Proper placement of Surge Protective Devices (SPDs) is the single most critical factor determining whether your facility withstands a catastrophic electrical event or suffers thousands of dollars in equipment damage. While selecting the correct voltage rating and discharge current capacity is important, even the highest-rated device will fail to protect your assets if installed in the wrong location or with excessive lead length.

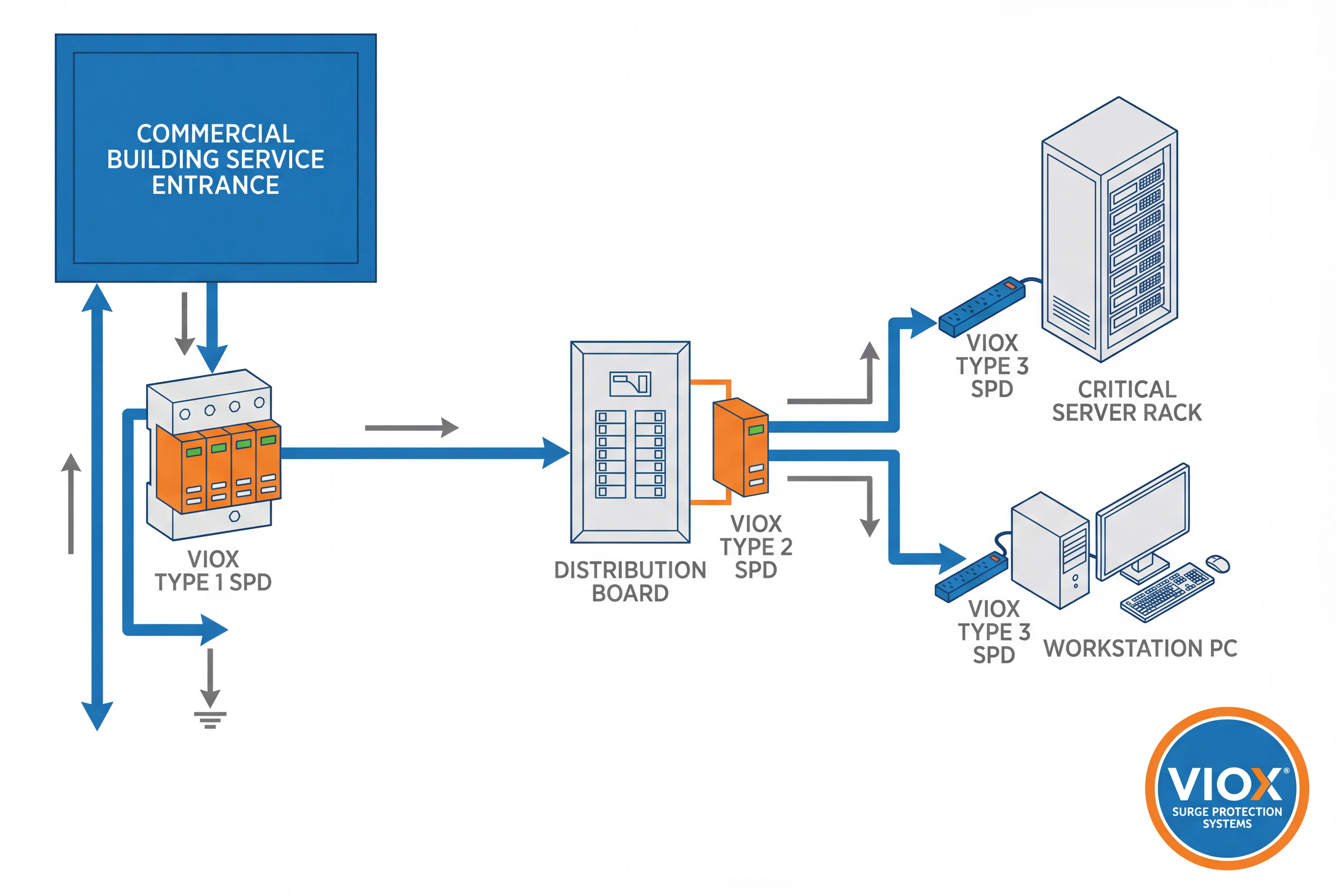

For electrical engineers and facility managers, the goal is clear: divert transient energy before it reaches sensitive downstream loads. This requires a coordinated approach to installation—known as cascading protection—starting at the service entrance and extending to individual branch circuits.

