Produsen Rel Din

VIOX Electric, produsen dan pemasok terkemuka, menghasilkan produk berkualitas tinggi Rel DIN. Dengan pengalaman industri yang luas, kami memastikan produk kami memenuhi standar keamanan dan kinerja yang ketat. DIN Rail kami memberikan dukungan yang andal dalam berbagai sistem kelistrikan. Sebagai pabrik yang dikenal dengan layanan pelanggan dan inovasi yang sangat baik, VIOX Electric adalah sumber tepercaya Anda untuk DIN Rail yang unggul.

Disertifikasi Oleh

Produk Rel Din VIOX

Nominasi Diri Singkat: Mengapa Memilih VIOX Electric?

VIOX Electric didedikasikan untuk menyediakan DIN Rail terbaik. Misi kami adalah menawarkan solusi khusus yang memenuhi kebutuhan spesifik Anda. Selama bertahun-tahun, kami telah berkolaborasi dengan para profesional industri untuk mengembangkan desain inovatif untuk solusi kelistrikan. Dengan memilih kami, Anda akan menerima kombinasi sempurna antara kualitas, fungsionalitas, dan keandalan.

Solusi Khusus: Kami fokus untuk memberikan solusi yang dapat menyelesaikan tantangan kelistrikan Anda yang unik. Apakah Anda memerlukan konfigurasi, ukuran, atau kemampuan khusus untuk DIN Rail Anda, kami dapat membuat solusi khusus hanya untuk Anda.

Bimbingan Ahli: Tim dukungan pelanggan kami terdiri dari para pakar industri. Mereka akan bekerja sama dengan Anda untuk memahami kebutuhan Anda dan memberikan solusi yang tepat untuk memenuhi kebutuhan Anda.

Teknik Produksi Tingkat Lanjut: Untuk memastikan Anda menerima DIN Rails yang unggul, kami menggunakan peralatan, bahan, dan proses produksi yang canggih. Hal ini menjamin bahwa solusi kami efisien dan tahan lama.

REL DIN VIOX BERBAGAI MACAM DIN

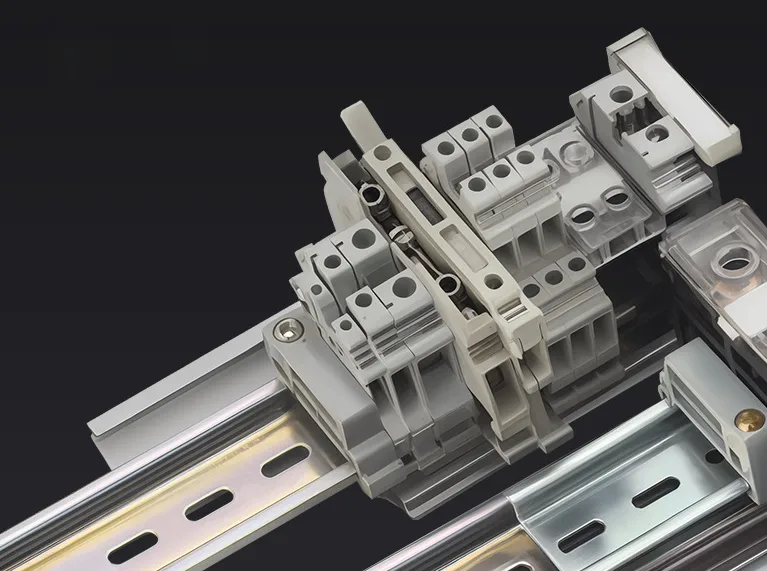

Diproduksi dengan mempertimbangkan presisi dan keandalan, DIN Rail kami dirancang untuk memberikan kinerja luar biasa di berbagai aplikasi, termasuk selungkup listrik, kabinet distribusi, dan panel kontrol. Komitmen VIOX terhadap keunggulan memastikan bahwa setiap produk memenuhi standar ketahanan, ketahanan korosi, dan kemudahan pemasangan yang tinggi. Hubungi kami untuk informasi lebih lanjut tentang bagaimana DIN Rail kami dapat memenuhi kebutuhan spesifik Anda.

