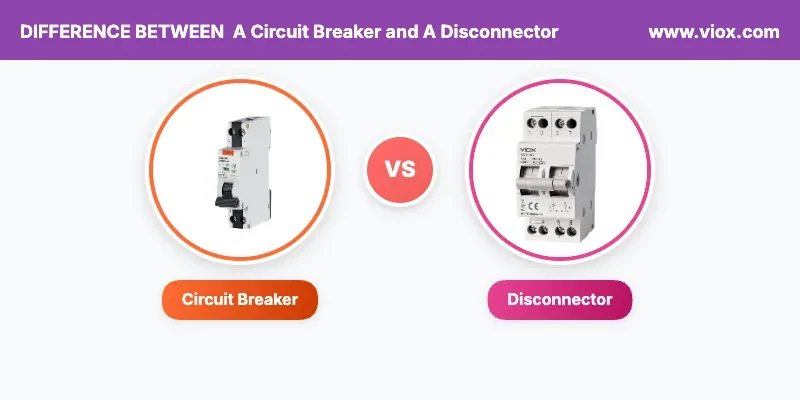

Câu Trả Lời Trực Tiếp: Aptomat tự động ngắt dòng điện trong điều kiện sự cố và có thể hoạt động dưới tải, trong khi dao cách ly cung cấp sự cách ly trực quan cho mục đích bảo trì và chỉ nên hoạt động khi mạch điện đã được cắt điện. Aptomat cung cấp bảo vệ; dao cách ly cung cấp sự cách ly.

Hiểu rõ sự khác biệt giữa aptomat và dao cách ly là rất quan trọng đối với an toàn điện, thiết kế hệ thống phù hợp và tuân thủ quy định. Cả hai thiết bị đều điều khiển mạch điện, nhưng chúng phục vụ các mục đích cơ bản khác nhau trong hệ thống điện.

Định nghĩa chính: Aptomat so với Dao cách ly

Cầu dao tự động là gì?

Một ngắt mạch là một thiết bị đóng cắt điện tự động được thiết kế để bảo vệ mạch điện bằng cách ngắt dòng điện khi xảy ra sự cố. Nó có thể đóng, dẫn và cắt dòng điện trong điều kiện bình thường và bất thường (sự cố).

Đặc điểm chính:

- Hoạt động tự động khi có sự cố

- Arc tuyệt chủng khả năng

- Có thể hoạt động trong điều kiện đầy tải

- Cung cấp bảo vệ quá dòng và ngắn mạch

- Có thể cài đặt lại sau khi tác động

Dao cách ly là gì?

Một dao cách ly, còn được gọi là isolator, là một thiết bị đóng cắt cơ khí cung cấp sự cách ly của mạch điện cho mục đích bảo trì và an toàn. Nó tạo ra một khoảng cách nhìn thấy được giữa các tiếp điểm điện khi mở.

Đặc điểm chính:

- Chỉ hoạt động bằng tay

- Khoảng cách cách ly nhìn thấy được

- Chỉ hoạt động khi mạch điện đã được cắt điện

- Không có khả năng ngắt sự cố

- Ngăn chặn việc vô tình cấp điện trong quá trình bảo trì

Bảng so sánh toàn diện

| Năng | Cầu dao điện | Dao cách ly |

|---|---|---|

| Mục đích chính | Bảo vệ chống lại các sự cố | Cách ly để bảo trì |

| Hoạt động | Tự động và thủ công | Chỉ hướng dẫn sử dụng |

| Arc Tuyệt Chủng | Có (SF6, chân không, dầu, khí) | Không - tối thiểu hoặc không có |

| Khả năng cắt tải | Có - khả năng đầy tải | Không - chỉ hoạt động không tải |

| Dòng điện Sự cố | Ngắt dòng điện sự cố | Không thể ngắt dòng điện sự cố |

| Khoảng cách nhìn thấy được | Không bắt buộc | Bắt buộc để đảm bảo an toàn |

| Tiêu chuẩn | IEC 62271-100, IEEE C37 | IEC 62271-102, IEEE C37.30 |

| Điện áp điển hình | Tất cả các cấp (LV đến EHV) | Điện áp trung bình đến cao |

| Chi phí lắp đặt | Cao hơn | Thấp hơn |

| Bảo trì | Cơ chế phức tạp | Cơ chế đơn giản |

Giải thích sự khác biệt quan trọng

1. Khả năng ngắt sự cố

Máy cắt mạch:

- Được thiết kế để ngắt dòng điện sự cố lên đến công suất định mức của chúng

- Sử dụng môi trường dập hồ quang (khí SF6, chân không, dầu hoặc khí)

- Có thể cắt dòng điện lớn hơn nhiều lần so với định mức bình thường của chúng trong các sự cố

- Cần thiết cho bảo vệ hệ thống

Dao cách ly:

- Không thể ngắt dòng điện sự cố một cách an toàn

- Có thể tạo ra hồ quang nguy hiểm nếu mở dưới tải

- Chỉ được sử dụng sau khi mạch điện đã được cắt điện bằng các phương tiện khác

- Chủ yếu là cách ly, không phải ngắt

2. Điều kiện hoạt động

Máy cắt mạch:

- Hoạt động trong điều kiện bình thường và sự cố

- Có thể đóng và cắt dòng điện đầy tải

- Tự động hoạt động trong điều kiện bất thường

- Thích hợp cho hoạt động thường xuyên

Dao cách ly:

- Chỉ hoạt động trong điều kiện không tải hoặc tải tối thiểu

- Yêu cầu mạch điện phải được cắt điện trước khi hoạt động

- Hoạt động bằng tay với chỉ báo vị trí có thể nhìn thấy

- Hoạt động không thường xuyên cho mục đích bảo trì

Dr. Trước An Toàn Cảnh Báo: Không bao giờ vận hành dao cách ly trong điều kiện có tải. Điều này có thể gây ra hồ quang nguy hiểm, hư hỏng thiết bị và các mối nguy hiểm an toàn nghiêm trọng.

Ứng dụng, Sử dụng trường Hợp

Khi nào nên sử dụng Aptomat

Ứng dụng công nghiệp:

- Bảo vệ và điều khiển động cơ

- Bảo vệ đường dây trong hệ thống phân phối

- Bảo vệ máy phát điện và máy biến áp

- Ngắt dòng điện sự cố trong hệ thống điện

Ứng dụng thương mại:

- Bảo vệ ngắt mạch dịch vụ chính

- Bảo vệ mạch nhánh

- Ứng dụng trung tâm tải

- Tích hợp công tắc chuyển mạch tự động

Ứng dụng dân dụng:

- Bảo vệ bảng điện chính

- Bảo vệ mạch riêng lẻ

- Bảo vệ GFCI và AFCI

- Tích hợp bảo vệ chống sét lan truyền toàn nhà

Khi nào nên sử dụng Dao cách ly

Ứng dụng trong trạm biến áp:

- Phân đoạn thanh cái

- Cách ly thiết bị để bảo trì

- Yêu cầu cách ly bằng mắt thường

- Chuyển mạch đường dây trong hệ thống truyền tải

Ứng dụng công nghiệp:

- Công tắc ngắt mạch động cơ

- Cách ly thiết bị

- Cách ly an toàn để bảo trì

- Điểm ngắt mạch khẩn cấp

Ứng dụng trong bảo trì:

- Tạo vùng làm việc an toàn

- Quy trình khóa/gắn thẻ

- Cách ly thiết bị để bảo dưỡng

- Xác nhận trực quan về việc ngắt điện

Tiêu chí lựa chọn và hướng dẫn của chuyên gia

Lựa chọn Aptomat (Máy cắt điện)

Các yếu tố chính cần xem xét:

- Dòng điện định mức: Phải lớn hơn dòng điện hoạt động bình thường

- Khả năng cắt: Phải lớn hơn dòng điện sự cố tối đa

- Điện áp định mức: Phải bằng hoặc lớn hơn điện áp hệ thống

- Loại tải: Cân nhắc cho động cơ, điện trở, điện dung

- Điều kiện môi trường: Trong nhà/ngoài trời, nhiệt độ, ô nhiễm

Chuyên Gia Mẹo: Luôn tham khảo các nghiên cứu về dòng điện sự cố khi lựa chọn aptomat. Khả năng cắt phải lớn hơn dòng điện sự cố tối đa có sẵn tại điểm lắp đặt.

Lựa chọn Dao cách ly

Các yếu tố chính cần xem xét:

- Yêu cầu cách ly: Thông số kỹ thuật về khoảng hở nhìn thấy được

- Độ bền cơ học: Chu kỳ hoạt động dự kiến

- Đánh giá môi trường: Khả năng chống chịu thời tiết cho các thiết bị ngoài trời

- Yêu cầu khóa liên động: Khóa liên động an toàn với các thiết bị khác

- Khả năng tiếp cận: Dễ vận hành và tiếp cận bảo trì

Chuyên Gia Mẹo: Chỉ định dao cách ly có tiếp điểm phụ để chỉ báo vị trí từ xa. Điều này tăng cường an toàn và nhận thức hoạt động.

