Vezető gyűjtősíngyártó és -szállító: VIOX Electric

A VIOX Electric egy vezető kínai székhelyű gyártó és beszállító, amely a kiváló minőségű rézfésűs gyűjtősín, fáziselosztó gyűjtősínek, és megszakítós gyűjtősínek. Több éves ipari tapasztalatunkkal megbízható, biztonságos és nagy teljesítményű gyűjtősín-megoldásokat kínálunk a legkülönfélébb elektromos rendszerekhez. ISO, UL, CE, RoHS és CSA tanúsítvánnyal rendelkező gyárként elkötelezettek vagyunk az innováció és a kivételes ügyfélszolgálat iránt, így a VIOX Electric ideális partner a szabványos és egyedi gyűjtősín szükségletek. Fedezze fel a csapos és villás gyűjtősínek választékát, vagy lépjen kapcsolatba velünk még ma, hogy egyedi árajánlatot kérjen.

Tanúsította

A gyűjtősín termékválasztékunk

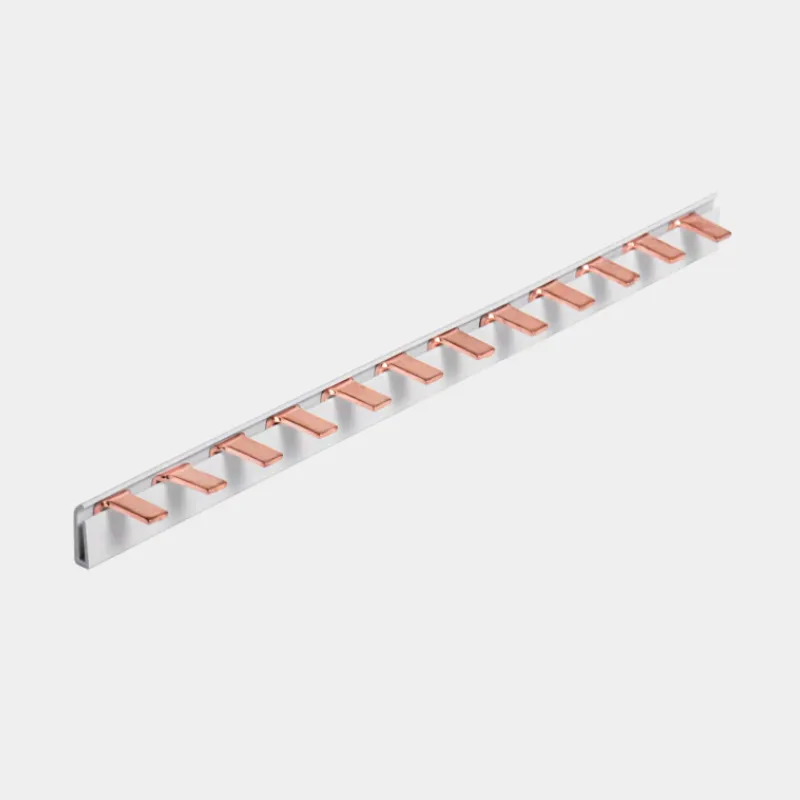

Tűs megszakítós gyűjtősínek

Ideális az MCB-kapcsokba való közvetlen behelyezéshez, egyszerű telepítést és biztonságos csatlakozást biztosít.

Villás megszakítós gyűjtősínek

U-alakú kialakítással rendelkezik a könnyű csatlakoztatás és leválasztás érdekében, különböző terminálkonfigurációkhoz alkalmas.

Gyűjtősín-csatlakozók és tartozékok

Egészítse ki telepítését kiváló minőségű csatlakozók és tartozékok választékával.

Miért érdemes a VIOX Electric partnereként együttműködni a VIOX Electric-el a gyűjtősín szükségleteihez?

A VIOX Electric elkötelezett a kiváló megszakítós gyűjtősínek és testre szabott megoldások biztosítása mellett, amelyek mögött ipari szakértelem és a minőség iránti elkötelezettség áll.

Egyedi megoldások: Olyan megoldások nyújtására összpontosítunk, amelyek megoldják az Ön egyedi elektromos kihívásait. Akár egyedi konfigurációkra, méretekre vagy képességekre van szüksége a megszakítós gyűjtősínekhez, mi egyedi megoldást tudunk készíteni az Ön számára.

Szakértői útmutatás: Ügyfélszolgálati csapatunk iparági szakértőkből áll. Szorosan együttműködnek Önnel, hogy megértsék az Ön igényeit, és megalapozott, gyakorlatias megoldásokat kínáljanak az Ön igényeinek kielégítésére.

Fejlett gyártási technikák: Annak érdekében, hogy Ön kiváló minőségű gyűjtősíneket kapjon, a legkorszerűbb berendezéseket, anyagokat és gyártási folyamatokat alkalmazzuk. Ez garantálja, hogy megoldásaink egyszerre hatékonyak és tartósak.

