I. Вступ

A. Визначення датчиків наближення

Датчики наближення - це складні безконтактні пристрої, призначені для виявлення наявності або відсутності об'єктів поблизу без будь-якої фізичної взаємодії. Ці геніальні датчики працюють, випромінюючи електромагнітне поле або пучок електромагнітного випромінювання, наприклад, інфрачервоне світло. Потім вони безперервно відстежують зміни в полі або зміни у зворотному сигналі, коли об'єкт, який часто називають "ціллю", потрапляє в зону їхнього виявлення.

B. Значення в сучасних технологіях

Датчики наближення відіграють вирішальну роль у сучасних технологіях, підвищуючи ефективність, безпеку та автоматизацію в різних галузях промисловості:

- Промислова автоматизація: Ці датчики оптимізують виробничі процеси, забезпечуючи автоматичне виявлення об'єктів, сортування та контроль якості.

- Автомобільна безпека: У транспортних засобах вони живлять системи запобігання зіткненням та допомоги при паркуванні, роблячи значний внесок у технології автономного водіння.

- Споживча електроніка: Датчики наближення у смартфонах запобігають випадковому натисканню на сенсорний екран під час дзвінків, покращуючи користувацький досвід.

- Робототехніка: Допомагають у навігації та уникненні перешкод як промисловим, так і сервісним роботам.

- Системи безпеки: Ці датчики посилюють заходи безпеки, виявляючи несанкціонований рух у зонах з обмеженим доступом.

- Адаптивність до навколишнього середовища: Здатність працювати в складних умовах робить їх придатними для різноманітних застосувань.

Таким чином, датчики наближення є незамінними компонентами, які підтримують технологічний прогрес у різних галузях, від виробництва до споживчих товарів. Їх безконтактний характер підвищує безпеку та ефективність, що робить їх життєво важливими в сучасному світі, який стає все більш автоматизованим.

II. Основи роботи датчиків наближення

A. Як працюють датчики наближення

1. Основні принципи

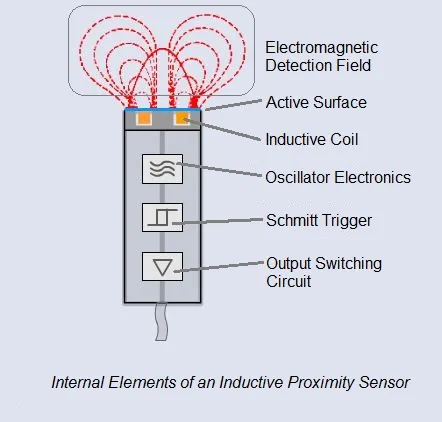

Основні принципи роботи датчиків наближення:

- Генерація поля: Індуктивна котушка створює електромагнітне поле виявлення, що поширюється від активної поверхні.

- Осциляція: Осциляторна електроніка підтримує енергію поля.

- Виявлення цілей: Коли металевий об'єкт потрапляє в поле виявлення, він порушує електромагнітну картину.

- Зміна поля: Присутність цілі змінює коливання датчика.

- Обробка сигналів: Тригер Шмітта виявляє зміни в коливаннях.

- Вихід: Вихідна комутаційна схема активується при виявленні цілі.

- Скидання: Коли ціль залишає поле виявлення, датчик повертається до початкового стану.

Заслуга в тому, що https://machinegeeks.blog/2016/05/26/basic-operating-principle-of-an-inductive-proximity-sensor/

