Introduction

In the rapidly evolving landscape of industrial automation and renewable energy, selecting the correct power switching device is not just a matter of functionality—it is a critical safety imperative. While AC (Alternating Current) and DC (Direct Current) contactors may appear nearly identical on a specification sheet or a warehouse shelf, they are engineered to handle fundamentally different physical forces.

A frequent question faced by electrical engineers and installers is: “Can I use a standard AC contactor to switch a DC load?” The answer is nuanced, but for high-voltage applications, it is generally a resounding no. The physics of how current flows—and more importantly, how it stops—dictates the internal architecture of these devices. Misapplying an AC contactor in a DC circuit can lead to catastrophic failure, sustained arcing, and electrical fires.

This comprehensive guide serves as the definitive resource for understanding the technical distinctions between AC and DC contactors. We will explore the engineering principles behind their design, the physics of arc suppression, and provide a practical selection guide to ensure your systems remain safe, compliant, and efficient.

Key Takeaways

- Arc Extinction is the Primary Differentiator: AC contactors rely on the natural zero-crossing of the current sine wave to extinguish arcs. DC contactors must employ magnetic blowouts and larger air gaps to forcibly break the continuous DC arc.

- Core Construction: AC contactors use laminated silicon steel cores to prevent overheating from eddy currents. DC contactors utilize solid steel cores for higher mechanical efficiency and durability.

- Coil Physics: AC coils rely on inductance to limit current, resulting in high inrush currents. DC coils rely on resistance and often require economizer circuits to manage power consumption.

- Safety Warning: Using an AC contactor for DC loads without significant derating is dangerous. The lack of arc suppression can cause contact welding and equipment destruction.

- Selection Rule: Always specify contactors based on the load type (IEC categories AC-3 vs. DC-1/DC-3) and voltage characteristics, not just amperage rating.

What is a Contactor?

Before diving into the differences, it is essential to understand the baseline. A contactor is an electromechanical switch used to control power circuits remotely. Unlike a standard switch, a contactor is operated by a control circuit (the coil) that is electrically isolated from the power circuit (the contacts).

For a deeper understanding of the basic components and working principles, refer to our guide: What is a Contactor?.

While relays perform a similar function for low-power signals, contactors are designed to handle high-current loads like motors, lighting banks, and capacitor banks. To understand when to use which, see Contactors vs. Relays: Understanding the Key Differences.

The Fundamental Physics: Why AC and DC Require Different Designs

The design divergence between AC and DC contactors stems from the nature of the current they control.

- Alternating Current (AC): The current direction reverses periodically (50 or 60 times per second). Crucially, the voltage and current pass through a “zero-crossing” point 100 or 120 times every second. At this instant, the energy in the circuit is zero.

- Direct Current (DC): The current flows continuously in one direction with a constant magnitude. There is no natural zero-crossing. Once an arc is established, it is self-sustaining and extremely difficult to extinguish.

This difference impacts two critical areas of contactor design: the electromagnet (coil and core) and the arc suppression mechanism.

Core Design Differences Explained

To handle these different electrical behaviors, manufacturers like VIOX Electric engineer the internal components differently.