- Rel DIN Aluminium

- Rel DIN Baja

- Rel DIN Baja Tahan Karat

- Rel DIN Topi Topi

- Rel DIN Tipe G

- Rel DIN Mini

- Rel DIN 35 × 7.5mm

- Rel DIN 35x15mm

- Rel DIN 32x15mm

- Rel DIN 15 × 5.5mm

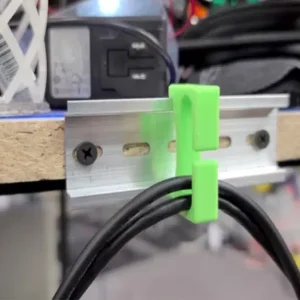

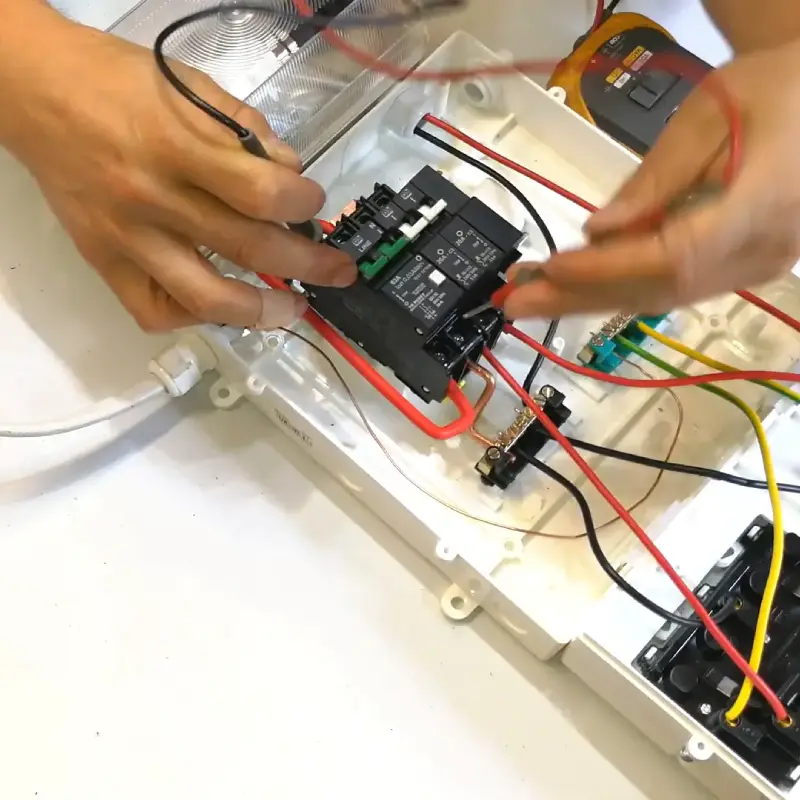

Cara memasang DIN Rails

01

02

03

04

05

06

Solusi Kabel Berkualitas Tinggi VIOX

Di VIOX, kami bangga menawarkan rangkaian lengkap solusi kabel berkualitas tinggi yang dirancang untuk memenuhi beragam kebutuhan di berbagai industri. Produk kami dirancang untuk daya tahan, keandalan, dan kinerja, memastikan bahwa Anda memiliki alat yang tepat untuk setiap aplikasi. Temukan rangkaian produk kami di bawah ini:

Dapatkan Sampel Gratis!

Kami menyediakan sampel secara gratis, Anda hanya perlu memberi tahu kami apa yang Anda butuhkan

Lebih Dari Sekedar Produsen Din Rail

Di VIOX, kami bangga dapat memberikan dukungan tepat waktu, mematuhi standar tinggi, dan menawarkan solusi yang dibuat khusus yang memenuhi kebutuhan pelanggan kami, membentuk fondasi reputasi kami yang terus berkembang dengan Din Rails.

Konsultasi Layanan

Jika persyaratan Din Rail Anda sangat mudah dan Anda tidak memerlukan konsultasi eksternal, tim kami dapat menawarkan saran dan panduan ahli dengan biaya yang masuk akal.

Rekomendasi DIN RAIL

Tidak yakin Din Rail mana yang harus dipilih untuk proyek Anda? Kami memberikan rekomendasi yang dipersonalisasi berdasarkan kebutuhan spesifik Anda, gratis untuk semua pelanggan kami.

