在水下照明、泳池设备及海洋工程应用中,电气连接点必须能承受持续浸没环境。标准防溅型接线盒无法满足这些严苛要求——只有IP68 防水接线盒 能提供真正的浸没防护。.

然而“IP68”标识在市场中已随处可见,许多采购经理和工程师对其真实含义存在误解。IP68并非单一标准,而是由制造商定义测试参数的保护等级。选择错误的产品可能导致进水、设备损坏及安全隐患。.

本文基于IEC 60529标准与NEC规范要求,系统阐述IP68防水接线盒的技术要求、应用场景与选型标准。作为专业电气设备制造商,VIOX Electric为您的项目提供可靠的浸没防护解决方案。.

什么是IP68等级?理解IEC 60529标准

IP(侵入防护)等级由国际电工委员会IEC 60529标准定义,用于划分电气设备外壳对固体异物和液体的防护程度。IP代码包含两位数字:首位数字表示防尘等级(0-6),第二位数字表示防水等级(0-8)。.

IP68的精确定义

IP68代表:

- 首位数字“6”:尘密——完全防止灰尘侵入

- 第二位数字“8”:持续浸水——适用于制造商规定条件下的长期浸没

关键理解点: IP68中的“8”并未规定统一的浸没深度与持续时间. According to IEC 60529, IPx8 test parameters are determined through agreement between manufacturer and customer, typically more severe than IPx7 (1 meter/30 minutes). Common IP68 specifications include:

- 2 meters/24 hours (common for polycarbonate enclosures)

- 5 meters/continuous immersion (stainless steel welded enclosures)

- 10 meters/continuous operation (specialized marine engineering applications)

Therefore, when specifying products, you must require manufacturers to clearly state the specific test depth and duration for IP68, not just the “IP68” label.

NEMA Equivalent Standards

In the U.S. market, نما (National Electrical Manufacturers Association) standards are often used alongside IP codes:

- NEMA 6: Temporary submersion (≈ IP67)

- نما 6P: Prolonged submersion (≈ IP68)

VIOX Electric’s IP68 junction boxes meet both IEC 60529 and NEMA 6P requirements, ensuring global project compliance.

IP67 vs IP68: Choosing the Right Submersible Protection Rating

Many engineering projects struggle to choose between IP67 and IP68. Both provide complete dust protection (first digit “6”), but differ critically in water protection:

| ویژگی | IP67 | استاندارد IP68 |

| Water Protection Definition | Temporary immersion | Continuous immersion |

| Test Conditions | ۱ متر depth for ۳۰ دقیقه | Depth ≫1 meter, duration ≫30 minutes (manufacturer-specified) |

| سناریوهای کاربردی | Brief accidental submersion (rain, washing) | Long-term underwater installation (pools, fountains, marine environments) |

| Pressure Consideration | Does not account for hydrostatic pressure | Must account for underwater hydrostatic pressure |

| هزینه | پایینتر | Higher (requires enhanced sealing standards) |

When Must You Use IP68?

Choose IP68 over IP67 in the following situations:

- Underwater installation exceeding 30 minutes: Pool lighting and fountain equipment require year-round continuous submersion operation

- Water depth exceeding 1 meter: Deep wells, harbor equipment, wastewater treatment systems

- Flowing water pressure: Water flow impact increases sealing failure risk; IP68’s superior sealing is essential

- Temperature cycling environments: IP68 testing typically includes temperature cycling to ensure gasket effectiveness after thermal expansion/contraction

If the application is merely outdoor splashing (no underwater installation), IP67 suffices. However, for true submersible applications like underwater lighting and submersible pumps, IP68 is the only reliable choice.

IP68 Junction Box Construction and Sealing Mechanisms

Achieving IP68 protection requires precision engineering design. A qualified IP68 waterproof junction box must be flawless in three aspects: materials, sealing structure, and entry point protection.

Enclosure Material Selection

IP68 junction boxes commonly use three materials, each with distinct advantages:

1. Polycarbonate

- Excellent transparency for inspecting internal connections

- Resists UV aging and impact

- Common specification: 2 meters/24 hours immersion test

- Suitable scenarios: Pools, fountains, landscape lighting

2. Stainless Steel 316

- Superior corrosion resistance, especially for seawater environments

- Welded seams eliminate leakage risk

- Common specification: 5 meters continuous immersion

- Suitable scenarios: Marine engineering, harbor equipment, wastewater treatment

3. Cast Bronze

- Particularly suitable for underwater fixture connections

- Excellent corrosion resistance and longevity

- Commonly used in premium water feature projects

VIOX Electric offers all the above material options, selecting the optimal material based on application environment.