2. Безконтактні методи виявлення

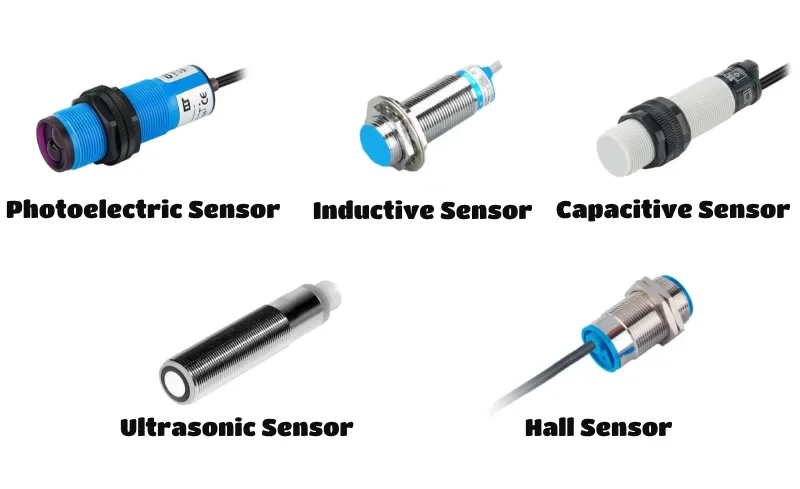

Безконтактні методи виявлення дозволяють сенсорам виявляти об'єкти без фізичного контакту. Ці методи мають вирішальне значення в різних промислових і технологічних застосуваннях. До основних типів відносяться

- Індуктивне зондування: Виявляє металеві об'єкти за допомогою електромагнітних полів. Зазвичай використовується в промисловій автоматизації та автомобілебудуванні.

- Ємнісне зондування: Виявляє як металеві, так і неметалеві об'єкти. Ефективний для визначення рівня в рідинах і сипучих продуктах.

- Фотоелектричне зондування: Використовує світлові промені для виявлення об'єктів. Універсальний для виявлення різних матеріалів на великих відстанях.

- Ультразвукове зондування: Випромінює звукові хвилі для виявлення об'єктів. Ідеально підходить для вимірювання відстаней і визначення рівня в складних умовах.

- Магнітне зондування: Виявляє магнітні поля або феромагнітні матеріали. Використовується для вимірювання швидкості та визначення положення.

Кожен метод має свої унікальні переваги і вибирається на основі конкретних вимог застосування, таких як тип матеріалу, що підлягає виявленню, умови навколишнього середовища і необхідний діапазон виявлення.

III. Типи датчиків наближення

A. Індуктивні датчики наближення

Індуктивні датчики наближення це електронні пристрої, які виявляють наявність металевих предметів без фізичного контакту, використовуючи принцип електромагнітної індукції. Вони особливо ефективні для виявлення чорних металів, але також можуть виявляти кольорові метали зі зменшеним діапазоном виявлення.

Як працюють індуктивні датчики

- Генерація електромагнітного поля: Датчик складається з індуктора (котушки) і генератора, який генерує високочастотний змінний струм, створюючи магнітне поле навколо котушки.

- Виявлення металевих предметів: Коли металевий об'єкт потрапляє в це магнітне поле, він індукує вихрові струми в металі, генеруючи власне магнітне поле.

- Зміна коливань: Присутність металу змінює індуктивність котушки, що призводить до зміни амплітуди або частоти коливань.

- Вихідний сигнал: Коли амплітуда коливань падає нижче заданого порогу, датчик генерує вихідний сигнал.

Додатки

- Промислова автоматизація: Виявлення деталей на складальних лініях, моніторинг позицій машин.

- Автомобільна промисловість: Виявлення положення таких компонентів, як двері та капоти.

- Побутова електроніка: Безконтактне виявлення металів.

- Робототехніка: Допомога роботам у навігації в навколишньому середовищі.

- Системи безпеки: Моніторинг точок доступу та виявлення несанкціонованого проникнення.

Переваги

- Безконтактна робота: Зменшує знос як датчика, так і цілі.

- Довговічність: Зазвичай стійкий до бруду, пилу та вологи.

- Надійність: Твердотільна конструкція без рухомих частин підвищує довговічність.

B. Ємнісні датчики наближення

Ємнісні датчики наближення це універсальні безконтактні пристрої, які виявляють наявність або відсутність різних об'єктів, зокрема металевих і неметалевих матеріалів. Вони працюють за принципом ємності, вимірюючи зміни електричного поля, спричинені розташованими поруч об'єктами.