VIOX teljes tartományú Mcb gyűjtősínek

A VIOX Electric az MCB gyűjtősínjeink kiegészítéseként átfogó tartozékválasztékot kínál, beleértve a gyűjtősín végsapkákat, csatlakozókat, 5 pólusú védőburkolatot és szárnyhidakat, serpenyős gyűjtősíneket, rézsíneket, sárgaréz csatlakozóblokkokat, sárgaréz síneket, csatlakozóblokk dobozokat, valamint acél és alumínium DIN síneket. Válassza a VIOX Electricet a megbízható és hatékony elektromos megoldásokért.

- Sínvégsapkák

- Csatlakozók

- 5 pólusú védőburkolat és szárnyhidak

- Pan szerelvény gyűjtősín

- Réz bár

- Sárgaréz terminálblokk

- Sárgaréz bár

- Terminálblokk doboz

- Acél és alumínium DIN sínek

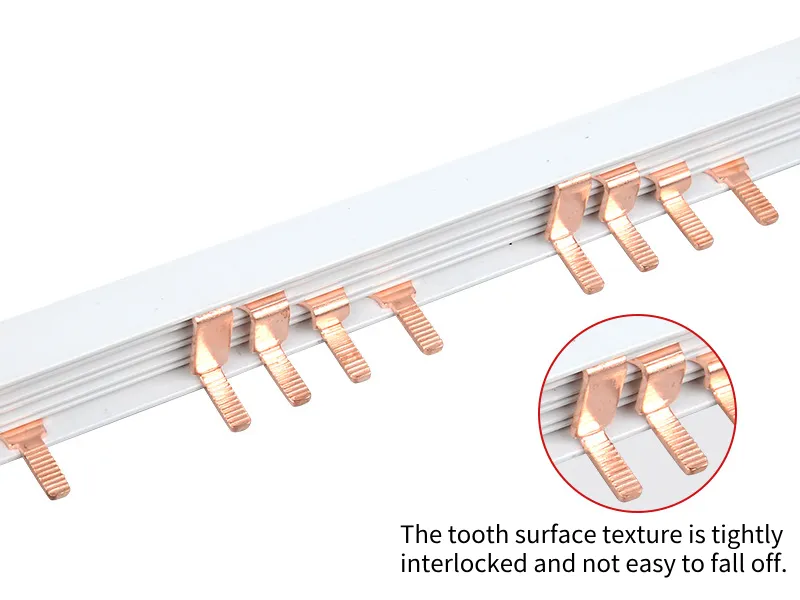

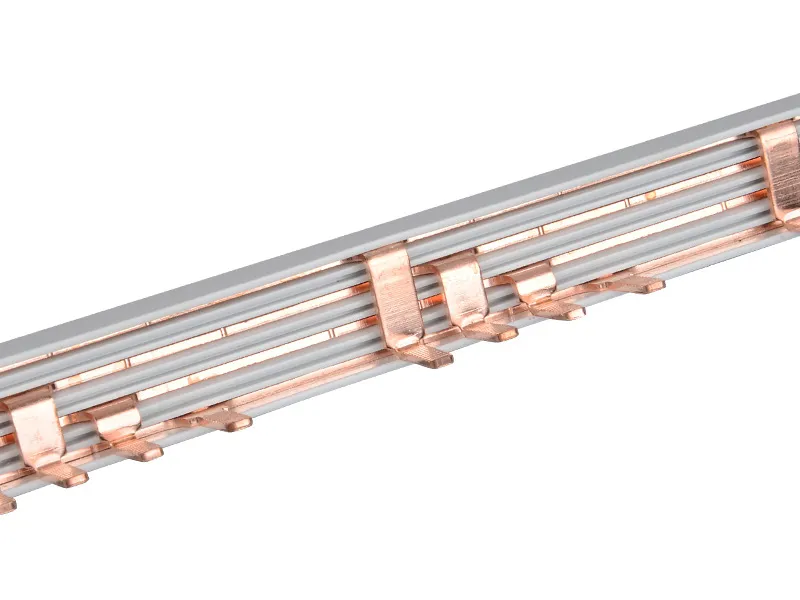

Precíz kivitelezés és kiváló anyagok

Prémium nagy vezetőképességű réz

Nagy szilárdságú, hengerelt réz (vagy meghatározott alumínium) felhasználásával biztosítjuk az optimális vezetőképességet és mechanikai integritást.

Hibátlan felület és méretpontosság

A gyűjtősínjeink sima felületűek, nem tartalmaznak súrlódásokat vagy hibákat. Szigorú folyamatellenőrzés garantálja a szélesség és a laposság nagyfokú stabilitását, pontosan betartva a szabványos méreteket.