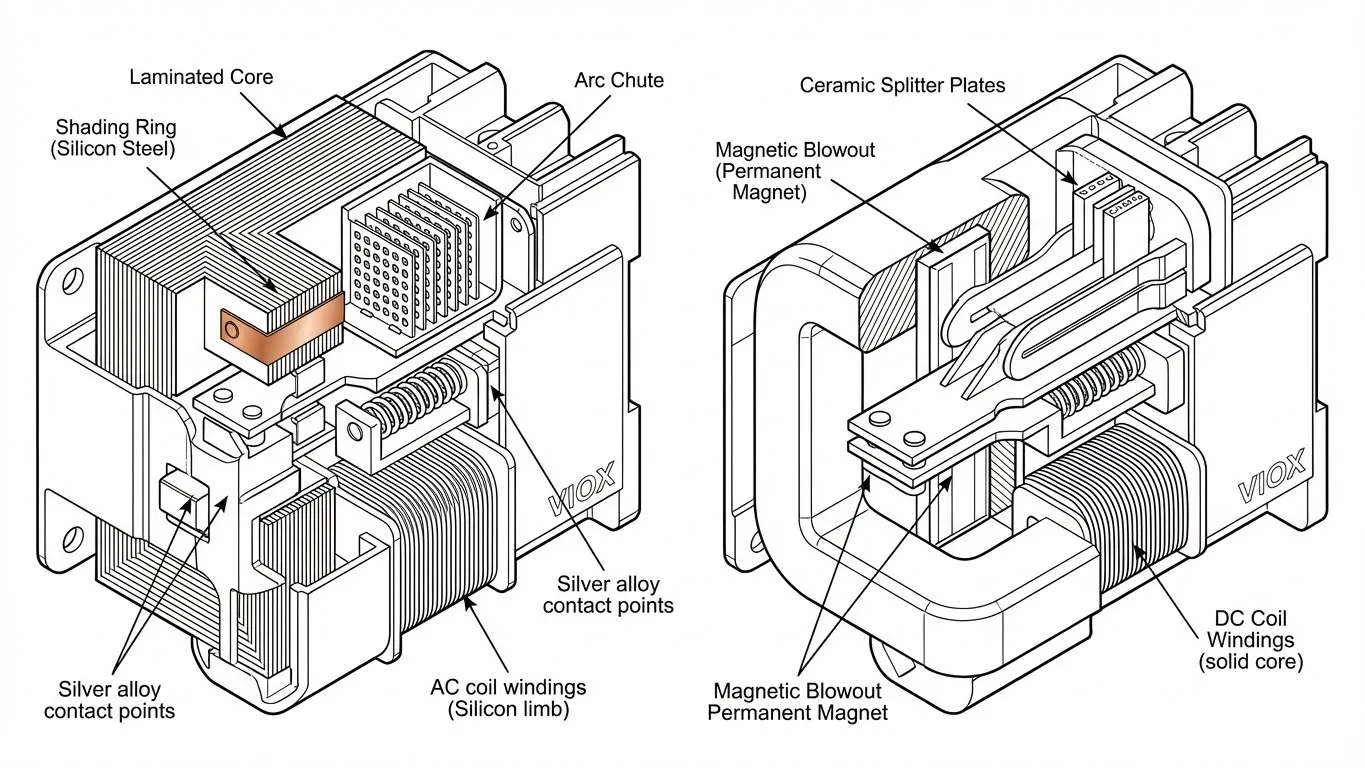

1. Magnetic Core Construction: Laminated vs. Solid

The most significant structural difference lies in the iron core of the electromagnet.

- AC Contactors (Laminated Core):

When AC flows through a coil, it generates a fluctuating magnetic field. If the core were a solid block of iron, this changing magnetic flux would induce circulating currents—known as eddy currents—within the core itself. These currents generate immense heat (Iron Loss), which would quickly destroy the contactor.- Solution: AC cores are made of laminated silicon steel sheets. These thin layers are insulated from one another, breaking the path of eddy currents and minimizing heat generation.

- Shading Ring: Because AC power hits zero 100+ times a second, the magnetic force also drops to zero, causing the armature to chatter (vibrate). A copper shading ring is embedded in the core to create a secondary magnetic flux that is out of phase, holding the contactor closed during the zero-crossing.

- DC Contactors (Solid Core):

DC current creates a steady, non-fluctuating magnetic field. Since there is no change in flux, there are no eddy currents.- Design: The core is made of solid cast steel or soft iron. This solid construction is mechanically stronger and more efficient at conducting magnetic flux. DC contactors do not require shading rings because the magnetic pull is constant.

2. Coil Design and Impedance

The physics of the coil winding also differs significantly.

- AC Coils: The current flowing through an AC coil is limited by impedance (Z), which is a combination of wire resistance (R) and inductive reactance (XL).

- Inrush Current: When the contactor is open, the air gap is large, making inductance low. This results in a massive inrush current (10–15 times the rated current) to pull the contacts closed. Once closed, inductance increases, and current drops to a low holding level.

- DC Coils: With no frequency (f=0), there is no inductive reactance (XL = 2πfL = 0). The current is limited only by the wire’s resistance.

- Heat Management: To prevent overheating, DC coils often use more turns of thinner wire to increase resistance. Large DC contactors use economizer circuits (or dual windings) that switch from a high-power “pickup” coil to a low-power “hold” coil once the contactor closes.

