Você está revisando o orçamento do projeto do painel. A especificação exige um disjuntor de entrada de serviço principal de 2500A. Você encontra duas opções:

- Opção A (Disjuntor em caixa moldada): Barato, compacto e classificado para 2500A.

- Opção B (ACB): Enorme, volumoso e cinco vezes o preço.

A pergunta inevitavelmente chega à mesa do engenheiro eletricista: “Por que estamos pagando tanto pelo volumoso quando o mais barato tem a mesma classificação de tensão e corrente?”

A resposta é simples, mas invisível na placa de identificação: **A Capacidade de Interrupção (Icu).**

Você não está comparando a capacidade de conduzir corrente (a classificação de corrente); você está comparando a capacidade de sobreviver a uma explosão. O ACB é construído para lidar com a violência que faria com que o MCCB falhasse catastroficamente.

1. O Número Oculto: Definindo a Barreira da Icu

O número mais crítico, mas mais incompreendido, na distribuição de energia em larga escala é **Icu (Capacidade Nominal de Interrupção de Curto-Circuito Final)**.

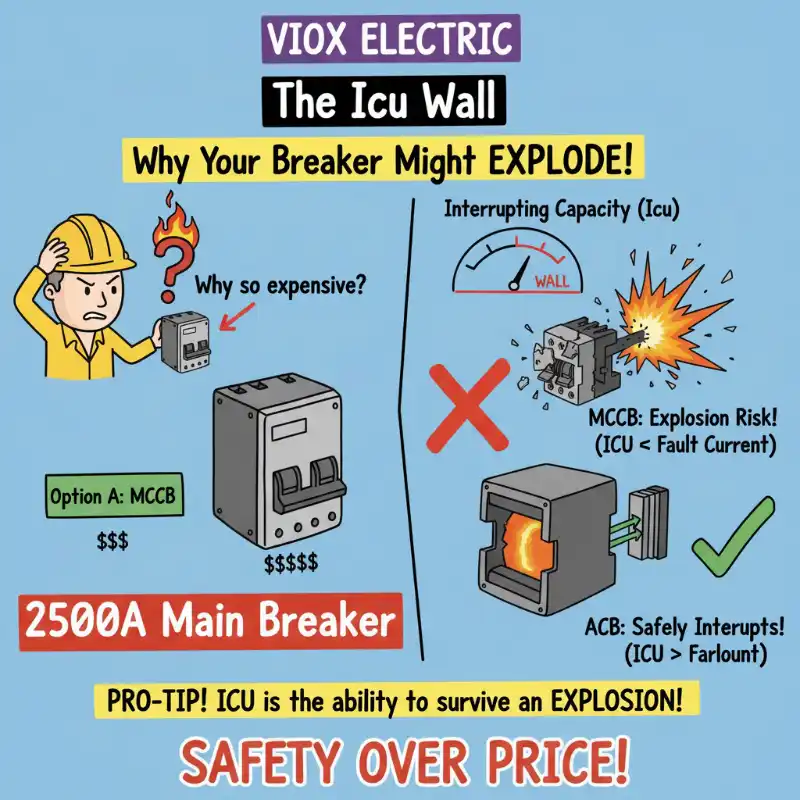

A Icu informa a corrente máxima de curto-circuito que o disjuntor pode interromper com segurança *sem ser destruído*. Se a corrente de falta real exceder a classificação de Icu do disjuntor, o disjuntor pode não conseguir eliminar a falta, levando a uma explosão maciça e descontrolada conhecida como arco elétrico.

O Limite Físico do MCCB

Devido ao seu invólucro de plástico confinado, os Disjuntores de Caixa Moldada (MCCBs) atingem um limite de segurança:

- Limite Típico do MCCB: A Icu normalmente atinge um máximo entre 65kA e 85kA.

- A Armadilha: Este limite é fixado pela resistência do invólucro de plástico.

Em sistemas de alta capacidade - especialmente aqueles alimentados por múltiplos transformadores grandes ou acoplados - a corrente de falta disponível pode facilmente exceder **100kA**. Esta é a Barreira da Icu.

