Kabinet elektrik bilik pelayan anda lebih padat daripada kereta api bawah tanah semasa waktu puncak. MCB, RCCB, pelindung lonjakan, blok terminal—setiap milimeter rel DIN 35mm itu dipenuhi. Kemudian juruaudit keselamatan kebakaran masuk, menunjuk ke panel anda, dan bertanya soalan yang anda elakkan selama ini: “Di mana sistem pemadam kebakaran?”

Anda menjeling ke ruang yang sempit itu. Tiada ruang untuk silinder pemadam tradisional. Bajet tidak meliputi sistem gas berpaip. Dan memikirkan air berdekatan dengan litar 480V hidup membuatkan perut anda memulas.

Inilah penyelesaian yang anda tidak tahu wujud: peranti pemadam kebakaran selebar 18mm yang dipasang terus pada rel DIN anda, diaktifkan secara automatik apabila suhu mencapai 170°C, dan membanjiri kabinet dengan aerosol pembunuh api dalam masa kurang daripada 6 saat. Tidak memerlukan kuasa luaran. Tiada paip. Tiada kompromi pada ruang.

Selamat datang ke penjana aerosol pepejal rel DIN 1P—pemadam kebakaran yang sesuai di tempat yang tiada apa-apa lagi boleh muat.

Apakah Penjana Aerosol Pepejal Rel DIN 1P?