နားလည်မှု SPD အမျိုးအစားများ and Classifications

Before identifying the physical installation points in your panel, you must distinguish between the three primary categories of SPDs defined by standards such as UL 1449 and IEC 61643-11. The installation location is strictly dictated by the device type.

- 1 SPDs အမျိုးအစား- Designed for the line side of the service entrance. These heavy-duty devices handle high-energy surges from external sources, including direct lightning strikes and utility grid switching. They contain no external overcurrent protection and are built to withstand the full brunt of incoming transients.

- အမျိုးအစား 2 SPDs- Intended for the load side of the main service disconnect. These are the workhorses of industrial surge protection, installed at distribution boards and sub-panels. They protect against residual energy that passes Type 1 devices and internally generated surges from motors and variable frequency drives (VFDs).

- 3 SPDs အမျိုးအစား- Point-of-use devices installed as close as possible to the protected load (typically within 10 meters). They handle low-level residual transients to protect sensitive electronics like PLCs, computers, and medical equipment.

Primary Installation Locations for SPDs

Effective surge protection requires a “defense-in-depth” strategy. Relying on a single device at the main service entrance is rarely sufficient for modern facilities filled with sensitive microprocessors.

1. The Main Service Entrance

This is your first line of defense. The SPD should be installed immediately after the secondary of the utility transformer and before the main service equipment’s overcurrent protective device (for Type 1) or immediately after the main disconnect (for Type 2). The objective here is to divert the massive energy from external surges to ground right at the entry point, preventing it from circulating through the building’s grounding system.

2. Distribution Boards and Sub-Panels

Large facilities often have long cable runs between the main switchgear and downstream distribution panels. These cables can pick up induced surges from lightning or nearby high-voltage equipment. Installing Type 2 SPDs at these intermediate panels clamps voltage ringing and protects branch circuits.

3. Equipment Level (Point-of-Use)

For critical loads like data center servers, CNC machines, or fire alarm control panels, a Type 3 SPD is installed directly at the equipment input. This addresses any surges generated internally on the branch circuit and provides the tightest voltage clamping.

Type 1 SPD Installation: Service Entrance Requirements

Installing a Type 1 SPD requires adherence to strict safety and performance protocols. Because these devices sit on the line side of the service disconnect, they are permanently connected and must handle high fault currents.

Location Specifics

Mount the Type 1 SPD as close as physically possible to the incoming phase conductors. In a standard main distribution panel, this often means mounting the device directly to the enclosure via a chase nipple or within a dedicated compartment if using an integrated switchboard design.

