Introduction

What is MCCBs

Moulded Case Circuit Breakers (MCCBs) are critical components in electrical systems, designed to protect circuits from overloads and short circuits. They are particularly valued in commercial and industrial applications due to their robust construction and operational reliability.

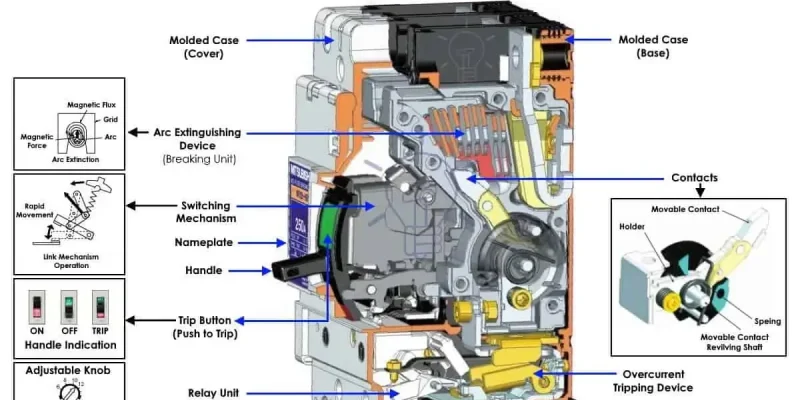

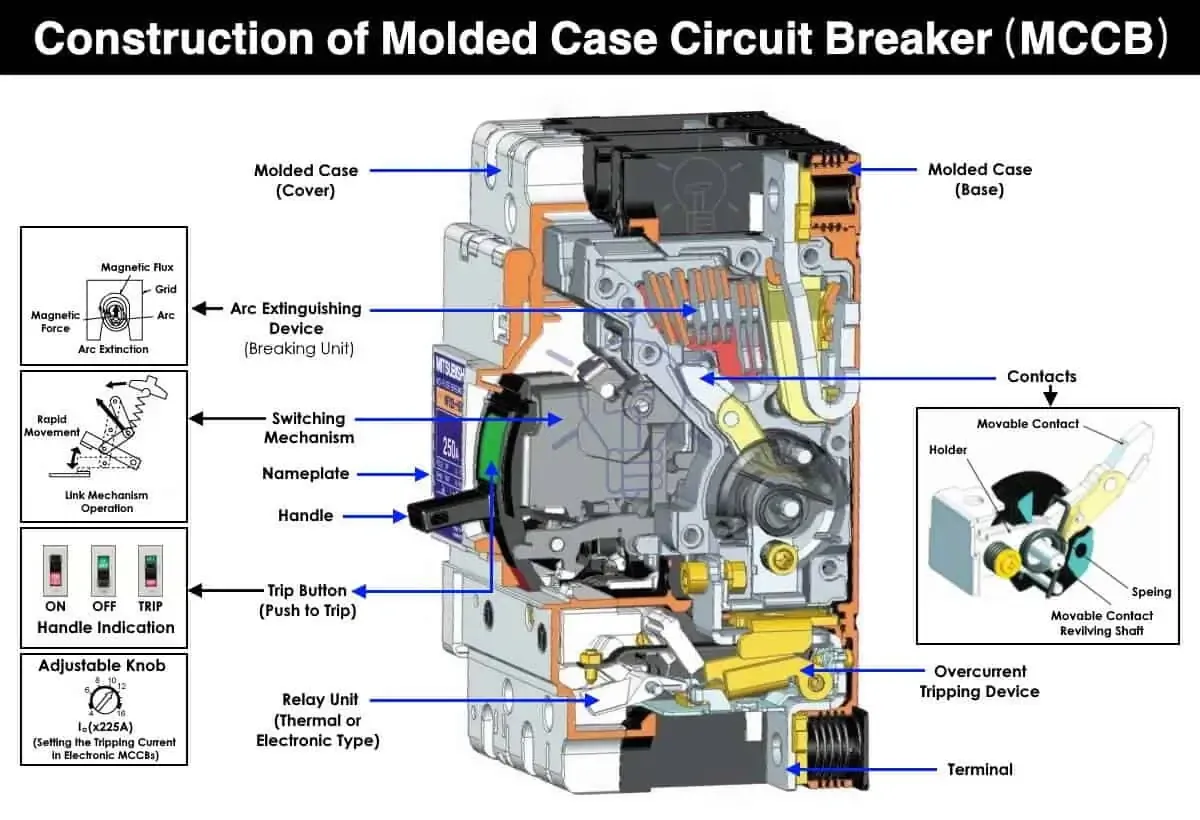

Construction of MCCBs

- Molded Case: The outer shell of the MCCB, typically made from thermoset composite resin or glass polyester, provides high dielectric strength and protects the internal components from environmental factors.

- Trip Mechanism: This is a critical feature that allows the MCCB to interrupt the circuit during fault conditions. It usually consists of:

- Thermal Element: A bimetallic strip that bends under heat generated by excessive current, triggering the trip mechanism. This provides overload protection by allowing the breaker to trip when current exceeds a preset level.

- Magnetic Element: A solenoid coil that generates an electromagnetic field during a short circuit, causing immediate tripping. This component ensures rapid response to fault conditions.

- Terminals: MCCBs have line and load terminals for connecting to the electrical circuit. These terminals facilitate the flow of current through the breaker.

- Adjustable Current Rating: Many MCCBs feature adjustable settings for both thermal and magnetic trip mechanisms, allowing customization based on specific load characteristics and operational requirements.

- Auxiliary Components: These may include:

- Auxiliary Contacts: For signaling or control purposes.

- Alarm Contacts: To indicate fault conditions.

- Shunt Release: For remote tripping operations.

- Undervoltage Release: To trip the circuit in case of voltage drops.

- Breaking Capacity Ratings: MCCBs are rated for their ability to interrupt fault currents safely, with two key ratings:

- Ultimate Short-Circuit Breaking Capacity (Icu): The maximum fault current that can be interrupted without damage.

- Rated Short-Circuit Breaking Capacity (Ics): The maximum current that can be interrupted while still allowing for multiple operations after tripping.