Következetes minőség

Az aprólékos kivitelezés egyenletes textúrát és egyenletesen jó minőségű gyűjtősíneket eredményez, amelyekben megbízhat.

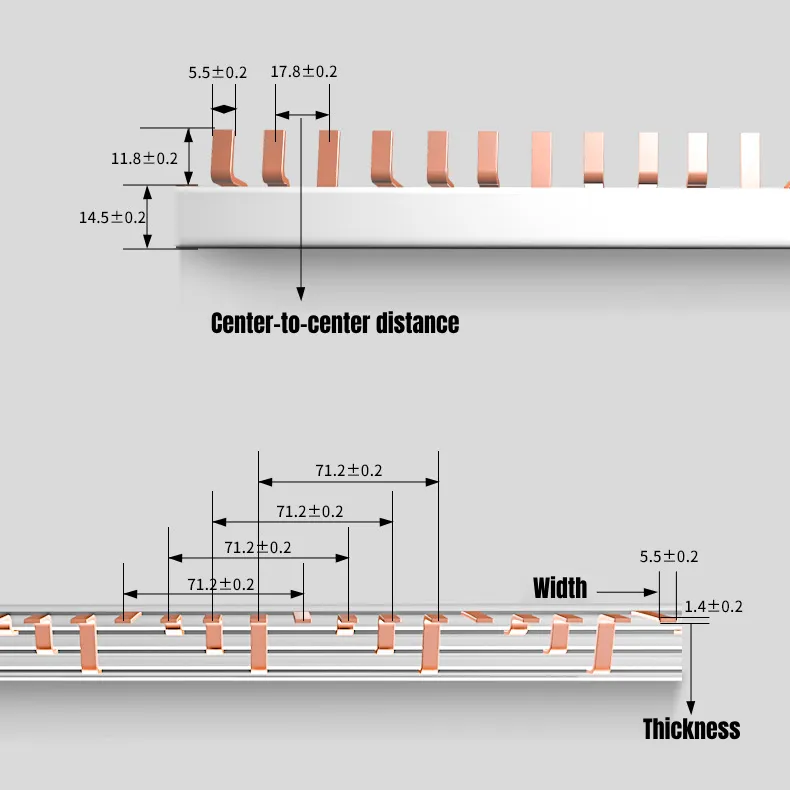

MCB GYŰJTŐSÍN MÉRETEK ÉS MÉRETTÁBLÁZAT

| Modell sorozat | Fázisok | Keresztmetszetek | Hosszúsági opciók (mm) | Maximális áram |

|---|---|---|---|---|

| S-1L | 1-fázisú | 8-16mm² | 210, 1000, 1016 | 50-80A |

| S-2L | 2-fázisú | 8-16mm² | 210, 1000, 1016 | 50-80A |

| S-3L | 3 fázisú | 8-16mm² | 210, 1000, 1016 | 50-80A |

| S-4L | 4-fázisú | 8-16mm² | 210, 1016 | 50-80A |

| S-3L+N | 3P+N | 8-16mm² | 210, 1000 | 50-80A |

| P-1L | 1-fázisú | 8-16mm² | 210, 1000, 1016 | 50-80A |

| P-2L | 2-fázisú | 8-16mm² | 210, 1000, 1016 | 50-80A |

| P-3L | 3 fázisú | 8-16mm² | 210, 1000, 1016 | 50-80A |

| P-4L | 4-fázisú | 8-16mm² | 210, 1016 | 50-80A |

| P-1+N | 1P+N | 8-16mm² | 210, 1000 | 50-80A |

| P-1+N-LE | 1P+N-LE | 8-16mm² | 210, 1000 | 50-80A |

| C-1L | 1-fázisú | 8-16mm² | 210, 1000, 1016 | 50-80A |

| C-2L | 2-fázisú | 8-16mm² | 210, 1000, 1016 | 50-80A |

| C-3L | 3 fázisú | 8-16mm² | 210, 1000, 1016 | 50-80A |

| C-4L | 4-fázisú | 8-16mm² | 210, 1016 | 50-80A |

| Modell sorozat | Fázisok | Csatlakozó típusa | Keresztmetszetek | Hosszúsági opciók (mm) | Maximális áram |

|---|---|---|---|---|---|

| F-1L | 1-fázisú | Villa (M6) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| F-2L | 2-fázisú | Villa (M6) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| F-3L | 3 fázisú | Villa (M6) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| F-3L (M5) | 3 fázisú | Villa (M5) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| F-4L | 4-fázisú | Villa (M6) | 8-16mm² | 210, 1016 | 50-80A |

| G-1L | 1-fázisú | Villa (M6) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| G-2L | 2-fázisú | Villa (M6) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| G-3L | 3 fázisú | Villa (M6) | 8-16mm² | 210, 1000, 1016 | 50-80A |

