Jurang Senyap dalam Sistem Keselamatan Elektrik Anda

Bayangkan ini: Anda baru sahaja mereka bentuk sistem elektrik yang canggih untuk bangunan komersial. Setiap panel bersaiz betul, setiap pemutus litar dinilai untuk bebannya, dan reka bentuk anda lulus pemeriksaan dengan cemerlang. Anda telah memasang pemutus litar terma-magnet yang akan tersandung serta-merta pada beban lampau atau litar pintas. Sistem anda “dilindungi.”

Kemudian penggera kebakaran berbunyi.

Asap memenuhi bilik elektrik. Anggota bomba tiba, tetapi pemutus litar anda masih bertenaga—membekalkan kuasa kepada peralatan yang boleh mengejutkan responden pertama atau memburukkan lagi kebakaran. Ketua bomba menunjuk ke panel anda dan bertanya soalan yang membuatkan perut setiap jurutera meragam: “Mengapa ini tidak tertutup secara automatik?”

Inilah kebenaran yang tidak selesa: Pemutus litar standard tidak boleh mendengar penggera kebakaran. Mereka tidak boleh bertindak balas kepada butang henti kecemasan. Mereka tidak tahu apabila kebocoran gas dikesan. Ia direka untuk bertindak balas kepada satu perkara sahaja—kerosakan elektrik. Ini mewujudkan titik buta yang berbahaya antara sistem keselamatan anda dan perlindungan elektrik anda.

Jadi, bagaimana anda merapatkan jurang ini? Bagaimana anda membuat pemutus litar anda bertindak balas kepada kecemasan dunia sebenar sebelum seseorang cedera?

Mengapa Perlindungan Tradisional Tidak Mencukupi

Mari kita fahami hadnya. Pemutus litar konvensional ialah peranti autonomi—ia memantau aliran arus dan tersandung apabila ia mengesan beban lampau (terlalu banyak arus dari semasa ke semasa) atau litar pintas (arus besar serta-merta). Anggap ia sebagai pengawal keselamatan yang hanya mengawasi satu pintu dan bertindak balas kepada satu jenis ancaman.

Tetapi bahaya elektrik tidak selalu mengumumkan diri mereka melalui lebihan arus. Kebakaran bermula di ruang bersebelahan. Seorang pekerja tergelincir berhampiran peralatan bertenaga. Banjir mengancam subpanel. Dalam senario ini, anda memerlukan kawalan jauh yang pintar—keupayaan untuk memotong kuasa berdasarkan keadaan luaran, bukan hanya ukuran elektrik.

Inilah sebabnya kod bangunan seperti Kod Elektrik Kebangsaan (NEC) dan piawaian antarabangsa seperti IEC 60947-2 semakin mewajibkan keupayaan pemutusan jauh dalam aplikasi kritikal. Jurang antara “perlindungan kerosakan automatik” dan “kawalan situasi kecemasan” telah menutup nyawa dan infrastruktur. Kita memerlukan penyelesaian yang lebih baik.

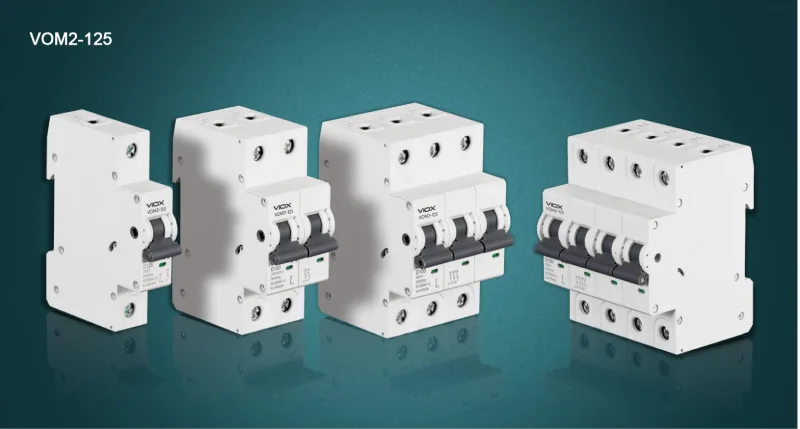

Jawapannya: Pemutus Litar Trip Shunt Dijelaskan

Masukkan trip shunt litar breaker—peranti yang mengubah perlindungan pasif anda menjadi sistem keselamatan aktif.

