within industrial facilities, modular contactors are critical for handling motors, pumps, and other heavy machinery, ensuring reliable and safe operation. They support automation in manufacturing facilities and production lines, contributing to increased efficiency and productivity. These devices are capable of managing heavy-duty electrical loads effectively. A primary application in industry is starting motors for machine tools, furnaces, and hoists, facilitating essential industrial processes. Modular contactors are also used to control air-conditioning and ventilation systems in industrial buildings, maintaining optimal operating conditions. Furthermore, they are employed in motor protection appliances to safeguard electric motors from damaging current fluctuations, ensuring their longevity and performance.

The wide range of applications across these major sectors underscores the broad applicability and adaptability of modular contactors. Their use in residential, commercial, and industrial settings highlights their versatility as a fundamental component in electrical control. The increasing integration of modular contactors with smart home systems and building automation indicates a significant trend driven by the growing demand for energy efficiency and user convenience. Finally, their critical role in motor control and protection within industrial environments emphasizes their importance in maintaining operational stability and preventing costly equipment damage.

Advantages of Using Modular Contactors

Modular contactors offer a multitude of advantages that contribute to their widespread adoption across various applications. One significant benefit is their hum-free operation, with most models designed to operate silently, making them ideal for use in residential and office environments where noise levels are a concern. Their design often incorporates features to minimize or eliminate humming noises, ensuring a quiet operational environment.

Another key advantage is their easy installation. Modular contactors are generally designed to be lightweight and compact, facilitating quick and straightforward installation, often as retrofits to existing systems. Their compatibility with DIN rail mounting, a standard in electrical panels, further simplifies the installation process. The compact design of modular contactors is also a significant benefit, as they save valuable space and can be neatly integrated into modular panels or consumer units, allowing for better organization and management of electrical systems. This space-saving feature is particularly advantageous in installations with limited space, such as home distribution boards or small commercial settings.

Energy efficiency is another notable advantage. Modern modular contactors are often designed to be energy-efficient, dissipating less heat due to their low coil consumption. This reduced energy consumption translates to lower electricity bills and a more sustainable operation. Their versatility allows them to be used in a wide range of applications, including lighting, HVAC systems, motors, and more, and they can handle diverse electrical loads effectively without requiring specialized components.

Modular contactors are available in a wide range of ratings, typically from 20A to 125A, making them suitable for various electrical load requirements. They are also built for high durability, designed to withstand frequent switching operations and demanding conditions, often boasting a long mechanical lifespan, sometimes exceeding millions of cycles. Some modular contactors offer a variety of operating modes, such as temporary ON, shutdown, or autonomous options, providing flexibility in control. Additionally, many advanced models can be supplied with either AC or DC power, increasing their adaptability to different electrical systems.

From a safety perspective, modular contactors offer enhanced safety by allowing for remote control of high-power circuits, thereby minimizing the need for manual switching and reducing the risk of electrical hazards. For residential applications, they can be cost-effective compared to traditional industrial-grade contactors, as their design is optimized for lower power demands. They also provide reliable operation, ensuring consistent switching and control of electrical circuits, which is crucial for the proper functioning of connected devices and equipment. Finally, their easy integration into electrical panels and systems, due to their standardized form factor, allows for convenient replacement or expansion of electrical circuits.

The combination of silent operation, ease of installation, and compact design makes modular contactors particularly advantageous for residential and commercial buildings, where aesthetics and space efficiency are often important considerations. Their energy efficiency aligns with the growing global emphasis on sustainability and reducing operational costs, making them an attractive choice for both environmentally conscious users and businesses. Furthermore, comparing them to traditional contactors and relays helps to understand their specific strengths as a modern solution for particular applications.

Disadvantages and Limitations

Despite their numerous advantages, modular contactors also have certain disadvantages and limitations that should be considered. One primary concern is the initial cost, which can be higher compared to traditional contactors and relays. This initial investment might be a factor for projects with strict budget constraints. Additionally, in specific three-phase applications, modular contactors may have a higher price point compared to their traditional counterparts.

Like all electromechanical devices, modular contactors have a limited lifespan based on the number of opening and closing cycles they perform. This means they will eventually require replacement, although the lifespan can be quite long depending on the application and the quality of the contactor. They are also not ideally suited for applications requiring a very high switching rate or for controlling fast-response systems due to their inherent mechanical operation speed.