ချိတ်ဆက်မှုနည်းလမ်း

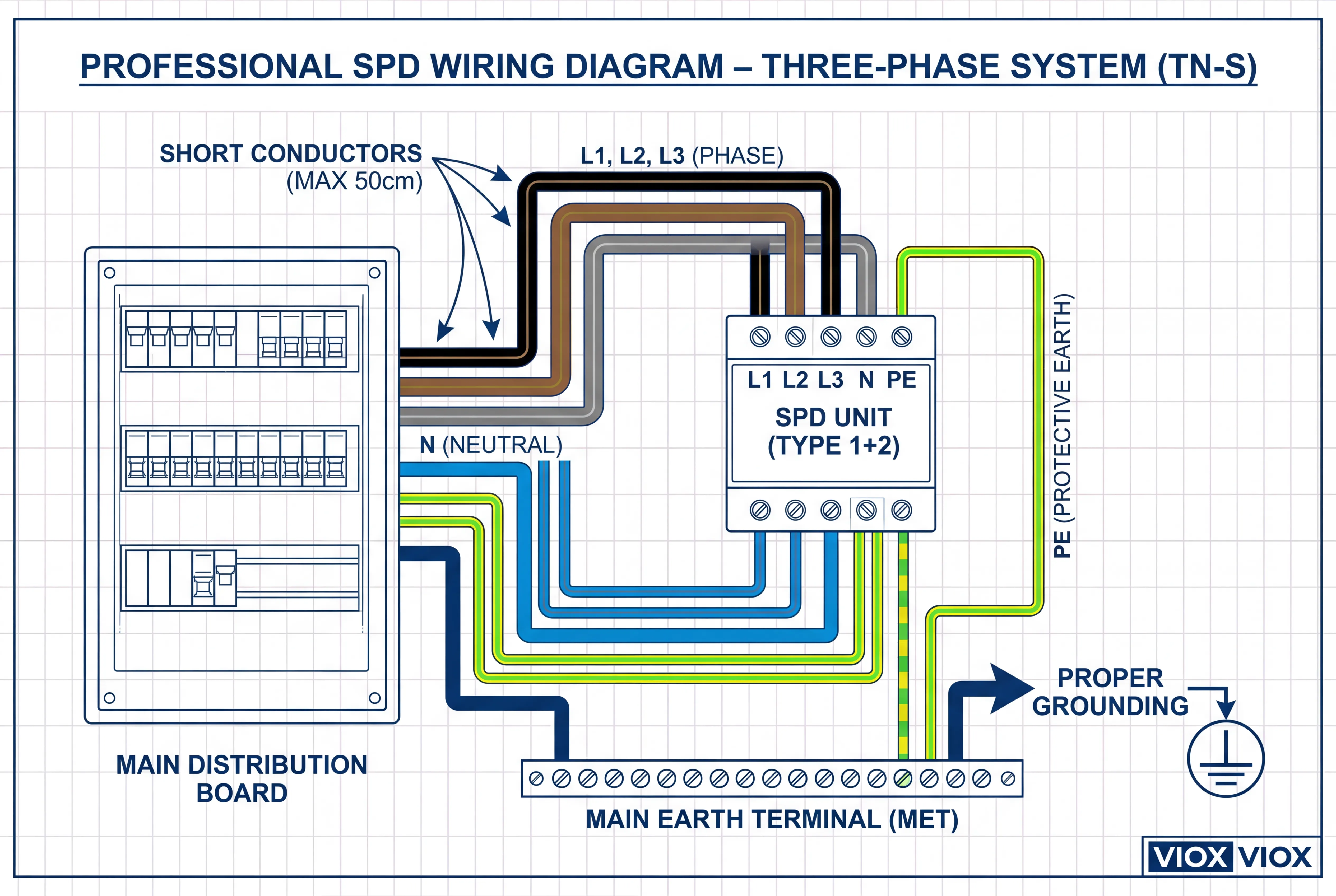

Type 1 devices are typically parallel-connected. You will tap the phases (L1, L2, L3) and the Neutral (N) directly from the service entrance conductors or the main busbars.

- ဘေးကင်းရေးမှတ်ချက်- Since there is no upstream breaker in the facility to trip, Type 1 devices often include internal fusing or thermal disconnects to safely isolate the unit if it fails.

- မြေပြင်- The grounding conductor must connect to the main grounding electrode conductor or the ground busbar with the shortest possible path.

Type 2 SPD Installation: Distribution Panel Placement

Type 2 SPDs are the most common devices encountered by commercial electricians. They are installed on the load side of the main breaker, usually connected via a dedicated circuit breaker.

Preferred Mounting Position

Within a panelboard, the optimal location for the SPD and its feeding circuit breaker is immediately adjacent to the main lugs or main circuit breaker.

- Why position matters: Placing the SPD at the top of the panel (closest to the incoming feed) minimizes the impedance of the busbar path. If you install the SPD at the bottom of a 42-circuit panel, the surge must travel down the entire busbar length, potentially inducing higher voltages across the panel structure before the SPD can activate.

Circuit Breaker vs. Direct Connection

While direct connection to the bus (using lug kits) offers the lowest impedance, using a dedicated circuit breaker (e.g., 30A or 60A, depending on manufacturer specs) is the standard practice for Type 2 devices. This allows for safe isolation of the SPD for maintenance or replacement without shutting down the entire panel.

Type 3 SPD Installation: Point-of-Use Protection

Type 3 SPDs are often overlooked but are essential for equipment protection. These can be hardwired into a junction box, DIN-rail mounted inside a control cabinet, or integrated into a receptacle.

- Proximity: Install these within 30 feet (10 meters) of the protected load. If the wire length exceeds this, the effectiveness of the voltage clamping diminishes due to oscillation and voltage reflection effects in the cable.

- ညှိနှိုင်းမှု- Ensure the Type 3 device is coordinated with upstream Type 1 and Type 2 devices. The clamping voltage of the downstream device should be lower than the withstand voltage of the equipment it protects, but high enough to ensure the upstream heavy-duty SPD handles the bulk of the surge energy.