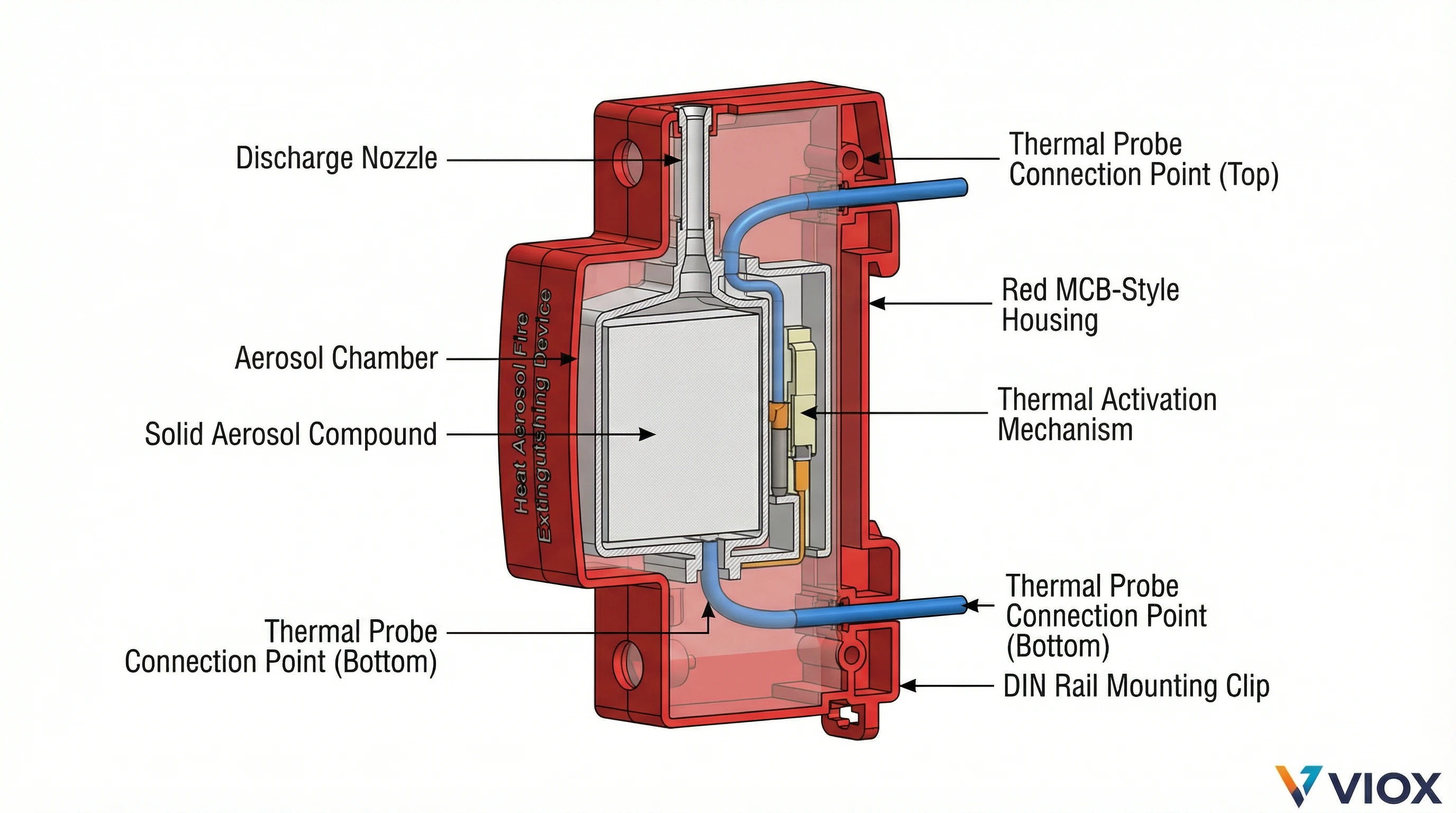

A Penjana aerosol pepejal rel DIN 1P ialah unit pemadam kebakaran padat dan kendiri yang direka untuk melindungi ruang elektrik tertutup kecil sehingga 0.1 m³—kira-kira volum panel pemutus litar standard 600mm × 400mm × 400mm.

Penandaan “1P” memberitahu anda segala-galanya tentang faktor bentuknya: satu kedudukan kutub. Lebarnya kira-kira 18mm, jejak yang sama seperti pemutus litar miniatur kutub tunggal standard. Anda boleh memasangnya secara literal pada rel DIN betul-betul di sebelah MCB dan kontaktor anda.

Cara Ia Berfungsi: Kimia Pepejal, Tanpa Tekanan

Tidak seperti alat pemadam api tradisional yang bergantung pada silinder bertekanan atau rangkaian penghantaran berpaip, penjana aerosol pepejal kekal tidak bertekanan sehingga saat pengaktifan.

Di dalam perumah yang tertutup rapat terdapat sebatian propelan pepejal—biasanya berasaskan kalium. Anggap ia seperti suar kimia terkawal. Apabila sensor haba mengesan suhu kabinet sekitar 170°C (ambang pengaktifan biasa), ia mencetuskan tindak balas eksotermik. Sebatian pepejal terbakar secara terkawal, menghasilkan:

- Zarah aerosol ultra halus (1-2 mikron)—terutamanya garam dan karbonat kalium

- Gas lengai (nitrogen, CO₂)—yang menekan nyahcas dan sedikit mencairkan oksigen

Tindak balas selesai dalam masa kurang daripada 6 saat. Awan aerosol membanjiri volum yang dilindungi, menyerang api pada peringkat molekul.

Spesifikasi utama sepintas lalu:

| Parameter | Nilai Tipikal |

| Lebar | 18mm (modular 1P) |

| Melekap | Rel DIN 35mm (EN 60715) |

| Pengaktifan | Terma (tidak memerlukan kuasa) |

| Suhu pencetus | 170°C |

| Masa nyahcas | ≤ 6 saat |

| Jisim agen | 10g (melindungi ~0.1 m³) |

| Jangka hayat perkhidmatan | Sehingga 10 tahun |

| Julat operasi | -50°C hingga +90°C |

专业提示: Suhu pengaktifan 170°C adalah kritikal. Ia cukup tinggi untuk mengelakkan pencetus palsu dalam panel yang kurang pengudaraan (walaupun dalam keadaan ambien 50°C), tetapi cukup rendah untuk menangkap kebakaran elektrik 抵达 plastik menyala sepenuhnya dan mengeluarkan wasap toksik.

Mengapa Aerosol untuk Kabinet Elektrik? “Kelebihan Tanpa Paip”

Kabinet elektrik menimbulkan masalah pemadaman kebakaran yang tidak dapat diselesaikan oleh kaedah tradisional dengan elegan. Ia tertutup, padat dengan komponen bertenaga, dan selalunya terletak di tempat yang aksesnya terhad.

Masalah: Pemadaman Tradisional Tidak Sesuai

Air dan buih? Konduktif, menghakis, malapetaka. Pengaktifan pemercik mungkin memadamkan api, tetapi ia juga akan memusnahkan setiap peralatan elektronik di dalam panel—dan mungkin panel di sebelahnya.

