Moduļu Slēdzējs Ražotājs

Kā vadošais modulāro kontaktoru ražotājs un piegādātājs Ķīnā, VIOX ELECTRIC piedāvā augstas kvalitātes risinājumus, kas izstrādāti, lai nodrošinātu uzticamību un veiktspēju. Mūsu BCH8 un BMC7 sērijas modulārie kontaktori demonstrē mūsu apņemšanos sasniegt inženiertehnisko izcilību, apvienojot inovatīvu dizainu un izturīgu konstrukciju. Izvēlieties VIOX Electric, lai apmierinātu modernu elektrotehnisko sistēmu prasības ar mūsu izcilajiem modulāro kontaktoru piedāvājumiem.

Sertificējis

AC/DC modulārais kontaktors - BMC7 sērija

AC/DC modulārais kontaktors - BCH8 sērija

BCH8 Manuālais modulārais kontaktors

Īsa pašnominācija: Kāpēc izvēlēties VIOX Electric?

Ar vairāk nekā desmit gadu pieredzi VIOX Electric ir kļuvis par uzticamu partneri elektrisko komponentu nozarē. Uzņēmuma modulārie kontaktori atbilst pasaules standartiem IEC/EN61095 un IEC 60947-4-1, nodrošinot savietojamību un uzticamību dažādiem lietojumiem.1. VIOX piedāvā pielāgojamus risinājumus, tostarp līdzstrāvas spoles konfigurācijas un specializētus polu izkārtojumus, lai apmierinātu īpašas klientu vajadzības. To produktiem ir UL94 V-0 liesmu slāpējoši materiāli un IP40 aizsardzība, kas apliecina apņemšanos nodrošināt drošību un ilgtspējību.

Pielāgotie risinājumi: Mēs koncentrējamies uz tādu risinājumu nodrošināšanu, kas atrisina jūsu unikālās elektrotehnikas problēmas. Neatkarīgi no tā, vai jums ir nepieciešamas īpašas konfigurācijas, izmēri vai iespējas jūsu modulārajiem kontaktoriem, mēs varam izveidot tieši jums pielāgotu risinājumu.

Ekspertu ieteikumi: Mūsu klientu atbalsta komandu veido nozares eksperti. Viņi cieši sadarbosies ar jums, lai izprastu jūsu prasības un piedāvātu pamatotus, praktiskus risinājumus, kas atbilst jūsu vajadzībām.

Uzlabotas ražošanas metodes: Lai nodrošinātu, ka jūs saņemat izcilus modulāros kontaktorus, mēs izmantojam vismodernākās iekārtas, materiālus un ražošanas procesus. Tas garantē, ka mūsu risinājumi ir gan efektīvi, gan izturīgi.

VIOX Lieliska materiālu izvēle, standarta dizains

Super enerģijas taupīšana

Darba režīmā kontaktoram ir nepieciešams ilgstoši pievadīt strāvu, lai uzturētu spoles spriegumu. Šī procesa laikā tiek patērēts liels daudzums elektroenerģijas. B sērijas kontaktors ar optimizētu elektromagnētisko sistēmu ievērojami samazina kontaktora noturēšanas jaudu.

Samazināts izmērs līdz 20%

B sērijas kontaktoru platums ir daudz mazāks nekā tradicionālo kontaktoru platums, tādējādi lietotājiem tiek ietaupīta vieta uzstādīšanai, un tos var ērti uzstādīt standarta sadales kastēs.

Premium materiālu izvēle

Izstrādājuma kvalitātes pamatā ir izejvielu izvēle. B sērijas kontaktori tiek ražoti no rūpīgi atlasītiem vietējiem un starptautiskiem izejmateriālu piegādātājiem, lai panāktu uzticamu kvalitāti, izmantojot augstākās kvalitātes materiālus.

MODUĻU KONTAKTORU IZMĒRU UN IZMĒRU TABULA

1-POLU KONFIGURĀCIJAS (1P, 1 MODULIS)

| MODELIS | IE RATING AC-1 | IE RATING AC-3 | IE VĒRTĒJUMS AC-7A | IE VĒRTĒJUMS AC-7B | PIEEJAMIE SPOLES SPRIEGUMI |

|---|---|---|---|---|---|

| BMC7-16/10 | 16A | 6A | 16A | 7A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-20/10 | 20A | 7A | 20A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-25/10 | 25A | 9A | 25A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-32/10 | 32A | 12A | 32A | 12A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-16/01 | 16A | 6A | 16A | 7A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-20/01 | 20A | 7A | 20A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-25/01 | 25A | 9A | 25A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-32/01 | 32A | 12A | 32A | 12A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

1-POLU KONFIGURĀCIJAS (1P, 2 MODUĻI)

| MODELIS | IE RATING AC-1 | IE RATING AC-3 | IE VĒRTĒJUMS AC-7A | IE VĒRTĒJUMS AC-7B | PIEEJAMIE SPOLES SPRIEGUMI |

|---|---|---|---|---|---|

| BMC7-40/10 | 40A | 18A | 40A | 18A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-63/10 | 63A | 25A | 63A | 25A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-40/01 | 40A | 18A | 40A | 18A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-63/01 | 63A | 25A | 63A | 25A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