3. Contact Materials and Erosion

DC switching is harsher on contact surfaces due to material transfer (migration) caused by the unidirectional current.

- AC Contacts: Typically use Silver-Nickel (AgNi) or Silver-Cadmium Oxide (AgCdO).

- DC Contacts: Often require harder materials like Silver-Tungsten (AgW) or Silver-Tin Oxide (AgSnO2) to resist the intense heat and erosion of DC arcing.

Arc Suppression: The Critical Safety Distinction

This is the most critical section for safety and SEO. The inability to extinguish an arc is the primary cause of electrical fires in misapplied contactors.

For a detailed explanation of arcing physics, read What is an Arc in a Circuit Breaker?.

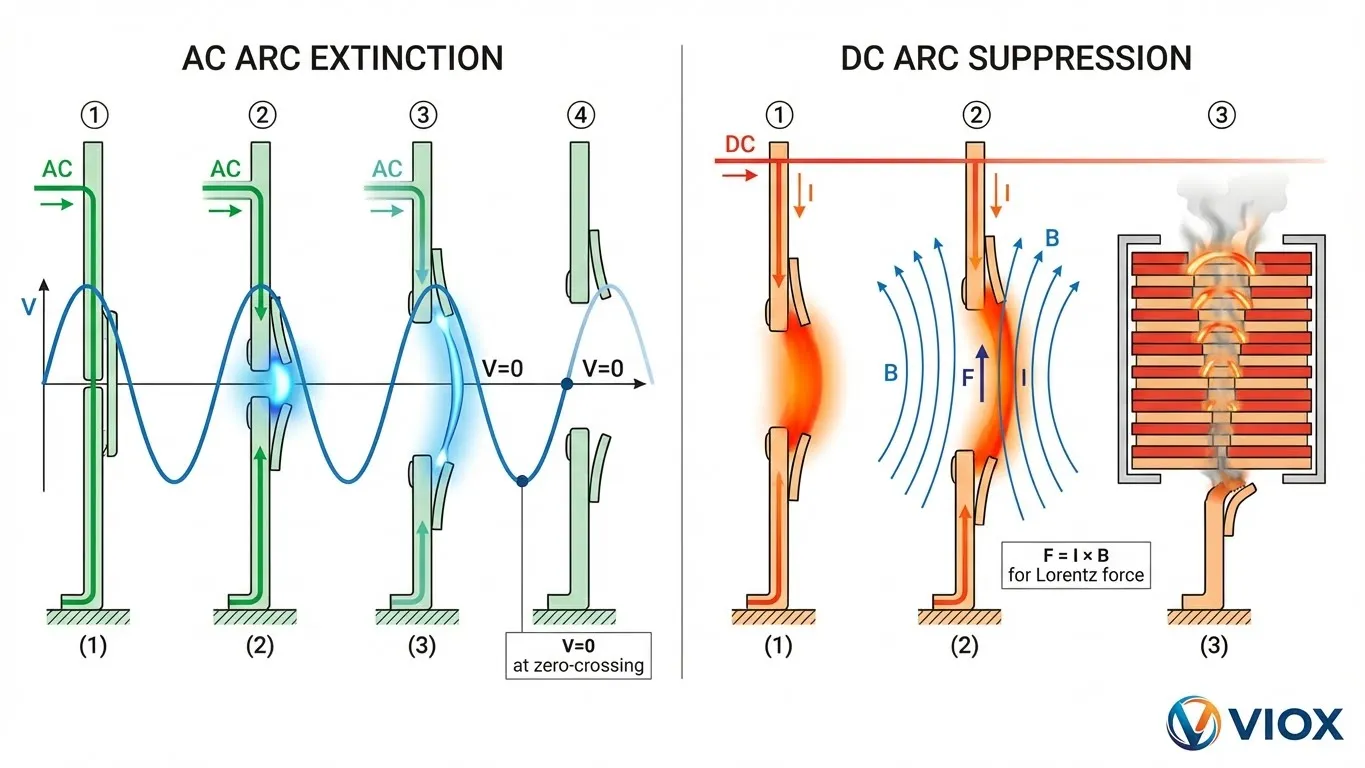

AC: The Zero-Crossing Advantage

In an AC circuit, the arc is naturally unstable. Every time the voltage passes through zero (every 8.3ms in 60Hz systems), the arc energy dissipates.

