Kapag nagdidisenyo ng mga electrical control panel at automation system, ang hamak na terminal block ay gumaganap ng mahalagang papel sa pagtiyak ng maaasahang mga koneksyon. Ngunit sa hindi mabilang na mga opsyon na magagamit, kung paano pumili ng DIN rail mounted terminal blocks na perpektong tumutugma sa iyong mga kinakailangan sa aplikasyon ay maaaring maging mahirap. Ang komprehensibong gabay na ito ay gagabay sa iyo sa lahat ng kailangan mong malaman upang makagawa ng matalinong mga desisyon para sa iyong mga pangangailangan sa koneksyon sa kuryente.

Pag-unawa sa DIN Rail Terminal Blocks at sa Kanilang mga Aplikasyon

Ano ang DIN Rail Terminal Blocks?

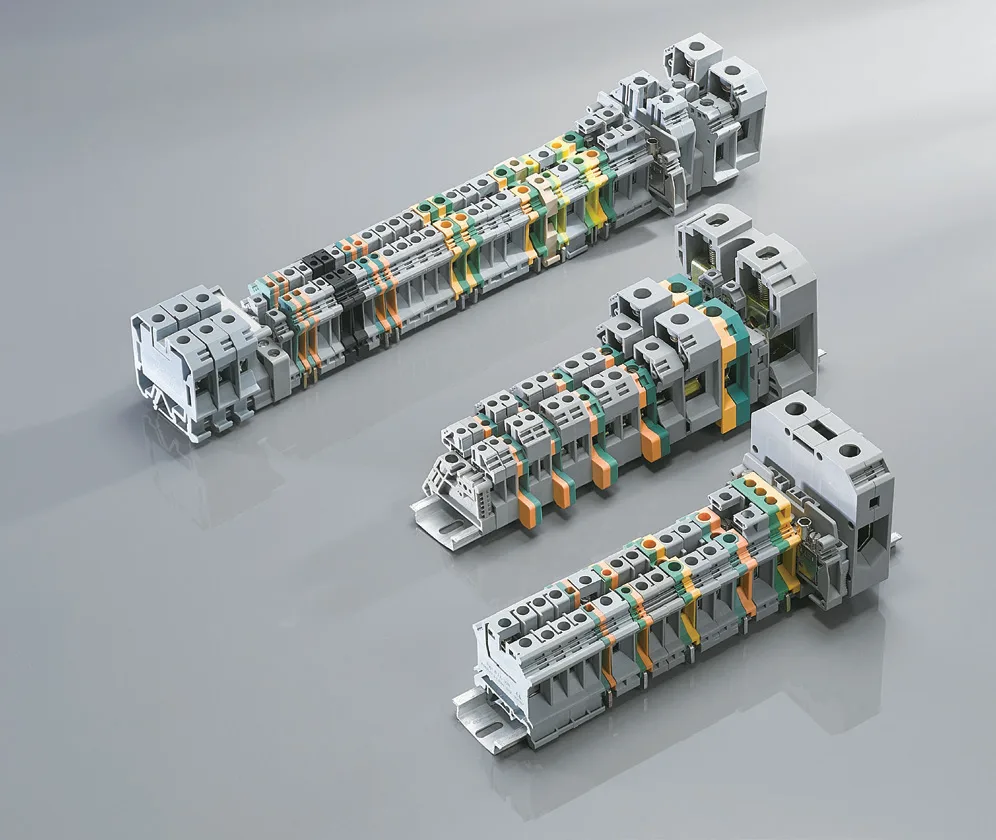

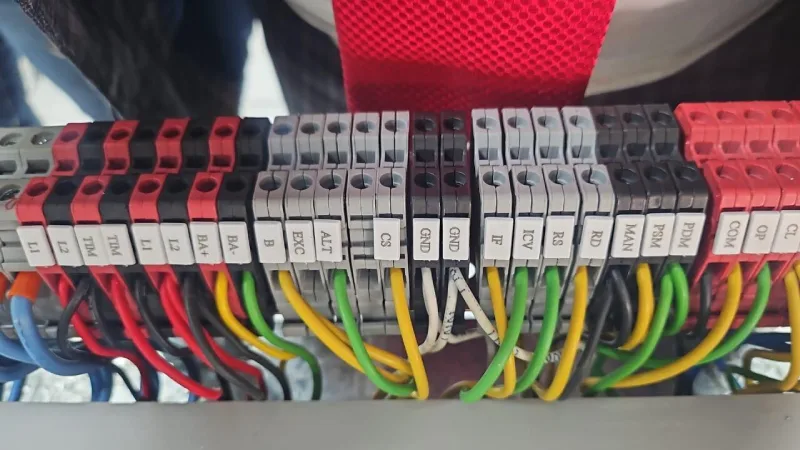

Ang mga bloke ng terminal ng DIN rail ay mga modular na electrical connector na naka-mount sa standardized na riles ng metal. Nagbibigay ang mga ito ng mga secure na punto ng koneksyon para sa mga wire sa mga electrical enclosure, na lumilikha ng organisado at naa-access na mga wiring system. Ang mga bahaging ito ay nagsisilbing mga junction point kung saan ang mga konduktor ay maaaring konektado, idiskonekta, at sistematikong ayusin.

Ang terminong "DIN" mismo ay nagmula sa Deutsche Institut für Normung (German Institute for Standardization), na nagpapahiwatig ng pagsunod sa isang hanay ng mga pamantayan na nagmula sa Germany noong 1920s at nakamit ang pandaigdigang pag-aampon mula 1950s pataas.

Mga Karaniwang Aplikasyon at Industriya

Ang mga bloke ng terminal na naka-mount sa mga riles ng DIN ay nakakahanap ng malawak na paggamit sa maraming industriya:

- Industrial automation at control system

- Building management system (BMS)

- Mga kagamitan sa HVAC

- Mga panel ng pamamahagi ng kuryente

- Mga aplikasyon ng riles

- Pagbuo ng makina

- Mga sistema ng kontrol sa proseso

- Mga instalasyon ng nababagong enerhiya