2 POLU KONFIGURĀCIJAS (2P, 1 MODULIS)

| MODELIS | IE RATING AC-1 | IE RATING AC-3 | IE VĒRTĒJUMS AC-7A | IE VĒRTĒJUMS AC-7B | PIEEJAMIE SPOLES SPRIEGUMI |

|---|---|---|---|---|---|

| BMC7-16/20 | 16A | 6A | 16A | 7A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-20/20 | 20A | 7A | 20A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-25/20 | 25A | 9A | 25A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-32/20 | 32A | 12A | 32A | 12A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-16/11 | 16A | 6A | 16A | 7A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-20/11 | 20A | 7A | 20A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-25/11 | 25A | 9A | 25A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-32/11 | 32A | 12A | 32A | 12A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-16/02 | 16A | 6A | 16A | 7A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-20/02 | 20A | 7A | 20A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-25/02 | 25A | 9A | 25A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-32/02 | 32A | 12A | 32A | 12A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

2 POLU KONFIGURĀCIJAS (2P, 2 MODUĻI)

| MODELIS | IE RATING AC-1 | IE RATING AC-3 | IE VĒRTĒJUMS AC-7A | IE VĒRTĒJUMS AC-7B | PIEEJAMIE SPOLES SPRIEGUMI |

|---|---|---|---|---|---|

| BMC7-40/20 | 40A | 18A | 40A | 18A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-63/20 | 63A | 25A | 63A | 25A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-40/11 | 40A | 18A | 40A | 18A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-63/11 | 63A | 25A | 63A | 25A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-40/02 | 40A | 18A | 40A | 18A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-63/02 | 63A | 25A | 63A | 25A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

3 POLU KONFIGURĀCIJAS (3P, 2 MODUĻI)

| MODELIS | IE RATING AC-1 | IE RATING AC-3 | IE VĒRTĒJUMS AC-7A | IE VĒRTĒJUMS AC-7B | PIEEJAMIE SPOLES SPRIEGUMI |

|---|---|---|---|---|---|

| BMC7-16/30 | 16A | 6A | 16A | 7A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-20/30 | 20A | 7A | 20A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-25/30 | 25A | 9A | 25A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-32/30 | 32A | 12A | 32A | 12A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-16/03 | 16A | 6A | 16A | 7A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-20/03 | 20A | 7A | 20A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-25/03 | 25A | 9A | 25A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-32/03 | 32A | 12A | 32A | 12A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

3 POLU KONFIGURĀCIJAS (3P, 3 MODUĻI)

| MODELIS | IE RATING AC-1 | IE RATING AC-3 | IE VĒRTĒJUMS AC-7A | IE VĒRTĒJUMS AC-7B | PIEEJAMIE SPOLES SPRIEGUMI |

|---|---|---|---|---|---|

| BMC7-40/30 | 40A | 18A | 40A | 18A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-63/30 | 63A | 25A | 63A | 25A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-40/03 | 40A | 18A | 40A | 18A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-63/03 | 63A | 25A | 63A | 25A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

4 POLU KONFIGURĀCIJAS (4P, 2 MODUĻI)

| MODELIS | IE RATING AC-1 | IE RATING AC-3 | IE VĒRTĒJUMS AC-7A | IE VĒRTĒJUMS AC-7B | PIEEJAMIE SPOLES SPRIEGUMI |

|---|---|---|---|---|---|

| BMC7-16/40 | 16A | 6A | 16A | 7A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-20/40 | 20A | 7A | 20A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-25/40 | 25A | 9A | 25A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-32/40 | 32A | 12A | 32A | 12A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-16/04 | 16A | 6A | 16A | 7A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-20/04 | 20A | 7A | 20A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-25/04 | 25A | 9A | 25A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-32/04 | 32A | 12A | 32A | 12A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-16/22 | 16A | 6A | 16A | 7A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-20/22 | 20A | 7A | 20A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-25/22 | 25A | 9A | 25A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-32/22 | 32A | 12A | 32A | 12A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-16/31 | 16A | 6A | 16A | 7A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-20/31 | 20A | 7A | 20A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-25/31 | 25A | 9A | 25A | 9A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-32/31 | 32A | 12A | 32A | 12A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

4 POLU KONFIGURĀCIJAS (4P, 3 MODUĻI)

| MODELIS | IE RATING AC-1 | IE RATING AC-3 | IE VĒRTĒJUMS AC-7A | IE VĒRTĒJUMS AC-7B | PIEEJAMIE SPOLES SPRIEGUMI |

|---|---|---|---|---|---|

| BMC7-40/40 | 40A | 18A | 40A | 18A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-63/40 | 63A | 25A | 63A | 25A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-40/04 | 40A | 18A | 40A | 18A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-63/04 | 63A | 25A | 63A | 25A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-40/22 | 40A | 18A | 40A | 18A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-63/22 | 63A | 25A | 63A | 25A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-40/31 | 40A | 18A | 40A | 18A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

| BMC7-63/31 | 63A | 25A | 63A | 25A | 12 V, 24 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 48 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 110 V MAIŅSTRĀVAS/LĪDZSTRĀVAS, 230 V MAIŅSTRĀVAS/LĪDZSTRĀVAS |

