Péntek, 16:45. Az Ön 1400 négyzetméteres kiskereskedelmi területét kiszolgáló tetőtéri egység elhallgatott. A kompresszor megszorult – a motor tekercsei elégtek, a csapágyak túlmelegedés miatt összehegedtek. Sürgősségi csere költsége: 8500 USD plusz túlóra. Kiváltó ok: 90 másodperces ciklus egy héten keresztül nulla rövid ciklus elleni védelemmel.

Egy 45 USD-s időzítőkésleltető relé megelőzhette volna ezt.

A rövid ciklus – gyors be-ki működés a ciklusok közötti megfelelő pihenés nélkül – a kompresszorhibák vezető, megelőzhető oka. Minden indítás 5–8-szoros futóáramot vesz fel. A motor tekercsei felmelegszenek. Az olaj a hűtőközeg vezetékekbe kerül. Ha a ciklusok túl gyorsan követik egymást, az olaj soha nem tér vissza, a hő felhalmozódik, és valami elromlik.

Időzítőkésleltető relék minimális kikapcsolási időt kényszerítenek ki azáltal, hogy a kompresszor működését a termosztát kielégülése után is meghosszabbítják. Nincs programozás. Nincsenek érzékelők. Csak megbízható védelem, amely kizárja a gyors újraindításokat a termosztát pattogása, a nyomásingadozás vagy a vezérlési hibák miatt.

Miért van szükségük a kompresszoroknak “zárolási védelemre”?”

A kompresszorok telepítve 1200–15 000 USD-be kerülnek. Minden indítás erőszakos: 5–8-szoros futóáram, azonnali hőcsúcs, olaj kilökődése a vezetékekbe.