- Telekomunikasyon

- Sektor ng enerhiya

- Transportasyon

- Marine at offshore engineering

Mga Pangunahing Benepisyo ng DIN Rail Mounting Systems

Ang katanyagan ng DIN rail system ay nagmumula sa ilang mga pakinabang:

- Pinahusay na Kaligtasan: Binuo mula sa matatag na insulating na materyales, ang mga terminal block ay nagbibigay ng isang ligtas na interface sa pagitan ng mga bahagi at mga seksyon ng mga kable, na pumipigil sa hindi sinasadyang pakikipag-ugnay sa mga live na bahagi.

- Standardized mounting method sa mga manufacturer

- Madaling pag-install at pagtanggal nang walang mga tool

- Mahusay na paggamit ng espasyo ng panel

- Pinasimpleng pagpapalawak at muling pagsasaayos

- Pinahusay na organisasyon at accessibility

- Nabawasan ang oras ng pagpapanatili

- Pinahusay na pagiging maaasahan sa mga secure na koneksyon

Mahahalagang Salik na Dapat Isaalang-alang Kapag Pumipili ng Mga Terminal Block

Boltahe at Kasalukuyang Rating

Ang isa sa mga unang pagsasaalang-alang kapag pumipili ng mga bloke ng terminal ay ang kanilang kapasidad sa kuryente:

- Rating ng boltahe: Karaniwang mula 300V hanggang 1000V

- Kasalukuyang rating (Ampacity): Karaniwang nasa pagitan ng 5A at 150A depende sa laki at disenyo

- Mga kinakailangan sa proteksyon ng surge: Para sa mga application na may mga spike ng boltahe

- AC vs. DC application: Ang ilang mga bloke ay na-optimize para sa mga partikular na kasalukuyang uri

Palaging pumili ng mga terminal block na may mga rating na lumalampas sa mga kinakailangan ng iyong application nang hindi bababa sa 20% upang matiyak ang mga margin ng kaligtasan at account para sa mga potensyal na pagbabago sa system. Para sa kasalukuyang mga rating, isang malawak na tinatanggap na pinakamahusay na kasanayan ay ang paglalapat ng margin sa kaligtasan na 150% ng pinakamataas na inaasahang kasalukuyang ng system.