While generally known for their silent operation, some electromechanical contactors may generate noise during switching operations, although this is less common in modern modular designs compared to traditional contactors. The mechanical components within the contactor may also necessitate regular maintenance to ensure continued proper operation.

The load capacity of modular contactors, while sufficient for many residential, commercial, and light industrial applications, may not be suitable for extremely high-power industrial loads that traditional, more robust contactors are designed to handle. Therefore, careful selection based on the specific load requirements is crucial. Finally, integrating modular contactors into complex control circuits might require more specialized knowledge compared to using simpler switching devices like manual switches.

The higher initial cost and potentially greater expense for certain three-phase applications could be a deterrent for some users operating under tight budgets. The inherent limitations in switching frequency and the finite lifespan of contactors indicate that they are not a universal solution for all switching needs and that the operational demands of the application must be taken into account. While generally quieter than traditional contactors, the potential for some noise in certain models or under specific conditions should still be considered, particularly in noise-sensitive environments.

Types and Specifications of Modular Contactors

Modular contactors are available in various types and specifications to suit a wide range of applications. These can be broadly categorized based on their contact configuration, the number of poles, and their specific application or function.

Types Based on Contact Configuration:

Normally Open (NO) Contacts: These contacts, sometimes referred to as ‘A’ contacts, are open when the contactor’s coil is de-energized, and they close when the coil is energized, allowing current to flow.

Normally Closed (NC) Contacts: Also known as ‘B’ contacts, these are closed when the coil is de-energized, allowing current to flow, and they open when the coil is energized, interrupting the current. Modular contactors can be found with various combinations of NO and NC contacts to meet different circuit control requirements.

Types Based on Number of Poles:

Single-pole contactors have one set of contacts and are less common, often found in older electrical installations like heating systems with a common neutral.

Two-pole contactors have two sets of contacts and are commonly used for switching single-phase circuits.

Three-pole contactors have three sets of contacts and are typically used for switching three-phase circuits.

Four-pole contactors have four sets of contacts and can be used for switching three-phase circuits with a neutral wire or for controlling multiple separate single-phase circuits simultaneously.

Types Based on Application/Function:

Domestic Contactors: These are specifically designed for residential applications, such as controlling peak/off-peak circuits or switching heating circuits via a central thermostat.

Motor Control Contactors: These are built to withstand frequent switching operations and have a longer contact life, making them suitable for controlling electric motors.

Reversing Contactors: These consist of two standard modular contactors combined with a mechanical interlock unit. They are used to reverse the power supply to a motor, thereby reversing its direction of rotation, commonly used in hoisting applications.

Safety Contactors: Easily identifiable by their bright colors (often red or yellow), these contactors use mirrored contacts to provide a reliable indication of the open or closed position of the power poles. They are used in safety-critical applications, such as emergency machine shutdowns.

Lighting Contactors: These are designed with features that meet the specific requirements of lighting control, such as the ability to handle high inrush currents from certain types of lamps.

AC Contactors: Designed for use in alternating current (AC) circuits.

DC Contactors: Designed for use in direct current (DC) circuits. Many advanced modular contactors can operate on both AC and DC supplies.

Single-phase Contactors: Specifically designed for single-phase electrical systems.

Power Contactors: Generally used for switching higher power loads in various applications.

Key Specifications:

When selecting a modular contactor, several key specifications must be considered:

Rated Current (Ie): This is the maximum current that the contactor can safely handle under normal operating conditions.

Rated Operating Voltage (Ue): This specifies the voltage at which the contactor is designed to operate, and it can be AC or DC.

Coil Voltage (Uc): This is the voltage required to energize the contactor’s coil. Common coil voltages include 12V, 24V, 230V, and 400V, available in both AC and DC.

Number of Poles: As discussed earlier, this indicates the number of independent circuits the contactor can switch.

Contact Configuration: This refers to the number of normally open (NO) and normally closed (NC) contacts present in the contactor.

Utilization Category: This IEC standard defines the type of load and the operating conditions for which the contactor is suitable (e.g., AC-1 for resistive loads, AC-3 for motor starting). Selecting the correct category is crucial for the contactor’s performance and lifespan.

Electrical and Mechanical Durability: Electrical durability refers to the expected number of switching cycles the contactor can perform under electrical load, while mechanical durability indicates the total number of switching cycles it can perform without any electrical load.

Standards Compliance: Compliance with international standards such as IEC/EN 61095 and IEC/EN 60947-4-1 ensures that the contactor meets recognized safety and performance requirements.