Dukungan Logistik

Jika Anda tidak memiliki perusahaan ekspedisi yang sesuai, kami dapat membantu mengatur pengangkutan Din Rails Anda dari pabrik kami ke lokasi proyek Anda tanpa biaya layanan tambahan.

Dukungan Instalasi

Jika Anda memiliki pertanyaan tentang pemasangan Din Rail, jangan ragu untuk menghubungi kami. Kami menawarkan bantuan pemasangan dan bahkan dapat mengirim teknisi ke lokasi proyek Anda untuk mendapatkan dukungan langsung.

PENGETAHUAN

Apa yang dimaksud dengan rel DIN?

Rel DIN adalah strip logam standar yang berfungsi sebagai fondasi untuk memasang berbagai komponen listrik dan industri di rak peralatan dan kabinet kontrol. Sistem pemasangan serbaguna ini berasal dari Jerman pada tahun 1928, dikembangkan oleh Rheinisch-Westfälisches Elektrizitätswerk untuk mengatasi kurangnya standardisasi dalam pengembangan panel listrik. Pada tahun 1950-an, rel DIN telah mendapatkan adopsi internasional yang luas, merevolusi pemasangan dan kompatibilitas peralatan listrik di berbagai produsen. Saat ini, mereka memainkan peran penting dalam pengaturan industri, memberikan solusi yang sederhana namun efektif untuk mengatur dan mengamankan berbagai perangkat, mulai dari pemutus sirkuit hingga pengontrol logika yang dapat diprogram.

Bahan DIN Rail Umum (Baja, Aluminium, Baja Tahan Karat)

Rel DIN dibuat dari berbagai bahan, masing-masing menawarkan sifat yang berbeda yang cocok untuk aplikasi yang berbeda. Bahan yang paling umum meliputi:

Baja Galvanis: Ini adalah bahan yang paling banyak digunakan karena daya tahan, ketahanan terhadap korosi, dan efektivitas biaya. Bahan ini cocok untuk lingkungan dalam ruangan standar dan dapat menopang komponen yang berat.

Aluminium: Ringan dan secara alami tahan terhadap oksidasi, rel DIN aluminium ideal untuk aplikasi yang sensitif terhadap berat dan lingkungan yang cukup korosif. Beratnya sekitar 2,5 kali lebih ringan dari rel baja tetapi memiliki kekuatan yang lebih rendah, biasanya mendukung komponen yang lebih ringan.

Baja Tahan Karat: Menawarkan ketahanan korosi yang unggul, rel DIN baja tahan karat cocok untuk lingkungan yang keras, terutama dalam industri pengolahan makanan, kimia, dan kelautan.

Tembaga: Meskipun kurang umum, rel DIN tembaga tersedia untuk aplikasi khusus, terutama di mana konduktivitas listrik diperlukan.

Pemilihan material tergantung pada faktor-faktor seperti persyaratan penahan beban, kondisi lingkungan, dan standar industri tertentu. Misalnya, rel DIN baja biasanya dapat menopang 15-20 kg per meter, sehingga ideal untuk alat berat, sedangkan rel aluminium lebih cocok untuk komponen yang lebih ringan

Jenis Rel DIN

DIN rail hadir dalam tiga varian utama, masing-masing dirancang untuk aplikasi tertentu:

- Bagian Top Hat (TH): Jenis yang paling umum, dengan lebar 35mm dan tersedia dalam kedalaman 7,5mm dan 15mm. Ini terutama digunakan untuk memasang pemutus sirkuit dan peralatan kontrol.

- Bagian C: Tersedia dalam varian C20, C30, C40, dan C50, dengan angka yang menunjukkan ketinggian vertikal. Tipe ini menawarkan keserbagunaan untuk berbagai ukuran komponen.

- Bagian G: Didesain untuk komponen yang lebih berat, dengan sisi bawah yang lebih dalam untuk meningkatkan dukungan dan stabilitas dalam pengaturan industri.

Jenis rel standar ini memastikan kompatibilitas di seluruh produsen, memungkinkan pemasangan dan pengaturan komponen listrik dan industri yang efisien di rak peralatan dan kabinet kontrol.

