Busbar trunking systems, also known as busways, are modern electrical distribution solutions that use enclosed copper or aluminum conductors to efficiently transmit power from source to load. These systems come in various types, including low voltage, medium voltage, compact, and sandwich configurations, each designed to meet specific power distribution needs in industrial, commercial, and high-rise building applications.

Key Components of Busbar Systems

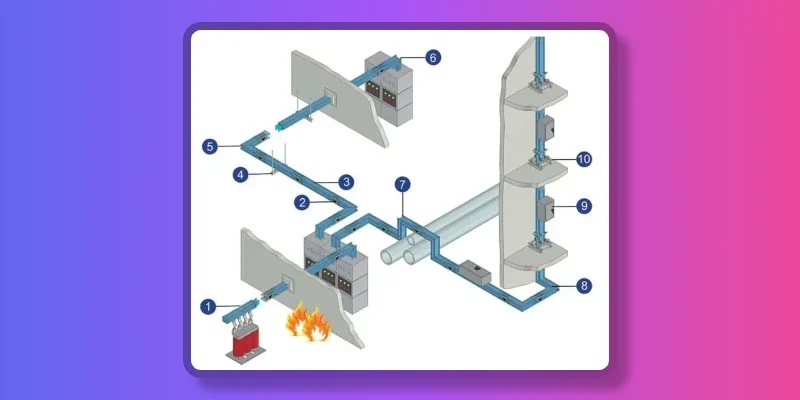

Busbar trunking systems comprise three essential components that work together to ensure efficient and safe power distribution:

- Conductors: Insulated copper or aluminum bars that serve as the primary means of electrical transmission.

- Protective Enclosure: A metal casing that houses the busbars, shielding them from external damage and enhancing safety.

- Tap-off Points: Regularly spaced connection points along the busway that allow for power distribution to various locations within a facility.

These key elements combine to create a compact and versatile electrical distribution system that offers superior thermal management and flexibility compared to traditional cabling methods.

Key Busway Features

Busbar trunking systems offer a range of features tailored to meet diverse electrical distribution needs:

- Material Selection: Copper and aluminum are the primary conductor materials, with copper offering higher conductivity and aluminum providing a lightweight, cost-effective alternative. Bimetallic options combine the benefits of both materials for optimal performance.

- Design Features: Compact designs minimize space requirements, while sandwich-type configurations enhance safety and efficiency. The sandwich structure encases conductors between insulating layers, reducing electromagnetic emissions and improving heat dissipation.

- Specification Range: Current capacities typically range from 25A to 5000A, accommodating various power distribution requirements. Sizes vary based on the application, with compact systems for lighting (25A-63A) and larger configurations for high-power industrial use (up to 5000A).

These features enable busbar trunking systems to provide flexible, efficient, and safe power distribution solutions across diverse industrial and commercial applications.

Types of Busbar Systems

Busbar trunking systems come in various configurations to meet diverse power distribution needs:

- Low Voltage: Designed for power transmission at lower voltages, featuring solid conductors with insulating materials and tap-off units for flexible power distribution.

- Medium Voltage: Operates at 12-24 kV with current ratings up to 5700A, utilizing copper and aluminum conductors embedded in a silicon mineral and epoxy resin insulation.

- Compact Air: Handles power ratings from 125A to 1250A, offering plug-in points every 500mm on both sides and an IP54 protection rating.

- Sandwich Type: Sophisticated solution for currents from 400A to 6300A, with operating voltage of 1000V and IP54/55/65 protection options.

These systems cater to different applications, with distribution trunking ideal for commercial buildings and industrial facilities, while feeder trunking specializes in interconnecting switchboards or transformers with enhanced mechanical strength.

Advantages of Busbar Systems VS Traditional Cable Distribution Methods

Busbar trunking systems offer several advantages over traditional cable distribution methods:

- Space Efficiency: The compact design requires significantly less space than conventional cabling systems, making it ideal for installations with limited room.

- Flexibility: These systems allow for easy modifications, expansions, and reconfigurations to meet changing power requirements, providing adaptability for evolving electrical needs.

- Enhanced Safety: The enclosed design protects against external damage and offers better short-circuit resistance, reducing the risk of electrical accidents.

- Improved Thermal Management: The metal enclosure provides superior heat absorption and cooling compared to conventional cables, ensuring efficient operation and prolonged system life.

- Easy Installation and Maintenance: Busbar systems are typically easier to install and maintain than traditional cabling, reducing downtime and labor costs.

Applications of Busbar Systems

Busbar trunking systems find widespread use across various sectors due to their efficient power distribution capabilities. They are particularly suited for environments with high power demands and complex electrical layouts:

- Industrial Facilities: These systems are ideal for factories and manufacturing plants, where they provide reliable power distribution to heavy machinery and equipment.