Ang rating ng boltahe ay pangunahing naiimpluwensyahan ng dielectric na lakas ng insulating material at ang mga pisikal na distansya ng paghihiwalay—partikular, ang pitch (center-to-center spacing sa pagitan ng mga terminal) at ang creepage at clearance distance na idinisenyo sa block.

Sukat ng Wire Compatibility

Ang mga bloke ng terminal ay tumanggap ng mga partikular na hanay ng wire gauge:

- Mga maliliit na bloke: 22-14 AWG

- Mga bloke ng katamtamang tungkulin: 20-10 AWG

- Mga bloke ng mabibigat na tungkulin: 12-4 AWG o mas malaki

Tiyakin na ang iyong napiling terminal block ay maaaring ligtas na humawak sa pinakamaliit at pinakamalaking konduktor sa iyong system. Isaalang-alang ang stranded versus solid wire compatibility at anumang mga espesyal na kinakailangan para sa ferruled o tinned conductors.

Ang hindi pagtutugma ng laki o uri ng wire sa mga tinukoy na kakayahan ng terminal block ay maaaring humantong sa mga maluwag na koneksyon, mataas na resistensya ng contact, pasulput-sulpot na operasyon, o kahit na kumpletong pag-pull-out ng wire sa ilalim ng kaunting stress.

Mga Uri ng Terminal Block (Screw, Spring, IDC, atbp.)

Ang paraan ng koneksyon ay makabuluhang nakakaapekto sa oras ng pag-install, pagiging maaasahan, at mga kinakailangan sa pagpapanatili:

- Uri ng tornilyo: Tradisyonal at malawakang ginagamit; maaasahan ngunit nangangailangan ng tamang metalikang kuwintas. Kasama sa mga bentahe ang mataas na puwersa ng pag-clamping at pagiging angkop para sa malalaking mga wire, ngunit maaari silang lumuwag sa panginginig ng boses kung hindi maayos na torque.

- Spring-clamp (Cage Clamp): Mas mabilis na pag-install, lumalaban sa vibration, walang maintenance. Ang mga spring clamp ay nag-aalok ng mahusay na paglaban sa panginginig ng boses at pagkabigla, dahil ang pare-parehong presyon na ibinibigay ng spring ay awtomatikong nag-a-adjust upang mabayaran ang maliit na wire deformation o mga pagbabago dahil sa mga pagbabago sa temperatura.

- Push-in (PIT): Mabilis na koneksyon nang walang mga tool, disenyong nakakatipid sa espasyo. Nagbibigay-daan ang mga push-in terminal para sa direktang pagpasok ng mga solid o ferruled wire na walang tool, na nag-aalok ng hanggang 40% na mas kaunting oras ng pag-install kumpara sa mga spring-loaded na terminal.

- Insulation displacement (IDC): Mabilis na pagwawakas nang hindi tinatanggal ang pagkakabukod. Tinatanggal ng teknolohiya ng IDC ang pangangailangan para sa wire stripping, na makabuluhang binabawasan ang kabuuang oras na ginugol sa paghahanda ng wire.

- Bolt-connection (Stud Terminals): Para sa mga high-current na application na nangangailangan ng pinakamataas na presyon ng contact. Lumilikha ang mga ito ng napakalakas at secure na koneksyon, na nag-aalok ng napakataas na pagtutol sa pagluwag na dulot ng vibration, shock, o mechanical stress.

- Mga Pluggable Terminal Blocks: Nagtatampok ng modular na disenyo na may magkahiwalay na plug at socket na mga bahagi, na nagpapahintulot sa buong wiring harnesses na mabilis na maikonekta at madiskonekta. Tamang-tama para sa mga application na nangangailangan ng madalas na pagpapanatili o pagpapalit ng bahagi.