Evolusi dan Pandangan Din Rails

Sejarah rel DIN berawal pada tahun 1928 ketika Rheinisch-Westfälisches Elektrizitätswerk (RWE) di Jerman mengembangkan sistem pemasangan standar pertama untuk komponen listrik. Awalnya terbuat dari porselen dengan batang bus logam, rel ini berevolusi menjadi konstruksi semua logam untuk meningkatkan daya tahan. Institut Standardisasi Jerman (DIN) menyempurnakan dan menstandarkan desain lebih lanjut pada tahun 1950-an, yang mengarah pada adopsi yang meluas di seluruh industri.

Melihat ke masa depan, teknologi DIN rail siap untuk kemajuan yang signifikan. Integrasi kemampuan Internet of Things (IoT) memungkinkan pemantauan jarak jauh, diagnostik, dan kontrol perangkat yang terhubung4. Inovasi yang sedang berlangsung dalam bahan dan desain meningkatkan daya tahan dan efisiensi komponen rel DIN, memperpanjang masa pakainya, dan meningkatkan kinerja sistem4. Karena industri terus merangkul otomatisasi dan teknologi pintar, rel DIN diharapkan memainkan peran penting dalam mendukung kebutuhan aplikasi kelistrikan dan industri yang terus berkembang, terutama di bidang-bidang seperti jaringan pintar dan sistem energi terbarukan.

Karakteristik Fisik Rel DIN

Rel DIN biasanya dibuat dari baja karbon canai dingin, dengan permukaan akhir yang cerah berlapis seng atau krom untuk ketahanan dan ketahanan terhadap korosi. Strip logam ini berfungsi sebagai struktur pendukung mekanis dan bukan konduktor listrik, meskipun strip logam ini dapat menyediakan koneksi pengardean sasis. Varian yang paling umum, yang dikenal sebagai bagian Top Hat (TH), memiliki lebar 35mm dan tersedia dalam kedalaman 7,5mm dan 15mm. Meskipun dirancang terutama untuk tujuan pemasangan, rel DIN tidak menghantarkan listrik, memastikan keamanan dan keserbagunaan dalam berbagai aplikasi industri dan kelistrikan.

Memilih Rel Din yang Tepat

Saat memilih DIN rail yang tepat untuk aplikasi Anda, pertimbangkan faktor-faktor utama berikut:

Bahan: Pilih dari baja, aluminium, tembaga, atau logam lain berdasarkan persyaratan daya tahan dan kondisi lingkungan1. Rel baja ideal untuk komponen berat karena kekuatannya.

Jenis profil: Pilih dari profil Top Hat (TS35), C-Rail, G-Rail, atau Miniatur DIN Rail tergantung pada kebutuhan spesifik dan batasan ruang Anda.

Dimensi: Pastikan kompatibilitas dengan komponen Anda, biasanya memilih lebar standar 35mm untuk sebagian besar aplikasi industri.

Opsi pemasangan: Pertimbangkan rel dengan slot pemasangan yang sudah dibuat sebelumnya untuk pemasangan yang lebih mudah dan mengurangi waktu penyiapan.

Kapasitas beban: Evaluasi berat komponen yang akan dipasang dan pilihlah rel yang dapat menopang beban total.

Selain itu, pertimbangkan juga persyaratan khusus aplikasi Anda, seperti ketahanan terhadap korosi, kebutuhan pengardean listrik, dan kompatibilitas dengan peralatan yang ada.. Untuk aplikasi khusus, konsultasikan dengan produsen atau pemasok untuk memastikan DIN rail yang dipilih memenuhi semua standar dan spesifikasi yang diperlukan.

Proses Produksi DIN Rail

Proses manufaktur untuk rel DIN melibatkan beberapa langkah utama untuk mengubah bahan mentah menjadi komponen pemasangan yang presisi dan terstandardisasi:

Persiapan Bahan: Lembaran baja karbon canai dingin biasanya digunakan sebagai bahan dasar, meskipun aluminium dan baja tahan karat juga umum digunakan untuk aplikasi tertentu.

Pembentukan Gulungan: Strip logam melewati serangkaian roller dies yang secara progresif menekuk dan membentuknya menjadi profil rel DIN yang diinginkan.