- Commercial Buildings: High-rise buildings, shopping malls, and office complexes benefit from the space-saving and flexible nature of busbars, which can easily adapt to changing electrical needs.

- Data Centers: With their high power density requirements, data centers utilize busbar trunking for efficient and scalable power distribution.

- Airports and Hotels: These facilities leverage busbar systems to ensure uninterrupted power supply across vast areas with diverse electrical loads.

- Warehouses: The adaptability of busbars makes them suitable for warehouses, where they can efficiently distribute power to lighting systems and material handling equipment.

Installation and Maintenance Guide

The installation and maintenance of busbar trunking systems require careful planning and adherence to safety protocols to ensure optimal performance and longevity. Here are key considerations for installation, maintenance, and troubleshooting:

Installation Steps and Precautions:

- Planning: Before installation, carefully assess the layout and power requirements. Ensure all necessary components and tools are available.

- Safety Measures: Always wear appropriate personal protective equipment, including long-sleeved jackets, trousers, gloves, safety shoes, helmets, and safety glasses.

- Surface Preparation: Clean all contact surfaces thoroughly to remove contaminants and ensure unblemished connections between busbar sections.

- Alignment: Properly align busbar sections during installation to prevent misalignment issues that could lead to overheating or electrical faults.

- Torque Application: Use calibrated torque wrenches to tighten bolts and connections to manufacturer-specified values, ensuring proper electrical contact and mechanical stability.

- Environmental Considerations: Take into account factors such as temperature fluctuations, humidity, and potential exposure to corrosive substances when selecting and installing busbar components.

Maintenance Methods:

- Regular Inspections: Conduct visual inspections to check for signs of wear, corrosion, or loose connections.

- Thermal Imaging: Utilize infrared cameras to detect hotspots that may indicate poor connections or overloading.

- Insulation Resistance Testing: Periodically measure insulation resistance to identify any degradation in the insulating materials.

- Cleaning: Remove dust and debris from busbar enclosures to maintain proper heat dissipation and prevent insulation breakdown.

Common Issues and Solutions:

- Overheating: Often caused by loose connections or overloading. Solution: Retighten connections and reassess load distribution.

- Corrosion: Can occur in humid environments. Solution: Use corrosion-resistant materials and apply protective coatings where necessary.

- Misalignment: May result from improper installation or structural movement. Solution: Realign busbar sections and reinforce mounting points.

- Insulation Failure: Can lead to short circuits. Solution: Replace damaged insulation and investigate root causes such as overheating or environmental factors.

By following these guidelines, facility managers can ensure the safe and efficient operation of busbar trunking systems, minimizing downtime and maximizing the system’s lifespan.

Cutting-Edge Busbar Innovations

Recent innovations in busbar technology have focused on enhancing efficiency, sustainability, and smart functionality. Advanced materials like aluminum-copper composites are being utilized to create lighter yet highly conductive busbars, reducing weight while maintaining performance. Intelligent busbar systems now incorporate IoT sensors and real-time monitoring capabilities, allowing for predictive maintenance and optimized power distribution. These smart systems can automatically adjust loads, detect faults, and provide data analytics for improved energy management.

Environmental protection and energy-saving technologies have also become central to busbar development. New designs prioritize energy efficiency through improved thermal management and reduced power losses. Some manufacturers are exploring eco-friendly insulation materials and recyclable components to minimize environmental impact. Additionally, busbar systems are increasingly being integrated with renewable energy sources and energy storage solutions, supporting the transition to more sustainable power infrastructures in commercial and industrial settings.

Market Trends and Analysis

The global busbar trunking system market is experiencing robust growth, with a projected CAGR of 6.5-6.8% from 2024 to 2032. This growth is primarily driven by increasing demand for efficient and reliable power distribution systems in industrial, commercial, and residential sectors. Key trends shaping the market include:

- Rising adoption of renewable energy sources, necessitating advanced power distribution solutions.

- Growing focus on energy efficiency and sustainability in construction projects.

- Increasing investments in smart grid technologies and infrastructure modernization.

The Asia Pacific region, particularly China, is emerging as a major market for busbar trunking systems. China’s rapid industrialization, urbanization, and commitment to renewable energy are fueling demand. The country’s emphasis on smart city development and green construction projects presents significant opportunities for busbar system manufacturers.

Leading players in the global busbar trunking system market include:

- VIOX Electric

- Siemens AG

- ABB Ltd

- Schneider Electric SE

- Eaton Corporation

- Larsen & Toubro Limited

These companies are focusing on product innovations, such as smart monitoring capabilities and eco-friendly materials, to maintain their competitive edge. The market is also seeing increased competition from regional manufacturers, particularly in Asia, who are offering cost-effective solutions tailored to local needs.

Reference:

https://www.mordorintelligence.com/industry-reports/busbar-trunking-market