| G-4L | 4-fázisú | Villa (M6) | 8-16mm² | 210, 1016 | 50-80A |

| G-3L+N | 3P+N | Villa (M6) | 8-16mm² | 210, 1000 | 50-80A |

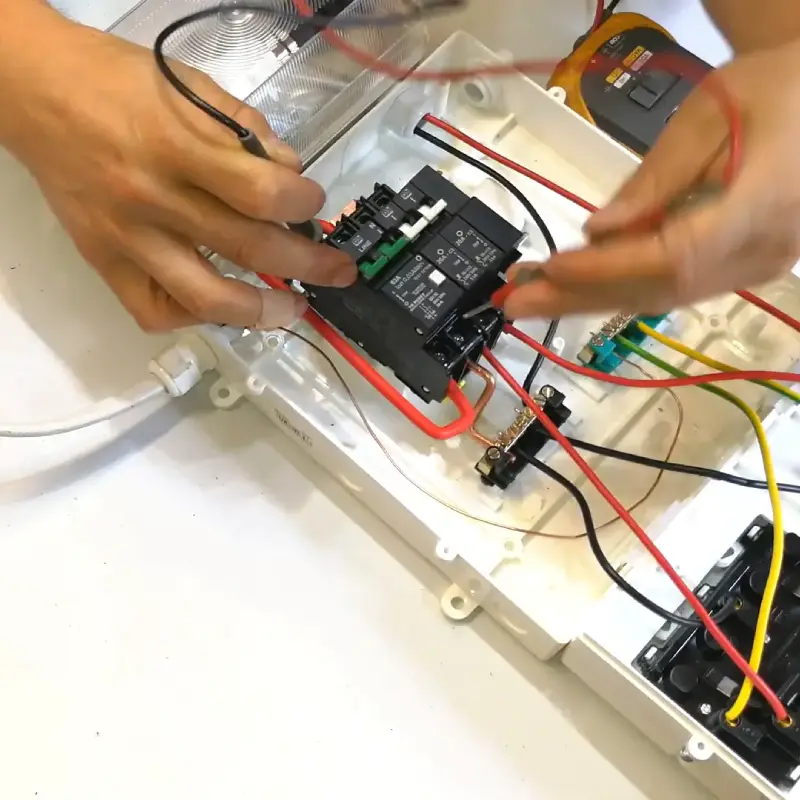

VIOX gyűjtősín lépésről lépésre történő telepítése

Az MCB gyűjtősínek szerelési folyamata gondos előkészítést és a részletekre való odafigyelést igényel. Kezdje az összes csatlakozócsavar teljes kinyitásával, és a legnagyobb besorolású MCB-k vagy RCBO-k elhelyezésével a fő bemeneti eszközhöz legközelebb12. A megfelelő telepítéshez kövesse az alábbi lépéseket

01

02

03

04

05

06

Get Your Ingyenes gyűjtősín minta!

Ingyenes mintákat biztosítunk, csak meg kell mondania nekünk, hogy mire van szüksége

Több mint egy gyűjtősíngyártó

A VIOX-nál büszkék vagyunk arra, hogy időben támogatást nyújtunk, betartjuk a magas színvonalat, és olyan testreszabott megoldásokat kínálunk, amelyek megfelelnek ügyfeleink igényeinek, ami a Busbarral való növekvő hírnevünk alapját képezi.

Szolgáltatás Konzultáció

Ha az Ön Busbar-követelményei egyszerűek, és nincs szüksége külső konzultációra, csapatunk ésszerű díj ellenében szakértői tanácsadást és útmutatást nyújt.

Ajánlások gyűjtősínre

Nem tudja, melyik gyűjtősínt válassza a projektjéhez? Személyre szabott ajánlásokat adunk az Ön egyedi igényei alapján, minden ügyfelünk számára ingyenesen.

Logisztikai támogatás

Ha nincs megfelelő szállítmányozója, segítünk megszervezni a kapcsoló helyzetjelzők szállítását gyárunkból a projekt helyszínére, külön szolgáltatási díj nélkül.

Telepítési támogatás

Ha kérdése van a Busbar telepítésével kapcsolatban, forduljon hozzánk bizalommal. Segítséget nyújtunk a telepítésben, és akár mérnököt is küldhetünk a projekt helyszínére, aki gyakorlati támogatást nyújt.

VIOX gyűjtősín műszaki műhely

Gyakran Ismételt Kérdések

Összegyűjtöttünk néhány gyakori kérdést ügyfeleinktől. Ha az Ön kérdése nem szerepel itt, ügyfélszolgálatunk mindig szívesen segít. Szívesen beszélgetünk Önnel.

Hogyan kaphatok árajánlatot a megszakítós gyűjtősínekre?