Sistem gas (CO₂, FM-200, Novec)? Berkesan, tetapi ia memerlukan:

- Silinder penyimpanan bertekanan (mengambil ruang lantai yang berharga)

- Paip pengedaran (mahal untuk dipasang, memerlukan penembusan panel)

- Pemantauan tekanan (overhead penyelenggaraan)

- Kos pendahuluan yang ketara

Untuk satu kabinet elektrik 0.5 m³, menentukan sistem gas berpaip adalah seperti mengupah jentolak untuk menggali lubang pasu bunga. Mampu secara teknikal? Pasti. Munasabah dari segi ekonomi? Sama sekali tidak.

Alat pemadam api mudah alih berdekatan? Hanya berguna jika:

- Seseorang hadir apabila kebakaran bermula

- Mereka dilatih untuk menggunakannya

- Mereka sanggup mendekati panel elektrik yang terbakar

- Mereka boleh membuka pintu kabinet tanpa terkena api

Semoga berjaya dengan keempat-empatnya pada pukul 2 pagi pada hari Ahad.

Penyelesaian Aerosol: Padat, Autonomi, Selamat Elektrik

Penjana aerosol pepejal menyelesaikan masalah ini dengan pendekatan yang berbeza secara asas:

1. Pemadaman tidak konduktif elektrik

Agen aerosol direka secara eksplisit untuk tidak konduktif elektrik (mengikut ISO 15779). Ia tidak akan memendekkan litar atau merosakkan elektronik sensitif. Sebaik sahaja api padam dan aerosol mendap, peralatan selalunya boleh meneruskan operasi selepas pemeriksaan dan pembersihan—tiada penggantian borong.

2. Tiada infrastruktur diperlukan

Setiap penjana adalah serba lengkap. Prosedur pemasangan:

- Pasangkannya pada rel DIN (pemasangan klip tanpa alat)

- Lalukan kabel probe terma ke lokasi strategik

- Selesai

Tiada saluran paip. Tiada bekas tekanan. Tiada bilik penindasan khusus. Masa pemasangan diukur dalam minit, bukan hari.

3. Banjir penuh untuk ruang tertutup

Zarah aerosol kekal tergantung selama beberapa minit, mewujudkan atmosfera penindasan kebakaran di seluruh isipadu kabinet. Walaupun api tersembunyi di sebalik berkas kabel atau blok terminal, aerosol tetap mencapainya.

Alat pemadam tradisional memerlukan garis penglihatan. Aerosol tidak peduli di mana api berada.

4. Operasi autonomi—tiada kuasa, tiada masalah

Sistem pengaktifan terma berfungsi sama ada bangunan mempunyai kuasa atau tidak. Penjana tidak peduli sama ada pukul 3 petang pada hari Selasa atau 3 pagi pada Hari Krismas. Apabila bahagian dalam kabinet mencapai 170°C, penindasan diaktifkan. Tiada bateri. Tiada litar kawalan. Tiada kebergantungan.

专业提示: Untuk aplikasi kritikal, anda boleh menyepadukan output penggera sesentuh kering tambahan ke BMS anda. Penjana masih beroperasi secara bebas, tetapi pemberitahuan jauh membolehkan anda menghantar penyelenggaraan sebelum kerosakan peralatan menjadi meluas.

Bagaimana Penindasan Kebakaran Aerosol Pepejal Sebenarnya Berfungsi

Jika anda tidak pernah menemui teknologi aerosol pepejal, mekanismenya kedengaran hampir seperti sci-fi: sebatian pepejal berubah menjadi awan pembunuh api dalam beberapa saat, dengan penyimpanan tanpa tekanan sifar. Berikut ialah kimianya, tanpa gebu pemasaran.

Tindak Balas Kimia: Dari Pepejal ke Aerosol

Di dalam penjana terdapat kartrij yang tertutup rapat yang diisi dengan propelan pepejal—biasanya sebatian berasaskan kalium seperti kalium nitrat yang dicampur dengan bahan api organik dan pengikat. Apabila sensor terma tersandung pada 170°C, ia memulakan tindak balas eksotermik terkawal.

Propelan tidak meletup. Ia terbakar, sama seperti suar yang terbakar perlahan atau bom tangan asap. Pembakaran ini menghasilkan dua output kritikal:

- Zarah aerosol ultra halus (1-2 mikron diameter)—terutamanya garam kalium dan karbonat

- Gas lengai (nitrogen dan CO₂)—yang memberikan tekanan dalaman untuk memecahkan membran pelepasan dan menyebarkan aerosol

Keseluruhan tindak balas selesai dalam masa kurang daripada 6 saat. Membran pelepasan pecah, dan awan putih tebal membanjiri isipadu yang dilindungi.