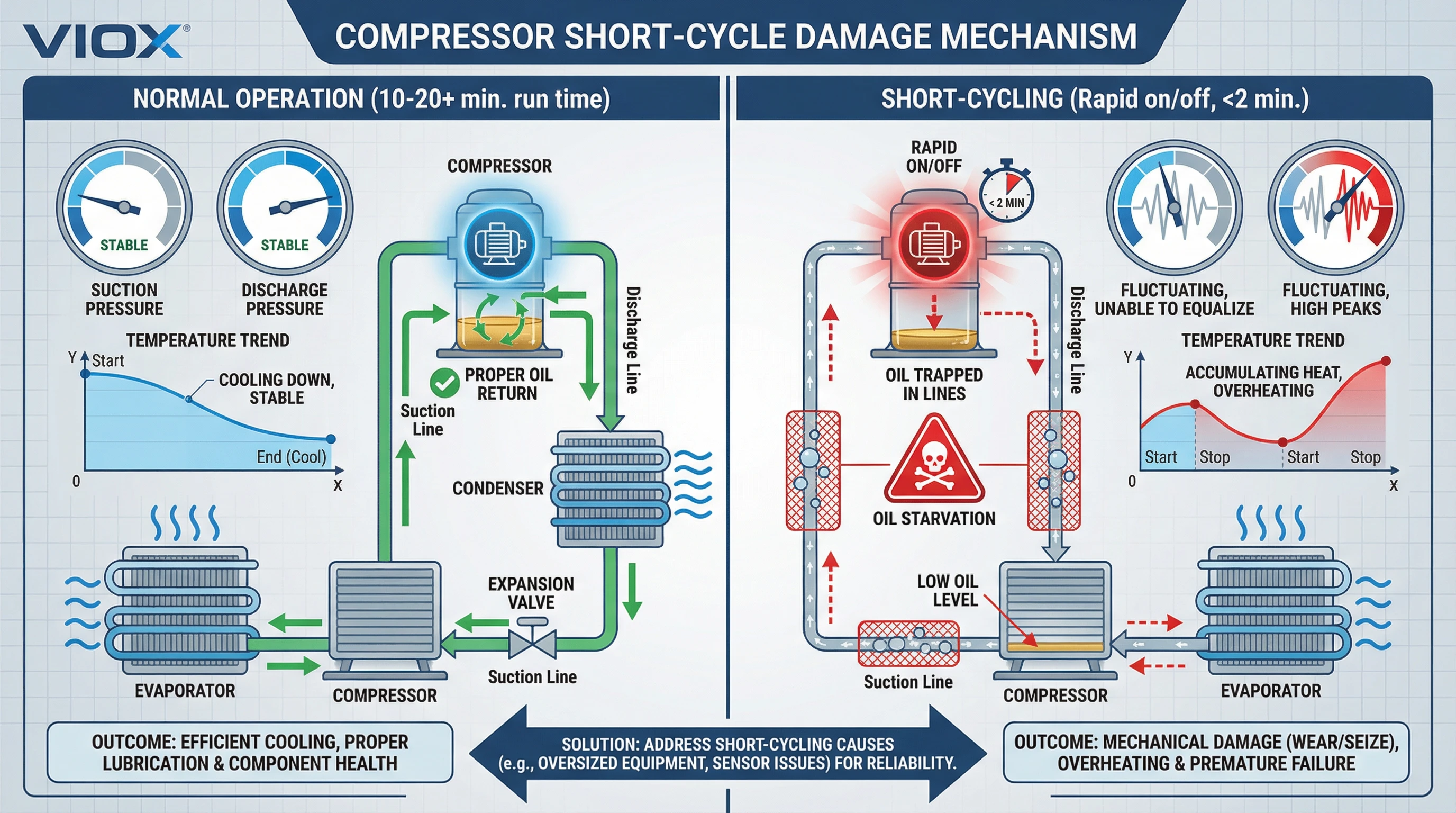

Normál ciklus: A kompresszor 10–20 percig működik. Az olaj befejezi a 2–5 perces körét a nyomóvezetékeken, a kondenzátoron, az elpárologtatón keresztül, és vissza a karterbe. A nyomások kiegyenlítődnek. A tekercsek lehűlnek. A rendszer stabilizálódik a következő indítás előtt.

Rövid ciklusú katasztrófa: Újraindítás 1–3 percen belül. A nyomások nem egyenlítődtek ki – a motor nagy nyomással küzd, és még nagyobb bekapcsolási áramot vesz fel. Az olaj nem tért vissza – a csapágyak szárazon futnak. A tekercsek nem hűltek le – a hőmérséklet minden ciklussal magasabbra ugrik.

Gyakori okok: Túlérzékeny termosztátok, amelyek kisebb ingadozásokra kapcsolnak. Alulméretezett berendezések, amelyek nagy terhelés alatt folyamatosan, de alacsony terhelés alatt gyorsan cikláznak. Hűtőközeg töltési problémák. Zörgő nyomáskapcsolók.

Gyártói garancia kalapács: A Copeland 3 perces minimális futási időt ír elő a spirálkompresszorokhoz, hosszabbat a kiterjesztett vezetékrendszerekhez. A Carrier, a Trane és a Tecumseh hasonló útmutatást tesz közzé. Védelem nélkül telepíti? Garancia megtagadása, ha hiba lép fel.

A “Rövid ciklusú halálspirál”: Hogyan történik a károsodás

Az olajhiány öl először. A kompresszorolaj a teljes hűtőközeg körben halad – a nyomóvezetékektől a kondenzátorig, a folyadékvezetékeken keresztül, az elpárologtatóba, ahol a gravitáció ellenében kell lefolynia, végül a szívóvezetékeken keresztül vissza a karterbe. Ez 2–5 percet vesz igénybe a lakossági rendszereknél 15 méteres vezetékrendszerekkel, sokkal többet a kereskedelmi berendezéseknél 30 méter feletti futásokkal.

Minden rövid ciklus több olajat ejt csapdába az elpárologtatóban. 10–20 ciklus után a karter szintje csökken. 50–100 ciklus után a csapágyak fém-fémhez érnek. A spirálkészletek megszorulnak. A kompresszor olajhiány miatt tönkremegy, még akkor is, ha a hűtőközeg töltése megfelelő volt.

A hőterhelés kiégeti a tekercseket. A motor szigetelése 130–155 °C maximális értékre van méretezve. Normál működés: rövid indítási hőcsúcs, majd az állandósult hűtés a tekercseket jóval a névleges érték alatt tartja. Rövid ciklus: minden indítás hőt ad az előző ciklusból származó maradék hőmérséklethez. A hőmérséklet felfelé ugrik. A szigetelés lebomlik. Tekercs-tekercs zárlatok alakulnak ki. A motor kiég – gyakran katasztrofálisan, az egész rendszert szénnel és savval szennyezve.

Az elektromos terhelés tönkreteszi az érintkezőket. Egy 3 tonnás kompresszor, amely 15 A futóáramot vesz fel, 75–120 A bekapcsolási áramot vesz fel 0,5–2 másodpercig. A kontaktorok napi 6–8 ciklusra vannak méretezve – évi 2000–3000 indításra. A rövid ciklus ezt 10-szer megszorozza: napi 60–80 indítás. Az érintkezők az ívképződés miatt erodálódnak. Az ellenállás növekszik. Végül összehegednek vagy nem zárnak.

A mechanikai ütés és a folyadéklökés befejezi a munkát. Az indítás-leállítás ciklusok becsapják az alkatrészeket, amikor a motor 2 másodperc alatt nulláról 3500 fordulat/percre gyorsul. Több ezer ciklus alatt fáradási repedések alakulnak ki. És 3 perc alatti rövid kikapcsolási idővel a folyékony hűtőközeg gyorsabban kondenzálódik a forgattyúházban, mint ahogy a fűtőberendezések el tudják párologtatni. Újraindításkor a folyadékok nem nyomódnak össze – a hidraulikus ütés eltöri a szelepeket és meghajlítja a rudakat.