Piliin ang teknolohiya ng koneksyon batay sa mga kinakailangan ng iyong application para sa vibration resistance, pagiging maaasahan ng koneksyon, at dalas ng pagpapanatili.

Mga Limitasyon sa Space at Mga Kinakailangan sa Pag-mount

Ang espasyo ng panel ay kadalasang nasa premium:

- Isaalang-alang ang terminal block pitch (lapad) – mula 3.5mm hanggang 20mm

- Suriin ang mga opsyon sa pagsasalansan para sa mga multi-level na bloke (single-level, dual-level, o triple-level)

- Account para sa accessory space (mga end bracket, separator, jumper)

- Magplano para sa pagpapalawak at mga pagbabago sa hinaharap

- Isaalang-alang ang oryentasyon at pagiging naa-access para sa mga kable

Ang mga miniature at micro terminal block ay partikular na inengineered upang magkasya sa mga masikip na enclosure o compact na makinarya kung saan ang mga terminal block ay hindi praktikal. Maaaring i-mount ang mga ito sa mas maliliit na profile ng DIN rail, tulad ng NS 15 rail, bilang karagdagan sa karaniwang NS 35 rail.

Mga Opsyon sa Espesyal na Terminal Block para sa Mga Tukoy na Aplikasyon

Ground at PE Terminal Blocks

Nagtatampok ang mga ground terminal block ng natatanging berde-dilaw na pangkulay at mga espesyal na disenyo para sa mga proteksiyon na koneksyon sa lupa:

- Kadalasan ay may kasamang mas malalaking metal na ibabaw para sa mas magandang kontak sa kuryente

- Maaaring mag-alok ng direktang koneksyon ng metal-to-rail para sa pinahusay na saligan

- Magagamit na may mga espesyal na kakayahan sa pagsubok para sa pag-verify ng kaligtasan

Ang mga bloke na ito ay partikular na idinisenyo upang magbigay ng isang secure at maaasahang de-koryenteng koneksyon mula sa isang circuit o piraso ng kagamitan patungo sa lupa (lupa), kadalasan sa pamamagitan ng mekanikal at elektrikal na pagkonekta sa papasok na ground wire sa mismong DIN rail.

Mga Fused Terminal Blocks

Ang mga ito ay nagsasama ng mga fuse holder nang direkta sa terminal block:

- Magbigay ng proteksyon sa circuit sa loob ng terminal system

- Magagamit para sa iba't ibang uri ng fuse (salamin, ceramic, automotive)

- Maaaring may kasamang mga blown fuse indicator (madalas na LED)

- Ang ilang mga disenyo ay nagpapahintulot sa pagpapalit ng fuse nang hindi dinidiskonekta ang mga wire

Ang disenyo ng mga fused terminal block ay kadalasang may kasamang hinged section, pivoting lever, o screw cap na nagbibigay-daan sa madaling pag-access sa fuse para sa inspeksyon o pagpapalit.

Mga Multi-Level na Terminal Block

Kapag limitado ang espasyo, pinapalaki ng mga multi-level na disenyo ang density ng koneksyon:

- Double-level: Dalawang independiyenteng circuit sa parehong footprint

- Triple-level: Tatlong antas ng koneksyon para sa maximum na density

- Maaaring pagsamahin ang iba't ibang uri ng circuit (power, signal, ground)

- Isaalang-alang ang pagiging naa-access para sa pagsubok at pagpapanatili

Habang ang mga multi-level na bloke ay nag-aalok ng malinaw na mga pakinabang sa mga tuntunin ng density ng koneksyon, maaari rin silang magpakilala ng mga praktikal na hamon tungkol sa pagiging naa-access para sa mga kable sa mas mababang antas at para sa kasunod na pagsubok o pag-troubleshoot.