Як працюють ємнісні датчики наближення

- Генерація електростатичного поля: Датчик складається з двох провідних пластин, що утворюють конденсатор, з генератором, що генерує змінний струм для створення електростатичного поля.

- Механізм виявлення: Об'єкт, що наближається до датчика, порушує електростатичне поле, змінюючи ємність між пластинами.

- Обробка сигналу: Внутрішня електроніка датчика відстежує зміни ємності та частоти, активуючи вихід при виявленні значних змін.

Цільові матеріали

- Метали: Усі види, такі як мідь, алюміній і сталь.

- Неметали: Пластмаси, дерево, скло, гума та текстиль.

- Рідини: Вода, олія, фарба та інші рідини.

Додатки

- Промислова автоматизація: Виявлення деталей, контроль рівня матеріалів і забезпечення правильного позиціонування.

- Побутова електроніка: Безконтактне керування або виявлення об'єктів.

- Харчова промисловість: Моніторинг рівнів у резервуарах.

- Пакувальна промисловість: Виявлення наявності та положення предметів на конвеєрних стрічках.

Переваги

- Безконтактне виявлення: Зменшує знос як датчика, так і матеріалів мішені.

- Універсальність: Може виявляти широкий спектр матеріалів без фізичного контакту.

- Довговічність: Зазвичай стійкі до пилу, вологи та перепадів температур.

C. Фотоелектричні датчики наближення

Фотоелектричні датчики наближення використовують світло для виявлення наявності або відсутності об'єктів у заданому діапазоні без фізичного контакту. Вони широко використовуються в різних сферах завдяки своїй надійності та універсальності.

Як працюють фотоелектричні датчики наближення

- Випромінювач: Цей компонент випромінює промінь світла (інфрачервоний, видимий або ультрафіолетовий).

- Приймач: Приймач виявляє випромінюване світло, вимірюючи або відбите світло від об'єкта, або переривання світлового променя.

- Обробка сигналу: Схема датчика обробляє зміни у світловому потоці та генерує вихідний сигнал.

Додатки

- Промислова автоматизація: Підрахунок, сортування та моніторинг предметів на конвеєрних стрічках.

- Пакувальне обладнання: Виявлення наявності продукту для автоматичних процесів пакування.

- Системи безпеки: Моніторинг точок входу та виявлення вторгнень.

- Автомобільні системи: Допомога при паркуванні та технології запобігання зіткненням.

- Побутова електроніка: Автоматичні змішувачі та безконтактне керування.

Переваги

- Безконтактна робота: Зменшує знос як датчика, так і матеріалів мішені.

- Універсальність: Здатний виявляти різні матеріали, включаючи непрозорі, прозорі та світловідбиваючі поверхні.

- Великий радіус дії: Може ефективно працювати на відстанях від кількох сантиметрів до кількох метрів.

D. Ультразвукові датчики наближення

Ультразвукові датчики наближення це безконтактні пристрої, які використовують високочастотні звукові хвилі для виявлення присутності або відстані до об'єктів. Вони особливо ефективні в різних сферах виробництва та автоматизації, зокрема для виявлення об'єктів і вимірювання відстані.

Як працюють ультразвукові датчики наближення

- Випромінювання звукових хвиль: Датчик випромінює ультразвуковий імпульс у напрямку до цільового об'єкта.

- Прийом відлуння: Коли звукова хвиля потрапляє на об'єкт, вона відбивається назад до датчика.

- Вимірювання часу: Датчик вимірює час, за який випромінюваний імпульс повертається після відскоку від об'єкта.

- Вихідний сигнал: Датчик генерує вихідний сигнал, який вказує на наявність і відстань до виявленого об'єкта.

Ключові особливості

- Безконтактне виявлення: Запобігає зносу як датчика, так і цілі.