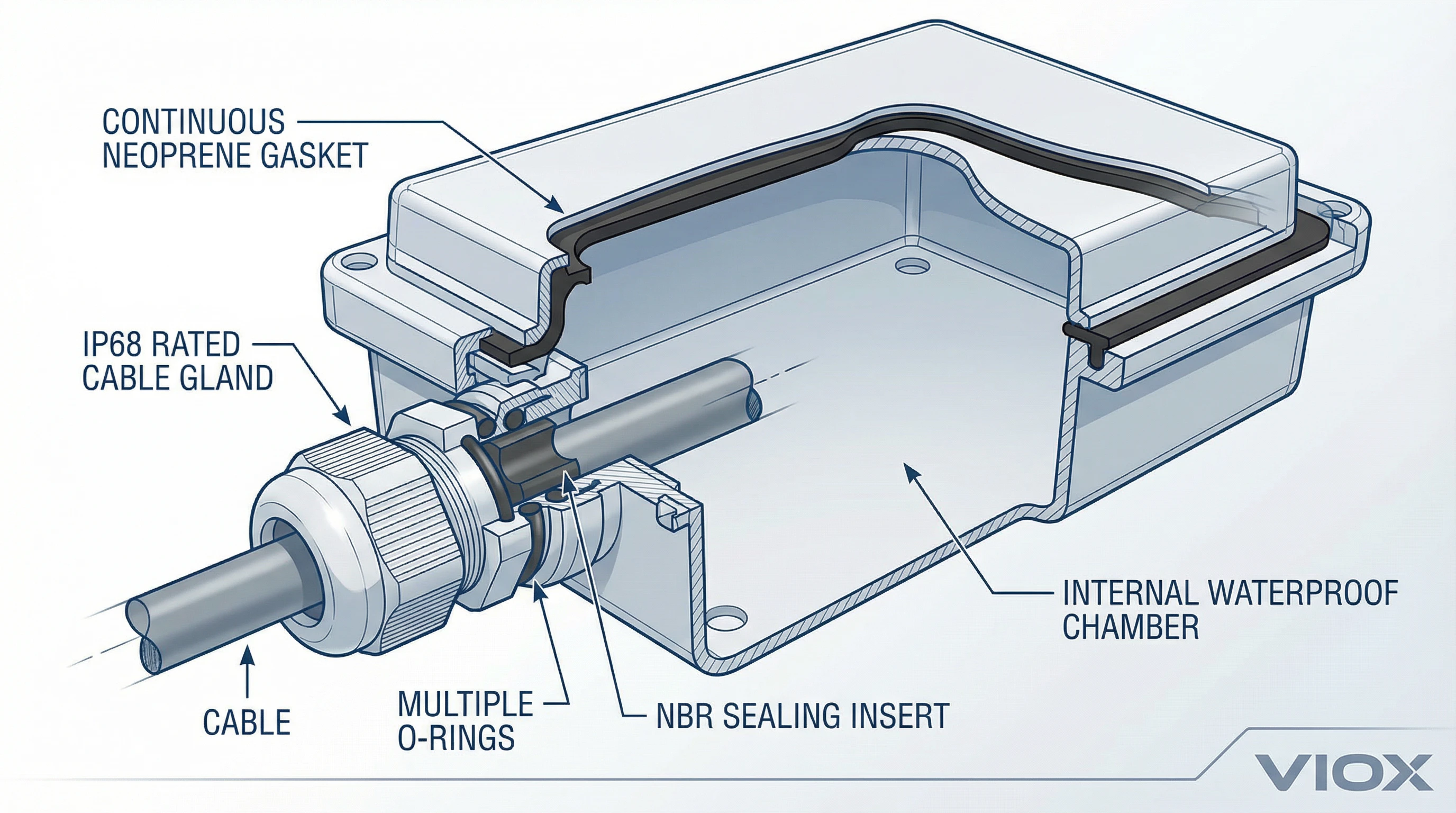

Critical Sealing Systems

The core of IP68 protection lies in triple sealing mechanisms:

I. Cover Seal

- Continuous neoprene or silicone gasket

- Bolted fastening ensures uniform compression

- Hinged cover design prevents gasket loss

II. Cable Entry Point Seal

- IP68-rated cable glands

- NBR/PA sealing inserts precisely match cable outer diameter

- Multiple O-ring structures isolate water molecules

III. Internal Potting Protection (Optional)

- High-risk applications like underwater lighting can use epoxy resin potting

- Completely eliminates microscopic leakage pathways at connection points

گلند کابل دستورالعملهای انتخاب

Cable entry points are the weakest link in IP68 systems. Incorrect selection leads to complete protection failure:

- Match cable outer diameter range: Selected gland diameter must precisely match cable outer diameter—neither too loose nor too tight

- IP68/IP69K certification: Confirm the gland itself has IP68 certification, not just the junction box

- Material compatibility: Nylon (freshwater) vs brass/nickel-plated (seawater)—choose materials compatible with the medium

- Thread standard matching: PG, M, NPT threads must match junction box pre-drilled holes

VIOX IP68 junction boxes provide multiple thread specifications and include tested, compatible cable glands to avoid selection errors.

Submersible Applications: Where IP68 Junction Boxes Are Essential

IP68 waterproof junction boxes are widely used in any scenario requiring long-term underwater electrical connections. Here are typical use cases:

1. Swimming Pools & Spa Centers

Application Equipment:

- Underwater fixtures (LED lighting systems)

- Underwater audio equipment

- Pumps and filtration systems

- Underwater sensors (temperature, pH)

Technical Requirements:

- Water depth: 0.5-2.5 meters

- Continuous immersion: Year-round operation

- Recommended materials: Polycarbonate or stainless steel 316

- Chemical resistance: Chlorine, pH adjusters

2. Fountains & Water Features

Application Equipment:

- Underwater nozzle lighting

- Fountain pumps and control systems

- Underwater misting devices

- LED color-changing strips

Technical Requirements:

- Water depth: 0.3-1.5 meters

- Flowing water pressure challenges

- Recommended materials: Cast bronze or stainless steel

- Aesthetic requirements: Concealed installation without affecting landscape

3. Marine & Harbor Engineering

Application Equipment:

- Dock lighting systems

- Ship-to-shore power connections

- Underwater sensors (water level, waves)

- Diver communication equipment

Technical Requirements:

- Water depth: 3-10 meters or deeper

- Stainless steel 316 mandatory: Seawater corrosion is extremely aggressive

- Salt spray testing: Pass ASTM B117 standard

- Recommended specification: 5 meters or deeper continuous immersion certification

4. Wastewater Treatment & Water Infrastructure

Application Equipment:

- Underwater pump stations

- Level sensors and flow meters

- Wastewater treatment equipment connections

- Irrigation system solenoid valves

Technical Requirements:

- Water depth: 1-5 meters

- Chemical corrosion: Resistance to hydrogen sulfide, methane, and other harmful gases

- Recommended materials: Stainless steel 316 or polycarbonate (depending on medium)

- Maintenance accessibility: Requires quick-access design

5. Aquaculture & Fisheries

Application Equipment:

- Underwater surveillance cameras (CCTV)

- Aerators and automatic feeders

- Water quality monitoring sensor arrays

- Net cage lighting systems

Technical Requirements:

- Water depth: 1-8 meters (deep-water net cages)

- Long-term reliability: Typically difficult to maintain; extremely low failure rate required

- Recommended materials: Stainless steel 316 (saltwater aquaculture) or polycarbonate (freshwater aquaculture)

6. Irrigation Systems & Underground Cables

Application Equipment:

- Buried cable splice points

- Irrigation solenoid valve controllers

- Soil moisture sensors

Technical Requirements:

- Burial depth: 0.5-2 meters

- Underground water erosion environment

- Recommended materials: Polycarbonate (cost consideration) or stainless steel (high requirements)

- NEC 314.29 requirement: Underground junction boxes must be accessible without excavating sidewalks or paved surfaces

NEC Code Requirements for Wet Locations

In the United States, IP68 junction box installations must comply with National Electrical Code (NEC) Article 314 requirements:

NEC 314.15: Damp and Wet Locations

الزامات کلیدی:

- Boxes, conduit bodies, and fittings installed in damp or wet locations shall be placed or equipped to prevent moisture from entering or accumulating within the box

- Boxes installed in wet locations shall be listed for use in wet locations

- Field-installed drainage openings must be approved and within specified size limits

VIOX Compliance: All VIOX IP68 junction boxes are UL listed for wet locations and include factory-installed drainage provisions where applicable.

