3:42 SA. Điện thoại của bạn rung. “Đường dây chính bị sập. Tủ điện bốc khói.”

Khi bạn đến nhà máy, bộ phận bảo trì đã ngắt điện vào tủ điều khiển động cơ của Bay 3. Mùi khét xộc vào mũi bạn ngay cả trước khi bạn mở cửa. Bên trong, những hàng kết nối dây điện gọn gàng giờ trông như một xưởng nến bị tan chảy. Ống co nhiệt mà bạn đã cẩn thận lắp đặt sáu tháng trước? Chúng không chỉ hỏng—chúng đã giúp đám cháy lan rộng.

Báo cáo của thanh tra tủ điện đến bàn làm việc của bạn hai ngày sau đó. Nguyên nhân gây ra sự cố: “Vật liệu cách điện không chống cháy góp phần vào sự lan truyền của đám cháy.” Dịch ra: bạn đã sử dụng ống co nhiệt tiêu chuẩn ở những nơi yêu cầu loại chống cháy.

Khoản tiết kiệm chi phí 40% cho ống “tương đương” đó vừa trở thành một sai lầm trị giá $67.000. Chào mừng bạn đến với sự khác biệt vô hình giữa ống co nhiệt polyolefin tiêu chuẩn và loại chống cháy UL 224 VW-1—một sự khác biệt có vẻ tầm thường cho đến khi nó hoàn toàn không phải vậy.