- Універсальність: Може виявляти широкий спектр матеріалів, включаючи тверді, рідкі та прозорі об'єкти.

- Імунітет до навколишнього середовища: Не схильний до впливу пилу, вологи та навколишнього освітлення.

Додатки

- Виробництво та автоматизація: Виявлення об'єктів на конвеєрних стрічках, контроль рівня матеріалу в резервуарах.

- Харчова промисловість та виробництво напоїв: Вимірювання рівня в резервуарах і виявлення присутності продукту під час пакування.

- Робототехніка: Допомога роботам у навігації та виявленні перешкод.

- Автомобільні системи: Використовується в системах допомоги при паркуванні для вимірювання відстані до найближчих транспортних засобів або перешкод.

Переваги

- Висока точність: Здатний забезпечити точне вимірювання відстані.

- Довговічність: Зазвичай міцні та здатні працювати в суворих умовах.

- Гнучке встановлення: Може встановлюватися в різних конфігураціях залежно від вимог програми.

E. Магнітні датчики наближення

Магнітні датчики наближення - це безконтактні датчики, які виявляють наявність магнітних полів, що зазвичай генеруються постійними магнітами. Ці датчики працюють без прямого фізичного контакту, що робить їх придатними для різних застосувань, де важливим є надійне виявлення.

Як працюють магнітні датчики наближення

- Виявлення магнітного поля: Чутливий елемент датчика реагує на зміну магнітного поля при наближенні магнітного об'єкта.

- Обробка сигналу: Датчик виявляє цю зміну і обробляє її за допомогою внутрішньої схеми.

- Вихідний сигнал: Коли магнітне поле перевищує заданий поріг, датчик генерує вихідний сигнал.

Ключові особливості

- Виявлення через кольорові матеріали: Може виявляти магніти через стіни з немагнітних матеріалів.

- Велика дальність виявлення: Дозволяє досягати значних відстаней зчитування (до 70 мм) у компактних конструкціях.

- Висока механічна стабільність: Міцний, витримує удари та вібрацію.

Додатки

- Промислова автоматизація: Визначення положення в машинах та обладнанні.

- Харчова промисловість: Моніторинг очисних пристроїв в системах "clean-in-place" (CIP).

- Системи безпеки: Виявлення положень дверей/вікон у системах безпеки.

- Застосування в автомобілебудуванні: Визначення положення компонентів, таких як двері та капоти.

Переваги

- Безконтактна робота: Зменшує знос як датчика, так і матеріалів мішені.

- Універсальність: Може виявляти різноманітні магнітні цілі з різних матеріалів.

- Довговічність: Розроблено для ефективної роботи в суворих умовах.

F. Порівняння переваг та обмежень кожного типу

| Особливість | Індуктивні датчики | Ємнісні датчики | Фотоелектричні датчики | Ультразвукові датчики | Магнітні датчики |

|---|---|---|---|---|---|

| Принцип виявлення | Електромагнітна індукція | Зміна ємності | Випромінювання/прийом світла | Відображення звукових хвиль | Виявлення магнітного поля |

| Матеріали, які можна виявити | Метали | Метали, неметали, рідини | Різні (непрозорі, прозорі, світловідбиваючі) | Більшість матеріалів, включаючи прозорі | Магнітні матеріали |

| Діапазон | Короткі (зазвичай < 60 мм) | Короткі та середні | Від коротких до довгих (до декількох метрів) | Від середнього до довгого | Середній (до 70 мм) |

| Чутливість до навколишнього середовища | Низька (стійкість до бруду/пилу) | Помірна (може впливати волога) | Високий (впливає зовнішнє світло, пил) | Низька (стійкість до пилу, вологи, світла) | Низький (може виявляти через кольорові матеріали) |

| Основні сфери застосування | Промислова автоматизація, автомобільна промисловість | Вимірювання рівня, виявлення матеріалів | Конвеєрні системи, пакування | Вимірювання відстані, вимірювання рівня | Визначення положення, охоронні системи |

| Переваги | Довговічність, надійність | Універсальність у виявленні матеріалів | Великий радіус дії, швидка реакція | Працює в запиленому/темному середовищі | Безконтактний, працює через матеріали |

| Обмеження | Обмежено металевими предметами | Чутливий до змін у навколишньому середовищі | Може залежати від навколишнього освітлення | Може мати перешкоди в шумному середовищі | Обмежено магнітними матеріалами |