- Contacts open.

- Arc forms and stretches.

- Zero-crossing occurs: The arc extinguishes.

- If the dielectric strength of the air gap is sufficient, the arc does not re-strike.

DC: The Constant Threat

In a DC circuit, the voltage never drops to zero. The arc is stable and continuous. If you open the contacts, the arc will stretch and burn until it physically melts the contacts or the device explodes. The energy stored in the arc is calculated by:

E = ½ L I2

Where L is the system inductance and I is the current. In highly inductive loads (like DC motors), this energy is massive.

DC Arc Suppression Techniques

To combat this, DC contactors employ active suppression methods:

- Magnetic Blowouts: Permanent magnets or coils create a magnetic field perpendicular to the arc. According to Fleming’s Left-Hand Rule, this creates a Lorentz force that physically pushes the arc away from the contacts.

- Arc Chutes: The arc is forced into ceramic or metal splitter plates (arc chutes) that stretch, cool, and fragment the arc to extinguish it.

- Wider Air Gap: DC contactors are designed with a larger travel distance between open contacts to ensure the arc breaks.

Detailed Comparison Table

| Feature | AC Contactor | DC Contactor |

|---|---|---|

| Core Material | Laminated Silicon Steel (E-Shape) | Solid Cast Steel / Soft Iron (U-Shape) |

| Eddy Current Loss | High (requires lamination) | Negligible (solid core allowed) |

| Arc Suppression | Grid arc chutes; relies on zero-crossing | Magnetic blowouts; larger air gap; arc runners |

| Coil Current Limiter | Inductive Reactance (XL) & Resistance | Resistance (R) only |

| Inrush Current | Very High (10-15x holding current) | Low (determined by resistance) |

| Shading Ring | Essential (prevents vibration/noise) | Not Required |

| Operating Frequency | ~600 – 1,200 cycles/hour | Up to 1,200 – 2,000+ cycles/hour |

| Contact Material | AgNi, AgCdO (Lower resistance) | AgW, AgSnO2 (High erosion resistance) |

| Hysteresis Loss | Significant | Zero |

| Cost | Generally Lower | Higher (complex construction) |

| Typical Applications | Induction Motors, HVAC, Lighting | EVs, Battery Storage, Solar PV, Cranes |

Operating Characteristics

Switching Frequency

DC contactors can generally handle higher switching frequencies. The solid core construction is mechanically more robust, and the lack of high inrush current reduces thermal stress on the coil during frequent cycling.

Starting Current

AC contactors must handle massive inrush currents on the coil itself. If an AC contactor fails to close completely (e.g., due to debris or low voltage), the inductance remains low, the current remains high, and the coil will burn out in seconds. DC coils are immune to this failure mode.