2. O Ponto de Ruptura: Extinção em Plástico vs. Ar Livre

A diferença entre as duas tecnologias reside em como elas lidam com a pura e violenta energia de um arco de curto-circuito maciço.

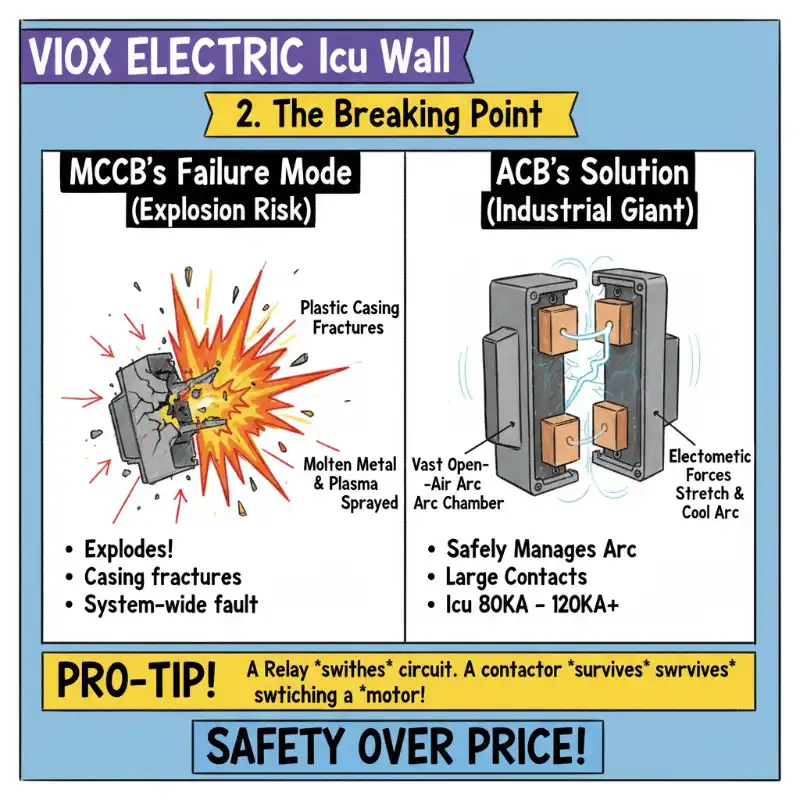

O Modo de Falha do MCCB (O Risco de Explosão)

Um MCCB elimina um arco confiando na pressão criada pelo plasma superaquecido dentro de suas pequenas câmaras de extinção de arco. Essa pressão deve ser contida pela carcaça de plástico circundante. Se a corrente de falta exceder a barreira da Icu, a pressão supera a resistência à tração do plástico.

O MCCB não apenas falha; ele explode. A carcaça se fratura, pulverizando metal fundido e gás ionizado (plasma) na aparelhagem, muitas vezes levando a uma falta em todo o sistema.

O dispositivo projetado para proteger seus ativos se torna a fonte do desastre.

A Solução do ACB (O Gigante Industrial)

O Disjuntor de Ar (ACB) usa um princípio completamente diferente:

- Estrutura Aberta: Os ACBs têm vastas câmaras de arco ao ar livre e contatos de cobre muito maiores.

- Gerenciamento de Arco: Eles usam fortes forças eletromagnéticas e grandes placas isoladas para esticar, resfriar e extinguir rapidamente o arco em um grande volume de ar, desviando a energia com segurança.

- Margem de Segurança: As classificações de Icu do ACB normalmente começam onde os MCCBs terminam - de 80kA e facilmente excedendo 100kA ou 120kA.

O ACB é projetado para lidar com segurança com a energia máxima de curto-circuito que o sistema pode gerar fisicamente, tornando-o o guardião de segurança final.