Dimensions: Modular contactors have standardized widths based on DIN rail modules, typically 17.5 mm per module.

Operating Temperature Range: This specifies the permissible ambient temperature range within which the contactor can operate reliably.

Ingress Protection (IP) Rating: This indicates the level of protection the contactor’s enclosure provides against dust and moisture.

Table 1: Key Specifications of Modular Contactors (Example)

| Specification | Description | Importance |

|---|---|---|

| Rated Current (Ie) | Maximum current the contactor can handle. | Ensures the contactor can safely handle the load current without overheating or damage. |

| Rated Voltage (Ue) | Operating voltage of the circuit. | The contactor must be compatible with the circuit voltage for proper operation and safety. |

| Coil Voltage (Uc) | Voltage required to energize the coil. | The control circuit voltage must match the coil voltage for the contactor to switch. |

| Number of Poles | Number of independent circuits the contactor can switch. | Determines the suitability for single-phase, three-phase, or multiple circuit control. |

| Contact Configuration | Arrangement of normally open (NO) and normally closed (NC) contacts. | Dictates the behavior of the circuit when the contactor is energized or de-energized. |

| Utilization Category | Indicates the type of load and operating conditions the contactor is suitable for. | Ensures the contactor is chosen for the appropriate application to maximize lifespan and reliability. |

| Electrical Durability | Number of switching cycles at rated load. | Represents the expected lifespan of the contactor under electrical load. |

| Mechanical Durability | Total number of switching cycles without electrical load. | Indicates the mechanical lifespan of the contactor. |

| Standards Compliance | Certifications like IEC/EN 61095. | Ensures the contactor meets recognized safety and performance standards. |

The wide array of types and specifications available underscores the versatility of modular contactors and highlights the necessity of careful selection based on the specific demands of the intended application. The utilization category, in particular, is a critical specification that directly affects the contactor’s lifespan and reliability depending on the nature of the load it is switching.

Installation of Modular Contactors: A Step-by-Step Guide

The installation of modular contactors, while generally straightforward, requires adherence to safety regulations and careful attention to detail to ensure proper and reliable operation.

Safety Precautions:

Before commencing any installation work, it is paramount to disconnect the power supply to the circuit where the contactor will be installed. Always adhere to all relevant electrical safety regulations and guidelines provided by local authorities and the contactor manufacturer.

Required Tools:

Gather the necessary tools, which typically include wire strippers for removing wire insulation, crimping tools for securing wire lugs, a set of screwdrivers (both flathead and an electric screwdriver with torque setting capabilities), a multimeter for testing continuity and voltage, and appropriately sized wires and wire lugs based on the contactor’s specifications and the load requirements.

Installation Location:

Select a suitable installation location that is dry, free from excessive dust, well-ventilated to prevent overheating, and protected from mechanical damage and direct sunlight. Ensure there is adequate space to mount the contactor and for the routing of wiring. In environments with high dust levels or potential for corrosive gases, consider using contactors with appropriate enclosures.