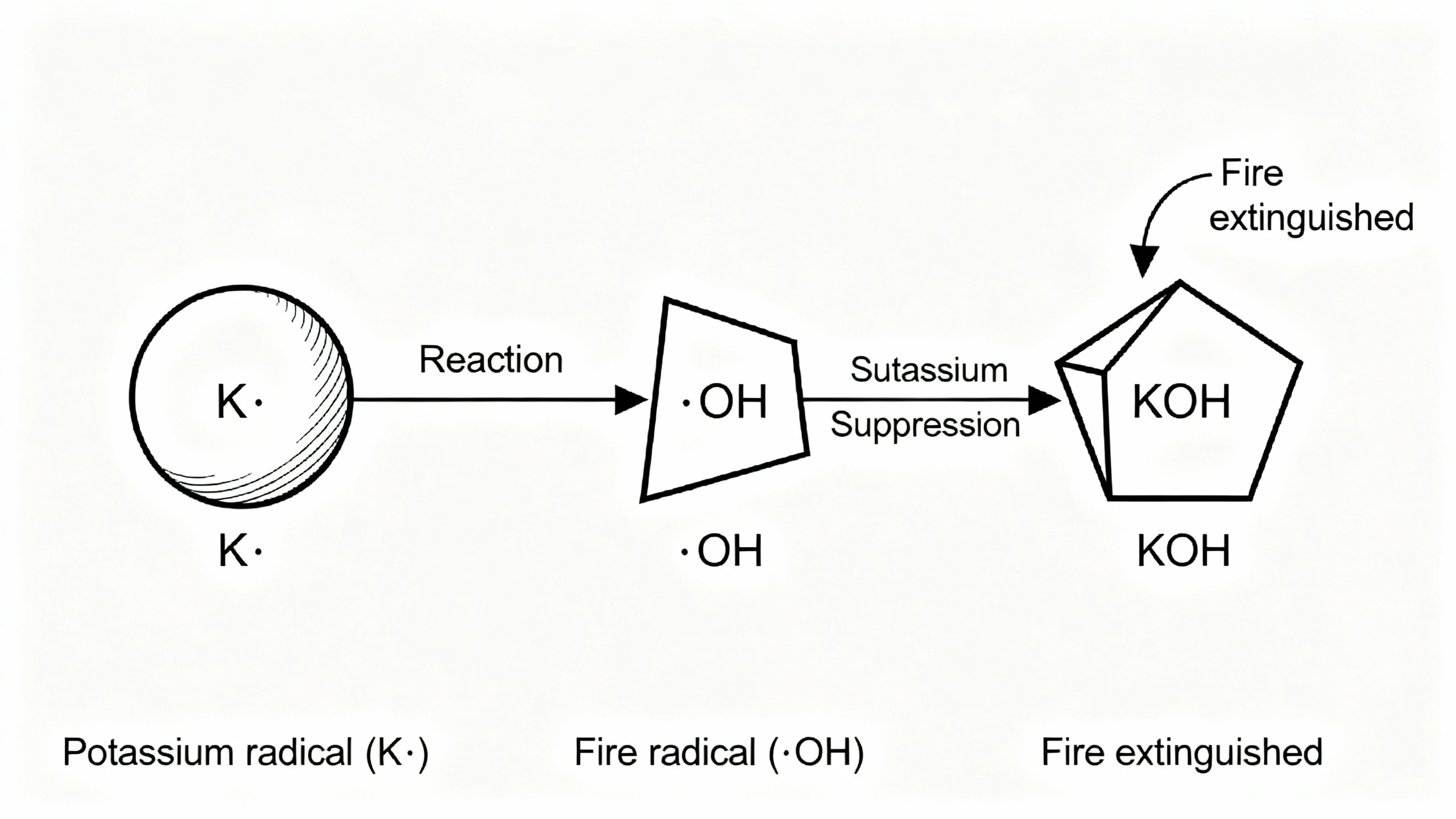

Mekanisme Penindasan: Gangguan Rantai Kimia

Penindasan aerosol menyerang api pada dua peringkat—tetapi mekanisme utama adalah kimia tulen.

Utama: Pembersihan radikal bebas (perencatan kimia)

Api bukan sekadar “bahan api + oksigen + haba.” Ia adalah tindak balas rantai yang melibatkan radikal bebas—serpihan molekul yang sangat reaktif seperti H·, OH·, dan O·. Radikal ini menyebarkan pembakaran dengan memecahkan molekul bahan api dan menjana lebih banyak radikal dalam gelung berterusan.