Ha árajánlatot szeretne kérni megszakítós gyűjtősínjeinkre, lépjen kapcsolatba ügyfélszolgálatunkkal. A nap 24 órájában rendelkezésre állunk. Csak adja meg a megrendelésének részleteit, mint például a típus, a méret és a mennyiség. Végigvezetjük Önt a teljes rendelési folyamaton.

Mi a MOQ a megrendeléshez?

Alacsony MOQ vagy minimális rendelési mennyiséggel rendelkezünk. Akár egy darabot is rendelhet, és mi az Ön specifikációi szerint szállítunk.

Mennyi a rendelésem átfutási ideje?

A megszakítós gyűjtősínek standard átfutási ideje 7-10 munkanap. A szállítási idő a tranzit miatt akár 15 munkanappal is meghosszabbodhat. Egyedi vagy tömeges megrendelések esetén a rendelés véglegesítése előtt megbeszélhetjük az átfutási időt.

Kaphatok mintát a megrendelés leadása előtt?

Igen, mintákat biztosítunk értékelésre és jóváhagyásra. A minták elkészítése általában 3-7 munkanapot vesz igénybe.

Tud egyedi megszakítós gyűjtősínt készíteni?

Igen, egyedi megszakítós gyűjtősíneket kínálunk. Tudassa velünk igényeit, és szakértő ügyfélszolgálati csapatunk együtt dolgozik Önnel a tervezési folyamat során.

Milyen garanciát vállal a megszakítós gyűjtősínekre?

Minden általunk gyártott megszakítós gyűjtősínre 5 év garanciát vállalunk. Ez biztosítja, hogy kiváló minőségű termékeket szállítunk. Minden terméket alaposan tesztelünk szállítás előtt.

Szakértői megszakítós gyűjtősín tudásforrások

Mi az a megszakító BUSBAR?

A megszakítós gyűjtősín egy speciális elektromos alkatrész, amelyet az áram hatékony elosztására és több megszakító összekapcsolására terveztek az elektromos rendszerekben. Ezek a gyűjtősínek jellemzően nagy vezetőképességű anyagokból, például rézből vagy alumíniumból készülnek, és központi csatlakozási pontként szolgálnak a bejövő és kimenő elektromos áram számára..

MCB gyűjtősín alkatrészek

A jellemzően rézből vagy alumíniumból készült fémvezetőkből álló MCB gyűjtősínek a kapcsolótáblák és az elektromos készülékek energiaelosztásának gerinceként szolgálnak.. Ezek az alapvető fontosságú alkatrészek különböző keresztmetszetekben kaphatók, a leggyakoribb méretek közé tartozik a 10mm² (63A névlegesen) és a 16mm² (80A névlegesen).. A rendszer olyan kritikus elemeket tartalmaz, mint:

- Egyenes szakaszok az energia szállításához és elosztásához

- További tartozékok a rendszer kiegészítéséhez

- Szigetelők és megszakítók a védelemhez

- Ketrec típusú csatlakozók a biztonságos csatlakozásokhoz

- Shunt kioldások a távoli kioldási képességek érdekében

A gyűjtősín működési elvei

A megszakítós gyűjtősínek hatékony áramelosztó rendszerként működnek, összegyűjtik az áramot a bejövő betáplálásokról és elosztják azt a kimenő betáplálásokon.. Központi elektromos csomópontként működnek, ahol a bejövő és kimenő áramok összefolynak.. A gyűjtősínrendszer a biztonság érdekében leválasztókkal és megszakítókkal van ellátva.. Hiba esetén a megszakító kiold, és a hibás szakasz leválasztja az áramkörről..

A gyűjtősín üzemeltetésének legfontosabb szempontjai a következők:

Vezetés: A gyűjtősínek az elektromos áramnak a tápegységekből a különböző alkatrészekhez történő továbbítására szolgálnak..

Elterjedés: Az elektromos rendszer különböző részein egyenletesen osztják el a teljesítményt..

Csatlakozás: A gyűjtősínek több elektromos eszközt, például transzformátorokat és generátorokat kötnek össze a fő tápegységgel..

Hőelvezetés: A gyűjtősínek kialakítása segít elvezetni az elektromos áram által termelt hőt, megelőzve a túlmelegedést és biztosítva a rendszer biztonságos működését..

Az áramelosztás központosításával a gyűjtősínek egyszerűsítik a vezetékezés bonyolultságát, növelik a biztonságot és biztosítják a megbízható áramellátást különböző alkalmazásokban, az ipari környezetektől a megújuló energiarendszerekig..

Miben különböznek a gyűjtősínek a többi elektromos vezetőtől?