3. O Requisito de Segurança: Quando Você Deve Usar o ACB

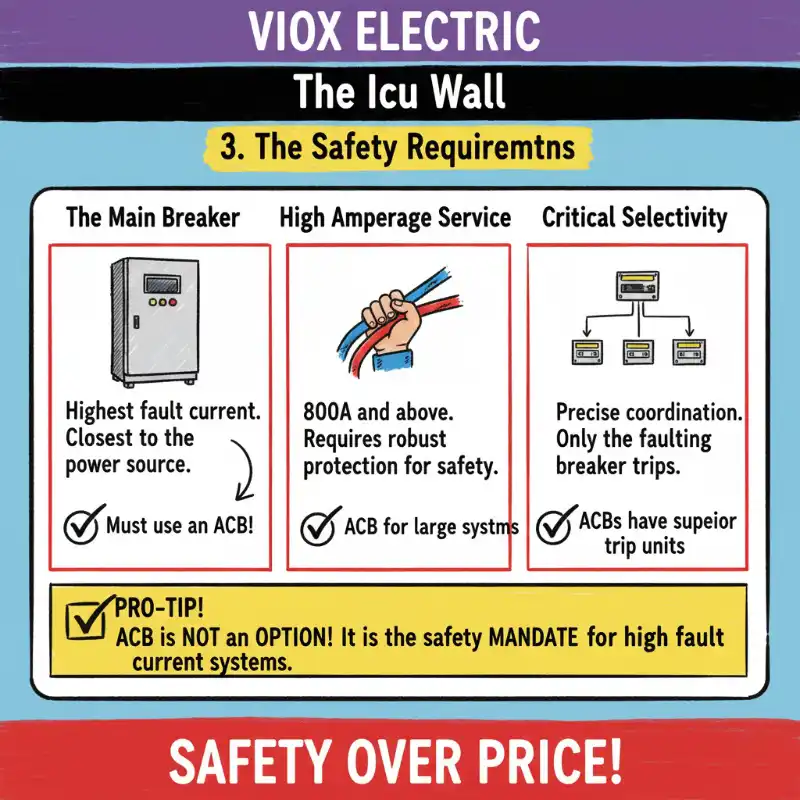

A escolha entre os dois é uma questão de definição de função na rede elétrica. Se você está projetando o serviço de entrada principal, sua principal preocupação é **Segurança e Sobrevivência**.

Você deve usar um ACB (ou outra proteção altamente classificada) quando:

- O Disjuntor Principal: A corrente de falta no serviço de entrada principal é mais alta, pois está mais próxima da fonte de energia ilimitada (o transformador da concessionária).

- Serviço de Alta Amperagem: Serviços classificados em 800A e acima geralmente exigem o uso de ACBs devido à alta corrente de falta inerente e à necessidade de manutenção a longo prazo.

- Seletividade Crítica: Os ACBs têm unidades de disparo eletrônicas superiores necessárias para coordenar precisamente com cada MCCB downstream, garantindo que apenas o disjuntor de falta mais próximo dispare (um recurso crítico para minimizar o tempo de inatividade da produção).

A verdade é que, embora o MCCB de 2500A possa ser mais barato inicialmente, o ACB de 2500A é o único dispositivo classificado para sobreviver ao pior cenário. Quando a segurança de toda a sua barra de distribuição, aparelhagem e pessoal está em jogo, a capacidade de interrupção superior do ACB é uma apólice de seguro não negociável.

O ACB não custa mais - ele simplesmente desempenha um nível mais alto de dever de segurança não opcional.

O Rigor Técnico Nota

Normas e Fontes Referenciadas

- IEC 60947-2: Norma regulamentadora para MCCBs e ACBs, definindo a classificação de Icu e os procedimentos de teste.

- Limites Físicos: A Icu do MCCB é limitada pela resistência do invólucro de plástico termoendurecido e pelo volume da câmara de extinção de arco; A Icu do ACB é gerenciada pelo volume de extinção ao ar livre e pela velocidade de separação dos contatos.

- Prática da Indústria: Os ACBs são padrão para quadros de distribuição principais acima de 800A devido às altas correntes de falta, margens de segurança obrigatórias e requisitos de manutenção.

Declaração de Atualidade

Todos os princípios relativos à capacidade de interrupção (Icu), cálculo da corrente de falta e os limites físicos das tecnologias de disjuntores permanecem fundamentais para a prática moderna da engenharia elétrica a partir de novembro de 2025.