IV. Застосування датчиків наближення

Датчики наближення є важливими компонентами в різних галузях промисловості, забезпечуючи ефективне та надійне виявлення об'єктів без фізичного контакту. Ось огляд їхнього застосування в різних галузях:

1. Промислова автоматизація

- Виявлення об'єктів: Широко використовуються на конвеєрних стрічках і складальних лініях для виявлення наявності або відсутності предметів, уможливлюючи автоматизоване сортування, підрахунок і пакування.

- Визначення положення: Допомагає визначити положення рухомих частин у механізмах, забезпечуючи точну роботу та запобігаючи зіткненням.

2. Автомобільна промисловість

- Виявлення перешкод: Використовується в автомобілях для систем допомоги при паркуванні, допомагаючи водіям уникати зіткнень, виявляючи найближчі перешкоди.

- Позиціонування компонентів: Використовується для контролю положення дверей, витяжок та інших рухомих частин, підвищуючи безпеку та функціональність.

3. Побутова електроніка

- Смартфони: Вимикайте екран, коли телефон тримають близько до вуха під час дзвінків, щоб запобігти випадковому сенсорному введенню.

- Побутова техніка: Міститься в таких пристроях, як автоматичні крани та дозатори для мила, що забезпечують безконтактне керування для зручності та гігієни.

4. Системи безпеки

- Виявлення вторгнення: Використовується в системах безпеки для виявлення несанкціонованого проникнення шляхом моніторингу дверей і вікон.

- Активація спостереження: Може викликати тривогу або активувати камери в разі виявлення руху в певному діапазоні.

5. Робототехніка

- Навігаційна допомога: Допомагають роботам орієнтуватися в навколишньому середовищі, виявляючи перешкоди та забезпечуючи безпечний рух.

- Обробка матеріалів: Використовується в автоматизованих керованих транспортних засобах (AGV) для запобігання зіткненням з іншими об'єктами або людьми.

6. Харчова промисловість та виробництво напоїв

- Вимірювання рівня: Ємнісні безконтактні датчики визначають рівень рідини в резервуарах і контейнерах без прямого контакту, забезпечуючи точний моніторинг запасів.

- Виявлення продукту: Використовується в пакувальних лініях для забезпечення правильного позиціонування продукції перед запаюванням або нанесенням етикетки.

7. Пакувальна промисловість

- Контроль якості: Перевірте наявність продукції на пакувальних лініях, щоб переконатися, що товари не пропали перед пакуванням.

- Сортувальні системи: Використовується для сортування продукції за розміром або типом під час її переміщення конвеєрними системами.

8. Медичне обладнання

- Моніторинг пацієнта: Виявлення присутності пацієнта біля медичного обладнання, що дає змогу автоматично регулювати його роботу або сповіщати про це осіб, які здійснюють догляд за ним.

- Автоматизація в лабораторіях: Використовується в лабораторному обладнанні для виявлення присутності зразка без фізичного контакту.

Заслуга в тому: https://creativecommons.org/

V. Вибір правильного датчика наближення

Вибір відповідного датчика наближення для конкретного застосування передбачає врахування кількох факторів для забезпечення оптимальної продуктивності та надійності. Ось вичерпний посібник, який допоможе вам прийняти обґрунтоване рішення:

1. Розуміння вимог до програми

- Тип виявлення: Визначте, який тип об'єктів вам потрібно виявити (металеві, неметалеві, рідини тощо).

- Приклад: Індуктивні датчики для металевих об'єктів, ємнісні датчики для металевих і неметалевих матеріалів, включаючи рідини.