Vấn đề không ai nói đến: Ống co nhiệt như nhiên liệu cháy

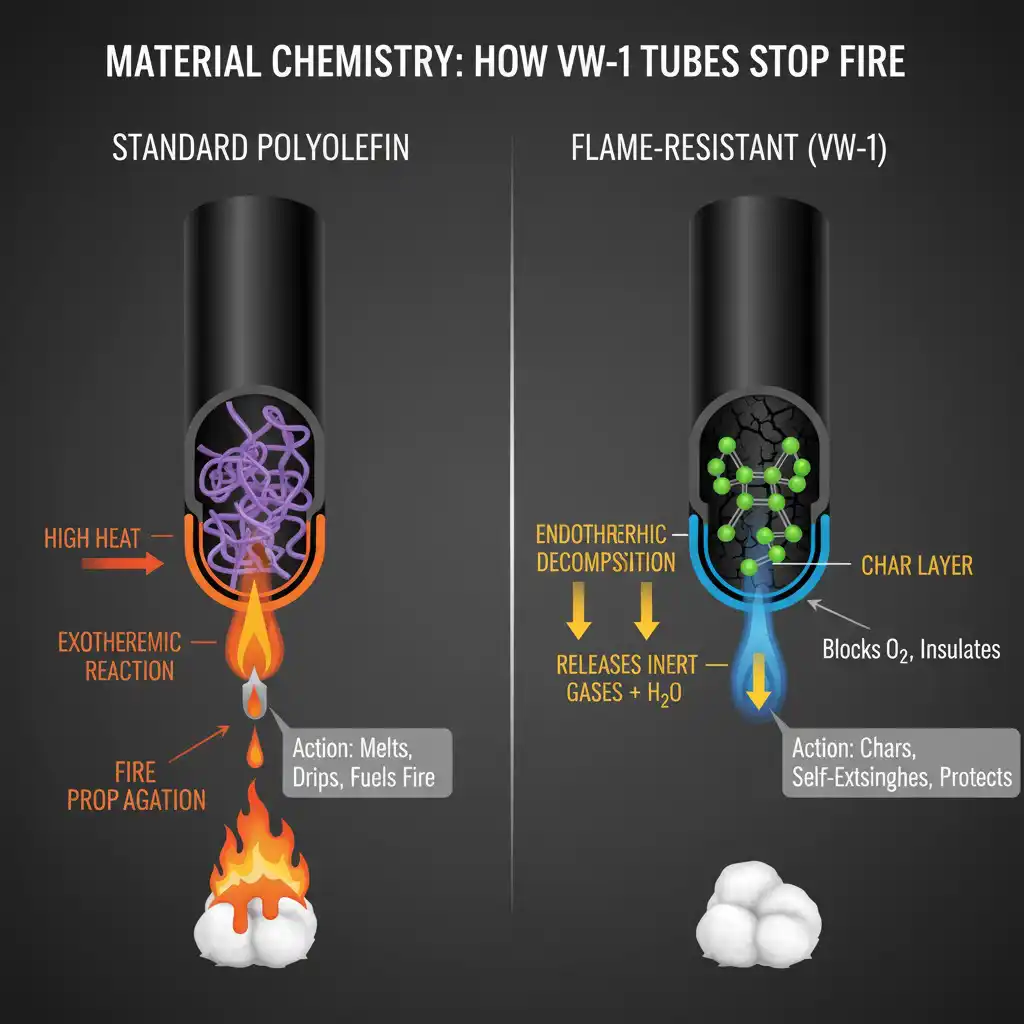

Đây là điều mà các bảng dữ liệu không nhấn mạnh đủ: ống co nhiệt tiêu chuẩn được làm từ polyolefin liên kết ngang. Polyolefin là nhựa. Nhựa cháy. Đôi khi rất mạnh.

Khi một sự cố điện giải phóng năng lượng vào một kết nối—hãy nghĩ đến dòng điện khởi động trong quá trình khởi động nguội, hoặc sự nóng lên hài hòa từ VFD, hoặc chỉ một đầu nối lỏng lẻo tạo ra điện trở—ống co nhiệt trở thành mắt xích yếu nhất. Ống tiêu chuẩn sẽ tan chảy. Chúng sẽ nhỏ giọt. Và nếu sự cố tạo ra đủ nhiệt, chúng sẽ bốc cháy.

Khi đã cháy, polyolefin tiêu chuẩn không chỉ tự cháy hết. Nó tiếp tục cháy. Các giọt nóng chảy có thể đốt cháy lớp cách điện dây bông bên dưới. Ngọn lửa lan dọc theo chiều dài của ống. Về cơ bản, bạn đã biến giải pháp quản lý dây của mình thành một cầu chì chất xúc tác.

Ống co nhiệt chống cháy làm điều ngược lại. Khi tiếp xúc với ngọn lửa, chúng sẽ tạo thành than và tự dập tắt. Hóa học vật liệu về cơ bản là khác nhau—không chỉ “tốt hơn”, mà được thiết kế với các chất phụ gia chống cháy không chứa halogen, phản ứng thu nhiệt khi đun nóng, hấp thụ năng lượng và tạo thành một lớp than bảo vệ. Hãy nghĩ về nó như sự khác biệt giữa xăng và bọt chống cháy. Cả hai đều là vật liệu, nhưng hành vi của chúng dưới tác động của lửa là một trời một vực.

Quy tắc 60 giây: Điều gì làm cho ống co nhiệt “chống cháy”

Ngành điện cần một cách để phân biệt các loại ống cháy và các loại ống không cháy. Tham gia thử nghiệm VW-1—chính thức được gọi là “Thử nghiệm ngọn lửa dây dọc” từ UL 1581 và được chỉ định trong tiêu chuẩn UL 224 cho ống cách điện.

Thiết lập thử nghiệm giống như một thí nghiệm hóa học ở trường trung học. Gắn một mẫu ống co nhiệt dài 24 inch theo chiều dọc. Đặt một đèn đốt kiểu Bunsen ở góc 20° bên dưới nó. Đặt bông phẫu thuật ở đáy (để hứng các giọt đang cháy). Treo một lá cờ giấy kraft ở trên cùng (để đo độ lan của ngọn lửa).

Bây giờ thử nghiệm bắt đầu:

- Áp dụng ngọn lửa trong 15 giây

- Loại bỏ ngọn lửa

- Chờ mẫu tự dập tắt (hoặc tối đa 60 giây)

- Lặp lại năm lần tổng cộng 75 giây tiếp xúc với ngọn lửa

Để vượt qua VW-1 và đạt được trạng thái “chống cháy”, ống phải:

- Tự dập tắt trong vòng 60 giây sau mỗi lần áp dụng ngọn lửa—đó là “Quy tắc 60 giây”

- Không đốt quá 25% của cờ chỉ báo

- Không đốt bông phẫu thuật bằng vật liệu nhỏ giọt

Ống co nhiệt polyolefin tiêu chuẩn? Thất bại thảm hại. Ống tan chảy, nhỏ vật liệu đang cháy lên bông (bốc cháy), và ngọn lửa lan lên trên quá vạch 25%. Ống chống cháy được xếp hạng VW-1? Vật liệu tạo thành than, ngọn lửa tự dập tắt trong vòng 10-20 giây và không có gì nhỏ giọt để đốt cháy bông bên dưới.