Off-Delay működés: A “futás meghosszabbítása”, amely megmenti a kompresszorokat

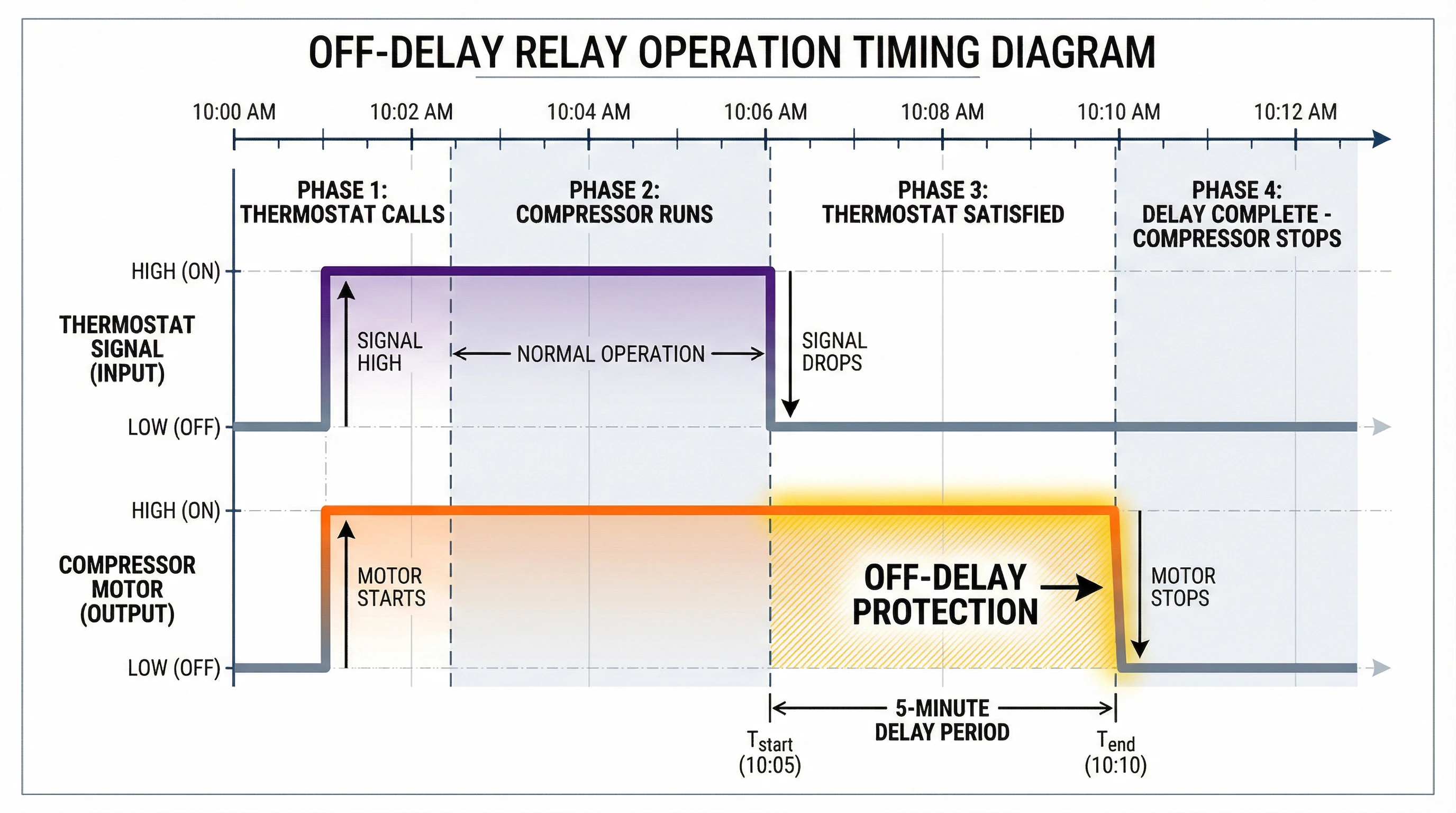

Az időzítőkésleltető relék többféle üzemmódban kaphatók – on-delay, off-delay, intervallum, ismétlés –, de a kompresszorvédelemhez szüksége van off-delay (késleltetés-megszakításkor).

Hogyan működik: A termosztát hűtést kér → a relé azonnal bekapcsol → a kompresszor elindul. A termosztát kielégült → a relé elkezdi az időzítést, de zárva tartja a kimenetet → a kompresszor a késleltetési időszakban (általában 3–10 perc) tovább működik → a késleltetés lejár → a kompresszor leáll.