Pada terasnya, pemutus litar trip shunt ialah pemutus litar standard yang ditambah dengan gegelung elektromagnet (dipanggil “gegelung shunt” atau “pelepas shunt”). Apabila gegelung ini menerima isyarat voltan daripada sumber luaran—panel penggera kebakaran, butang henti kecemasan, sistem pengurusan bangunan, atau bahkan sensor keselamatan—ia menjana medan magnet yang secara mekanikal membuka pemutus litar. Kuasa dipotong. Serta-merta. Tiada campur tangan manusia diperlukan.

Anggap ia sebagai menaik taraf pengawal keselamatan anda: kini mereka bukan sahaja memerhatikan kerosakan elektrik di pintu mereka—mereka juga mendengar radio yang disambungkan ke penggera kebakaran, sistem keselamatan dan kawalan kecemasan di seluruh kemudahan. Satu isyarat, dan mereka mengambil tindakan.

Ambilan Utama: Pemutus litar trip shunt tidak menggantikan perlindungan arus lebih—ia menambah mekanisme trip kedua yang bebas. Anda mendapat kedua-dua perlindungan kerosakan automatik DAN kawalan kecemasan jauh dalam satu peranti.

Keindahan reka bentuk ini ialah kesederhanaan dan kebolehpercayaannya. Gegelung shunt beroperasi pada litar kawalan yang berasingan (biasanya 24V DC, 120V AC, atau 240V AC, bergantung pada voltan sistem kawalan anda). Apabila diberi tenaga, ia secara fizikal melepaskan mekanisme trip pemutus litar—tindakan mekanikal yang sama yang berlaku semasa peristiwa arus lebih. Ini bermakna anda tidak bergantung pada elektronik yang kompleks; anda memanfaatkan teknologi elektromekanikal terbukti yang telah melindungi kemudahan selama beberapa dekad.

Rangka Kerja Pemilihan & Pemasangan Trip Shunt Lengkap

Sekarang anda faham apa pemutus litar trip shunt ialah dan why ia penting, mari kita telusuri proses kejuruteraan untuk menentukan, memasang dan menyelenggara peranti ini dengan betul. Ikuti rangka kerja empat langkah ini untuk memastikan sistem anda memberikan perlindungan kecemasan yang boleh dipercayai.

Langkah 1: Kenal Pasti Aplikasi Yang Memerlukan Perlindungan Trip Shunt

Tidak setiap litar memerlukan pemutus litar trip shunt—tetapi sesetengah aplikasi sememangnya memerlukannya. Inilah cara untuk membuat panggilan:

Aplikasi Yang Ditetapkan Kod (Tidak Boleh Dirunding):

- Bilik Peralatan Elektrik: NEC Artikel 110.26(C)(3) memerlukan cara pemutusan pada titik masuk untuk ruang tertentu dengan peralatan besar. Apabila anda tidak boleh meletakkan pemutus standard berhampiran pintu, pemutus litar trip shunt yang dikawal oleh butang jauh memenuhi keperluan ini.

- Pengawal Pam Kebakaran: NEC Artikel 695.4(B) membenarkan pemutus litar trip shunt untuk pemutusan pam kebakaran apabila diaktifkan oleh sistem penggera kebakaran bangunan.

- Sistem Penindasan Tudung Dapur Komersial: Apabila sistem penindasan kebakaran diaktifkan, kuasa kepada peralatan memasak mesti dipotong untuk mengelakkan penyalaan semula. Pemutus litar trip shunt berintegrasi terus dengan kawalan penindasan.