Thử nghiệm này rất khắc nghiệt theo thiết kế. Năm lần áp dụng ngọn lửa riêng biệt mô phỏng ứng suất nhiệt lặp đi lặp lại—chính xác những gì xảy ra trong nhiều chu kỳ khởi động động cơ hoặc các điều kiện sự cố không liên tục. Nếu ống có thể sống sót qua thử thách này và vẫn tự dập tắt mỗi lần, nó sẽ đạt được xếp hạng VW-1 được đánh dấu trên các sản phẩm được chứng nhận.

Hóa học vật liệu: Tại sao một số ống ngừng cháy và những ống khác thì không

Ống co nhiệt polyolefin tiêu chuẩn được liên kết ngang để tăng cường độ bền và ổn định nhiệt độ. Liên kết ngang ngăn các chuỗi polyme tan chảy trở lại thành chất lỏng, điều này rất tốt cho các đặc tính cơ học. Thật không may, nó không làm gì để ngăn chặn sự đốt cháy.

Ống chống cháy thêm các hợp chất chống cháy không chứa halogen—thường là các chất phụ gia gốc phốt pho hoặc hydroxit kim loại làm thay đổi hóa học đốt cháy:

Khi tiếp xúc với nhiệt độ cao:

- Các chất phụ gia phân hủy thu nhiệt (hấp thụ năng lượng nhiệt từ môi trường)

- Chúng giải phóng hơi nước hoặc khí trơ làm loãng khí dễ cháy

- Chúng tạo thành một lớp than cacbon bảo vệ vật liệu bên dưới

- Lớp than ngăn oxy tiếp cận vật liệu chưa cháy bên dưới

Những gì bạn thấy: bề mặt ống bị đen và cứng lại thay vì tan chảy. Điều gì đang xảy ra về mặt hóa học: vật liệu đang tích cực chống lại ngọn lửa ở cấp độ phân tử.

Xếp hạng nhiệt độ vẫn tương tự giữa các loại tiêu chuẩn và chống cháy—cả hai thường hoạt động từ -55°C đến 125°C đối với các công thức polyolefin. Các chất phụ gia chống cháy không ảnh hưởng đến các đặc tính cách điện hoặc tỷ lệ co ngót. Một ống chống cháy có tỷ lệ co ngót 2:1 hoặc 3:1 hoạt động giống hệt như ống tiêu chuẩn trong điều kiện hoạt động bình thường. Sự khác biệt chỉ quan trọng khi có sự cố xảy ra.

Tính đến tháng 11 năm 2025, thị trường ống co nhiệt chống cháy toàn cầu được định giá khoảng $3,3 tỷ đô la và dự kiến sẽ đạt $4,32 tỷ đô la vào năm 2032, phần lớn là do các quy định về an toàn cháy nổ ngày càng nghiêm ngặt trong các ứng dụng công nghiệp, ô tô và hàng không vũ trụ.

Khi nào khả năng chống cháy thực sự quan trọng (và khi nào thì không)

Không phải ứng dụng nào cũng yêu cầu ống được xếp hạng VW-1. Sử dụng các loại chống cháy ở mọi nơi sẽ là một sự lãng phí tốn kém. Nhưng một số môi trường nhất định biến việc thiếu khả năng chống cháy từ một chi tiết thông số kỹ thuật nhỏ thành một mối nguy hiểm an toàn thực sự.

Bạn hoàn toàn cần ống co nhiệt chống cháy cho:

Tủ điều khiển động cơ và các ứng dụng VFD: Ổ đĩa tần số thay đổi tạo ra sự nóng lên hài hòa có thể gây ứng suất cho các kết nối theo thời gian. Kết hợp điều đó với dòng điện khởi động cao trong quá trình khởi động động cơ (thường là 5-7 lần cường độ dòng điện đầy tải), và bạn có các điều kiện hoàn hảo cho sự nóng lên cục bộ. Nếu một kết nối bị lỗi, ống chống cháy sẽ ngăn chặn một sự cố điện nhỏ trở thành đám cháy tủ điện. Các tiêu chuẩn tủ điều khiển UL 508A ngày càng tham khảo các thành phần dây chống cháy vì lý do này.