Ez fordítva tűnik. Miért kell futni a termosztát kielégülése után? A védelem a következő ciklusban történik.

A forgatókönyv – Gyors ciklus: A termosztát újra hív, mielőtt a késleltetés befejeződik. A relé folyamatos igényt lát. A kompresszor egyszerűen tovább működik – nem történik káros újraindítási esemény. A rövid ciklusú kísérletek folyamatos működéssé válnak.

B forgatókönyv – Normál ciklus: A termosztát a késleltetés befejezése után hív. A kompresszor megfelelő pihenést kapott (kényszerített hosszabbítás plusz természetes kikapcsolási idő) az újraindítás előtt.

Konkrét példa 5 perces off-delay-vel:

- 14:00: A termosztát hív. A kompresszor azonnal elindul.

- 14:08: A termosztát kielégült. A relé elkezdi az 5 perces visszaszámlálást, a kompresszor tovább működik.

- 14:13: A késleltetés befejeződik. A kompresszor leáll. Teljes futás: 13 perc.

- Ha a termosztát 14:10-kor ciklázik (a visszaszámlálás alatt): A kompresszor soha nem áll le. A védelem működik.

- Ha a termosztát 14:15-kor ciklázik (a visszaszámlálás után): Az újraindítás megfelelő pihenéssel engedélyezett.

Miért nem on-delay? Az on-delay relék késleltetik az indítást, amikor a bemenet bekapcsol. Több kompresszort is ütemeznek, de nem akadályozzák meg a rövid ciklusokat. A gyors termosztát ciklus továbbra is gyors ki-be eseményeket okoz, nem megfelelő pihenéssel.

A “Rendszerméret táblázat”: A késleltetési beállítások kiválasztása

Gyártói alapértékek:

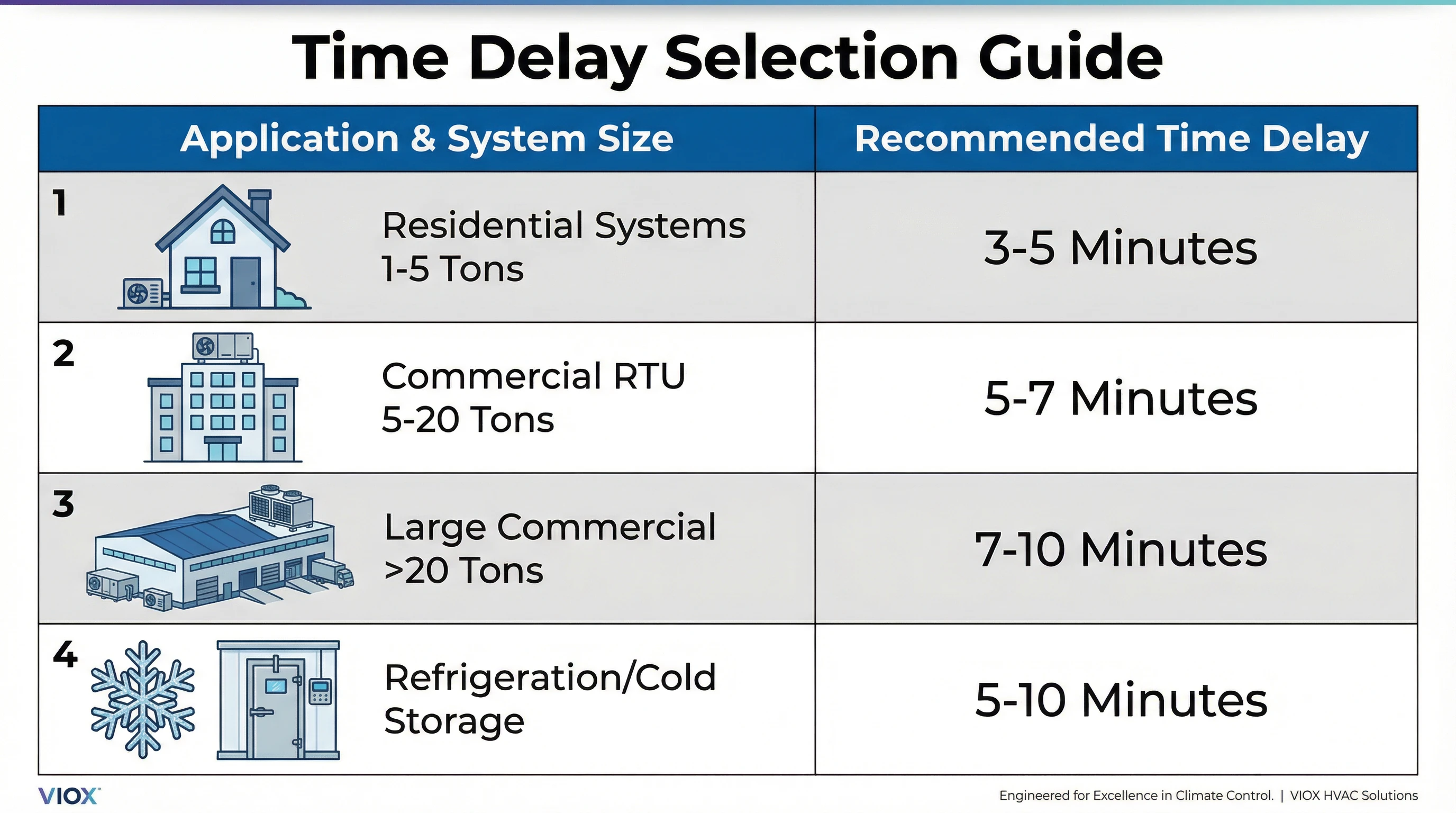

- Lakossági (1–5 tonna): 3–5 perc. Rövid vezetékrendszerek (7,5–15 méter), kisebb olajtöltetek. Használjon 5 percet, ha a vezetékrendszerek meghaladják a 15 métert, vagy rövid ciklusú előzmények vannak.

- Kereskedelmi RTU (5–20 tonna): 5–7 perc. A hosszabb áramkörök több olaj visszatérési időt igényelnek. A nagyobb hőtehetetlenség elviseli a hosszabb futást.

- Nagy kereskedelmi (>20 tonna): 7–10 perc. A kiterjesztett vezetékrendszerek, a több elpárologtató és a komplex csővezetékek hosszabb futási időt igényelnek a teljes olaj visszatéréséhez.

- Hűtés/hűtőtárolás: 5–10+ perc. A hideg elpárologtatók növelik az olaj viszkozitását, lassítva a lefolyást. A hosszú szívóemelőknek megfelelő gázsebességre van szükségük az olaj felfelé szállításához.

Helyszíni beállítási protokoll:

- A gyártó által javasolt beállításokkal szerelje fel.

- Ellenőrizze 5–7 napig. Naponta naplózza a ciklusokat (cél: 6–12 lakossági, 8–15 kereskedelmi).

- Ellenőrizze a védelem működését: néhány ciklusnak azt kell mutatnia, hogy a kompresszor röviden jár a termosztát elégedettsége után.

- Szükség esetén állítsa be: A lakók hőmérséklet-túllépésre panaszkodnak? Csökkentse 1–2 perccel. Még mindig gyors ciklusokat lát? Növelje a késleltetést.

- Dokumentálja a végső beállítást a berendezés címkéjén.

Ne kövesse el ezeket a hibákat: A 3 perc alatti beállítás megszünteti a védelmet. Az on-delay használata nem akadályozza meg a rövid ciklusokat. Ugyanazt az időzítést alkalmazza minden méretre. Kikapcsolás a hibaelhárítás során, és elfelejti újra engedélyezni.