BCH8-1P (viena pola) kontaktori

| Vērtējums (In) | AC-7a | AC-7b | Vadības spriegums | Kontaktinformācija | Platums (18 mm moduļi) |

|---|---|---|---|---|---|

| 16A | 16A | 6A | 230V | 1NO | 1 |

| 16A | 16A | 6A | 230V | 1NC | 1 |

| 20A | 20A | 7A | 230V | 1NO | 1 |

| 20A | 20A | 7A | 230V | 1NC | 1 |

| 25A | 25A | 9A | 230V | 1NO | 1 |

| 25A | 25A | 9A | 230V | 1NC | 1 |

BCH8-2P (divpolu) kontaktori

| Vērtējums (In) | AC-7a | AC-7b | Vadības spriegums | Kontaktinformācija | Platums (18 mm moduļi) |

|---|---|---|---|---|---|

| 16A | 16A | 6A | 230V | 2NO | 1 |

| 16A | 16A | 6A | 230V | 2NC | 1 |

| 16A | 16A | 6A | 230V | 1NO+1NC | 1 |

| 20A | 20A | 7A | 230V | 2NO | 1 |

| 20A | 20A | 7A | 230V | 2NC | 1 |

| 20A | 20A | 7A | 230V | 1NO+1NC | 1 |

| 25A | 25A | 9A | 230V | 2NO | 1 |

| 25A | 25A | 9A | 230V | 2NC | 1 |

| 25A | 25A | 9A | 230V | 1NO+1NC | 1 |

| 40A | 40A | 18A | 230V | 2NO | 2 |

| 40A | 40A | 18A | 230V | 2NC | 2 |

| 40A | 40A | 18A | 230V | 1NO+1NC | 2 |

| 63A | 63A | 25A | 230V | 2NO | 2 |

| 63A | 63A | 25A | 230V | 2NC | 2 |

| 63A | 63A | 25A | 230V | 1NO+1NC | 2 |

| 100A | 100A | – | 230V | 2NO | 3 |

| 100A | 100A | – | 230V | 2NC | 3 |

| 100A | 100A | – | 230V | 1NO+1NC | 3 |

BCH8-3P (trīs polu) kontaktori

| Vērtējums (In) | AC-7a | AC-7b | Vadības spriegums | Kontaktinformācija | Platums (18 mm moduļi) |

|---|---|---|---|---|---|

| 16A | 16A | 6A | 230V | 3NO | 2 |

| 25A | 25A | 9A | 230V | 3NO | 2 |

| 40A | 40A | 18A | 230V | 3NO | 3 |

| 63A | 63A | 25A | 230V | 3NO | 3 |

| 100A | 100A | – | 230V | 3NO | 6 |

BCH8-4P (četru polu) kontaktori

| Vērtējums (In) | AC-7a | AC-7b | Vadības spriegums | Kontaktinformācija | Platums (18 mm moduļi) |