2. Розглянемо діапазон зондування

- Оцініть необхідну відстань виявлення, виходячи з особливостей вашого застосування.

- Різні датчики мають різний діапазон чутливості:

- Індуктивні датчики: зазвичай від міліметра до метра

- Ємнісні датчики: регульовані діапазони залежно від матеріалу та середовища

- Ультразвукові датчики: можуть виявляти об'єкти на більших відстанях, часто на відстані кількох метрів

3. Оцініть умови навколишнього середовища

- Температура і вологість: Переконайтеся, що датчик може працювати в необхідному діапазоні температур і витримувати рівень вологості.

- Пил і волога: Вибирайте датчики, стійкі до пилу і вологи, якщо вони будуть використовуватися в суворих умовах.

4. Визначте тип виходу

- Цифровий вихід: Забезпечує простий сигнал увімкнення/вимкнення при виявленні об'єкта.

- Аналоговий вихід: Пропонує різні сигнали залежно від відстані або присутності, що корисно для застосунків, які потребують точних вимірювань.

5. Оцініть розмір і варіанти кріплення

- Враховуйте фізичний розмір датчика, особливо для вбудованих застосувань, де простір обмежений.

- Переконайтеся, що тип кріплення відповідає вашим вимогам до інсталяції.

6. Частота оновлення

- Оцініть, наскільки швидко датчик повинен реагувати на зміни в навколишньому середовищі.

- Деякі програми можуть вимагати високої частоти оновлення для точного виявлення, тоді як інші можуть бути не настільки чутливі до часу.

7. Вартісні міркування

- Враховуйте бюджет на датчик.

- Збалансуйте вартість і вимоги до продуктивності, щоб знайти підходящий варіант.

8. Репутація та підтримка виробника

- Дослідницькі виробники, відомі виробництвом надійних датчиків наближення.

- Зверніть увагу на їхню клієнтську підтримку, варіанти гарантії та наявність технічної документації.

VI. Майбутні тенденції в технології датчиків наближення

Майбутнє технології датчиків наближення позначене кількома захоплюючими розробками:

- Мініатюризація та підвищення точності: Дозволяє інтегрувати датчики в менші пристрої без шкоди для продуктивності.

- Інтеграція штучного інтелекту та машинного навчання: Підвищення здатності датчиків аналізувати дані в режимі реального часу та адаптивно реагувати на них.

- Експансія в нові галузі: Знаходить застосування в охороні здоров'я, сільському господарстві та побутовій електроніці за межами традиційних галузей.

- Зосередьтеся на сталості: Розробка датчиків з меншим енергоспоживанням.

- Покращений зв'язок: Особливо з Інтернетом речей, який дозволяє краще обмінюватися даними та розумніше автоматизувати роботу.

- Диверсифікація сенсорних технологій: Більші можливості налаштування для задоволення конкретних потреб додатків.

Ці тенденції в сукупності вказують на майбутнє, в якому датчики наближення будуть відігравати все більш важливу роль в різних галузях, стимулюючи інновації та ефективність в автоматизації і не тільки.

VII. Поширені запитання (FAQ)

1. Чи може індуктивний датчик наближення виявити алюміній?

Так, індуктивні датчики наближення можуть виявляти алюміній. Завдяки своєму функціональному принципу індуктивні датчики можуть виявляти не тільки магнітні, але й електропровідні матеріали, зокрема алюміній, латунь, мідь і нержавіючу сталь. Однак діапазон виявлення кольорових металів, таких як алюміній, може бути меншим порівняно з чорними металами.

2. Який типовий термін служби датчика наближення?

Термін служби датчика наближення може сильно відрізнятися залежно від типу датчика, умов використання та факторів навколишнього середовища. Як правило, високоякісні датчики наближення можуть працювати від 5 до 10 років і більше за нормальних умов експлуатації. Твердотільні датчики, такі як індуктивні та ємнісні, часто мають довший термін служби завдяки відсутності рухомих частин.