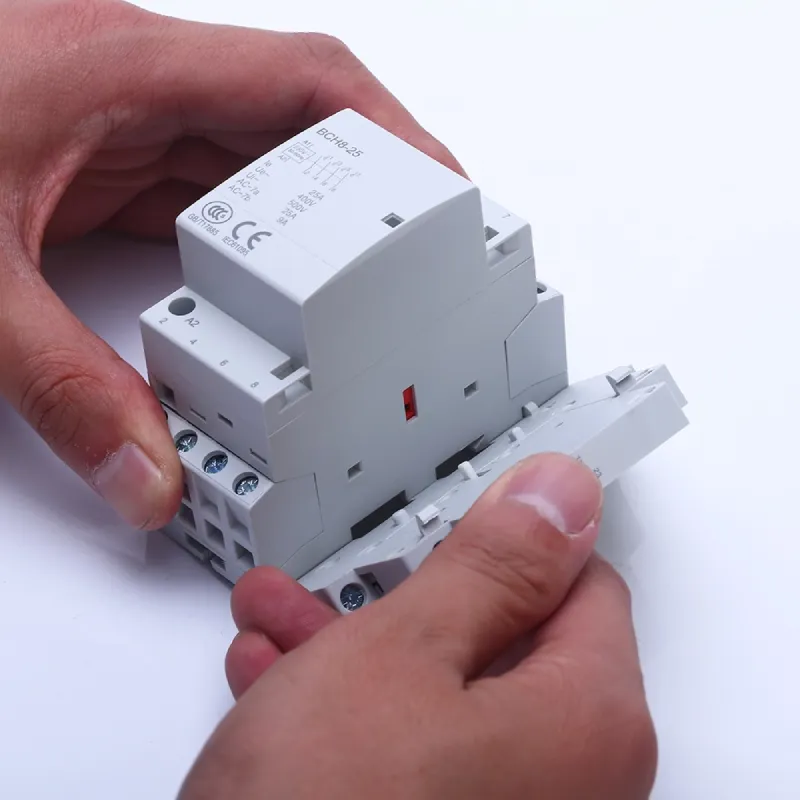

DIN Rail Mounting:

Modular contactors are designed to be mounted on standard 35mm DIN rails. Align the contactor with the DIN rail and engage its locking mechanism. Some models may simply snap into place with gentle pressure. To remove the contactor, disengage the locking mechanism, typically by using a flathead screwdriver to gently pry it open, then lift the contactor and tilt it to detach it from the rail.

Wiring Procedures:

Always refer to the specific wiring diagram provided with the contactor, which is often found on its nameplate or datasheet. Select wires with the correct cross-sectional area based on the contactor’s rated current and the requirements of the electrical system. Carefully strip the outer insulation from the ends of the wires, typically around 10-12 mm. For secure connections, it is recommended to crimp wire lugs onto the exposed wire ends using appropriate crimping tools. Connect the control circuit wires to the designated terminals, such as A1 and A2 for the coil. Then, connect the main circuit’s input and output wires to their respective terminals. Finally, using a calibrated electric screwdriver set to the manufacturer’s specified torque value, tighten all terminal screws. Proper torque is crucial for ensuring a stable and safe electrical connection.

Testing and Verification:

After completing the wiring, double-check all connections for accuracy and ensure they are securely tightened. Once the wiring is verified, you can carefully restore power to the control circuit. Use a multimeter to perform a continuity test on the main contacts of the contactor to confirm they are operating as expected (normally open contacts should be open, and normally closed contacts should be closed when the coil is de-energized). Then, test the contactor’s switching function by energizing the coil (applying the control voltage) and observing whether the contacts change state correctly. If any issues arise during testing, consult the fault analysis guide provided by the manufacturer for troubleshooting steps.

The installation process, while seemingly straightforward, necessitates meticulous attention to detail, particularly concerning the selection of appropriate wire sizes and the correct torque settings for terminal connections. These factors are critical for preventing overheating, ensuring good electrical contact, and maintaining the overall safety and reliability of the installation. The modular design of these contactors, with their compatibility with DIN rails, greatly simplifies the installation process within modern electrical panels, making integration with other modular devices more efficient.

Maintenance Best Practices for Modular Contactors

Regular maintenance is essential for ensuring the reliable, safe, and prolonged operation of modular contactors. Implementing a schedule of maintenance best practices can help prevent unexpected failures and extend the lifespan of these critical components.

One of the most important aspects of maintenance is conducting regular visual inspections. This involves carefully examining the contactor for any signs of wear, damage, or overheating. Look for loose connections, contamination from dust or debris, and any discoloration that might indicate a problem.

Testing procedures should also be a routine part of maintenance. This includes performing continuity tests to verify that the contacts are opening and closing correctly. Insulation resistance testing can help identify potential insulation faults that could lead to safety hazards. In some cases, load testing might be necessary to ensure the contactor can still handle the intended current without issues. Always use appropriate testing equipment and follow all safety precautions during these procedures.

When troubleshooting common problems, such as a contactor failing to switch, operating intermittently, or exhibiting abnormal heating, a systematic approach is necessary. Begin by checking all wiring connections to ensure they are secure and correct. Verify that the voltage and current levels are within the specified ranges for both the control circuit and the main circuit. Inspect the contact surfaces for any signs of excessive wear or damage. Pay attention to any unusual noises, such as humming or chattering, which could indicate issues with the coil or the contacts.

Contact maintenance involves inspecting the contacts for pitting, discoloration, and general wear. It is generally recommended to avoid filing or grinding the contacts, as this can increase their resistance. Instead, worn contacts should be replaced. In multipole contactors, it’s often advisable to replace all contacts at the same time, even if only one appears to be significantly worn. Keeping the contacts free from dust and debris is also important for ensuring proper operation.