NEC 314.29: Junction Box Accessibility

الزامات کلیدی:

- Boxes, conduit bodies, and handhole enclosures shall be installed so that the wiring contained in them can be accessed without removing any part of the building or structure

- Underground boxes and handholes shall be installed so that access to the enclosed wiring is not required to excavate sidewalks, paving, earth, or other material

Design Implication: Submersible junction boxes in pools or underground installations must have accessible covers or be positioned for service without major excavation.

NEC 250.148: Grounding Continuity

All metal junction boxes must provide grounding continuity. IP68 metal enclosures include:

- Grounding lugs or terminals

- Bonding provisions for cable glands

- Continuous electrical path to grounding system

Nonmetallic enclosures (polycarbonate) do not require grounding but must include grounding provisions for enclosed equipment ground conductors.

How to Select the Right IP68 Junction Box

Selecting the appropriate IP68 junction box requires evaluating multiple technical and environmental factors:

Step 1: Determine Submersion Parameters

- Maximum water depth: Add safety margin (typically 1.5× expected depth)

- Submersion duration: Continuous vs intermittent

- Hydrostatic pressure: Calculate based on depth (1 meter ≈ 0.1 bar)

- Flow conditions: Static water vs flowing water (fountains, rivers)

VIOX توصیه: For continuous submersion beyond 3 meters, specify IP68 with manufacturer-declared depth rating ≥1.5× actual depth.

Step 2: Evaluate Environmental Conditions

Freshwater vs Saltwater:

- Freshwater: Polycarbonate or stainless steel acceptable

- Saltwater: Stainless steel 316 mandatory (verify salt spray test certification)

قرار گرفتن در معرض مواد شیمیایی:

- Chlorinated pools: Verify chlorine resistance

- Wastewater: Verify resistance to H₂S, ammonia, organic acids

- Industrial: Check compatibility with specific chemicals

محدوده دما:

- Standard: -20°C to +60°C

- Extended: -40°C to +85°C (specify if needed)

- Thermal cycling: Ensure gasket materials maintain seal across range

Step 3: Calculate Box Fill Requirements

Follow NEC 314.16 box fill calculations:

- Count conductors: Each insulated conductor = 1 unit

- Count devices: Each device (splice, terminal) = varies by wire gauge

- Calculate volume: Total units × wire gauge volume (see NEC Table 314.16(B))

- Select box size: Must exceed calculated volume

VIOX Sizing Guide: Our online box fill calculator automatically computes required volume based on your wire configuration.

Step 4: Select Entry Configuration

- Number of cable entries: Count incoming/outgoing cables (add 20% spare capacity)

- Cable diameter range: Measure actual cable OD; select glands within range

- Thread type: Verify project standard (PG threads common in Europe; NPT in North America; metric M threads in Asia)

- Entry orientation: Side entry vs bottom entry (affects drainage)

Step 5: Verify Certifications

Essential Certifications:

- IEC 60529 IP68 (with stated depth/duration)

- UL listing for wet locations (North America)

- CE marking (Europe)

- NEMA 6P (U.S. projects)

Testing Documentation:

- Request IP68 test reports showing actual immersion parameters

- Salt spray test certificates (for marine applications)

- Material compatibility certifications

VIOX Advantage: All VIOX IP68 junction boxes include complete certification packages and third-party test reports.

بهترین شیوههای نصب

Proper installation is critical to maintaining IP68 protection. Even certified products will fail if incorrectly installed.