Aplikasi Berisiko Tinggi (Sangat Disyorkan):

- Bilik Mesin Lif: Keupayaan pemutusan jauh melindungi pekerja penyelenggaraan dan membolehkan anggota bomba mengawal kuasa lif semasa kecemasan.

- Pusat Data & Bilik Pelayan: Mengintegrasikan pemutus litar trip shunt dengan pengesanan kebakaran amaran awal (sistem VESDA) atau pengesanan kebocoran air membolehkan penutupan serta-merta sebelum kerosakan peralatan kritikal.

- Jentera Perindustrian dengan Henti Kecemasan: Mana-mana barisan pengeluaran di mana keselamatan pekerja bergantung pada pemotongan kuasa serta-merta—mesin CNC, sistem penghantar, sel robotik—harus menggunakan perlindungan trip shunt yang terikat pada litar E-stop.

- Lokasi Berbahaya: Dalam persekitaran dengan gas atau habuk mudah terbakar (lokasi Kelas I/II/III), menggandingkan pemutus litar trip shunt dengan sistem pengesanan gas menyediakan lapisan keselamatan kritikal.

专业提示: Jangan kelirukan “pemutusan kecemasan” dengan “kawalan hidup/mati biasa.” Pemutus litar trip shunt adalah untuk senario pemotongan kuasa kecemasan di mana keselamatan adalah yang terpenting. Untuk penutupan rutin, gunakan kontaktor standard atau penghidup motor. Trip shunt ialah barisan pertahanan terakhir anda, bukan suis harian anda.

Langkah 2: Saiz Voltan Gegelung Shunt dengan Betul (Kesilapan Pemasangan #1)

Di sinilah kebanyakan projek menjadi salah—dan di mana anda tidak boleh melakukan kesilapan.

Gegelung shunt memerlukan sumber voltan luaran untuk memberi tenaga dan tersandung pemutus litar. Voltan ini mesti sepadan dengan litar kawalan anda. Jika ini salah, trip shunt anda tidak akan tersandung apabila anda memerlukannya.

Voltan Gegelung Shunt Biasa:

- 24V DC: Paling biasa dalam automasi bangunan moden, panel penggera kebakaran dan PLC perindustrian. Voltan rendah bermakna pemasangan yang lebih selamat dan penyepaduan yang lebih mudah dengan sistem kawalan.

- 120V AC: Standard dalam bangunan komersial Amerika Utara di mana kuasa kawalan mudah didapati daripada litar lampu atau kemudahan.

- 240V AC: Digunakan dalam tetapan perindustrian atau apabila litar kawalan memperoleh kuasa daripada panel 240V.

Peraturan Pemilihan Kritikal:

- Padankan Voltan Sumber Kawalan: Jika panel penggera kebakaran anda mengeluarkan 24V DC, nyatakan gegelung shunt 24V DC. Jangan cuba menggunakan transformer atau penukar untuk “membuatnya berfungsi”—anda menambah titik kegagalan pada litar keselamatan nyawa.

- Sahkan Keperluan Arus Masuk: Gegelung shunt menarik arus masuk yang ketara apabila mula-mula diberi tenaga (selalunya 3-5x keadaan mantap). Pastikan bekalan kuasa dan pendawaian litar kawalan anda boleh mengendalikan lonjakan ini. Pendawaian kawalan bersaiz kecil ialah mod kegagalan biasa.

- Semak Penggunaan Kuasa Gegelung: Kebanyakan gegelung pirau dinilai untuk tugas berterusan, tetapi ada yang untuk tugas berselang (direka untuk diaktifkan seketika). Semak helaian data pengeluar untuk mengesahkan gegelung boleh kekal diaktifkan sepanjang senario kecemasan anda tanpa terlalu panas.

- Memahami Masa Trip: Mekanisme trip pirau berkualiti beroperasi dalam 50-100 milisaat. Jika aplikasi anda memerlukan masa trip yang lebih cepat atau lebih perlahan, sahkan spesifikasi ini sebelum membeli.