Working Principle of MCCBs

MCCBs protect electrical circuits using two main mechanisms:

- Thermal Protection

- Uses a bimetallic strip

- Bends when heated by excessive current

- Trips the breaker for sustained overloads

- Magnetic Protection

- Employs a solenoid

- Creates strong magnetic field during short circuits

- Quickly trips the breaker for sudden high currents

Additional Features:

- Current-carrying contacts

- Arc quenching system to safely interrupt current

- Trip unit to monitor and signal when to open contacts

MCCBs provide:

- Overload protection (gradual response)

- Short circuit protection (immediate response)

- Manual control for operational flexibility

Types of MCCBs

MCCBs come in several configurations tailored for different applications:

- Thermal Magnetic MCCB: Combines both thermal and magnetic trip mechanisms for comprehensive protection.

- Electronic MCCB: Incorporates advanced electronics for precise trip settings and additional monitoring capabilities.

- Ground Fault MCCB: Specifically designed to detect ground faults, enhancing safety in sensitive environments.

Difference between MCB and MCCB

| Feature | MCB | MCCB |

|---|---|---|

| Full Form | Miniature Circuit Breaker | Molded Case Circuit Breaker |

| Current Ratings | Typically up to 100A | Ranges from 10A to 2500A or more |

| Interrupting Capacity | Up to 10 kA | Up to 100 kA |

| Size | Compact and lightweight | Larger and more robust |

| Tripping Mechanism | Fixed thermal-magnetic | Thermal-magnetic and adjustable settings |

| Applications | Residential and light commercial | Industrial and large commercial setups |

| Cost | Generally less expensive | More expensive due to higher capacity |

| Resetting | Easy to reset without replacement | Requires manual intervention for reset |

Detailed Explanation

- Current Ratings:

- MCBs are designed for lower current applications, typically up to 100A, making them suitable for residential circuits.

- MCCBs, on the other hand, can handle much higher currents, ranging from 10A to 2500A, which is essential for industrial applications.