Tuân thủ quy định và an toàn

Điện quốc gia Mã (ĐƯỢC...) yêu Cầu

Điều 240 – Bảo Vệ Quá Dòng:

- Aptomat phải cung cấp bảo vệ quá dòng

- Phối hợp thích hợp với các thiết bị bảo vệ ở thượng nguồn

- Yêu cầu bảo vệ chống hồ quang và chạm đất

Điều 430 – Động Cơ:

- Bảo vệ ngắn mạch nhánh động cơ

- Yêu cầu ngắt mạch động cơ trong tầm nhìn

- Thông số kỹ thuật của bộ điều khiển động cơ kết hợp

Tuân thủ tiêu chuẩn IEEE

Các tiêu chuẩn IEEE C37 Series:

- C37.04: Tiêu chuẩn về cấu trúc định mức của aptomat

- C37.06: Tiêu chuẩn aptomat cao áp AC

- C37.30: Tiêu chuẩn dao cách ly

Các điểm tuân thủ chính:

- Ứng dụng thích hợp trong phạm vi định mức

- Kiểm tra chất lượng môi trường

- Đánh giá chất lượng địa chấn khi có yêu cầu

- Yêu cầu về tương thích điện từ

Dr. Trước Đề Nghị Chuyên Nghiệp: Luôn tham khảo ý kiến của các kỹ sư điện được cấp phép cho các ứng dụng trung và cao áp. Việc lựa chọn không đúng cách có thể dẫn đến những sự cố nghiêm trọng.

Những cân nhắc về lắp đặt và bảo trì

Thực hành tốt nhất khi lắp đặt Aptomat

Quy trình lắp đặt từng bước:

- Lập kế hoạch trước khi cài đặt

- Xác minh các thông số điện phù hợp với ứng dụng

- Xác nhận mức dòng điện sự cố có sẵn

- Kiểm tra điều kiện môi trường

- Lắp đặt vật lý

- Tuân theo các thông số kỹ thuật về mô-men xoắn của nhà sản xuất

- Đảm bảo kết nối dây dẫn thích hợp

- Xác minh khoảng hở cơ học

- Thử nghiệm và Đưa

- Kiểm tra sơ cấp cho rơ le bảo vệ

- Kiểm tra hoạt động cơ học

- Kiểm tra thời gian và điện trở tiếp xúc

Thực hành tốt nhất khi lắp đặt Dao cách ly

Quy trình lắp đặt từng bước:

- Chuẩn bị địa điểm

- Xác minh các yêu cầu về nền móng

- Kiểm tra khoảng cách đến các bộ phận mang điện

- Đảm bảo khả năng tiếp cận để vận hành

- Lắp đặt cơ khí

- Tuân theo quy trình căn chỉnh của nhà sản xuất

- Xác minh chức năng của cơ cấu vận hành

- Kiểm tra hệ thống khóa liên động

- Kết nối điện

- Sử dụng các phương pháp kết nối dây dẫn thích hợp

- Áp dụng áp suất tiếp xúc được chỉ định

- Kiểm tra kết nối mạch phụ trợ

Sự Cố Vấn Đề Chung

Các vấn đề về cầu dao (Circuit Breaker)

Triệu chứng: Cầu dao không đóng được

- Kiểm tra nguồn điện điều khiển

- Kiểm tra cơ cấu nạp lò xo

- Kiểm tra khóa liên động cơ khí

- Kiểm tra tính liên tục của cuộn đóng

Triệu chứng: Cắt mạch do nhiễu

- Phân tích đường cong dòng tải

- Kiểm tra các kết nối lỏng lẻo

- Kiểm tra sự phối hợp thời gian-dòng điện thích hợp

- Xem xét các yếu tố môi trường

Các vấn đề về dao cách ly (Disconnector)

Triệu chứng: Khó thao tác

- Kiểm tra bôi trơn cơ cấu vận hành

- Kiểm tra sự ràng buộc cơ học

- Kiểm tra điều chỉnh thích hợp

- Kiểm tra độ mòn tiếp điểm

Triệu chứng: Hiệu suất tiếp xúc kém

- Kiểm tra cài đặt áp lực tiếp điểm

- Kiểm tra ô nhiễm

- Kiểm tra căn chỉnh thích hợp

- Xem xét tính tương thích của vật liệu tiếp điểm

Nhanh Hướng Dẫn Tham Khảo

Thông tin nhanh về cầu dao (Circuit Breaker)