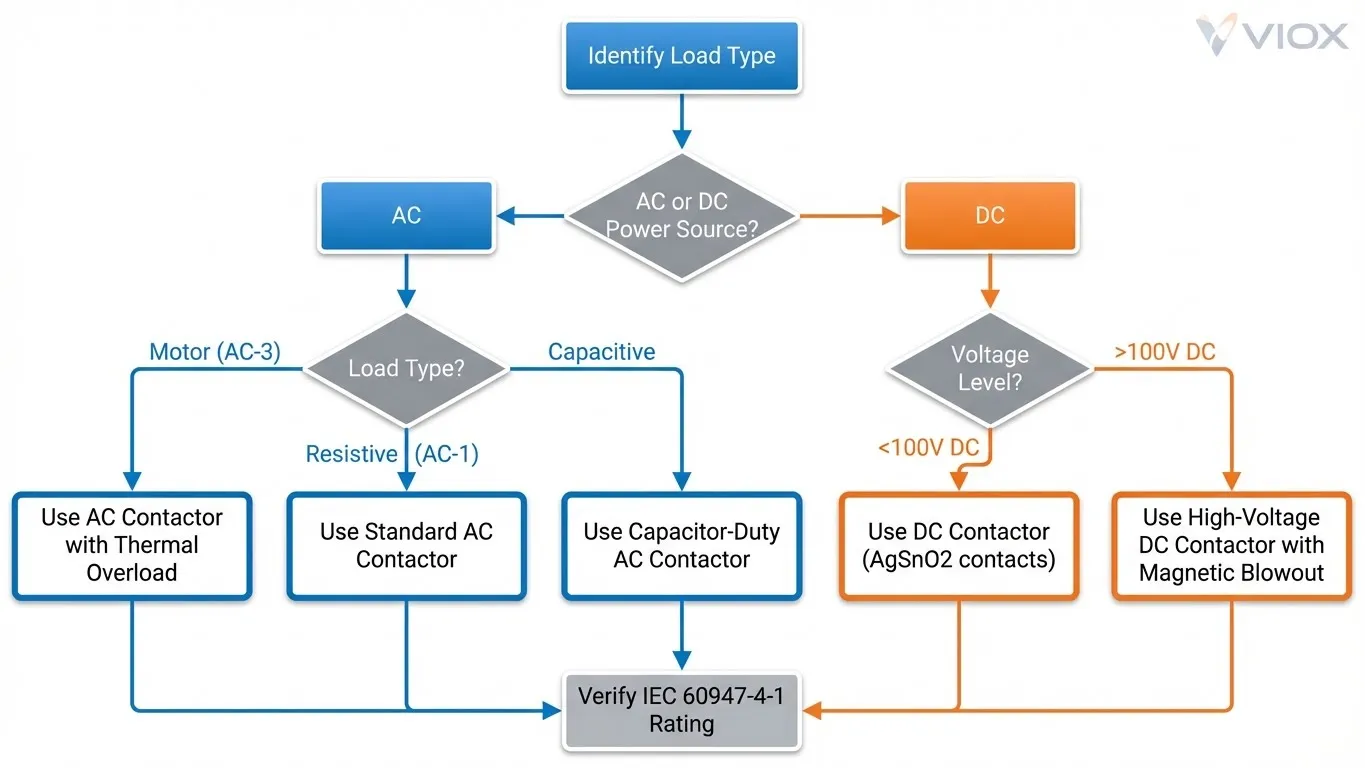

Can You Interchange AC and DC Contactors?

This is the most common source of field failures.

Scenario A: Using an AC Contactor for a DC Load

Verdict: DANGEROUS.

- Risk: Without magnetic blowouts, the AC contactor cannot extinguish the DC arc. The arc will persist, welding the contacts together or melting the unit.

- Exception (Derating): For low voltage (≤24V DC) or purely resistive loads (DC-1), you may be able to use an AC contactor if you connect the poles in series (e.g., wiring 3 poles in series to triple the air gap). However, you must derate the current capacity significantly (often to 30-50% of the AC rating). Always consult the manufacturer.

Scenario B: Using a DC Contactor for an AC Load

Verdict: Possible, but Inefficient.

- A DC contactor can easily break an AC arc because its suppression mechanism is “over-engineered” for AC.

- Drawback: DC contactors are more expensive and physically larger. Also, the coil must still be powered by the correct DC voltage (unless it has an AC/DC electronic coil).

Application Guide: When to Use Each Type

Choose an AC Contactor For:

- AC Motor Control: Starting 3-phase induction motors (compressors, pumps, fans). See Contactor vs. Motor Starter.

- Lighting Control: Switching large banks of LED or fluorescent lights.

- Heating Loads: Resistive AC heaters and furnaces.

- Capacitor Banks: Power factor correction (requires special capacitor-duty contactors).

Choose a DC Contactor For:

- Electric Vehicles (EVs): Battery disconnects and fast-charging stations.

- Renewable Energy: Solar PV combiners and battery energy storage systems (BESS).

- DC Motors: Forklifts, AGVs, and heavy industrial cranes.

- Transportation: Railway systems and marine power distribution.

Selection Guide for Engineers

When specifying a contactor, “Amps” and “Volts” are not enough. You must select based on the IEC 60947-4-1 Utilization Categories.

1. Identify the Load Category

- AC-1: Non-inductive or slightly inductive loads (Heaters).

- AC-3: Squirrel-cage motors (Starting, switching off during running).

- AC-4: Squirrel-cage motors (Plugging, inching – heavy duty).