Dây điện xe điện cao áp: Hệ thống pin EV hoạt động ở điện áp 400V đến 800V DC với dòng điện sự cố có thể vượt quá 1.000 ampe. Trong các sự kiện mất kiểm soát nhiệt hoặc sự cố kết nối điện trở cao, ống co nhiệt tiêu chuẩn có thể bốc cháy và lan truyền lửa qua toàn bộ bó dây. Các nhà sản xuất EV thường yêu cầu xếp hạng VW-1 hoặc cao hơn (một số thông số kỹ thuật yêu cầu FMVSS 302 dành riêng cho ô tô) cho tất cả các dây điện của bộ pin.

Các ứng dụng hàng không vũ trụ và quân sự: Các thông số kỹ thuật quân sự MIL-DTL-23053 yêu cầu ống co nhiệt chống cháy cho hệ thống dây điện máy bay. Ở độ cao, áp suất không khí giảm làm thay đổi hành vi đốt cháy và hỏa hoạn trong cabin là những mối đe dọa hiện hữu. Ống chống cháy được xếp hạng để sử dụng trong hàng không vũ trụ phải vượt qua các thử nghiệm nghiêm ngặt hơn so với VW-1 tiêu chuẩn.

Môi trường chế biến thực phẩm và công nghiệp có bụi dễ cháy: Nếu nhà máy của bạn chế biến ngũ cốc, đường, nhựa hoặc bột kim loại, bất kỳ nguồn gây cháy nào cũng có thể gây ra một vụ nổ bụi. Các thành phần dây chống cháy ngăn chặn các sự cố điện trở thành nguồn gây cháy. Các tiêu chuẩn máy móc công nghiệp NFPA 79 khuyến nghị hoặc yêu cầu vật liệu chống cháy trong các môi trường này.

Bạn có thể sử dụng ống co nhiệt tiêu chuẩn cho:

Dây tín hiệu điện áp thấp (dưới 50V) trong môi trường văn phòng, thiết bị đo đạc không quan trọng trong các tòa nhà có kiểm soát khí hậu, tạo mẫu và bàn thí nghiệm, sửa chữa dân dụng nơi mã xây dựng không chỉ định xếp hạng ngọn lửa.

Khuôn khổ quyết định:

Đặt ba câu hỏi:

- Dòng điện sự cố có sẵn tại kết nối này là bao nhiêu?

- Có gì gần đó có thể bắt lửa nếu kết nối này bị lỗi?

- Tiêu chuẩn quản lý (UL 508A, NEC, IEC 60204) có chỉ định vật liệu chống cháy không?

Nếu dòng điện sự cố vượt quá 10 ampe, hoặc nếu vật liệu dễ cháy nằm trong vòng 3 feet, hoặc nếu mã yêu cầu—hãy chỉ định ống chống cháy.

Cách xác minh bạn thực sự đang nhận được ống được xếp hạng VW-1

Đây là một sự thật khó chịu: không phải tất cả các ống co nhiệt “chống cháy” đều thực sự như vậy. Thị trường ống giả và kém chất lượng là có thật, đặc biệt đối với các sản phẩm nhập khẩu mà không có chứng nhận UL thích hợp.

Tìm các dấu hiệu này trên chính ống:

- “VW-1” hoặc “VW-1 Flame Retardant” được in trên ống

- Số hồ sơ UL (bắt đầu bằng chữ “E” theo sau là 6 chữ số, ví dụ: E228117)

- “Tham chiếu tiêu chuẩn ”UL 224“ hoặc ”CSA C22.2 No. 198.1”

- Định mức nhiệt độ (thường là “125°C” cho polyolefin)

- Nhận dạng nhà sản xuất

Các dấu hiệu cảnh báo cho thấy ống có thể không tuân thủ:

- Hoàn toàn không có dấu hiệu nào trên bề mặt ống

- Các dấu hiệu dễ bị rửa trôi (các dấu hiệu chính hãng được in bằng mực và vĩnh viễn)

- Bao bì tuyên bố xếp hạng VW-1 nhưng ống không được đánh dấu

- Giá thấp một cách đáng ngờ so với các nhà cung cấp được chứng nhận

- Nhà cung cấp không thể cung cấp số hồ sơ UL hoặc báo cáo thử nghiệm

Đối với các ứng dụng quan trọng, hãy yêu cầu tài liệu:

- Thư chứng nhận UL hiển thị dòng sản phẩm cụ thể

- Báo cáo thử nghiệm xác nhận tuân thủ VW-1

- Bảng dữ liệu an toàn vật liệu (MSDS) hiển thị các chất phụ gia chống cháy

- Chứng chỉ tuân thủ RoHS (chất chống cháy không chứa halogen phải tuân thủ RoHS)