A gyűjtősínek és más elektromos vezetékek kialakításuk, alkalmazásuk és teljesítményjellemzőik tekintetében jelentősen különböznek egymástól. A gyűjtősínek jellemzően nagyobb, lapos vagy rúd alakú, nagyáramú alkalmazásokra tervezett szerkezetek, amelyeket gyakran használnak ipari környezetben elektromos panelek vagy kapcsolóberendezések áramelosztására. Ezek általában nem szigeteltek, és nagyobb felületüknek köszönhetően hatékonyabban képesek nagyobb mennyiségű áramot kezelni. Ezzel szemben a hagyományos elektromos vezetékek, mint a vezetékek és kábelek általában hengeresek, szigeteltek és sokoldalúbbak az alkalmazásukban, beleértve a lakossági vezetékeket is.

A gyűjtősínek legfontosabb előnyei közé tartozik, hogy nagyobb áramot képesek átvinni, jobb hőelvezetést biztosítanak, és az alacsonyabb ellenállásnak köszönhetően javítják az energiaelosztó rendszerek hatékonyságát. Emellett bizonyos körülmények között könnyebb hozzáférést biztosítanak a tápcsapoláshoz és egyszerűbb telepítést. A kábelek azonban nagyobb rugalmasságot biztosítanak, és alkalmasabbak olyan környezetben, ahol az alkalmazkodóképesség és a szigetelés döntő fontosságú. A gyűjtősínek és más vezetékek közötti választás az elektromos rendszer egyedi követelményeitől függ, beleértve az áramkapacitást, a telepítési környezetet és az alkalmazási igényeket.

MCB gyűjtősíntípusok

Az MCB gyűjtősínek különböző típusokban kaphatók, hogy megfeleljenek a különböző elektromos rendszerkövetelményeknek és konfigurációknak. Az alábbiakban áttekintjük a főbb típusokat:

Egyfázisú (1P): Egyfázisú áramkörökhöz tervezték, jellemzően lakossági és kis kereskedelmi alkalmazásokban használják.

Kétfázisú (2P): Alkalmas kétpólusú MCB-k vagy egyfázisú készülékek csatlakoztatására semleges csatlakozással.

Háromfázisú (3P): Háromfázisú rendszerekben használatos, ipari és nagyobb kereskedelmi létesítményekben gyakori.

Négyfázisú (4P): Háromfázisú rendszereket fogad nullával, átfogó védelmet biztosítva minden vezeték számára.

Tüske-típus: Rézcsapokkal rendelkezik, amelyek közvetlenül az MCB csatlakozókba illeszkednek, és így könnyű telepítést és eltávolítást tesznek lehetővé.

Fésűs típus: Fésűs szerkezetre hasonlít, amely lehetővé teszi több eszköz rugalmas csatlakoztatását a hossza mentén.

Fix hosszúságú: Előre meghatározott méretekben kaphatók a meghatározott panelkonfigurációkhoz.

Hosszra vágva: Nagyobb rugalmasságot kínálva, a helyszínen testreszabható a panel pontos méreteire.

Ezek a különböző típusok biztosítják, hogy az MCB gyűjtősíneket a különböző elektromos rendszerigényeknek megfelelően lehet kialakítani a lakossági, kereskedelmi és ipari alkalmazásokban.

Gyűjtősín alkalmazási területek

A megszakítós gyűjtősíneket széles körben használják a különböző elektromos rendszerekben, hatékony energiaelosztást és védelmet biztosítva. A legfontosabb alkalmazások közé tartoznak:

Az épületek áramelosztó táblái, ahol a gyűjtősínek a bejövő áramot külön áramkörökre osztják fel.

Adatközpontok, a szerverek és berendezések megbízható áramellátásának biztosítása

Kórházak, a műtők és intenzív osztályok kritikus energiaigényének biztosításához

Ipari gépek, amelyek megkönnyítik a belső energiaelosztást a főcsatlakozóktól az alkatrészekig

Megújuló energiarendszerek, például nap- és szélerőművek, ahol a gyűjtősínek hatékony energiaátvitelt biztosítanak.

Elektromos járművek és akkumulátortároló rendszerek, a súlycsökkentés érdekében szigetelt alumínium gyűjtősínek alkalmazásával

Ezek az alkalmazások kihasználják a gyűjtősínrendszerek kompakt kialakítását, rugalmasságát és biztonsági jellemzőit, ami a modern elektromos infrastruktúra alapvető elemeivé teszi őket a lakossági, kereskedelmi és ipari szektorokban..

A tűs és villás MCB gyűjtősínek összehasonlítása

A tűs és villás MCB gyűjtősínek különböző előnyöket kínálnak a különböző elektromos alkalmazásokhoz. A tűs gyűjtősínek rézcsapokkal rendelkeznek, amelyek közvetlenül az MCB-kapcsokba illeszkednek, és így egyszerű telepítést és eltávolítást biztosítanak.. Szélesebb érintkezési felületet kínálnak, ami alacsonyabb energiafogyasztást és kisebb hőmérséklet-emelkedést eredményez.. A villás gyűjtősínek, más néven spade-kapcsok U-alakú kialakítással rendelkeznek, amely lehetővé teszi a könnyű csatlakoztatást és leválasztást a csatlakozási pont teljes eltávolítása nélkül..