Perawatan Permukaan: Rel menjalani pelapisan seng atau finishing permukaan cerah kromat untuk meningkatkan daya tahan dan ketahanan terhadap korosi.

Pemotongan dan Pelubangan: Rel yang dibentuk dipotong sesuai panjang yang ditentukan, dan lubang pemasangan dilubangi sesuai kebutuhan.

Kontrol Kualitas: Unit inspeksi memeriksa rel terhadap standar kualitas untuk memastikan akurasi dimensi dan hasil akhir permukaan.

Lini produksi rel DIN modern sering kali menggabungkan fitur otomatis untuk manufaktur berefisiensi tinggi, termasuk proses inline untuk membersihkan, meluruskan, dan menghilangkan lemak. Proses manufaktur terstandardisasi ini memastikan kompatibilitas di berbagai produsen, memfasilitasi pemasangan dan pemeliharaan sistem kelistrikan yang efisien di seluruh dunia

Aplikasi Din Rail

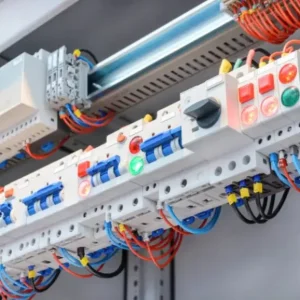

DIN rail digunakan secara luas dalam berbagai aplikasi industri dan komersial, memberikan solusi pemasangan standar untuk komponen listrik. Berikut adalah beberapa aplikasi utama sistem rel DIN:

Sistem Kontrol Industri: Rel DIN banyak digunakan di lingkungan manufaktur dan kontrol proses untuk memasang PLC, relai, dan perangkat kontrol lainnya.

Otomasi Gedung: Mereka memainkan peran penting dalam mengatur komponen untuk sistem kontrol pencahayaan, pemanasan, dan pendinginan di gedung pintar.

Distribusi Daya: Rel DIN sangat penting dalam panel listrik untuk memasang pemutus sirkuit, surge arrester, dan blok terminal.

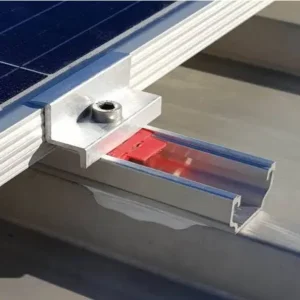

Sistem Energi Terbarukan: Instalasi energi surya dan angin menggunakan komponen yang dipasang di rel DIN untuk manajemen dan kontrol daya.

Telekomunikasi: Peralatan jaringan dan sistem pemantauan data sering kali ditempatkan dalam penutup rel DIN untuk pengaturan yang efisien.

Transportasi: Sistem persinyalan kereta api dan proses manufaktur otomotif menggabungkan perangkat yang dipasang di rel DIN.

Otomasi Industri: DIN rail mendukung integrasi sensor, aktuator, dan perangkat kontrol dalam jalur produksi otomatis.

Keserbagunaan dan standarisasi sistem rel DIN membuatnya sangat diperlukan dalam mengatur dan mengamankan komponen listrik di berbagai aplikasi ini, meningkatkan efisiensi dan kemudahan perawatan.

Keuntungan Menggunakan DIN Rails dalam Sistem Industri

Rel DIN menawarkan keuntungan yang signifikan dalam sistem industri, menjadikannya pilihan yang lebih disukai untuk memasang komponen listrik. Desain modular dan standarnya memungkinkan konfigurasi yang fleksibel, perluasan yang mudah, dan perawatan yang disederhanakan, sehingga mengurangi waktu pemasangan dan kerumitan. Pendekatan ini mengarah pada penghematan biaya dan peningkatan efisiensi ruang, memungkinkan pemasangan dengan kepadatan tinggi dalam kabinet kontrol yang ringkas.

Manfaat utama dari sistem rel DIN meliputi:

- Organisasi dan aksesibilitas komponen yang ditingkatkan

- Keamanan yang lebih baik melalui pemasangan standar

- Fleksibilitas untuk memadupadankan komponen dari berbagai produsen

- Pembuangan panas yang efisien dalam penutup listrik

- Mengurangi waktu henti selama perbaikan atau peningkatan

- Pemecahan masalah yang mudah karena pelabelan yang jelas dan tata letak yang terorganisir

Keunggulan ini berkontribusi pada peningkatan produktivitas, biaya perawatan yang lebih rendah, dan peningkatan keandalan sistem secara keseluruhan dalam aplikasi industri.

