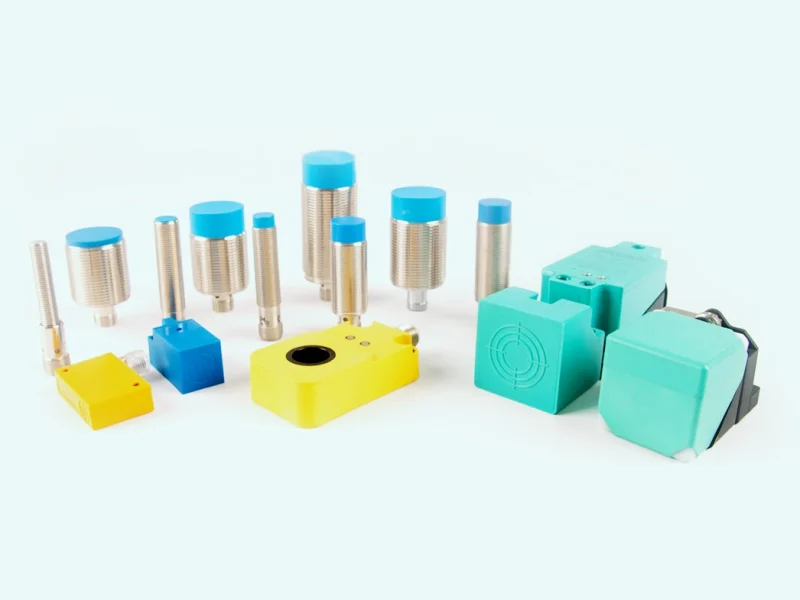

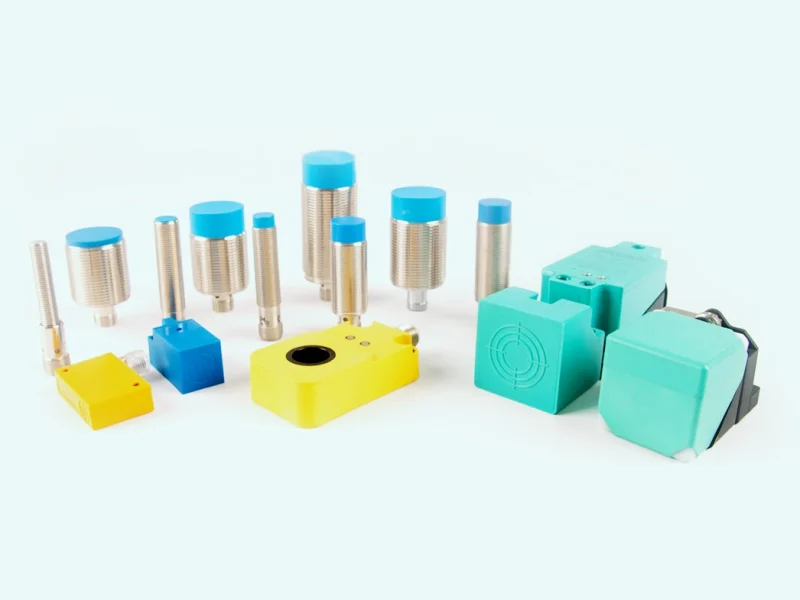

Proximity Sensor Manufacturer

VIOX manufactures advanced proximity sensors for industries like automotive, packaging, and machine engineering. Our range includes magnetic, capacitive, and inductive sensors, with inductive types available in cylindrical, rectangular, slot, ring, and double sensor designs. VIOX sensors provide precise detection and control for diverse industrial applications, enhancing operational efficiency and reliability.

VIOX Made Sensors

VIOX welcomes OEM and ODM partnerships, actively collaborating with renowned global corporations on tailored sensor solutions. Our expertise in proximity sensor design and manufacturing positions us as industry leaders, delivering cutting-edge technology to meet diverse client needs. With a proven track record of successful collaborations, we offer unparalleled flexibility and innovation in custom sensor development, ensuring our partners stay at the forefront of their respective markets.

VIOX Sensors: From Inductive to Hall - Comprehensive Detection Solutions

Inductive Proximity Sensors

Inductive proximity sensors are non-contact devices that detect metallic objects using electromagnetic induction. They generate an electromagnetic field and sense changes in this field when a metal target approaches. These sensors are widely used in industrial automation and manufacturing for reliable, non-contact detection of metal objects, offering durability and versatility in various applications.

Photoelectric Sensors

Photoelectric sensors, based on the photoelectric effect, are devices that detect objects using light. They emit a light beam and sense changes when objects interrupt or reflect it. These sensors come in through-beam, reflex, and diffuse types, each suited for different applications. Widely used in industrial automation, safety systems, and object detection, photoelectric sensors offer non-contact, versatile, and high-speed sensing capabilities.