- Chức năng chính: Tự động bảo vệ sự cố

- Có thể hoạt động: Trong điều kiện tải và sự cố

- Sự tuyệt chủng của hồ quang: Có – có nhiều công nghệ khác nhau

- Ứng dụng điển hình: Bảo vệ và chuyển mạch

- Mã tham chiếu: NEC Điều 240, IEEE C37 series

Thông tin nhanh về dao cách ly (Disconnector)

- Chức năng chính: Cách ly để bảo trì

- Có thể hoạt động: Chỉ khi mất điện

- Sự tuyệt chủng của hồ quang: Không – dựa vào khe hở không khí

- Ứng dụng điển hình: Cách ly và ngắt kết nối có thể nhìn thấy

- Mã tham chiếu: NEC Điều 430.102, IEEE C37.30

Những Câu Hỏi Thường

Dao cách ly có thể thay thế cầu dao không?

Không, dao cách ly không thể thay thế cầu dao. Dao cách ly thiếu khả năng ngắt sự cố và không thể cung cấp bảo vệ quá dòng theo yêu cầu của các quy tắc điện.

Khi nào nên sử dụng cả hai thiết bị cùng nhau?

Cả hai thiết bị thường được sử dụng cùng nhau trong các ứng dụng trung và cao áp, nơi cả chức năng bảo vệ (cầu dao) và cách ly (dao cách ly) đều cần thiết cho vận hành và bảo trì an toàn.

Điều gì xảy ra nếu bạn vận hành dao cách ly khi có tải?

Vận hành dao cách ly khi có tải có thể gây ra hồ quang nguy hiểm, hư hỏng thiết bị, nguy cơ hỏa hoạn và thương tích tiềm ẩn. Thực hành này vi phạm các quy tắc an toàn và khuyến nghị của nhà sản xuất.

Có sẵn thiết bị kết hợp không?

Có, một số nhà sản xuất cung cấp các thiết bị kết hợp cầu dao-dao cách ly, đặc biệt cho các ứng dụng động cơ. Các thiết bị này cung cấp cả bảo vệ và cách ly trực quan trong một thiết bị duy nhất.

Làm thế nào để bạn xác định trình tự hoạt động thích hợp?

Đối với các hệ thống có cả hai thiết bị, luôn vận hành cầu dao trước để ngắt dòng điện, sau đó vận hành dao cách ly để cách ly. Đảo ngược trình tự này khi cấp lại điện.

Chu kỳ bảo trì điển hình là gì?

Cầu dao thường yêu cầu bảo trì 5-10 năm một lần tùy thuộc vào ứng dụng và khuyến nghị của nhà sản xuất. Dao cách ly có thể yêu cầu bảo trì 10-15 năm một lần do cơ chế đơn giản hơn của chúng.

Dao cách ly có thể được tự động hóa không?

Có, dao cách ly có thể được trang bị bộ vận hành bằng động cơ để điều khiển từ xa, nhưng chúng vẫn chỉ nên hoạt động trong điều kiện không tải và thường yêu cầu các khóa liên động an toàn bổ sung.

Các loại công nghệ cầu dao khác nhau là gì?

Các loại chính bao gồm cầu dao khí (ACB), cầu dao chân không (VCB), cầu dao khí SF6 và cầu dao dầu, mỗi loại phù hợp với các mức điện áp và ứng dụng khác nhau.

Đề Nghị Chuyên Nghiệp: Đối với bất kỳ cài đặt hoặc sửa đổi điện nào liên quan đến cầu dao hoặc dao cách ly, hãy tham khảo ý kiến của kỹ sư điện được cấp phép hoặc thợ điện được chứng nhận. Việc áp dụng đúng các thiết bị này là rất quan trọng đối với sự an toàn, tuân thủ quy tắc và vận hành đáng tin cậy.

Hãy nhớ: Cầu dao bảo vệ hệ thống điện của bạn khỏi các sự cố, trong khi dao cách ly bảo vệ bạn trong quá trình bảo trì. Cả hai đều là thành phần thiết yếu của thiết kế điện an toàn, nhưng chúng phục vụ các mục đích khác nhau rõ rệt và không bao giờ được nhầm lẫn hoặc áp dụng sai.