专业提示: Sentiasa pesan aksesori trip pirau daripada pengeluar pemutus litar asal. Kit pirau pihak ketiga mungkin muat secara fizikal, tetapi perbezaan halus dalam rintangan gegelung, pemasangan, atau geometri bar trip boleh menyebabkan operasi yang tidak boleh dipercayai. Menjimatkan RM50 pada kit pirau generik tidak berbaloi dengan liabiliti apabila ia gagal semasa kecemasan sebenar.

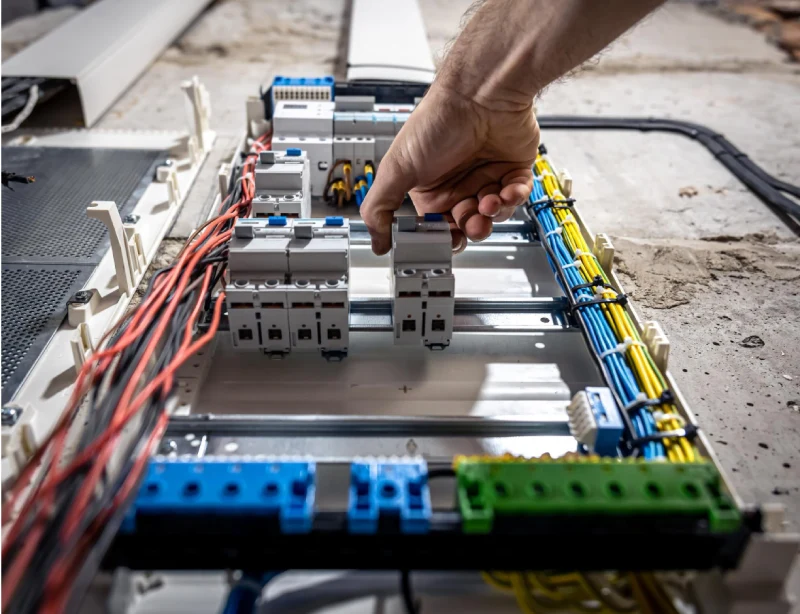

Langkah 3: Mengintegrasikan dengan Sistem Kecemasan (Pendawaian dan Logik Kawalan)

Sekarang tiba pelaksanaan praktikal—menyambungkan pemutus trip pirau anda ke sistem kecemasan yang akan mengaktifkannya.

Prinsip Pendawaian Asas:

Gegelung pirau mempunyai dua terminal (seperti mana-mana elektromagnet). Apabila anda mengenakan voltan merentasi terminal ini, pemutus akan trip. Litar kawalan diasingkan sepenuhnya daripada litar kuasa utama—anda bekerja dengan pendawaian voltan rendah atau voltan kawalan, bukan bahagian beban arus tinggi.

Senario Integrasi Tipikal:

Integrasi Penggera Kebakaran: Panel penggera kebakaran anda mempunyai output geganti (sesentuh kering atau output voltan). Sambungkan salah satu output ini untuk mengaktifkan gegelung pirau apabila pengesan asap diaktifkan di zon tertentu. Contoh: Apabila pengesan asap bilik elektrik trip, panel penggera kebakaran menutup geganti, menghantar 24V DC ke gegelung pirau, yang mentripkan pemutus dan menyahaktifkan bilik.

Integrasi Hentian Kecemasan (E-Stop): Butang E-stop industri biasanya menggunakan sesentuh normally-closed (NC) secara bersiri. Apabila E-stop ditekan, litar terbuka. Untuk aplikasi trip pirau, sambungkan litar E-stop supaya menekan butang mengaktifkan gegelung pirau. Ini sering memerlukan geganti perantara untuk menukar logik NC kepada isyarat aktifkan-untuk-trip.