Érintkező adatok: A “Tekercs áram vs. Motor áram” megkülönböztetés

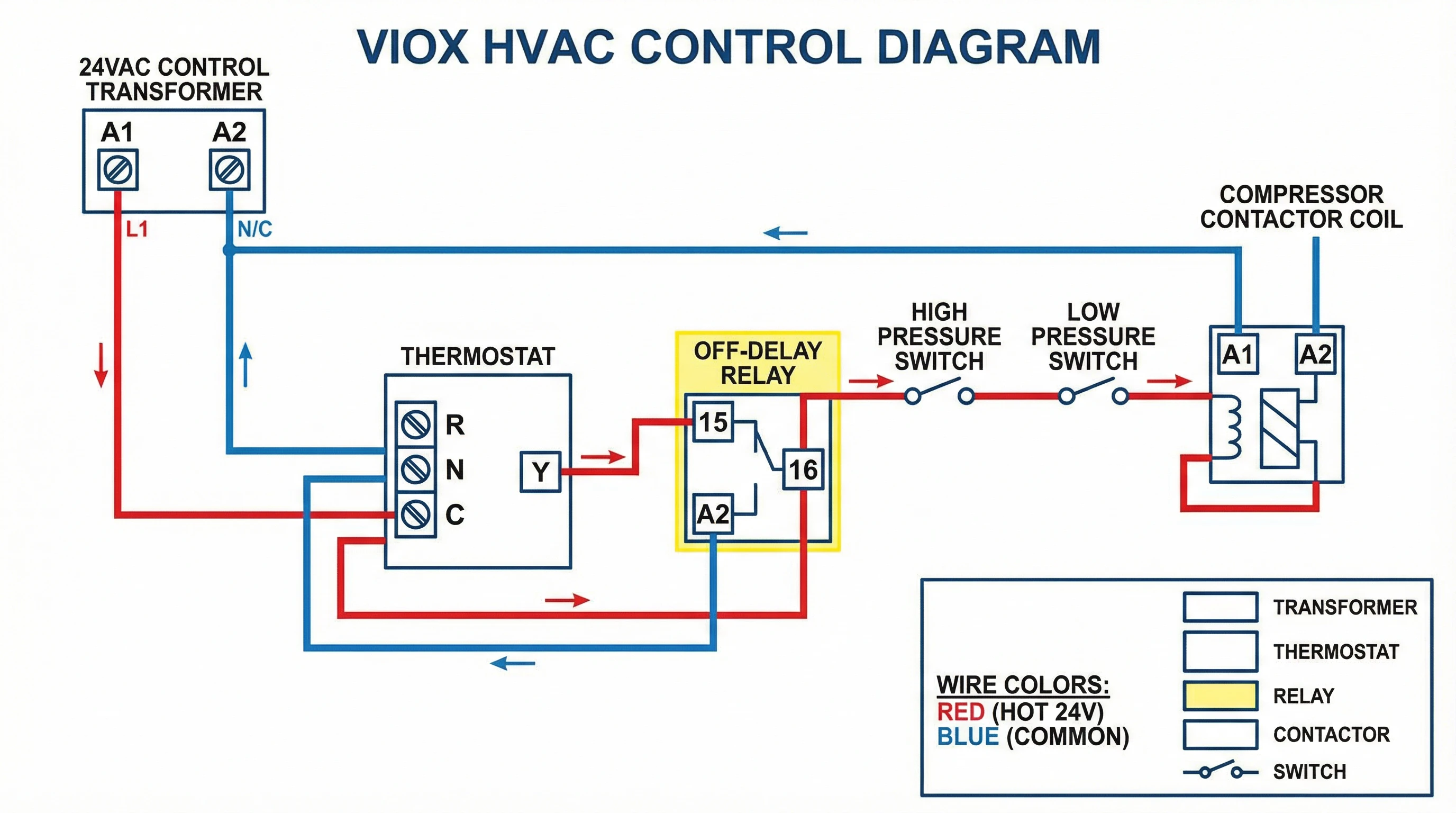

Kritikus koncepció: Az időzítő relék a kontaktor tekercsét, vezérlik, nem közvetlenül a kompresszor motort.

A legtöbb HVAC rendszer alacsony feszültségű vezérlést használ (24 VAC egy transzformátorból, néha 120/240 VAC) a kontaktor tekercsének táplálására. A kontaktor fő érintkezői ezután kapcsolják a nagy áramú kompresszor motort (20–200+ amper). Az időzítő relé csak a tekercs áramát kapcsolja.

A kontaktor tekercsek 0,15–0,5 A folyamatos áramot vesznek fel, 2–3× bekapcsolási árammal 50–100 milliszekundumig. Az elektromágneses terhelésekre (IEC AC-15 kategória) 1–5 A-re méretezett időzítő relék ezt könnyen kezelik.

A végzetes hiba: A tekercs áramának összekeverése a motor áramával. Az 5 tonnás kompresszor 25 A-t vesz fel futás közben, 150 A-t lezárt rotorral. Ezek a terhelések a kontaktor fő érintkezőin vannak – nem a relén. A relé csak a 0,3 A-es tekercset kapcsolja. A kompresszor áramának közvetlen kapcsolására tett kísérlet azonnali érintkező hegesztést okoz.

Főbb specifikációk: Az univerzális feszültségű relék (18–240 VAC/DC) működnek lakossági 24 VAC, kereskedelmi 120 VAC, ipari 240 VAC feszültségen. Az üzemi hőmérsékletnek legalább 50–60°C-nak kell lennie – a tetőtéri burkolatok elérik a 60°C+-t. Az időzítési pontosság ±5–10% megfelelő. DIN sín A rögzítés szabványos.

Vezetékezési integráció: A “Biztonsági lánc” elhelyezése

Integrációs minta: termosztát → biztonsági eszközök → időzítő relé → kompresszor kontaktor tekercs.

Lakossági osztott rendszer (24 VAC):

- Azonosítsa a vezérlő vezetékeket: A termosztát Y kivezetése csatlakozik a kontaktor tekercséhez. A C vezeték biztosítja a visszatérést.

- Válassza le az Y vezetéket a kontaktor tekercséről.

- Csatlakoztassa az Y vezetéket a relé bemeneti kivezetéséhez (A1). Csatlakoztassa a relé bemeneti közös pontját (A2) a C vezetékhez.