For coil maintenance, periodically check the coil for any discoloration or signs of overheating, which could indicate a potential failure. Ensure that the noise level emanating from the coil is within normal limits. The coil should also be kept clean and free from dust and moisture.

Consider the environmental conditions in which the contactor is operating. Ensure that the temperature, humidity, and the presence of dust or corrosive gases are within the manufacturer’s specifications for the contactor. Periodically tighten all terminal screws to the specified torque to prevent loose connections, which can lead to overheating and potential failures.

Using a thermal imaging gun can be a valuable tool for identifying components that are overheating, which could indicate a developing problem within the contactor or its connections.

The approach to replacement schedules can vary. For less critical applications, a “run to fail” strategy might be adopted, where the contactor is replaced only when it malfunctions. However, for critical applications or those with a high number of switching cycles, a preventative replacement schedule based on the manufacturer’s recommendations for lifespan might be more appropriate.

Consistent adherence to these maintenance best practices is crucial for ensuring the reliable and safe operation of modular contactors and can significantly extend their operational lifespan. Regular maintenance that goes beyond just visual checks, including thorough testing, is essential for identifying potential issues that might not be immediately apparent, ensuring a more comprehensive assessment of the contactor’s health and functionality.

Real-World Applications and Case Studies

Modular contactors are integral to a vast array of real-world applications across various sectors, demonstrating their versatility and widespread adoption.

HVAC Systems: They are extensively used in residential, commercial, and industrial HVAC units to control compressors, fan motors, and heating elements. For instance, they are used to manage large air-conditioning systems in industrial facilities, ensuring efficient climate control.

Lighting Control: Modular contactors are widely employed for switching lighting circuits in buildings, enabling energy-efficient control based on time schedules or occupancy. They are used in large building installations to provide centralized lighting control, enhancing convenience and energy management.

Industrial Automation: These contactors are integral components in controlling motors for various industrial machinery, production lines, and equipment. They facilitate remote switching and automatic control in industrial facilities, contributing to operational efficiency and safety.

Smart Homes: Increasingly, modular contactors are being used in smart home systems to automate lighting, heating, and other home appliances, integrating with central control systems for enhanced convenience and energy savings.

EV Charging Stations: Modular contactors are employed in electric vehicle charging stations to control the power flow to the chargers, ensuring safe and efficient charging.

Pumps and Ventilation Systems: They are used to control pumps in various applications, such as water supply and industrial processes, and for managing ventilation systems in residential, commercial, and industrial buildings, ensuring proper air circulation and system operation.

Heat Pumps: Modular contactors are also used in heat pump systems to control their operation, providing efficient heating and cooling solutions.

Hoisting Applications: Reversing contactors, a specific type of modular contactor, are essential in hoisting machinery to control the direction of motor rotation, allowing for the lifting and lowering of loads.

Railway Sector: Specialized modular contactors are designed for use in railway applications, meeting stringent fire and smoke safety standards to ensure the safety of passengers and equipment.

The extensive range of real-world applications across diverse sectors underscores the versatility and widespread adoption of modular contactors as a fundamental component in electrical control systems. Their integration into both traditional and emerging technologies highlights their adaptability to evolving electrical system needs.

Conclusion: The Role of Modular Contactors in Modern Electrical Systems

In conclusion, modular contactors are vital components in contemporary electrical systems, offering a blend of efficiency, reliability, and safety for controlling electrical circuits across residential, commercial, and industrial domains. Their key characteristics, including a standardized modular design, ease of installation, compact form factor, and often, silent operation, make them particularly well-suited for modern building automation and energy management systems. The wide variety of types and specifications available ensures that there is a modular contactor suitable for almost any low-voltage switching application.

While there are limitations to consider, such as initial cost and suitability for extremely high-power applications, the advantages of using modular contactors often outweigh these drawbacks, especially in scenarios where space, energy efficiency, and ease of integration are paramount. To ensure optimal performance and longevity, proper selection based on the specific application requirements, adherence to correct installation procedures, and the implementation of regular maintenance practices are essential.

Looking ahead, the role of modular contactors in electrical systems is likely to continue to grow, driven by trends such as increasing automation, the proliferation of smart building technologies, and a global focus on energy efficiency. As electrical systems become more sophisticated and interconnected, the reliable and versatile switching capabilities of modular contactors will remain indispensable for managing power distribution and control in a safe and efficient manner.

Related Blog

https://viox.com/modular-contactor-types-a-comprehensive-guide/