A legfontosabb különbségek a következők:

Telepítés: A csapos gyűjtősínt általában gyorsabb és könnyebb felszerelni, míg a villás típus rugalmasabb eltávolítást és cserét tesz lehetővé..

Vezetőképesség: Mindkét típus jó vezetőképességet biztosít, de a csapos gyűjtősíneknek gyakran kisebb az érintkezési ellenállása..

Alkalmazások: A villás gyűjtősínek különösen akkor hasznosak, ha két bemeneti csatlakozó van a feszültséghez, míg a csaposok univerzálisabbak az MCB-khez..

Testreszabás: A villás gyűjtősínek könnyebben személyre szabhatók a hosszuk csökkentésével, ami egyes berendezésekben nagyobb alkalmazkodóképességet biztosít..

A tűs és villás gyűjtősínek közötti választásnál vegye figyelembe az olyan tényezőket, mint az adott MCB-konfiguráció, a karbantartás egyszerűsége és az elektromos rendszer jövőbeli módosításainak lehetséges szükségessége.

Biztonsági jellemzők és minősítések

Az MCB gyűjtősínrendszerek biztonsági jellemzői közé tartoznak a beépített megszakítók, amelyek hiba esetén automatikusan kioldanak, és a további károk megelőzése érdekében elkülönítik a hibás szakaszokat. Ezeket a rendszereket úgy tervezték, hogy 415V-ig terjedő feszültségen működjenek, és mérettől függően 63A-tól 225A-ig terjedő áramok kezelésére alkalmasak.. A névleges impulzusállósági feszültség 4 kV, ami biztosítja a feszültségcsúcsok elleni védelmet. A 36 mm²-es maximális gyűjtősínméret használatakor fontos megjegyezni, hogy a legnagyobb kompatibilis kábel 6 AWG (16 mm²)..

A gyűjtősín kiválasztásának kritériumai

A megszakítós gyűjtősínek kiválasztásakor vegye figyelembe a következő kulcsfontosságú tényezőket:

Jelenlegi kapacitás: A várható legnagyobb áramterhelésre méretezett gyűjtősínek kiválasztása, figyelembe véve olyan tényezőket, mint a környezeti hőmérséklet és a tengerszint feletti magasság..

Névleges feszültség: Biztosítani kell, hogy a gyűjtősín képes legyen kezelni a rendszer üzemi feszültségét, beleértve az esetleges túlfeszültségeket is..

Rövidzárlati áram: Olyan gyűjtősínt kell választani, amely képes ellenállni a rendszer maximális hibaáramának..

Az oszlopok száma: A gyűjtősín-konfiguráció (1P, 2P, 3P, 4P) az áramköri követelményekhez igazodik..

Kompatibilitás: Ellenőrizze, hogy a gyűjtősín kompatibilis-e az adott megszakító modellekkel és szerelési elrendezésekkel..

Környezeti feltételek: Az anyagok és a szigetelés kiválasztásakor vegye figyelembe az olyan tényezőket, mint a páratartalom, a hőmérséklet és a korróziós elemeknek való esetleges kitettség..

A megszakítós gyűjtősínek megfelelő kiválasztása és beszerelése érdekében mindig konzultáljon a gyártó előírásaival és a helyi elektromos szabályzatokkal az adott alkalmazáshoz.

A réz vs. alumínium gyűjtősínek előnyei

A réz és az alumínium gyűjtősínek mindegyike különböző előnyöket kínál az elektromos rendszerekben. A réz gyűjtősínek vezetőképességben kiemelkednek, körülbelül 60%-vel magasabb elektromos vezetőképességgel, mint az alumínium.. Ez a kiváló vezetőképesség lehetővé teszi, hogy a réz gyűjtősínek kisebb keresztmetszet mellett nagyobb áramot vezessenek, így ideálisak a helyszűkös alkalmazásokhoz.. A réz kiváló korrózióállóságot és hőkezelést is mutat, hatékonyan elvezeti a hőt és csökkenti a rendszer meghibásodásának kockázatát..

Másrészt az alumínium gyűjtősínek a költséghatékonyság és a súly szempontjából is ragyognak. Az alumínium általában megfizethetőbb, mint a réz, így vonzó választás nagyszabású projektek vagy költségvetés-érzékeny alkalmazások esetén.. Ezenkívül az alumínium kisebb sűrűsége könnyebb gyűjtősíneket eredményez, ami előnyös lehet olyan iparágakban, mint a repülőgépipar és az autóipar, ahol a súlycsökkentés kulcsfontosságú.. Míg az alumínium további felületkezelést igényel a korrózióállóság fokozásához, természetes oxidrétege bizonyos fokú védelmet nyújt.. Végső soron a réz és alumínium gyűjtősínek közötti választás a projekt egyedi követelményeitől függ, olyan tényezők kiegyensúlyozásával, mint a vezetőképesség, a költségek, a súly és a környezeti feltételek.