Sự khác biệt về giá giữa ống co nhiệt polyolefin chống cháy VW-1 và tiêu chuẩn thường là 30-50%, tùy thuộc vào kích thước và số lượng. Với việc một vụ cháy bảng điện duy nhất có thể gây thiệt hại $75.000+ cho việc thay thế thiết bị, thời gian ngừng sản xuất và khắc phục hậu quả, thì việc tính toán ROI rất đơn giản. Hãy chi thêm một đô la cho mỗi mét. Ngủ ngon hơn vào ban đêm.

Hướng dẫn lựa chọn: Chọn loại chống cháy phù hợp với ứng dụng của bạn

Không phải tất cả các ống chống cháy đều được tạo ra như nhau. Ngoài việc tuân thủ VW-1 cơ bản, hãy xem xét các thông số kỹ thuật sau:

Tỷ lệ co:

- 2:1 (phổ biến nhất): Phù hợp với đường kính dây từ 2mm đến 4mm khi bạn sử dụng ống 4mm

- 3:1 (linh hoạt hơn): Bao phủ phạm vi kích thước rộng hơn, hữu ích cho các hình dạng không đều

- 4:1 (chuyên dụng): Ống có tỷ lệ cao để che các đầu nối hoặc mối nối lớn với số lượng tồn kho tối thiểu

Độ dày thành ống:

- Thành mỏng (0,3-0,5mm): Không gian chật hẹp, trọng lượng tối thiểu, vẫn đạt VW-1

- Thành trung bình (0,5-1,0mm): Các ứng dụng công nghiệp tiêu chuẩn, khả năng chống mài mòn tốt hơn

- Thành dày (1,0mm+): Ứng suất cơ học cao, tiếp xúc ngoài trời, lắp đặt dưới lòng đất

Các tính năng đặc biệt:

- Hai lớp với chất kết dính: Tạo lớp bịt kín hơi ẩm khi được làm nóng (quan trọng đối với ngoài trời hoặc hàng hải)

- Chứng nhận không chứa halogen: Bắt buộc ở Châu Âu (RoHS), được ưu tiên trong không gian kín

- Công thức chống tia cực tím: Dành cho các công trình lắp đặt ngoài trời có ánh nắng trực tiếp

- Các biến thể nhiệt độ cao: Lên đến 150°C hoặc 175°C cho các ứng dụng gần động cơ hoặc máy biến áp

Đối với các ứng dụng bảng điều khiển động cơ điển hình, hãy chỉ định:

- Tỷ lệ co 2:1 hoặc 3:1

- Thành mỏng hoặc trung bình

- Đánh giá UL 224 VW-1

- Không chứa halogen nếu có thể

- Định mức nhiệt độ: Tối thiểu -55°C đến 125°C

- Định mức điện áp: 600V (tiêu chuẩn cho hầu hết các mạch điều khiển)

Pro mẹo: Mua từ các nhà phân phối có thể cung cấp dịch vụ cắt theo chiều dài với chứng nhận VW-1 được duy trì. Ống cắt sẵn giúp giảm thời gian lắp đặt và đảm bảo bạn đang sử dụng vật liệu được chứng nhận trong toàn bộ kho của mình thay vì trộn lẫn hàng được chứng nhận và không được chứng nhận.

Chi phí thực tế của việc sử dụng ống tiêu chuẩn ở những nơi bạn không nên

Hãy xem xét các con số về vụ cháy bảng điện lúc 3 giờ sáng từ phần mở đầu:

Chi phí trực tiếp:

- Thay thế bảng điện và hệ thống dây điện: $18.000

- Gọi thợ điện khẩn cấp: $2.400

- Kiểm tra và chứng nhận: $3.200

- Tổng phụ: $23.600

Chi phí gián tiếp:

- Thời gian ngừng hoạt động của dây chuyền sản xuất (14 giờ với giá $3.200/giờ): $44.800

- Vận chuyển nhanh các bộ phận thay thế: $1.800

- Khoản khấu trừ bảo hiểm: $5.000

- Tổng phụ: $51.600

Tổng chi phí sự cố: $75.400

Chi phí sử dụng ống co nhiệt chống cháy VW-1 ban đầu:

- 50 mét ống co nhiệt chống cháy thay vì ống tiêu chuẩn: Chi phí bổ sung $145

Đó là hệ số nhân chi phí là 520:1. Vụ cháy thậm chí không quá nghiêm trọng—không có thương tích, không có thiệt hại cho thiết bị xung quanh, chỉ giới hạn trong một bảng điện. Một sự cố nghiêm trọng hơn có thể dễ dàng vượt quá $250.000 khi bạn tính đến các hợp đồng bị mất, tiền phạt theo quy định và thiệt hại về uy tín.