چک لیست قبل از نصب

- Inspect gaskets: Check for damage, deformation, or contamination

- Verify cable glands: Ensure correct size for actual cable diameter

- Check threads: Confirm gland threads match junction box entry holes

- Clean surfaces: Remove any dirt, oil, or debris from gasket seating surfaces

Cable Gland Installation Procedure

Step 1: Prepare Cable

- Strip outer jacket to required length (typically 50-100mm inside box)

- Remove any sharp edges or burrs that could damage gasket

- Measure actual outer diameter at gland position

Step 2: Install Gland Components

- Sequence: Locknut → Washer → Body → Sealing insert → Cable → Compression nut

- Thread gland body into junction box entry (hand-tight, then 1/4 turn with wrench)

- Apply thread sealant if specified by manufacturer

Step 3: Secure Cable

- Insert cable through sealing insert

- Tighten compression nut gradually (do not over-torque)

- Verify sealing insert compresses evenly around cable

- Check cable cannot be pulled out with moderate force

Step 4: Seal Unused Entries

- Install blanking plugs with O-rings in all unused entry holes

- Tighten plugs to specified torque (typically 2-3 Nm)

- Verify no gaps between plug and housing

Cover Installation

- Inspect gasket: Check for proper seating in gasket groove

- Clean mating surfaces: Use isopropyl alcohol; allow to dry

- Position cover: Align carefully without disturbing gasket

- Torque bolts: Use star pattern (diagonal sequence), torque to specification (typically 3-5 Nm)

- Verify seal: Visually inspect gasket compression around entire perimeter

تست پس از نصب

For Critical Applications:

- Pressure test (if accessible before final installation)

- Continuity test (verify grounding path)

- IR (insulation resistance) test between conductors and ground

- Megger test (500V DC) should read >100 MΩ

Submersion Test (if feasible):

- Submerge to 1.5× operating depth

- Monitor for 2× maximum operating duration

- Inspect for bubbles or internal condensation

Maintenance and Common Failure Modes

Periodic Inspection Schedule

Every 6 months (critical applications):

- Visual inspection for physical damage

- Check for condensation inside enclosure (if transparent)

- Verify all cable glands are tight

- Test grounding continuity

سالانه:

- Open enclosure and inspect gasket condition

- Check for corrosion on internal terminals

- Verify cable insulation integrity

- Replace gasket if showing wear, compression set, or cracking

After Storm/Flood Events:

- Immediate inspection for water ingress

- Check for physical damage or displacement

- Verify all seals remain intact

Common Failure Modes and Prevention

1. Cable Gland Seal Failure

- علت: Incorrect cable diameter, over-torquing, damaged sealing insert

- پیشگیری: Precise cable measurement, use torque wrench, inspect before installation

- تشخیص: Water tracks along cable inside box

2. Gasket Compression Set

- علت: UV exposure (if above water), thermal cycling, aging

- پیشگیری: Use UV-resistant gaskets for exposed installations, replace per schedule

- تشخیص: Visible gap between cover and housing, water ingress

3. Thread Seal Failure

- علت: Cross-threading, insufficient torque, damaged threads

- پیشگیری: Hand-start all threads, use proper tools, inspect threads before assembly

- تشخیص: Water seepage around cable gland body

4. Physical Damage

- علت: Impact, dropping during installation, freeze-thaw cycling

- پیشگیری: Handle carefully, protect during installation, use impact-resistant materials

- تشخیص: Visible cracks, chips, or deformation

When to Replace vs Repair

Replace Immediately If:

- Cracks or punctures in enclosure body

- Damaged or cross-threaded entry holes

- Corrosion penetration (rust through on steel enclosures)

- Repeated seal failures despite gasket replacement

Repair If:

- Gasket wear (replace gasket)

- Cable gland wear (replace individual gland)

- Minor surface corrosion (clean and apply protective coating)

- Loose connections (re-torque per specification)

VIOX IP68 Waterproof Junction Box Solutions

VIOX Electric manufactures a comprehensive range of IP68-certified junction boxes engineered for demanding submersible applications:

محدوده محصول

Polycarbonate Series (2m/24h rated):

- Sizes: 80×80mm to 300×220mm

- Transparent cover for visual inspection

- UV-stabilized material for outdoor exposure

- Cable gland entries: PG, M, NPT threads available

- Applications: Pools, fountains, landscape lighting

Stainless Steel 316 Series (5m continuous):

- Sizes: 100×100mm to 400×300mm

- Continuously welded seams

- Salt spray tested (1000h, ASTM B117)

- Heavy-duty cable glands included

- Applications: Marine, harbor, wastewater, aquaculture

Cast Bronze Series (Premium water features):

- Custom sizes available

- Traditional aesthetic for high-end installations

- Natural patina finish option

- Applications: Luxury fountains, architectural water features

VIOX Quality Assurance

- 100% factory tested: Every unit pressure-tested before shipment

- Complete documentation: Test certificates, material certifications, installation manuals

- Global certifications: UL, CE, IEC, NEMA compliance

- 5-year warranty: Comprehensive coverage for materials and workmanship

- پشتیبانی فنی: Engineering team available for project consultation

Why Choose VIOX?