Minőségi MCB gyűjtősín kritériumai

A kiváló minőségű MCB gyűjtősínt több kulcsfontosságú jellemzővel lehet meghatározni:

- Anyagösszetétel: A kiváló elektromos tulajdonságai és korrózióállósága miatt a rezet részesítik előnyben..

- Szigetelés: A minőségi gyűjtősínek robusztus szigeteléssel rendelkeznek, gyakran olyan anyagokat használnak, mint a PET-fólia vagy hőálló műanyag, például a Cycoloy 3600, ami biztosítja a biztonságot és megakadályozza az elektromos szivárgást..

- Jelenlegi kapacitás: A jó gyűjtősíneknek a tervezett alkalmazásuknak megfelelő áramerősséggel kell rendelkezniük, az általános névleges értékek 63A és 225A között mozognak..

- A tanúsításnak való megfelelés: A kiváló minőségű gyűjtősínek megfelelnek vagy meghaladják az ipari szabványokat, például az UL489, CSA C22.2 No.5 és a RoHS követelményeket..

- Tartósság: A kiváló gyűjtősínek nagy mechanikai szilárdságot mutatnak, ütésállósági besorolással, mint például IK10, és ellenállnak a zord környezeti körülményeknek..

A jó minőségű MCB gyűjtősínnek rugalmasságot kell nyújtania a telepítés során, például méretre vághatónak kell lennie, és olyan tartozékokat kell biztosítania, mint a végsapkák és védőburkolatok a fokozott biztonság és funkcionalitás érdekében.. Ezenkívül alacsony elektromágneses kibocsátással és hatékony hőelvezetéssel kell rendelkeznie, hogy megbízható teljesítményt nyújtson a különböző elektromos rendszerekben..

A gyűjtősín vizsgálati módszerei

Ha ellenőrizni szeretné, hogy a megszakítós gyűjtősín megfelelően működik-e, kövesse az alábbi lépéseket:

Végezzen szemrevételezéses ellenőrzést a sérülések, korrózió vagy laza csatlakozások jeleinek feltárására..

Használjon multimétert a feszültség vizsgálatához:

Állítsa be a multimétert váltakozó feszültség mérésére

Helyezze az egyik szondát a gyűjtősín csatlakozójára, a másikat pedig a semleges sínre.

A névleges feszültséghez közeli érték (pl. 120 V vagy 240 V) azt jelzi, hogy a gyűjtősín feszültség alatt áll.

Ellenőrizze a folytonosságot:

Állítsa a multimétert folytonossági vagy ellenállás üzemmódba.

Teszt a gyűjtősíncsatlakozó és a megszakító kimeneti csatlakozója között

A nulla közeli ellenállásérték megfelelő csatlakozást jelez.

Végezze el a szigetelési ellenállás vizsgálatát:

Használjon meggert a fázisok közötti, valamint az egyes fázisok és a föld közötti szigetelési ellenállás mérésére.

A leolvasásoknak meg kell felelniük a gyártó előírásainak

Végezze el az érintkezési ellenállás vizsgálatát egy digitális alacsony ellenállású ohmméterrel (DLRO), hogy biztosítsa az alacsony ellenállást a csatlakozási pontokon.

Ha e vizsgálatok során bármilyen problémát észlel, forduljon szakképzett villanyszerelőhöz további ellenőrzés és esetleges javítás céljából.

Kínai MCB gyűjtősín gyártók

Kína az MCB (Miniature Circuit Breaker) gyűjtősínek vezető globális gyártójává vált, számos vállalat szakosodott erre az alapvető elektromos alkatrészre. Közülük, VIOX Electric kiemelkedik fejlett gyártási technikáival és a minőség iránti elkötelezettségével, és precíziós termékekkel elégíti ki a legkülönbözőbb ipari igényeket.A globális piac megbízható beszállítójaként, VIOX Electric a különböző specifikációkhoz igazított gyűjtősín-megoldások széles választékát kínálja. Az innovációra és a szigorú minőségellenőrzésre helyezett hangsúly kiemeli Kína vezető szerepét az MCB gyűjtősíniparban.

Egyedi OEM megszakítós gyűjtősínek

A VIOX Electric készen áll arra, hogy segítséget nyújtson Önnek az OEM megszakítós gyűjtősín igényeivel kapcsolatban. Kiváló minőségű és költséghatékony megoldásokat kínálunk.