Quyết định kỹ thuật không thực sự là về việc ống chống cháy có giá cao hơn hay không. Mà là về việc bạn có sẵn sàng đặt cược 75.000 đô la rằng các kết nối của bạn sẽ không bao giờ bị lỗi do ứng suất nhiệt hay không. Hầu hết các tủ điện sẽ ổn. Nhưng trong một cơ sở có 200 tủ điện hoạt động 24/7 trong 10 năm? Câu hỏi trở thành tủ điện nào sẽ là tủ điện không may mắn về mặt thống kê.

Phải Làm Gì Ngay Bây Giờ

Nếu bạn đang đặc tả một cài đặt mới:

- Xem xét các tiêu chuẩn áp dụng (UL 508A cho tủ điều khiển, NEC Điều 300-400 cho phương pháp đi dây)

- Xác định bất kỳ khu vực nào có dòng điện sự cố vượt quá 10A hoặc có vật liệu dễ cháy

- Chỉ định “ống co nhiệt chống cháy UL 224 VW-1” trong danh mục vật tư

- Yêu cầu tài liệu chứng nhận từ nhà cung cấp của bạn

- Xác minh dấu ống trong quá trình kiểm tra tiếp nhận

Nếu bạn có các cài đặt hiện có với ống tiêu chuẩn:

- Tiến hành đánh giá rủi ro: dòng điện sự cố là bao nhiêu? Có gì ở gần đó?

- Ưu tiên thay thế ở các khu vực có rủi ro cao trước (đường cấp động cơ, kết nối VFD, điện áp cao)

- Lên lịch thay thế trong thời gian ngừng hoạt động theo kế hoạch thay vì chờ đợi sự cố

- Ghi lại việc nâng cấp cho mục đích bảo hiểm và tuân thủ

Nếu bạn không chắc chắn về những gì bạn hiện có:

- Kiểm tra dấu ống dưới ánh sáng tốt với kính đọc sách nếu cần

- Liên hệ với người lắp đặt hoặc nhà cung cấp ban đầu của bạn để có tài liệu sản phẩm

- Nếu dấu không đọc được hoặc không có, hãy cho rằng tiêu chuẩn không chống cháy và lên kế hoạch thay thế

Các ống bạn đã lắp đặt có lẽ là “đủ tốt” khi mọi thứ hoạt động hoàn hảo. Nhưng hệ thống điện không phải lúc nào cũng hoạt động hoàn hảo. Lớp cách điện bị lão hóa. Các kết nối bị lỏng. Xảy ra đột biến điện. Khi có sự cố xảy ra lúc 3 giờ sáng, bạn muốn lớp cách điện chống lại lửa thay vì tiếp thêm lửa.

Tại Sao Ống Co Nhiệt Chống Cháy VIOX ELECTRIC

VIOX ELECTRIC sản xuất ống co nhiệt chống cháy được chứng nhận UL 224 VW-1 được thiết kế đặc biệt cho điều khiển động cơ công nghiệp và các ứng dụng phân phối điện. Ống của chúng tôi đáp ứng hoặc vượt quá:

- Tiêu chuẩn UL 224 / CSA C22.2 Số 198.1

- Yêu cầu kiểm tra ngọn lửa dọc VW-1

- Tuân thủ RoHS cho các công thức chống cháy không chứa halogen

- Phạm vi nhiệt độ: -55°C đến 125°C

- Định mức điện áp: 600V

- Tỷ lệ co: có sẵn 2:1, 3:1 và 4:1

Mỗi lô bao gồm tài liệu chứng nhận và dấu ống vĩnh viễn để truy xuất nguồn gốc. Có sẵn dịch vụ cắt theo chiều dài cho các nhà sản xuất tủ điện và OEM.

Liên hệ với Bộ phận Hỗ trợ Kỹ thuật VIOX để được các đề xuất cụ thể cho ứng dụng và giá số lượng lớn.