|---|---|---|---|---|---|

| 16A | 16A | 6A | 230V | 4NO | 2 |

| 16A | 16A | 6A | 230V | 2NO+2NC | 2 |

| 16A | 16A | 6A | 230V | 3NO+1NC | 2 |

| 20A | 20A | 7A | 230V | 4NO | 2 |

| 20A | 20A | 7A | 230V | 4NC | 2 |

| 25A | 25A | 9A | 230V | 4NO | 2 |

| 25A | 25A | 9A | 230V | 2NO+2NC | 2 |

| 25A | 25A | 9A | 230V | 3NO+1NC | 2 |

| 40A | 40A | 18A | 230V | 4NO | 3 |

| 40A | 40A | 18A | 230V | 4NC | 3 |

| 40A | 40A | 18A | 230V | 2NO+2NC | 3 |

| 63A | 63A | 25A | 230V | 4NO | 3 |

| 63A | 63A | 25A | 230V | 4NC | 3 |

| 63A | 63A | 25A | 230V | 2NO+2NC | 3 |

| 100A | 100A | – | 230V | 4NO | 6 |

| 100A | 100A | – | 230V | 2NO+2NC | 6 |

| 100A | 100A | – | 230V | 3NO+1NC | 6 |

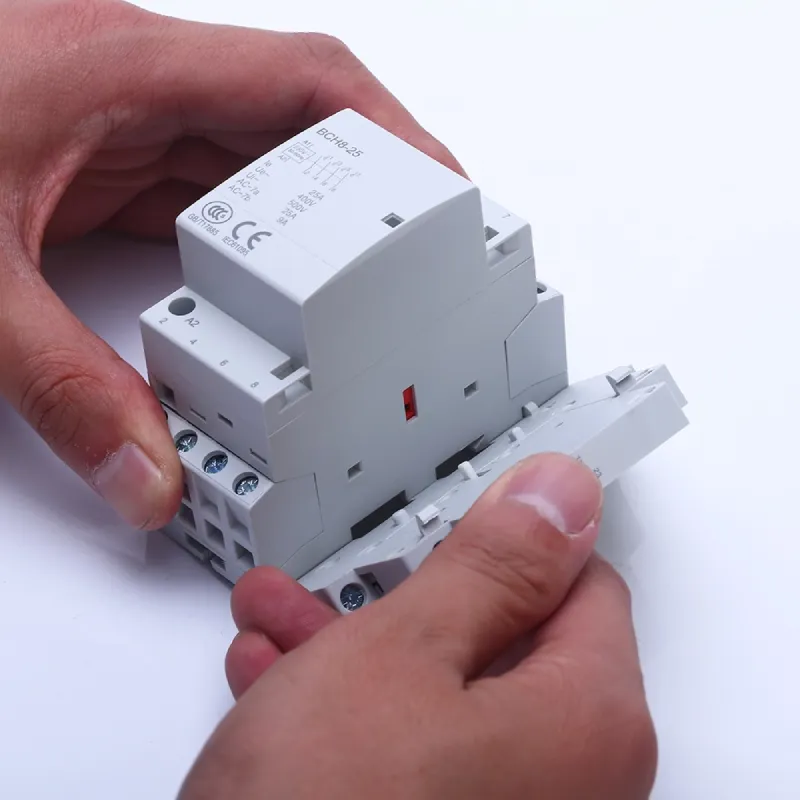

VIOX modulāro kontaktoru uzstādīšanas rokasgrāmata

VIOX modulāro kontaktoru uzstādīšana ir vienkārša, nepieciešama tikai DIN sliede (35 mm), skrūvgriezis un atbilstoši vara kabeļi. Process ietver trīs galvenos soļus:

01

02

03

Lai nodrošinātu optimālu veiktspēju, nodrošiniet pareizu griezes momenta piemērošanu un izmantojiet ieteiktos kabeļu izmērus. Šis vienkāršais uzstādīšanas process apvienojumā ar VIOX precīzo inženiertehniku garantē uzticamu darbību dažādos elektriskās vadības lietojumos.

Iegūstiet savu Bezmaksas paraugs!

Mēs piedāvājam paraugus bez maksas, jums tikai jāpasaka, kas jums nepieciešams

Vairāk nekā tikai modulāro kontaktoru ražotājs

VIOX piedāvā ne tikai modulāro kontaktoru ražošanu, bet arī virkni pakalpojumu ar pievienoto vērtību, kas pielāgoti jūsu projekta vajadzībām. Mūsu apņemšanās sasniegt izcilību nodrošina, ka ikviens klients saņem individuālu uzmanību, ekspertu konsultācijas un nepārtrauktu atbalstu visā tā sadarbības laikā ar mums.

Pakalpojumu konsultācijas

Neatkarīgi no tā, vai jūsu modulāro kontaktoru prasības ir vienkāršas vai sarežģītas, mūsu komanda sniedz ekspertu konsultācijas un tehniskās konsultācijas. Sarežģītākiem projektiem mēs piedāvājam padziļinātu inženiertehnisko atbalstu, lai nodrošinātu optimālu produkta izvēli un pielietojumu.

Produktu ieteikumi

Neesat pārliecināts, kurš modulārais kontaktors ir piemērots jūsu sistēmai? Mūsu speciālisti sniedz bezmaksas, pielāgotus ieteikumus, pamatojoties uz jūsu īpašajām ekspluatācijas un vides prasībām, tādējādi nodrošinot, ka jūs saņemat ideāli piemērotu risinājumu.

Loģistikas atbalsts

Ja jums trūkst uzticama ekspeditora, mēs bez papildu maksas varam organizēt transportēšanu no mūsu rūpnīcas uz jūsu projekta īstenošanas vietu. Mūsu loģistikas komanda nodrošina savlaicīgu un drošu piegādi, lai jūsu projekts netiktu kavēts.

Uzstādīšanas atbalsts

Nepieciešama palīdzība ar uzstādīšanu? Mūsu tehniskā komanda ir pieejama, lai atbildētu uz jūsu jautājumiem vai sniegtu praktisku atbalstu. Lielāku projektu gadījumā mēs pat varam nosūtīt inženieri uz jūsu objektu, lai sniegtu palīdzību uz vietas.

Bieži Uzdotie Jautājumi

Esam apkopojuši dažus biežāk uzdotos klientu jautājumus. Ja jūsu jautājums šeit nav iekļauts, mūsu klientu apkalpošanas dienests vienmēr ir gatavs jums palīdzēt. Mēs labprāt ar jums parunāsim.

Kā es varu saņemt moduļu kontaktora cenu piedāvājumu?