3. Як підвищити точність мого датчика наближення?

Підвищити точність датчика наближення:

- Забезпечити правильне встановлення та вирівнювання

- Використовуйте екранування для зменшення електромагнітних перешкод

- Регулярно очищайте та обслуговуйте датчик

- Виберіть датчик з відповідною чутливістю для вашого застосування

- Враховуйте фактори навколишнього середовища та обирайте датчик, який може витримати ці умови

- За потреби регулярно калібруйте датчик

4. Як фактори навколишнього середовища впливають на роботу датчика?

Фактори навколишнього середовища можуть суттєво впливати на роботу датчика:

- Температура: Екстремальні температури можуть вплинути на точність і термін служби датчика

- Вологість: Висока вологість може спричинити конденсацію, що може вплинути на показання датчика

- Пил і сміття: Може заважати роботі оптичних датчиків або накопичуватися на поверхні датчика

- Електромагнітні перешкоди: Можуть впливати на точність індуктивних і ємнісних датчиків

- Вібрація: Надмірна вібрація може спричинити хибні спрацьовування або пошкодження компонентів датчика

Вибирайте датчики, розраховані на конкретні умови навколишнього середовища, щоб забезпечити оптимальну продуктивність.

5. Якого обслуговування та калібрування потребують датчики наближення?

Вимоги до обслуговування та калібрування залежать від типу датчика:

- Регулярне прибирання для видалення пилу та сміття

- Періодична перевірка на наявність фізичних пошкоджень або перекосів

- Перевірка та затягування електричних з'єднань

- Калібрування може знадобитися для деяких типів датчиків, особливо тих, що використовуються в прецизійних додатках

- Дотримуйтесь вказівок виробника щодо конкретних процедур та інтервалів технічного обслуговування

Більшість сучасних датчиків наближення не потребують особливого обслуговування, але регулярні перевірки можуть забезпечити довготривалу надійність і точність.

Поширені марки та моделі безконтактних датчиків

VIOX Електричний:

Перевага бренду: Китайський бренд, відомий своїми конкурентними цінами, надійністю та широким асортиментом продукції.

Рекомендовані моделі:

Ємнісний безконтактний датчик VIOX CM30

Датчики кольорових міток серії VIOX BZJ-211

Індуктивні безконтактні вимикачі серії VIOX LMF1

Фотоелектричний вимикач VIOX G30

Omron:

Перевага бренду: Японський бренд, відомий своєю високою якістю, зручним дизайном та економічністю.

Рекомендовані моделі:

E3Z-LS61: Індуктивний датчик наближення на великі відстані, відстань виявлення до 10 мм, ступінь захисту IP67

E2A-M18KS08-WP-C1: Високотемпературний індуктивний датчик наближення, відстань виявлення 8 мм, підходить для суворих умов експлуатації

E2K-C04MC1: Ємнісний датчик наближення, здатний виявляти рідину, відстань спрацьовування 4 мм

B5W-LA415: Компактний оптичний датчик з дальністю виявлення до 5 м

IFM:

Перевага бренду: Німецький бренд, відомий інноваційними технологіями, високоякісною продукцією та простотою монтажу.

Рекомендовані моделі:

O2D222:Датчик розпізнавання об'єктів

PN7692: Датчик тиску з дисплеєм

UCG252: Ультразвуковий датчик з діапазоном виявлення до 250 мм, підходить для вимірювання відстані та контролю рівня рідини

O1D100: Оптичний датчик з відстанню виявлення 100 мм, ідеально підходить для виявлення об'єктів і підрахунку.

висновок

На закінчення, розуміння принципів, типів і застосувань датчиків наближення має вирішальне значення для всіх, хто займається промисловою автоматизацією, розробкою продуктів або впровадженням технологій. Оскільки ці датчики продовжують розвиватися, вони, безсумнівно, відіграватимуть ще більш важливу роль у формуванні майбутнього технологій і промисловості.