- DC-1: Non-inductive or slightly inductive DC loads.

- DC-3: Shunt motors (Starting, plugging, inching).

- DC-5: Series motors (Starting, plugging, inching).

2. Calculate Electrical Life

DC applications often shorten contact life. Ensure the contactor’s electrical life curves match your expected duty cycle.

3. Environmental Considerations

For safety-critical environments, consider using contactors with force-guided contacts to ensure fail-safe operation. Learn more in our Safety Contactor Guide.

Common Brands and Models

At VIOX Electric, we manufacture a comprehensive range of contactors tailored for global standards.

- VIOX AC Contactors: Our CJX2 and LC1-D series are industry standards for motor control, featuring high-conductivity silver alloy contacts and robust laminated cores.

- VIOX Modular Contactors: Compact, DIN-rail mounted units ideal for building automation and lighting control.

- VIOX High-Voltage DC Series: Specifically designed for the EV and Solar markets, featuring sealed arc chambers and magnetic blowout technology.

Other reputable brands in the market include Schneider Electric (TeSys), ABB (AF Series), and Siemens (Sirius), though VIOX offers comparable performance at a more competitive price point for OEMs and panel builders.

Testing Procedures

Testing a contactor requires verifying both the coil and the contacts.

- Coil Resistance: Measure with a multimeter. An open circuit (∞ Ω) means a burnt coil.

- Contact Continuity: With the coil energized, resistance across poles should be near zero.

- Visual Inspection: Check for blackened contacts or melted arc chutes—signs of arcing issues.

Safety Note: Always perform Lockout/Tagout Procedures before testing.

Common Mistakes to Avoid

- Mismatched Coil Voltage: Applying 24V DC to a 24V AC coil will burn it out (due to lack of inductive reactance). Applying 24V AC to a 24V DC coil will cause it to chatter and fail to close.

- Ignoring Polarity: DC contactors with magnetic blowouts are often polarity-sensitive. Wiring them backward pushes the arc into the mechanism instead of into the chute, destroying the device.

- Under-sizing for DC: Assuming a 100A AC contactor can handle 100A DC. It usually can only handle ~30A DC safely.

FAQ

Can I use an AC contactor for a 48V DC battery system?

It is not recommended. While 48V is relatively low, the high current of a battery system can cause sustained arcing. If you must, wire all three poles in series to increase the arc breaking distance, but a dedicated DC contactor is safer.

Why do AC contactors hum or buzz?

The hum is caused by the magnetic flux passing through zero 100 times a second, causing the laminations to vibrate. A broken or loose shading ring will cause loud buzzing and chattering.

Are DC contactors polarity sensitive?

Yes, many high-power DC contactors are polarity sensitive because the magnetic blowout coils rely on the direction of current flow to push the arc in the correct direction (into the chutes).

What is the difference between an AC-3 and AC-1 rating?

A single contactor will have different amperage ratings for different loads. An AC-1 rating (resistive) is always higher than an AC-3 rating (inductive motor) because resistive loads are easier to switch off.

Can I replace a DC contactor with an AC one in an emergency?

Only if the AC contactor is significantly oversized and the poles are wired in series. This should only be a temporary measure until the correct DC unit is obtained.

How do electronic coils work?

Modern “universal” contactors use electronic coils that rectify AC to DC internally. This allows the contactor to accept a wide range of voltages (e.g., 100-250V AC/DC) and operate without hum.

What causes contact welding?

Contact welding occurs when the arc heat melts the silver alloy surface, and the contacts fuse together as they close or bounce. This is common when using AC contactors on DC loads or during short-circuit events.

Conclusion

The distinction between AC and DC contactors is not merely a labeling preference—it is a fundamental engineering requirement driven by the physics of electricity. AC contactors leverage the natural zero-crossing of the grid to operate efficiently, while DC contactors employ robust magnetic engineering to tame the continuous energy of direct current.

For electrical professionals, the rule is simple: Respect the load. Never compromise on safety by misapplying these devices.

At VIOX Electric, we are committed to providing high-quality, application-specific switching solutions. Whether you are designing a next-generation solar combiner box or a standard motor control center, our engineering team is ready to assist.

Need help selecting the right contactor for your project? Explore our Product Catalog or Contact Us for a technical consultation today.