Lai saņemtu cenu piedāvājumu par mūsu moduļu kontaktierīci, sazinieties ar mūsu klientu apkalpošanas komandu. Mēs esam pieejami 24 stundas diennaktī, 7 dienas nedēļā, 7 dienas nedēļā, 7 dienas nedēļā. Vienkārši norādiet sava pasūtījuma specifiku, piemēram, veidu, izmēru un daudzumu. Mēs palīdzēsim jums veikt visu pasūtīšanas procesu.

Kāds ir jūsu pasūtījuma MOQ?

Mums ir zems MOQ jeb minimālais pasūtījuma daudzums. Jūs varat pasūtīt tikai vienu vienību, un mēs piegādāsim atbilstoši jūsu specifikācijām.

Kāds ir mana pasūtījuma izpildes laiks?

Modulārā kontaktora standarta izpildes laiks ir 7 līdz 10 darba dienas. Piegādes laiks var paildzināties līdz 15 darba dienām tranzīta dēļ. Ja pasūtījums ir pielāgots vai apjomīgs, mēs varam apspriest pasūtījuma izpildes laiku pirms pasūtījuma pabeigšanas.

Vai es varu saņemt paraugu pirms pasūtījuma veikšanas?

Jā, mēs piedāvājam paraugus novērtēšanai un apstiprināšanai. Paraugu izveide parasti aizņem no 3 līdz 7 darba dienām.

Vai jūs varat izgatavot pielāgotu modulāro kontaktoru?

Jā, mēs piedāvājam pielāgotus modulāros kontaktorus. Dariet mums zināmas savas prasības, un mūsu klientu apkalpošanas speciālistu komanda sadarbosies ar jums projektēšanas procesā.

Kāda ir jūsu modulārā kontaktora garantija?

Mēs piedāvājam 3 gadu garantiju visiem mūsu ražotajiem modulārajiem kontaktoriem. Tas nodrošina, ka mēs piegādājam augstas kvalitātes produktus. Pirms piegādes katrs produkts tiek rūpīgi pārbaudīts.

ZINĀJUMI par modulāro kontaktoru

Kas ir Moduļu Slēdzējs?

Modulārais kontaktors ir elektromehāniska komutācijas ierīce, kas paredzēta montāžai uz DIN sliedes sadales skapjos. To izmanto apgaismojuma, apkures, ventilācijas un citu elektrisko slodžu tālvadībai dzīvojamās, komerciālās un rūpnieciskās ēkās.

Modulārā kontaktora galvenie kontaktora komponenti

Modulārie kontaktori sastāv no trim galvenajām sastāvdaļām, kas darbojas kopā, lai kontrolētu elektriskās ķēdes:

Spoles: Kontaktiera elektromagnētiskais kodols, kas atbild par magnētiskā lauka ģenerēšanu, kurš darbina ierīci. Kad tas ir zem sprieguma, tas rada spēku, kas pārvieto kontaktus..

Kontakti: Tie ir fiziskie savienojuma punkti, kas veido vai pārtrauc elektrisko ķēdi. Modulārajiem kontaktoriem parasti ir galvenie kontakti jaudas pārslēgšanai un palīgkontakti vadības un signalizācijas vajadzībām..

Pielikums: Kompakts, modulārs korpuss, kas paredzēts uzstādīšanai uz DIN sliedēm, nodrošinot aizsardzību un vieglu uzstādīšanu. Korpuss bieži vien ietver spaiļu savienojumus vadiem un var būt aprīkots ar manuālu pārslēgšanas slēdzi testēšanai vai avārijas darbībai..

Mūsdienu modulārajos kontaktoros var iebūvēt arī papildu elementus, piemēram, loka slāpēšanas tehnoloģiju, elektroniskos vadības moduļus uzlabotai funkcionalitātei un iebūvētu aizsardzību pret pārspriegumiem, lai uzlabotu veiktspēju un drošību dažādos lietojumos.

Modulāro kontaktoru darbības principi

Modulārie kontaktori darbojas, izmantojot vienkāršu elektromagnētisko mehānismu, kas paredzēts efektīvai un uzticamai ķēdes vadībai. To pamatā ir trīs galvenās sastāvdaļas: spole, kontakti un korpuss. Kad spolei tiek pievadīts vadības spriegums, tā rada magnētisko lauku, kas pievelk kustīgos kontaktus pie nekustīgajiem kontaktiem, noslēdzot ķēdi un ļaujot strāvai plūst uz pieslēgto slodzi. Atvienojot strāvas padevi spolei, magnētiskais lauks sabrūk, un atsperu mehānisms izstumj kontaktus, pārtraucot ķēdi..

Šis mehānisms ļauj modulārajiem kontaktoriem apstrādāt lielas jaudas ķēdes, izmantojot mazjaudas vadības signālus. Tie ir pieejami ar normāli atvērtu (NO) vai normāli slēgtu (NC) konfigurāciju, nodrošinot elastību dažādiem lietojumiem. To ātrā atvēršanas un aizvēršanas darbība nodrošina precīzu pārslēgšanu, tāpēc tie ir ideāli piemēroti apgaismojuma sistēmu, HVAC iekārtu un motoru slodžu pārvaldībai dzīvojamās, komerciālās un rūpnieciskās ēkās..