- Interrupting Capacity:

- The interrupting capacity of an MCB is generally limited to 10 kA, while MCCBs can interrupt fault currents up to 100 kA, providing greater protection in high-load scenarios.

- Size and Construction:

- MCBs are compact, making them ideal for installations with limited space. MCCBs are larger due to their robust construction needed for handling higher currents and voltages.

- Tripping Mechanism:

- MCBs typically have fixed trip settings that respond quickly to overloads or short circuits. In contrast, MCCBs offer adjustable trip settings, allowing for customization based on specific load requirements.

- Applications:

- MCBs are commonly used in residential settings for individual circuit protection, while MCCBs are utilized in industrial environments where higher power loads are present.

- Cost Considerations:

- Due to their advanced features and higher capacity, MCCBs tend to be more expensive than MCBs, which are a cost-effective solution for smaller electrical systems.

Selection Criteria

When choosing an MCCB, several factors should be considered:

- Current Rating: Select based on the maximum expected load; ratings typically range from 10A to several hundred amperes.

- Breaking Capacity: This indicates the maximum fault current the MCCB can interrupt without damage. Common ratings include 25kA, 36kA, and higher.

- Voltage Rating: Ensure compatibility with the electrical system’s nominal voltage.

Applications

MCCBs are widely used across various sectors:

- Residential Buildings: To protect household electrical systems from overloads.

- Commercial Facilities: Ensuring safety in office buildings and retail environments.

- Industrial Settings: Providing robust protection for heavy machinery and equipment.

Installation and Maintenance

Proper installation and maintenance are vital for optimal performance:

- Qualified Personnel: Installation should be conducted by licensed electricians familiar with local codes.

- Regular Maintenance: Periodic checks can prevent failures and extend the lifespan of MCCBs. This includes inspecting connections, testing trip settings, and ensuring cleanliness of the breaker.

How to Test MCCBs

- Insulation Resistance Test

- Use megohmmeter to measure resistance between phases and terminals

- Ensure it meets manufacturer’s specifications

- Contact Resistance Test

- Measure resistance across contacts during normal operation

- Compare with manufacturer’s acceptable range

- Tripping Test

- Thermal: Apply 300% rated current; check if it trips within specified time

- Magnetic: Use high current pulses to test instant tripping

- Mechanical Test

- Open and close breaker repeatedly to check smooth operation

- Dielectric Test

- Apply high voltage between terminals and ground to test insulation strength

Safety: Always disconnect MCCB from power before testing. Follow manufacturer guidelines.

Regular testing ensures reliable MCCB operation and effective circuit protection.

Manufacturers and Models of MCCBs

VIOX Electric

Brand advantage: A Chinese brand recognized for its competitive pricing, reliability, and comprehensive product range.

Recommended models:

- VIOX VM1-400L/4300 Multi-Purpose Industrial MCCB

- VIOX VMM3-400 3P 400A MCCB

EATON

Eaton Corporation plc is a global power management company headquartered in Dublin, Ireland, specializing in energy-efficient electrical, hydraulic, and mechanical power solutions for diverse industries worldwide.

Recommended models:

- Eaton FD3020 3 Pole Circuit Breaker

- Eaton/Cutler-Hammer KD3400 3 Pole Circuit Breaker

- Eaton HFD3070 3 Pole Circuit Breaker

ABB

ABB is a Swiss-Swedish multinational company headquartered in Zurich, Switzerland. It primarily operates in the fields of robotics, motors, energy, automation, and railway trains. The company has also ventured into motor racing and was the title sponsor of the FIA Formula E Championship in 2017.

Recommended models:

- S3N-3P-60A – ABB Bolt-On 600V 60A 3 pole circuit breaker 25kA@480V

- ABB XT1NU3040AFF000XXX Molded Case Circuit Breaker

- 1SDA066732R1 ABB – A1N 125 TMF 125-1250 3P F F

Conclusion

In summary, Moulded Case Circuit Breakers play a crucial role in electrical safety by providing reliable protection against overloads and faults. Their robust design, adjustable features, and versatility make them essential components in modern electrical systems.