Kesalahan Umum dalam Instalasi

Saat memasang rel DIN, beberapa kesalahan umum dapat membahayakan integritas dan keamanan sistem. Salah satu kesalahan yang sering terjadi adalah penyelarasan yang tidak tepat, yang dapat menyebabkan ketidakstabilan dan potensi kerusakan pada komponen yang dipasang. Membebani rel melebihi kapasitas beratnya adalah kesalahan kritis lain yang dapat mengakibatkan kegagalan struktural.Para pemasang juga harus berhati-hati:

- Ventilasi yang tidak memadai, menyebabkan komponen menjadi terlalu panas

- Sambungan kabel yang salah, berpotensi menyebabkan korsleting atau kebakaran listrik

- Pengardean yang tidak memadai, meningkatkan risiko sengatan listrik

- Menggunakan komponen yang tidak kompatibel atau ukuran rel yang salah

- Gagal mengamankan komponen yang longgar setelah terjadi getaran atau pemasangan yang buruk

Untuk menghindari masalah ini, sangat penting untuk mengikuti panduan dari produsen, menggunakan alat yang sesuai, dan melakukan pemeriksaan perawatan rutin. Pemasangan yang tepat tidak hanya memastikan keamanan tetapi juga meningkatkan umur panjang dan efisiensi sistem kelistrikan.

Mengidentifikasi Rel DIN Berkualitas

Untuk membedakan rel DIN berkualitas tinggi, pertimbangkan faktor-faktor kunci berikut ini:

Kualitas material: Rel DIN premium menggunakan baja atau aluminium bermutu tinggi dengan ketahanan korosi yang unggul. Carilah rel yang terbuat dari baja galvanis dengan lapisan pasif yang tebal untuk daya tahan yang optimal.

Manufaktur yang presisi: Rel berkualitas tinggi memiliki dimensi yang konsisten dan tepi yang halus. Periksa ketebalan dan kelurusan yang seragam di sepanjang rel.

Kepatuhan sertifikasi: Produsen terkemuka memastikan rel DIN mereka memenuhi standar internasional seperti IEC 60715. Carilah produk dengan sertifikasi MID untuk akurasi dan keandalan yang terjamin.

Kapasitas beban: Rel DIN superior menawarkan kemampuan menahan beban yang lebih tinggi. Rel baja biasanya menopang 15-20 kg per meter, sementara varian bermutu tinggi dapat menangani beban yang lebih besar.

Permukaan akhir: Rel berkualitas memiliki lapisan permukaan yang halus dan rata yang tahan terhadap keausan dan korosi. Periksa warna yang seragam dan tidak adanya ketidaksempurnaan.

Dengan mengevaluasi aspek-aspek ini, Anda dapat mengidentifikasi rel DIN yang menawarkan kinerja, umur panjang, dan keandalan yang lebih baik untuk kebutuhan aplikasi spesifik Anda.

Produsen Rel DIN Cina

Cina telah muncul sebagai pusat manufaktur DIN rail terkemuka, menawarkan berbagai macam produk berkualitas tinggi dengan harga yang kompetitif. Di antara produsen terkemuka adalah VIOX Electric, pemasok global peralatan listrik bertegangan rendah, termasuk rel DIN, dengan fasilitas manufaktur bersertifikasi ISO. Dengan memanfaatkan teknik produksi yang canggih dan mesin modern, VIOX memastikan kepatuhan terhadap standar internasional seperti DIN, IEC, dan RoHS.

Kombinasi kualitas, keterjangkauan, dan inovasi telah memposisikan pabrikan Cina seperti VIOX sebagai pemain kunci di pasar rel DIN global, yang melayani beragam aplikasi industri dan kelistrikan.

Minta Penawaran Rel DIN OEM

VIOX Electric siap membantu Anda dengan kebutuhan DIN Rail OEM Anda. Kami menawarkan solusi berkualitas tinggi dan hemat biaya.