- Csatlakoztassa a relé kimeneti érintkezőjét (NO, 15-16 kivezetések) a kontaktor tekercséhez.

- Táplálja a relét 24 VAC transzformátorról.

Működés: A termosztát hív → a relé bekapcsol → a kimenet azonnal zár → a kompresszor elindul. A termosztát elégedett → a relé megkezdi a kikapcsolási késleltetést zárt kimenettel → a kompresszor folytatja → a késleltetés befejeződik → a kimenet kinyílik → a kompresszor leáll.

Kereskedelmi tetőtéri egység (120/240 VAC biztonsági lánccal):

A kereskedelmi rendszerek biztonsági láncokat tartalmaznak – sorba kapcsolt eszközöket (nagynyomású megszakító, alacsonynyomású megszakító, fagyásgátló, túlterhelés), amelyeknek mindegyikének zárva kell lennie a kompresszor működéséhez.

- Keresse meg a vezérlő áramkört: A termosztát/vezérlő kimenete a biztonsági láncon keresztül fut a kontaktor tekercséhez.

- Szakítsa meg az áramkört a biztonsági lánc kimenete és a kontaktor tekercse között.

- Csatlakoztassa a biztonsági lánc kimenetét a relé bemenetéhez. Csatlakoztassa a relé kimenetét a kontaktor tekercséhez.

- Táplálja a relét a vezérlő feszültségről (120 vagy 240 VAC).

Ez az elhelyezés biztosítja, hogy a biztonsági leoldások azonnal leállítsák a kompresszort, míg az időzítés megakadályozza az azonnali újraindítást a biztonsági visszaállítások után – védelmet nyújtva a szakaszos biztonsági leoldásokból eredő gyors ciklusok ellen (gyakori a zörgő nyomáskapcsolóknál).

Kritikus vezetékezési szabályok:

- Feszültségillesztés: 24 VAC relé 120 VAC-ra = azonnali tönkremenetel. Mindig ellenőrizze.

- Érintkező kiválasztása: Használjon alaphelyzetben nyitott (NO) érintkezőt. Az NC használata invertálja a logikát.

- Biztonsági integritás: Soha ne hidalja át a biztonsági eszközöket. A relét az összes biztonsági eszköz után kösse be.

- Többlépcsős rendszerek: A kétlépcsős hűtéshez külön relékre van szükség az Y1 és Y2 számára.

Hibaelhárítás: A “Nem indul / Nem áll le” diagnosztika

Probléma: A kompresszor nem indul el, amikor a termosztát hív

Diagnózis: Mérje meg a feszültséget a relé bemeneti kivezetésein, amikor a termosztát hív – a vezérlő feszültséget kell mutatnia (általában 24 VAC). Ellenőrizze, hogy a relé kimenete zár-e, amikor a bemenet be van kapcsolva.

Javítás: Várjon 10 percet az időzítési ciklus befejezéséhez, vagy kapcsolja ki és be a tápfeszültséget a visszaállításhoz. Ellenőrizze a kikapcsolási késleltetésű modellt, ellenőrizze a NO érintkező vezetékezését, cserélje ki, ha hibás.

Probléma: A kompresszor folyamatosan jár a termosztát elégedettsége után

Diagnózis: A kikapcsolási késleltetés alatt ez normális – a relé védelmet nyújt. Ha a kompresszor a beállított késleltetésen túl (15+ perc 5 perces beállítással) jár, ellenőrizze a relé időzítését.

Javítás: Ha az időzítés helyes, de túlzott, a relé meghibásodhatott. Ha a beállítás túl hosszú, csökkentse 1–2 perccel. Ellenőrizze, hogy a termosztát differenciálja nem ciklikusan működik-e folyamatosan.

Probléma: Még mindig rövid ciklusok a relé ellenére

Diagnózis: Ellenőrizze, hogy a relé sorba van-e kötve a vezérlő jellel, nincs-e áthidalva. Győződjön meg arról, hogy NO érintkezőket használnak – az NC invertálná a logikát. Mérje meg a tényleges időzítést stopperrel.

Javítás: Helyes vezetékezés. Cserélje ki a hibás relét. Ha a ciklusok alig esnek a védelmi ablakon kívül, növelje a késleltetést 1–2 perccel.

Probléma: A relé időzítése szabálytalan

Diagnózis: A névlegesnél magasabb környezeti hőmérséklet eltolódást okoz. A vezérlő feszültség csökkenése időzítési hibákat okoz – mérje meg a relé kivezetésein terhelés alatt.

Javítás: Ellenőrizze, hogy a környezeti hőmérséklet a specifikáción belül van-e. Helyezze át hűvösebb helyre. Ellenőrizze a vezérlő transzformátor kapacitását. Cserélje ki az elöregedett reléket.