Critical Installation Best Practices

The physical installation of the SPD is just as important as the device’s internal specifications. A 100kA SPD installed with long, bent wires performs significantly worse than a 50kA SPD installed with short, straight leads.

The “Lead Length” Rule

Surges are high-frequency events. At these frequencies, wire inductance creates significant voltage drop. The general rule of thumb is: keep connecting leads as short as possible, ideally under 10 inches (250mm).

- Equation: vlet-through = vclamping + (ဌ × di/dt)

- ဘယ်မှာလဲ ဌ is inductance (function of wire length) and di/dt is the rate of current rise.

- Every inch of wire adds roughly 15-25 volts to the let-through voltage during a surge. A 3-foot cable can add hundreds of volts, rendering the protection useless.

Straight Wiring Paths

Avoid sharp 90-degree bends in the conductors. Bends increase inductance and impedance. Use sweeping curves if a turn is necessary. The wire should look like a direct, taut line from the breaker/bus to the SPD terminals.

Grounding နှင့် Bonding

The SPD diverts energy to the ground. If the ground path is high resistance or high impedance, the energy has nowhere to go. Ensure the green/yellow ground conductor is bonded directly to the panel’s ground bus. Do not use the metal enclosure chassis as the sole ground path for the SPD; run a dedicated wire.

ရှောင်ရှားရန် အဖြစ်များသော တပ်ဆင်မှု အမှားများ

Even experienced electricians can make errors when installing surge protection. Avoid these frequent pitfalls:

- “Pigtailing” Leads: Coiling excess wire inside the panel to make it look “neat.” This creates an air-core inductor that blocks the surge from reaching the SPD, forcing it into your equipment instead. Cut wires to length.

- Undersized Conductors: While surge currents are brief, they are intense. Follow the manufacturer’s recommended gauge (typically #10 AWG or #8 AWG) to handle the mechanical stress and current density.

- Installing SPDs on Ungrounded Systems: Most standard SPDs require a reference to ground. Installing a standard Wye SPD on an ungrounded Delta system without checking the spec sheet can lead to immediate device failure or safety hazards.

- အချက်ပြမီးများကို လျစ်လျူရှုခြင်း- Install the SPD where the status LEDs or display are visible. A hidden SPD that has sacrificed itself to protect the system provides zero protection against the next surge.

Industry-Specific Installation Considerations

လုပ်ငန်းသုံး အဆောက်အဦများ

In office towers and retail spaces, the focus is often on lighting and HVAC systems.

- တပ်ဆင်နေရာ: Install Type 2 SPDs at lighting distribution panels. LED drivers are notoriously sensitive to transients.

- Data Rooms: Use a combination of Type 2 at the panel and Type 3 rack-mounted SPDs for server protection.

စက်မှုအသုံးအဆောင်များ

Manufacturing plants deal with constant internal switching transients from VFDs and motors.

- တပ်ဆင်နေရာ: Every Motor Control Center (MCC) should have a Type 2 SPD.

- PLC Panels: Dedicated DIN-rail SPDs inside control cabinets are mandatory to prevent logic corruption and downtime.

လူနေ

Modern homes are essentially smart grids with appliances, EV chargers, and solar inverters.

- တပ်ဆင်နေရာ: A Type 1 or Type 2 SPD at the main consumer unit meets 2020/2023 NEC requirements (Article 242).

- Exterior: AC condensers and pool pumps often require dedicated disconnect-mounted SPDs.

နိဂုံး

Determining where to install SPDs in your electrical panel is not a matter of guesswork—it is a calculated engineering decision based on device hierarchy and physics. A Type 1 device at the service entrance keeps external lightning energy out, while Type 2 and Type 3 devices at distribution panels and equipment inputs handle the internal switching transients that degrade electronics over time.

Remember the golden rule: Location, Length, and Straightness. Install the right type of SPD at the right zone, keep conductors shorter than 10 inches, and avoid sharp bends.

မှာ VIOX, we engineer our surge protective devices to meet the rigorous demands of modern industrial and commercial infrastructure. Our technical teams are available to assist with coordination studies and site assessments to ensure your facility achieves a verified protection level. Don’t leave your critical assets vulnerable to the next power spike—secure your system with VIOX today.