Modulāro kontaktoru veidi

Četras galvenās modulāro kontaktoru saimes ir paredzētas konkrētiem lietojumiem:

Sadzīves kontaktori pīķa/izslēguma stundām un apkures ķēžu pārslēgšanai

Motoru vadības kontaktori ar pagarinātu kontaktu kalpošanas laiku biežai darbībai

Reversošie kontaktori, kas apvieno standarta ierīces ar mehāniskiem bloķētājiem strāvas padeves maiņai

Drošības kontaktori, kas izmanto spoguļkontakti, lai norādītu pozīciju, bieži avārijas izslēgšanas gadījumos.

Šie specializētie tipi nodrošina precīzu vadību dažādos scenārijos, sākot no dzīvojamo ēku enerģijas pārvaldības līdz rūpniecisko motoru vadībai un drošības sistēmām.

Kompakts un modulārs dizains Moduļu Slēdzējs

Modulārajiem kontaktoriem ir raksturīgs kompakts, standartizēts dizains, kas optimizēts efektīvai uzstādīšanai un vietas izmantošanai. Parasti šo ierīču platums ir no 18 līdz 54 mm 2-4 polu konfigurācijās, un tās ir ievērojami mazākas nekā tradicionālie kontaktori, tādējādi nodrošinot lielāku blīvumu elektrības paneļos.. To konstrukcijai ir izturīgs plastmasas vai metāla korpuss ar integrētām DIN sliedes montāžas skavām, kas atvieglo uzstādīšanu..

Galvenās fiziskās īpašības:

Standartizēti izmēri, kas saderīgi ar DIN sliedes sistēmām

Papildu kontaktu un taimera moduļu modulārās paplašināšanas iespējas

Pieskaroties droša termināla konstrukcija, lai samazinātu nejaušas saskares risku

Uzlabotas terminālu konfigurācijas, piemēram, būrīša skavas tehnoloģija drošai vadu noturēšanai.

Integrētas loka slāpēšanas kameras ekspluatācijas ilguma pagarināšanai

Pēc izvēles pieejami manuālās pārslēgšanas slēdži tiešai vadībai

Pateicoties šīm fiziskajām īpašībām, modulārie kontaktori nodrošina izcilu elastību un drošību plašā elektriskās vadības lietojumu klāstā, sākot ar dzīvojamo ēku apgaismojuma sistēmām un beidzot ar rūpniecisko motoru vadību.

Modulārie un tradicionālie kontaktori

Modulārie kontaktori un tradicionālie kontaktori būtiski atšķiras pēc izmēra, efektivitātes un pielietojuma. Modulārie kontaktori ir līdz pat 70% mazāki par saviem tradicionālajiem analogiem, un daži modeļi ir tikai 18 mm šaurāki 2 polu konfigurācijās.. Šis kompaktais dizains ļauj efektīvi izmantot vietu elektrības paneļos, tāpēc tie ir ideāli piemēroti dzīvojamām un nelielām komerciālām telpām, kur paneļa vieta ir ierobežota..

Energoefektivitātes ziņā modulārajos kontaktoros tiek izmantotas energotaupīgas spoles, kas patērē tikai 0,5-2 W jaudas, salīdzinot ar 5-10 W, kas nepieciešami tradicionālajiem kontaktoriem.. Šis samazinātais enerģijas patēriņš padara modulāros kontaktorus ekonomiski izdevīgākus izmantošanai dzīvojamās ēkās.. Turklāt modulārie kontaktori ir daudzpusīgāki, jo spēj darboties gan maiņstrāvas, gan līdzstrāvas ķēdēs, savukārt tradicionālie kontaktori parasti ir paredzēti konkrētiem ķēdes veidiem.. Modulārie kontaktori atšķiras arī ar to, ka tos ir viegli uzstādīt un integrēt modernās elektrosistēmās, tāpēc tie ir ieteicama izvēle lietojumiem, kuros bieži jāveic atjauninājumi vai modifikācijas..

Pareizā kontaktora izvēle

Izvēloties piemērotu modulāro kontaktoru savam lietojumam, ņemiet vērā šos galvenos faktorus:

Slodzes prasības: Nosakiet elektriskās slodzes tipu (rezistīvā, induktīvā vai kapacitatīvā) un nominālo vērtību. Motoru vai transformatoru gadījumā ņemiet vērā ieslēgšanas strāvu, kas var būt 5-10 reizes lielāka par normālo darba strāvu..

Sprieguma nominālvērtības: Pārliecinieties, ka kontaktora nominālais spriegums atbilst vai pārsniedz jūsu sistēmas darba spriegumu gan galvenajā, gan vadības ķēdē..

Kontaktu konfigurācija: Izvēlieties atbilstošu polu skaitu (parasti 1-4), pamatojoties uz sistēmas prasībām (piemēram, vienfāzes, trīsfāzes)..