Capacitive Proximity Sensor

Capacitive proximity sensors detect objects without contact by measuring capacitance changes. They use conductive plates to form a capacitor, sensing alterations in the electric field when objects approach. These versatile sensors can detect both metallic and non-metallic materials, making them ideal for various applications in industrial automation, consumer electronics, and automotive industries. They offer non-contact operation and adjustable sensitivity but may be affected by environmental factors and have limited detection range.

Color Mark Sensor

VIOX Color Mark Sensors offer precise color and mark detection using true color recognition and RGB LEDs. Key features include automatic optimal LED selection, built-in amplifiers, IP67 rating for harsh environments, two-detection modes, digital adjustment functions, and bank switching for up to 8 settings. Ideal for label detection, seal detection, color matching, and plating detection, these sensors ensure high precision and reliability in various industrial applications.

Hall Sensor

VIOX’s Hall effect sensors detect magnetic fields with high sensitivity and low power consumption. Perfect for proximity sensing, positioning, speed detection, and current sensing, they feature a compact design and are used in diverse applications such as computer keyboards and industrial automation. Available in single and dual Hall elements, analog, and digital types, VIOX sensors offer contactless sensing, high accuracy, and low maintenance

what sets VIOX Sensors apart

Inspection range

VIOX proximity sensors excel within their inspection range, offering crucial detection capabilities. They monitor elevator movements, prevent vehicle collisions, and determine machinery positions in industrial settings. These versatile sensors enhance safety and efficiency, making them essential in modern automation systems. Their precise detection of stop, start, and limit positions ensures smooth operations across various applications.

High Reaction Frequency

VIOX proximity sensors boast exceptional repeatability, making them ideal for precise object positioning. Their high reaction frequency ensures stable detection even for rapidly moving objects. This combination of accuracy and speed makes VIOX sensors crucial in applications requiring quick, reliable responses. From fast-paced production lines to dynamic industrial environments, these sensors deliver consistent performance, enhancing efficiency and reliability in various automation processes.

Information Transmission

VIOX proximity sensors utilize ASI bus technology for efficient data exchange. This network enables sensors to communicate over 50-100 meters in manufacturing lines. By facilitating seamless information flow, VIOX sensors enhance real-time monitoring and control, improving industrial automation efficiency and responsiveness.

KNOWLEDGE

How do capacitive proximity sensors work

Capacitive proximity sensors operate by generating an electromagnetic field and detecting changes in capacitance when objects enter this field. The sensor creates the field around its sensing area, and when an object approaches, it disturbs the field, altering the capacitance. The sensor’s circuitry detects this change and triggers an output signal. These sensors can detect various materials, including non-metallic objects, making them versatile for applications like level sensing, object detection, and touch interfaces in both industrial and consumer settings. Their non-contact detection method allows for efficient and reliable sensing in diverse environments.

What are the advantages of using Proximity Sensors over traditional switches?

Proximity sensors offer significant advantages over traditional mechanical switches. They operate without physical contact, which increases durability, reduces maintenance needs, and improves safety in automated systems. These sensors are typically more responsive and faster than mechanical switches, enhancing efficiency in high-speed processes. Their versatility allows for detection of various materials, and many models offer adjustable sensitivity for specific applications. The compact design of proximity sensors enables integration into tight spaces, providing greater flexibility in equipment design.

Moreover, proximity sensors often demonstrate better resistance to harsh environmental conditions, making them suitable for challenging industrial settings. Their non-contact operation leads to a longer lifespan and reduced wear and tear compared to mechanical switches. This combination of durability, versatility, and performance makes proximity sensors a preferred choice for modern automation and control systems, offering improved reliability and efficiency over traditional switches in a wide range of applications.

How should proximity sensors be maintained

Proximity sensors require minimal maintenance due to their non-contact nature and durability. However, to ensure optimal performance and longevity, several maintenance practices are recommended. Regular cleaning of the sensor surface is essential to prevent dust, dirt, and debris from obstructing the sensing area. Periodic inspections should be conducted to check for physical damage, wear, and secure mounting. Depending on the application, recalibration may be necessary to maintain accuracy, especially in environments with varying conditions.

Additionally, it’s important to monitor environmental conditions to ensure they remain within the sensor’s specified operating range. Electrical connections should be inspected for corrosion or loose wires, and power supply levels should be verified. Regular testing of the sensors’ functionality, including response times and detection ranges, is advisable. Maintaining documentation of all maintenance activities, inspections, and any issues encountered helps track performance over time. By following these practices, users can enhance the reliability and extend the lifespan of their proximity sensors across various applications.