Zarah kalium daripada aerosol memintas dan mengikat dengan radikal penting pembakaran ini, membentuk sebatian yang stabil dan tidak reaktif:

- K· + OH· → KOH (kalium hidroksida)

- K· + O· → KO (kalium oksida)

Dengan rantai radikal terputus, pembakaran tidak dapat mengekalkan dirinya. Api padam—walaupun bahan api dan oksigen masih ada.

Ini pada asasnya berbeza daripada:

- Melemaskan (yang mengecualikan oksigen)

- Menyejukkan (yang menghilangkan haba)

Aerosol menyerang kimia api pada peringkat molekul. Itulah sebabnya ia memerlukan jisim agen yang jauh lebih sedikit daripada sistem CO₂ atau gas lengai.

Sekunder: Penyerapan haba dan pencairan oksigen

Awan aerosol juga menyerap haba sinaran daripada api, mengurangkan tenaga pembakaran. Gas lengai (N₂, CO₂) yang dihasilkan semasa tindak balas mencairkan kepekatan oksigen sebanyak kira-kira 2-3%, tidak cukup untuk menjadi tidak selamat bagi orang ramai, tetapi cukup untuk menjadikan penyalaan semula lebih sukar.

Penggantungan dan Pencegahan Penyalaan Semula: “Atmosfera Penindasan”

Tidak seperti CO₂ (yang hilang dengan cepat) atau air (yang mengalir keluar), zarah aerosol kekal tergantung di udara selama beberapa minit. Ini mewujudkan apa yang saya panggil “Atmosfera Penindasan”—awan pelindung yang berlarutan yang menghalang penyalaan semula semasa kabinet menyejuk.

Walaupun komponen yang membara cuba menyala semula 60 saat selepas penindasan awal, aerosol masih ada, bersedia untuk menyerang sebarang radikal bebas baharu.

专业提示: Selepas pelepasan, ventilasi kawasan tersebut sebelum masuk semula. Walaupun aerosol tidak toksik (diluluskan untuk ruang yang biasanya diduduki setiap EPA SNAP), persekitaran selepas pelepasan akan mempunyai pengurangan penglihatan dan zarah halus di udara. Pakai topeng habuk semasa pembersihan dan pemeriksaan—paru-paru anda akan berterima kasih kepada anda.

Di Mana Penjana Aerosol 1P Sebenarnya Digunakan

Peranti ini dibina khas untuk ruang elektrik tertutup kecil di mana kebakaran boleh meningkat dalam beberapa saat tetapi penindasan tradisional tidak praktikal atau mustahil.

1. Kabinet pengagihan elektrik dan suis gear

Panel MCCB, papan suis voltan rendah, pusat kawalan motor. Di mana-mana sahaja anda mempunyai komponen bertenaga dalam kotak logam tertutup.

2. Rak pelayan dan peralatan telekom

Pusat data, stesen pangkalan menara sel, nod pengkomputeran tepi. Elektronik berketumpatan tinggi di mana air bukan permulaan dan ruang adalah premium.

3. Inverter solar dan penutup penyimpanan bateri

Inverter fotovolta, kabinet BESS, stesen pengecasan EV. Peralatan bertenaga tinggi dalam pemasangan luar atau separa luar di mana akses terhad dan suhu ambien berubah dengan liar.

4. Panel kawalan industri

Kabinet PLC, penutup VFD, peralatan SCADA di kilang, kilang penapis dan loji pemprosesan. Kawalan misi kritikal yang tidak mampu mengalami masa henti.

5. Stesen transformer kecil dan saluran kabel

Ruang transformer step-down, kotak sambungan kabel, peralatan ruang bawah tanah. Ruang terkurung di mana tindak balas kebakaran manual tertangguh atau berbahaya.

Persamaan yang ketara? Isipadu tertutup di bawah 1 m³, peralatan kritikal, dan tiada toleransi untuk kerosakan air. Jika bajet pemadaman kebakaran anda terhad dan kabinet anda kecil, penjana aerosol selalunya merupakan satu-satunya penyelesaian kos efektif yang benar-benar berkesan.

Menentukan Saiz Penjana Aerosol Anda: Kaedah 3 Langkah

Memilih penjana aerosol yang betul bergantung kepada tiga pengiraan dan satu keputusan pemasangan. Berikut ialah kaedahnya.