Integrasi Sistem Pengurusan Bangunan (BMS): Sistem BMS moden boleh mengaktifkan trip pirau melalui output digital. Programkan BMS anda untuk memantau keadaan (suhu, kelembapan, penghunian, jadual masa) dan mencetuskan trip pirau seperti yang diperlukan. Ini membolehkan strategi kawalan yang canggih seperti memutuskan sambungan beban yang tidak penting secara automatik semasa peristiwa penggera kebakaran sambil memastikan lampu kecemasan diaktifkan.

Pertimbangan Pendawaian Utama:

- Gunakan Litar Penyeliaan: Untuk aplikasi keselamatan nyawa, gunakan litar kawalan yang dipantau yang mengesan wayar putus atau pintas. Litar yang diselia secara berterusan mengesahkan integriti litar dan membunyikan penggera jika pendawaian trip pirau terjejas.

- Sediakan Override Manual: Pasang butang ujian trip pirau manual tempatan (sebagai tambahan kepada pencetus automatik) supaya juruteknik boleh menguji mekanisme semasa pentauliahan dan penyelenggaraan.

- Wayar untuk Operasi Selamat-Gagal: Reka bentuk logik kawalan anda supaya kehilangan kuasa kawalan tidak secara tidak sengaja mentripkan pemutus. Trip pirau harus memerlukan pengaktifan aktif, bukan kehilangan isyarat pasif.

专业提示: Labelkan segala-galanya dengan teliti. Litar trip pirau yang salah dilabel atau kurang didokumentasikan akhirnya akan dikalahkan oleh juruteknik yang bermaksud baik yang tidak memahami interlock keselamatan. Gunakan label yang jelas dan kekal seperti “KAWALAN TRIP PIRAU—JANGAN PUTUS SAMBUNG” di semua titik penamatan.

Langkah 4: Uji, Tauliah, dan Selenggara Sistem

Pemasangan hanyalah separuh daripada pertempuran. Sistem trip pirau yang tidak pernah diuji adalah rasa selamat palsu.

Pentauliahan Awal:

- Ujian Bangku: Sebelum mengaktifkan beban, uji mekanisme trip pirau dengan isyarat kawalan. Sahkan pemutus trip dengan bersih dan menetapkan semula dengan betul.

- Ujian Sistem Bersepadu: Dengan sistem hidup, cetuskan penggera kebakaran, E-stop, atau isyarat BMS dan sahkan pemutus trip seperti yang direka. Dokumentasikan masa trip dan prosedur tetapan semula.

- Ujian Beban: Kendalikan litar di bawah keadaan beban biasa, kemudian cetuskan trip pirau. Pastikan pemutus boleh mengganggu arus beban dengan bersih (tiada kimpalan sesentuh atau kegagalan untuk trip).

Penyelenggaraan Berterusan:

- Ujian Fungsi Bulanan: Aktifkan mekanisme trip pirau sekurang-kurangnya setiap bulan. Ini menghalang genangan mekanikal dan mengesahkan litar kawalan kekal berfungsi.

- Ujian Sistem Penuh Tahunan: Sekali setahun, uji integrasi lengkap—cetuskan isyarat kecemasan sebenar (dengan penyelarasan dengan kakitangan keselamatan) dan sahkan operasi yang betul dari sensor ke trip pemutus.

- Pemeriksaan Visual: Periksa kakisan pada terminal gegelung pirau, pendawaian longgar, atau kerosakan fizikal pada mekanisme trip. Ini adalah peranti mekanikal yang tertakluk kepada haus.

专业提示: Pemutus trip pirau memerlukan tetapan semula manual selepas trip. Ini adalah ciri, bukan pepijat. Tetapan semula manual memaksa orang yang berkelayakan untuk menyiasat punca trip dan mengesahkan bahaya telah diselesaikan sebelum mengaktifkan semula. Jangan sekali-kali memintas langkah keselamatan ini dengan mekanisme tetapan semula jauh—kod tidak membenarkannya, dan insurans anda tidak akan melindungi anda jika anda melakukannya.