- Precise IP68 specification: We clearly state test depth and duration—no ambiguous claims

- Material traceability: Every batch includes mill certificates for stainless steel, material test reports for polymers

- Compatible accessories: Cable glands tested and certified with our enclosures

- Application expertise: 15+ years manufacturing submersible electrical equipment

- Custom solutions: In-house engineering for specialized requirements

سوالات متداول

Q1: Can I use IP67 junction boxes underwater?

IP67仅适用于临时浸水防护(1米水深,30分钟)。若需持续水下安装,必须采用IP68防护等级。在水下使用IP67设备将导致进水并最终造成设备故障。.

Q2: How deep can IP68 junction boxes be submerged?

It depends on the manufacturer’s specification. IP68 is not a fixed depth—it must be specified. VIOX polycarbonate boxes are rated for 2 meters continuous; our stainless steel boxes are rated for 5 meters continuous. Always verify the specific depth rating with your supplier.

Q3: Do I need to use thread sealant on cable glands?

对于IP68应用,仅当电缆接头制造商明确指定时方可使用螺纹密封剂。大多数IP68接头采用螺纹处的O型圈密封,无需额外密封剂。错误使用密封剂可能污染O型圈,降低密封效果。.

Q4: Can I drill additional holes in an IP68 junction box?

现场钻孔将导致IP68等级和认证失效。内部几何结构与密封设计是作为完整系统进行工程设计的。如需额外入口,请订购具有更多进线孔的箱体或使用更大尺寸的产品。.

Q5: How often should I replace gaskets?

对于连续浸没应用,应每年检查密封垫。若出现压缩永久变形(永久性变形)、裂纹或硬化,则需更换。在氯化泳池环境中,密封垫可能需要每2-3年更换一次。在清洁淡水环境中,通常可使用5年以上。.

Q6: What’s the difference between IP68 and IP69K?

IP69K是一种针对高温高压冲洗(通常为80°C、100巴水射流)的专业防护等级。IP68适用于浸水环境。对于水下应用场景,IP68才是正确的规格标准。IP69K通常应用于食品加工和工业清洁领域。.

Q7: Can I submerge a junction box deeper than its rating?

否。超过额定深度会增加静水压力,使其超出设计极限,这可能导致水渗入密封件或使外壳变形。务必保持安全裕度——若在3米水深操作,应选用至少5米额定深度的防护盒。.

Q8: Are VIOX junction boxes suitable for saltwater?

是的。我们的316系列不锈钢产品专为海洋环境设计。所有单元均按照ASTM B117标准进行盐雾测试,并配备耐腐蚀紧固件和电缆防水接头。聚碳酸酯外壳也可用于海水环境,但需搭配适用的黄铜/镀镍防水接头。.

نتيجه گيری

IP68 waterproof junction boxes are the critical infrastructure enabling reliable submersible electrical installations. Understanding the distinction between IP67 and IP68, selecting appropriate materials for your environment, and following proper installation procedures ensures long-term system reliability.

Key takeaways:

- Verify specific IP68 parameters: Demand manufacturers specify exact depth and duration

- Material selection matters: Stainless steel 316 for saltwater, polycarbonate for cost-effective freshwater applications

- Cable glands are critical: The weakest point in any IP68 system—select and install with precision

- Code compliance is mandatory: Follow NEC 314.15 (wet locations) and 314.29 (accessibility)

- Maintenance prevents failure: Annual inspection and gasket replacement prevent costly failures

VIOX Electric stands ready to support your submersible electrical projects with certified IP68 solutions, technical expertise, and reliable manufacturing quality. Our engineering team can assist with product selection, custom configurations, and installation guidance.

تماس با ما ویوکس الکتریک today for IP68 junction box specifications, test certificates, and project consultation.