Langkah 1: Kira Isipadu Dalaman Kabinet

Ukur dimensi dalaman kepungan anda—bukan dimensi label luaran. Tolak ketebalan dinding (biasanya 1.5-2mm untuk kabinet logam lembaran standard).

Formula: Isipadu (m³) = Lebar (m) × Tinggi (m) × Dalam (m)

Contoh: Kabinet 600mm × 400mm × 250mm (dimensi luaran):

Dalaman: ~596mm × 396mm × 246mm

0.596 × 0.396 × 0.246 = 0.058 m³

Bundarkan ke atas kepada 0.06 m³ untuk margin keselamatan.

Langkah 2: Guna Ketumpatan Reka Bentuk

Penjana aerosol ditentukan saiznya mengikut jisim agen per isipadu terlindung. Standard industri untuk perlindungan banjir total dalam kabinet elektrik adalah lebih kurang 100 g/m³.

Formula: Jisim agen yang diperlukan (g) = Isipadu (m³) × Ketumpatan reka bentuk (100 g/m³)

Untuk contoh 0.06 m³ kita: 0.06 × 100 = 6 g

Jadi penjana 10g (seperti VIOX QRR0.01G/S) menyediakan liputan yang mencukupi dengan margin keselamatan yang baik (~67% melebihi minimum).

Langkah 3: Ambil Kira Halangan dan Aliran Udara

Jika kabinet anda mempunyai berkas kabel yang padat, sekatan pepejal, atau peredaran udara dalaman yang lemah, anda perlu mengimbangi:

- Pilihan A: Berbilang penjana yang lebih kecil. Letakkan unit untuk meliputi zon yang berbeza. Contohnya, dua penjana 10g untuk kabinet 0.15 m³ dengan sekatan tengah yang pepejal.

- Pilihan B: Tingkatkan jisim agen sebanyak 20-30%. Gunakan unit tunggal yang lebih besar untuk mengatasi cabaran pengagihan.

- Pilihan C: Penempatan prob strategik. Letakkan prob terma berhampiran kawasan yang diketahui terdedah kepada kebakaran: bar bas, transformer, terminal arus tinggi, titik masuk kabel.

Langkah 4: Letakkan Prob Terma Seperti Seorang Profesional

Kebanyakan penjana 1P dilengkapi dengan prob terma dwi (atas dan bawah). Berikut ialah tempat untuk meletakkannya:

- Prob atas: Pasang berhampiran titik tertinggi di mana gas panas berkumpul—biasanya bumbung kabinet, betul-betul di atas bar bas atau komponen berkuasa tinggi.

- Prob bawah: Letakkan berhampiran sumber pencucuhan yang berpotensi di dasar—transformer, blok terminal beban tinggi, kelenjar masuk kabel.

Udara panas naik, tetapi kerosakan elektrik boleh berpunca dari mana-mana sahaja. Prob dwi memastikan liputan tanpa mengira lokasi kebakaran.

专业提示: Jika kabinet anda mempunyai “titik panas” yang diketahui—katakan, transformer yang beroperasi pada 80°C di bawah beban biasa—letakkan prob dalam jarak 10cm daripadanya. Jangan bergantung pada perolakan sahaja untuk membawa haba ke sensor yang jauh. Pengesanan terus sentiasa lebih pantas.

Jadual Saiz Rujukan Pantas

| Isipadu Kabinet | Jisim Agen Minimum | Produk yang Disyorkan |

| Sehingga 0.1 m³ | 10g | VIOX QRR0.01G/S (1P) |

| 0.1 – 0.3 m³ | 30g | Unit rel yang lebih besar atau 3× unit 10g |

| 0.3 – 1.0 m³ | 100g | Aerosol industri (bukan rel DIN) |

| Lebih 1.0 m³ | Tersuai | Sistem kejuruteraan atau penindasan gas |

Untuk kabinet melebihi 1.0 m³: Pertimbangkan sistem aerosol kejuruteraan atau penindasan agen bersih konvensional. Penjana rel DIN dioptimumkan untuk kecil kepungan di mana kaedah tradisional tidak masuk akal dari segi ekonomi.

Pemasangan: Lebih Mudah Daripada Memasang MCB

Memasang penjana aerosol 1P adalah lebih mudah daripada yang anda jangkakan. Jika anda boleh memasang pemutus litar, anda boleh memasang salah satu daripadanya.