Contoh Aplikasi Dunia Sebenar

Mari kita asas ini dalam senario praktikal:

Senario 1: Pusat Data Korporat

Sebuah syarikat perkhidmatan kewangan mengendalikan pusat data misi kritikal. Mereka memasang pengesanan asap awal (VESDA) dan sensor kebocoran air di bawah lantai yang dinaikkan. Kedua-dua sistem terikat ke pemutus trip pirau pada suapan panel pelayan utama. Apabila VESDA mengesan zarah asap, trip pirau memotong kuasa serta-merta—melindungi anggota bomba dan menghalang peralatan bertenaga daripada meningkatkan kebakaran. Jumlah kerosakan sistem: RM1K. Tanpa trip pirau: berpotensi RM5M+ dan kehilangan data lengkap.

Senario 2: Makmal Penyelidikan Universiti

Makmal kimia menggunakan gas termampat dan peralatan analisis voltan tinggi. Pengesan kebocoran gas kecemasan berintegrasi dengan pemutus trip pirau pada semua panel elektrik. Apabila paras metana melebihi ambang, trip pirau menyahaktifkan makmal, menghapuskan sumber pencucuhan. Tetapan semula manual selepas pengudaraan memastikan keselamatan sebelum pengaktifan semula.

Senario 3: Loji Pembuatan

Sebuah kedai fabrikasi logam mempunyai mesin CNC dengan litar E-stop. Pemutus litar utama setiap mesin mempunyai trip pirau yang terikat pada rantai E-stop. Apabila pengendali menekan E-stop, trip pirau memotong kuasa ke mesin dalam masa 100ms—lebih cepat daripada bergantung pada kawalan dalaman mesin. Lapisan keselamatan berlebihan ini telah menghalang pelbagai kecederaan remuk.

Intinya: Trip Pirau = Perlindungan Proaktif

Dengan mengikuti rangka kerja empat langkah ini, anda akan mencapai:

- ✓ Keselamatan Nyawa yang Dipertingkatkan: Pemotongan kuasa jauh semasa kebakaran, banjir, atau kecemasan melindungi responden pertama dan penghuni

- ✓ Pematuhan Kod: Memenuhi keperluan NEC, IEC, dan tempatan untuk infrastruktur kritikal dan ruang awam

- ✓ Fleksibiliti Operasi: Mengintegrasikan perlindungan elektrik dengan automasi bangunan, penggera kebakaran, dan sistem keselamatan

- ✓ Liabiliti Dikurangkan: Menunjukkan usaha wajar dalam kesiapsiagaan kecemasan dan reka bentuk sistem keselamatan

Pemutus litar trip pirau mengubah sistem elektrik anda daripada perlindungan pasif kepada keselamatan aktif. Ia adalah jambatan antara “pemutus akan trip jika terdapat kerosakan” dan “pemutus akan trip apabila bahaya dikesan.” Dalam aplikasi di mana saat penting—dan ia sentiasa berlaku dalam kecemasan—keupayaan ini boleh menyelamatkan nyawa.

Jangan tunggu panggilan rapat untuk menaik taraf sistem keselamatan anda. Jika kemudahan anda mempunyai bilik peralatan elektrik, sistem penindasan kebakaran, hentian kecemasan, atau proses berbahaya, perlindungan trip pirau bukanlah pilihan—ia adalah penting. Sama ada anda memasang semula MCB sedia ada, MCCB, atau pemutus ACB atau menentukan pemasangan baharu, pastikan reka bentuk anda termasuk lapisan keselamatan kritikal ini.

Perlukan bantuan menentukan penyelesaian trip pirau yang betul untuk aplikasi anda? Jurutera aplikasi kami mempunyai pengalaman 15+ tahun mengintegrasikan pemutus trip pirau merentasi kemudahan komersial, perindustrian dan institusi. Hubungi kami untuk pengesahan keserasian voltan, semakan reka bentuk litar kawalan, atau penyelesaian OEM tersuai. Sistem keselamatan anda hanya sekuat pautan terlemahnya—mari pastikan perlindungan trip pirau bukan milik anda.