Darbības vide: Ņemiet vērā tādus faktorus kā temperatūra, putekļi, mitrums un vibrācija, kas var ietekmēt kontaktora darbību vai kam nepieciešami īpaši aizsardzības rādītāji..

Pārslēgšanas frekvence: Pusvadītāju kontaktori var piedāvāt ilgāku kalpošanas laiku: lietojumiem ar biežu cikliskumu..

Turklāt novērtējiet kontaktora elektrisko un mehānisko izturību un apsveriet, vai jūsu lietojumam ir nepieciešama īpaša sertifikācija vai atbilstība standartiem.. Rūpīgi izvērtējot šos faktorus, varat izvēlēties modulāro kontaktoru, kas nodrošina optimālu veiktspēju un efektivitāti jūsu elektroinstalācijā.

Modulāro kontaktoru biežāk sastopamo problēmu novēršana

Novēršot modulāro kontaktoru problēmas, var rasties vairākas bieži sastopamas problēmas. Viena no biežāk sastopamajām problēmām ir tā, ka kontaktors neaizveras vai neatveras, bieži zema vadības sprieguma vai spoles bojājuma dēļ. Pārliecinieties, ka barošanas avots atbilst kontaktora spoles sprieguma prasībām, jo nepareiza sprieguma izmantošana var izraisīt darbības traucējumus vai pārkaršanu.. Kontaktu nodilums ir vēl viena problēma, uz ko jāraugās, un to norāda bedrīšu, loka veidošanās vai oglekļa nogulsnes uz kontaktvirsmām.. Šīs pazīmes liecina, ka ir pienācis laiks veikt apkopi vai nomaiņu.

Pārtraukta darbība vai pārmērīgs troksnis pārslēgšanas laikā var liecināt par mehāniskām problēmām vai piesārņojumu. Regulāra tīrīšana un pārbaude var novērst daudzas problēmas. Pastāvīgu problēmu gadījumā skatiet ražotāja kļūdu analīzes rokasgrāmatu un apsveriet iespēju veikt profesionālu diagnostiku.. Atcerieties, ka, strādājot ar elektriskajiem komponentiem, drošība ir vissvarīgākā - pirms kontaktoru pārbaudes vai apkopes vienmēr atvienojiet strāvas padevi..

Galvenās nozares, kurās izmanto modulāros kontaktorus

Modulārie kontaktori tiek plaši izmantoti dažādās nozarēs, pateicoties to daudzpusībai un kompaktajam dizainam. Galvenās nozares, kurās izmanto šīs ierīces, ir:

Ēku automatizācija: Viedās ēkās modulārie kontaktori kontrolē apgaismojuma, HVAC un drošības sistēmas, uzlabojot energoefektivitāti un iedzīvotāju komfortu..

Atjaunojamā enerģija: Saules enerģijas instalācijās tiek izmantoti modulārie kontaktori invertoru kontrolei un tīkla pieslēguma pārvaldībai..

Ražošana: Rūpnieciskās automatizācijas sistēmas izmanto modulārus kontaktorus, lai kontrolētu motorus, konveijeru lentes un ražošanas līniju iekārtas..

E-mobilitāte: Elektromobiļu uzlādes stacijās ir iebūvēti modulārie kontaktori drošai un efektīvai enerģijas sadalei..

Datu centri: Šajos objektos enerģijas sadales un dublēšanas sistēmu pārvaldībai izmanto modulārus kontaktorus, kas nodrošina nepārtrauktu darbību..

Modulāro kontaktoru pielāgojamība padara tos nenovērtējamus šajās nozarēs, jo tie piedāvā uzticamus vadības risinājumus, vienlaikus optimizējot telpu un enerģijas patēriņu..

Uzturēšanas un ilgmūžības apsvērumi

Modulārie kontaktori tiek plaši izmantoti dažādās nozarēs, pateicoties to daudzpusībai un kompaktajam dizainam. Galvenās nozares, kurās izmanto šīs ierīces, ir:

Ēku automatizācija: Viedās ēkās modulārie kontaktori kontrolē apgaismojuma, HVAC un drošības sistēmas, uzlabojot energoefektivitāti un iedzīvotāju komfortu..

Atjaunojamā enerģija: Saules enerģijas instalācijās tiek izmantoti modulārie kontaktori invertoru kontrolei un tīkla pieslēguma pārvaldībai..

Ražošana: Rūpnieciskās automatizācijas sistēmas izmanto modulārus kontaktorus, lai kontrolētu motorus, konveijeru lentes un ražošanas līniju iekārtas..

E-mobilitāte: Elektromobiļu uzlādes stacijās ir iebūvēti modulārie kontaktori drošai un efektīvai enerģijas sadalei..

Datu centri: Šajos objektos enerģijas sadales un dublēšanas sistēmu pārvaldībai izmanto modulārus kontaktorus, kas nodrošina nepārtrauktu darbību..

Modulāro kontaktoru pielāgojamība padara tos nenovērtējamus šajās nozarēs, jo tie piedāvā uzticamus vadības risinājumus, vienlaikus optimizējot telpu un enerģijas patēriņu.