Pemasangan Perkakasan (5 minit)

- Pasang penjana pada rel DIN 35mm TS35

Klip berpegas bersepadu terus terpasang pada rel. Tidak memerlukan alat. Tidak memerlukan pengikat. Hanya tekan dan klik. - Laluan kabel probe terma

Kabel probe standard adalah sepanjang 10cm. Panjang tersuai sehingga 50cm tersedia jika anda perlu mencapai titik panas tertentu. Lalukan satu probe ke bahagian atas kabinet, satu lagi ke bahagian bawah (atau berhampiran komponen berisiko tinggi yang diketahui). - Pemasangan alternatif (jika ruang rel DIN terhad)

Lapisan pelekat 3M tersedia sebagai pilihan tersuai. Bersihkan permukaan pemasangan, kupas, lekatkan. Selesai.

Pentauliahan (0 minit)

Tiada pentauliahan. Tiada pengaturcaraan. Tiada sambungan elektrik.

Setelah dipasang, penjana segera beralih ke mod siap sedia operasi. Ia memantau suhu secara berterusan melalui elemen terma pasif—tiada bateri, tiada bekalan kuasa, tiada kebergantungan.

Pengaktifan dan Penggantian

Pengaktifan adalah automatik dan tidak boleh diubah. Apabila suhu kabinet mencapai 170°C, unit akan dinyahcas. Selepas nyahcas, unit mesti diganti—ia adalah peranti guna tunggal yang direka untuk satu peristiwa pengaktifan.

Anggap ia seperti beg udara kereta: anda berharap anda tidak memerlukannya, tetapi jika anda memerlukannya, ia berfungsi sekali sahaja dan kemudian diganti.

Pertimbangan Operasi:

- Direka untuk ruang tertutup yang biasanya tidak diduduki

- Aerosol tidak toksik dan selamat untuk alam sekitar (ODP/GWP sifar)

- Nyahcas menghasilkan awan partikel tumpat yang mengurangkan penglihatan buat sementara waktu

- Penutup hendaklah ditutup dengan munasabah untuk mengekalkan kepekatan penindasan

- Selepas nyahcas, berikan pengudaraan selama beberapa minit sebelum masuk semula

- Peralatan biasanya boleh diperiksa dan dikembalikan kepada perkhidmatan mengikut protokol selepas kebakaran standard

专业提示: Tandakan tarikh pemasangan pada perumah penjana dengan pen penanda kekal. Walaupun jangka hayat perkhidmatan dinilai sehingga 10 tahun, anda perlu menjejaki usia untuk perancangan penggantian. Tetapkan peringatan kalendar pada tahun ke-9.

Piawaian & Pensijilan: Perkara yang Perlu Dicari

Penindasan kebakaran aerosol ialah teknologi yang dikawal selia. Apabila menentukan penjana rel DIN 1P, sahkan ia memenuhi piawaian ini—jangan hanya menerima kata-kata pengilang.

Piawaian Amerika Utara

NFPA 2010 (Sistem Pemadam Api Aerosol Tetap)

Piawaian pemasangan utama di Amerika Utara. Mentakrifkan keperluan reka bentuk, pemasangan, ujian dan penyelenggaraan. Jika anda bekerja dengan AHJ (ketua bomba, penaja jamin insurans, pemeriksa bangunan) yang berpangkalan di AS, pematuhan NFPA 2010 selalunya tidak boleh dirunding.

UL 2775 / ULC-S508

Piawaian keselamatan produk Underwriters Laboratories untuk unit sistem pemadam aerosol pekat. Produk yang disenaraikan UL telah menjalani ujian bebas untuk:

- Prestasi penindasan kebakaran

- Keselamatan elektrik

- Impak alam sekitar

- Kebolehpercayaan di bawah syarat yang dinyatakan

Penyenaraian UL tidak diperlukan secara sah, tetapi sukar untuk mendapatkan kelulusan insurans tanpanya.

Piawaian Antarabangsa

ISO 15779:2011 (Sistem Pemadam Api Aerosol Pekat)

Piawaian antarabangsa yang meliputi keperluan, kaedah ujian dan cadangan keselamatan. Yang dikemas kini ISO/DIS 15779.2 semakan sedang dijalankan mulai 2025, dengan jangkaan penerbitan pada 2026.

EN 15276-1 (Sistem Memadam Kebakaran Tetap – Sistem Pemadam Aerosol Pekat)

Piawaian Eropah untuk komponen dan pemasangan sistem aerosol. Diperlukan untuk penandaan CE di pasaran EU.