VIOX időzítő relék: Az “Univerzális védelem” megoldás

A VIOX többfunkciós időreléket gyárt, amelyeket zord HVAC környezetekhez terveztek. A VIOX modellek az egyfunkciós reléktől eltérően kikapcsolási késleltetést, bekapcsolási késleltetést, intervallum és ismétlési módokat tartalmaznak, amelyek DIP kapcsolóval választhatók ki – egy cikkszám lefedi a kompresszor védelmét, a lépcsőzetes szekvenálást és a leolvasztási időzítést.

Főbb specifikációk HVAC-hez:

- 18–240 VAC/DC univerzális bemenet: Működik lakossági 24 VAC, kereskedelmi 120 VAC, ipari 240 VAC feszültségen.

- –20°C és +60°C közötti működési tartomány: Kezeli a tetőtéri paneleket, amelyek közvetlen napfényben elérik a 60°C+-t.

- 5 A 250 VAC-n (AC-15 kategória): Kényelmes tartalék a kontaktor tekercsekhez (0,2–0,5 A), több kontaktort is kezel.

- 0,1 másodperctől 100 óráig terjedő időzítés: Lefedi a teljes HVAC tartományt (3–10 perc) precíz beállítással.

- ±5% pontosság: Az 5 perces beállítás 4:45–5:15 között tartja a hőmérsékleti tartományban.

- DIN sínre szerelhető: Standard 35 mm-es sín, 22,5 mm-es szélesség, professzionális integráció.

- Kettős LED-es jelzők: Zöld tápellátás, sárga/piros kimenet az azonnali állapot láthatóságához.

Tanúsítványok: IEC 61812-1 (időrelé teljesítmény), UL 508 (ipari vezérlés), CE (EU kisfeszültség + EMC). Az EMC megfelelőség biztosítja a megbízható működést zajos HVAC panelekben.

Támogatás: Kapcsolási rajzok lakossági, kereskedelmi, többlépcsős konfigurációkhoz. Az alkalmazási megjegyzések az időzítés kiválasztását, a helyszíni beállítást és az integrációt fedik le. Műszaki támogatás HVAC tapasztalattal.

Következtetés: A “45 dolláros biztosítási kötvény”

A kompresszor meghibásodások költségesek (1200–15 000 dollár), zavaróak, és mindig a legrosszabbkor történnek – csúcshűtési terhelés, ünnepi hétvége, kritikus műveletek. A rövid ciklus a vezető megelőzhető ok.

40–80 dollárért és egy óra telepítésért kiküszöböli a leggyakoribb meghibásodási módot. A megtérülés azonnali: egy megelőzött meghibásodás fedezi a 20–100 rendszer védelmét.

A mechanizmus egyszerű: a kikapcsolási késleltetés minimális futási időt ír elő azáltal, hogy a működést a termosztát elégedettségén túlra terjeszti ki. A gyors termosztát ciklus káros újraindítások helyett folyamatos működéssé válik. A helyszíni adatok megerősítik: a védett kompresszorok 15–20 éves élettartamot érnek el. A 1–2 percenként ciklusba lépő védelem nélküli kompresszorok 1–3 éven belül meghibásodnak.

Megvalósítás: Válasszon kikapcsolási késleltetésű relét. Méretezze a késleltetést a kompresszorához (3–5 perc lakossági, 5–7 perc kereskedelmi, 7–10 perc nagy rendszerek). Ellenőrizze az AC-15 érintkező besorolását 1–5 A. Kösse sorba a termosztát/biztonsági berendezések és a kontaktor tekercse között. Állítsa be az időzítést, tesztelje, dokumentálja. Nincs programozás. Nincs kalibrálás. Nincs karbantartás.

Vállalkozók számára: Vegye fel standard gyakorlatként az új telepítéseknél. Adja hozzá a kompresszor cseréjekor. Javasolja karbantartás során, ha rövid ciklust észlel. Kevesebb visszahívás. Elégedett ügyfelek.

Létesítmény mérnökök számára: Csökkentse a teljes birtoklási költséget. Adja hozzá a meglévő berendezésekhez, amelyek rövid ciklusú mintákat mutatnak. Adja meg standardként az új beszerzésekhez.

OEM-ek számára: Csökkentse a garanciális igényeket. Mutassa be a mérnöki minőséget. A berendezés árának kevesebb mint 1%-a, de a garanciális hatás jelentős.

Ne várja meg a meghibásodást. Ha gyors ciklust lát – különösen 3 perc alatt –, azonnal adjon hozzá védelmet. A kompresszor minden ciklussal károsodik. A ma telepített relé megakadályozza a következő hónapban esedékes 5000 dolláros cserét.

Kapcsolat VIOX Electric vagy a HVAC forgalmazójától a kiválasztási segítségért és a műszaki támogatásért.