Modulāro kontaktoru uzstādīšanas paraugprakse

Uzstādot modulāros kontaktorus, optimālai darbībai un drošībai ir ļoti svarīga pareiza montāža un vadu ierīkošana. Uzstādiet kontaktoru uz 35 mm DIN sliedes labi vēdināmā vietā, prom no siltuma avotiem un mitruma.. Nodrošiniet pareizu vadu savienošanu, pievienojot vadības vadus A1 un A2 spoles spailēm un slodzes vadus galvenajiem kontaktu spailēm (L1, L2, L3), kā norādīts ražotāja instrukcijās.. Izmantojiet atbilstoša izmēra vadus un pievilciet visus savienojumus atbilstoši norādītajām griezes momenta vērtībām..

Pārbaudiet kontaktoru saderību ar jūsu sistēmas sprieguma un strāvas prasībām.

Nodrošiniet pietiekamu atstarpi ap kontaktoru, lai nodrošinātu ventilāciju.

Drošai uzstādīšanai izmantojiet stiepļu noņēmējus, presēšanas instrumentus un izolētus skrūvgriežus.

Pēc uzstādīšanas veiciet nepārtrauktības testu ar multimetru, lai pārbaudītu pareizu darbību.5

Regulāra apkope, tostarp vizuālas pārbaudes, lai konstatētu nodiluma vai pārkaršanas pazīmes, ir būtiska, lai pagarinātu kontaktora kalpošanas laiku un nodrošinātu nepārtrauktu drošu darbību..

Ražošanas procesa pārskats

Modulāro kontaktoru ražošanas process ietver vairākus precīzus posmus, kuros apvienota progresīva inženierija un stingra kvalitātes kontrole:

Dizains un prototipu izveide: Inženieri izmanto CAD programmatūru, lai radītu 3D modeļus, kas ļauj veikt virtuālo testēšanu pirms fizisko prototipu izgatavošanas..

Sastāvdaļu ražošana: Tiek ražotas galvenās detaļas, tostarp sudraba sakausējuma vai vara un volframa kompozītu kontaktpunkti, precīzi veidoti polimēru korpusi un elektromagnētiskās spoles..

Montāža: Hibrīda pieeja apvieno automatizētu precizitāti ar kvalificētu manuālu uzraudzību. Robotika nodrošina konsekventu komponentu izvietojumu, bet tehniķi veic kvalitātes pārbaudi..

Testēšana: Visaptveroša testēšana ietver dielektriskās izturības, kontakta pretestības, mehāniskās izturības un termiskās veiktspējas novērtēšanu..

Sertifikācija: CE, NF, Semko, ISI, UKCA un SAA..

Vadošie ražotāji ievieš elastīgas ražošanas metodoloģijas, līdzsvarojot efektivitāti ar pielāgošanas iespējām. Tas ietver automatizētas ražošanas līnijas ar augstas precizitātes robotiku un "tieši laikā" ražošanas praksi, lai optimizētu ražošanas plūsmu un samazinātu krājumu izmaksas..

Yueqing kontaktoru tirgus daļa

Yueqing, kas ir Ķīnas pilsēta Džedžeņdzjanas provincē, ir kļuvusi par nozīmīgu spēlētāju globālajā modulāro kontaktoru tirgū. Juecina, kas pazīstama kā "Ķīnas elektrības pilsēta", ir kļuvusi par elektroiekārtu, tostarp modulāro kontaktoru, ražošanas centru..

Pilsētas tirgus daļa modulāro kontaktoru nozarē ir pastāvīgi augusi, un to noteica tādi faktori kā:

Specializētu ražotāju koncentrācija, vairāk nekā 600 tirdzniecības organizāciju, kas izveidotas iekšzemē.

Spēcīgs valdības atbalsts elektrorūpniecībai, tostarp politikas stimuli un infrastruktūras attīstība.

Koncentrēšanās uz inovācijām un augsto tehnoloģiju attīstību, un tādi uzņēmumi kā CHINT Group ir vadošie viedo tīklu tehnoloģiju jomā.

Konkurētspējīgas cenas un ražošanas iespējas, kas ļauj Yueqing bāzētiem uzņēmumiem iekarot ievērojamu daļu gan vietējā, gan starptautiskā tirgus.

Lai gan precīzi Yueqing tirgus daļas rādītāji nav pieejami, nozares prognozes liecina, ka līdz 2030. gadam modulārie kontaktori ieņems 60% pasaules tirgus daļu, ko noteiks viedo ēku pieprasījums un energoefektivitātes noteikumi.. Yueqing ražotāji ir labi sagatavojušies, lai izmantotu šo izaugsmi, izmantojot savu pieredzi elektroiekārtu ražošanā un savu klātbūtni galvenajos tirgos Āzijā, Tuvajos Austrumos un citur..

Pieprasīt OEM modulāro kontaktoru citātu

VIOX Electric ir gatavs palīdzēt jums ar jūsu OEM moduļu kontaktoru vajadzībām. Mēs piedāvājam augstas kvalitātes un rentablus risinājumus.