Kelulusan Alam Sekitar

Kelulusan EPA SNAP

Program Dasar Alternatif Baharu Penting Agensi Perlindungan Alam Sekitar AS. Mensijilkan agen aerosol sebagai selamat untuk digunakan di ruang yang diduduki dengan:

- Sifar potensi penipisan ozon (ODP = 0)

- Boleh diabaikan potensi pemanasan global (GWP < 1)

- Tiada kegigihan atmosfera jangka panjang

Kelulusan SNAP bermakna agen tidak akan menyumbang kepada penipisan lapisan ozon atau perubahan iklim—penting jika syarikat anda mempunyai matlamat alam sekitar.

Maksud Ini untuk Perolehan

Jika anda menentukan untuk projek dengan pengawasan kawal selia:

- Amerika Utara: Memerlukan Penyenaraian UL 2775 + Pematuhan NFPA 2010

- Eropah: Memerlukan Pematuhan EN 15276-1 + penandaan CE

- Projek antarabangsa: carilah Pematuhan ISO 15779

专业提示: Sentiasa minta dokumen pensijilan dan manual pemasangan 抵达 pesanan belian. Jika pengilang tidak dapat memberikan laporan ujian pihak ketiga daripada makmal yang diiktiraf (UL, FM Approvals, VdS, LPCB), beredar. “Memenuhi ISO 15779” dan “Diuji kepada ISO 15779” adalah tuntutan yang sangat berbeza.

Kesimpulan: Pemadam Api yang Sesuai di Tempat yang Lain Tidak Boleh

Inilah realiti tentang kebakaran kabinet elektrik: ia jarang berlaku, tetapi apabila ia berlaku, anda mengukur masa tindak balas dalam beberapa saat, bukan minit. Arka bar bas, terminal yang terlebih beban, belitan transformer yang gagal—mana-mana daripadanya boleh menyalakan penebat dan merebak menjadi kebakaran yang menghabiskan kabinet sebelum anda mendapat pemberitahuan penggera.

Kaedah penindasan tradisional menghadapi kebenaran yang pahit:

- Air memusnahkan apa yang tidak dimusnahkan oleh api

- Sistem gas berpaip lebih mahal daripada peralatan yang mereka lindungi (untuk kabinet kecil)

- Alat pemadam api mudah alih memerlukan kehadiran dan campur tangan manusia

Penjana aerosol pepejal rel DIN 1P menyelesaikan ini dengan kesederhanaan yang elegan:

- 18mm ruang rel

- 10 gram propelan pepejal

- Sifar kebergantungan luaran

- 170°C pencetus terma

- 6 saat sehingga pelepasan penuh

- 10 tahun kewaspadaan senyap

Tiada paip. Tiada silinder. Tiada isian semula tahunan. Tiada bekalan kuasa. Tiada pentauliahan. Hanya klipkannya pada rel, posisikan probe terma, dan lupakan mengenainya sehingga tarikh pembuatan mengatakan sudah tiba masanya untuk mengganti.

Jika anda menentukan kabinet elektrik untuk aplikasi kritikal—bilik pelayan, ladang solar, stesen telekom, kawalan industri—tanya pada diri sendiri: bolehkah anda mampu tidak untuk melindunginya?

Penjana aerosol 10g berharga kurang daripada satu panggilan perkhidmatan kecemasan. Penggantian kabinet selepas kebakaran? Itu bermakna minggu henti tugas dan lima angka dalam kos penggantian, minimum. Ditambah penyiasatan, tuntutan insurans, penjelasan kepada pengurusan tentang mengapa peralatan kritikal tidak dilindungi.

Matematiknya tidak rumit. Keputusan itu juga tidak sepatutnya.

Bersedia untuk melindungi kabinet elektrik anda? Terokai Penjana Aerosol Pepejal Rel DIN 1P Siri QRR0.01G/S VIOX—direka khusus untuk aplikasi yang terhad ruang di mana kebolehpercayaan bukanlah pilihan. Hubungi pasukan teknikal kami untuk panduan saiz, sokongan pemasangan dan dokumentasi pensijilan.

Perlukan bantuan dengan pemasangan tertentu? Jurutera aplikasi kami boleh menyemak reka letak kabinet anda dan mengesyorkan penempatan penjana dan kedudukan probe yang optimum. Hubungi melalui borang hubungan atau hubungi talian hotline teknikal kami.