Idiskonekta at Knife-Edge Terminal Blocks

Para sa mga circuit na nangangailangan ng mga kakayahan sa paghihiwalay:

- Ang mga bloke ng pagdiskonekta ng kutsilyo ay nagbibigay-daan sa pagkagambala ng circuit para sa pagsubok

- Ang mga terminal ng test point ay nagbibigay ng access sa pagsukat nang walang disconnection

- Ang mga kumbinasyon ng fuse-disconnect ay nag-aalok ng proteksyon at paghihiwalay

- Isaalang-alang ang mga plug-in bridge system para sa nakagrupong pagdiskonekta

Pinapadali ng mga terminal block na ito ang ligtas at maginhawang pagkagambala o pagsubok ng mga de-koryenteng circuit nang hindi kailangang pisikal na alisin o abalahin ang konektadong mga kable. Ang mga ito ay partikular na mahalaga sa mga sistema ng kontrol sa proseso, automation ng industriya, at mga aplikasyon ng utility kung saan kailangan ang regular na pagkakalibrate o pagsubok.

Mga bloke ng Terminal ng Sensor/Actuator

Dalubhasa para sa mahusay na mga kable ng mga sensor at actuator:

- Magbigay ng maraming natatanging potensyal na antas (power, ground, signal)

- Kadalasan ay nagtatampok ng mga makitid na profile para sa mga high-density na mga kable

- Maaaring may kasamang mga LED indicator upang ipakita ang status ng signal

- Gumamit ng mga color-coded na elemento para sa madaling pagtukoy ng mga potensyal

Ang isang pangunahing katangian ng disenyo ay ang kanilang kakayahang pagsama-samahin ang maraming mga punto ng koneksyon sa loob ng isang compact, solong housing, perpekto para sa 3-wire proximity sensor, photoelectric sensor, o maliliit na actuator.

Power Distribution Terminal Blocks

Idinisenyo upang pasimplehin at isentro ang pamamahagi ng kuryente:

- Nagtatampok ng mataas na kasalukuyang kapasidad ng pagdadala

- Maaaring may dalawahang terminal ng pag-input para sa mga redundant na pag-setup ng power

- Magbigay ng maramihang mga output point para sa pamamahagi ng kapangyarihan

- I-minimize ang kalat ng mga kable at bawasan ang mga potensyal na failure point

Thermocouple Terminal Blocks

Partikular na idinisenyo para sa mga circuit ng pagsukat ng temperatura:

- Panloob na conductive parts na gawa sa thermocouple-grade alloys

- Pigilan ang pagpapakilala ng hindi gustong thermal EMF sa mga termination point

- Maaaring may kasamang built-in na mga miniature na thermocouple connector

- Color-coded at minarkahan ng thermocouple type (K, J, T, atbp.)

Mga Pagsasaalang-alang sa Kapaligiran para sa Pagpili ng Terminal Block

Mga Rating ng Temperatura at Pag-aalis ng init

Ang mga bloke ng terminal ay dapat makatiis sa operating environment:

- Karaniwang na-rate ang mga karaniwang bloke para sa -30°C hanggang +85°C

- Available ang mga variant na may mataas na temperatura hanggang sa +125°C

- Isaalang-alang ang pagbuo ng init mula sa kasalukuyang daloy

- Account para sa pagtaas ng temperatura ng enclosure at bentilasyon

- Suriin ang mga plastik na materyales para sa katatagan ng temperatura

Ang mga materyales sa pabahay (karaniwang polyamide tulad ng PA66) ay may mga partikular na limitasyon sa temperatura. Kung ang aktwal na temperatura ng pagpapatakbo ay lumampas sa tinukoy na itaas na limitasyon ng materyal, ang plastic housing ay maaaring lumambot, mag-deform, o mag-degrade, na makompromiso ang mga katangian ng pagkakabukod at mekanikal na lakas.

Paglaban sa Panginginig ng boses

Sa mga kapaligirang may paggalaw o panginginig ng boses:

- Ang mga spring-clamp terminal ay nag-aalok ng mahusay na vibration resistance

- Isaalang-alang ang mga bloke na may mga tampok sa pag-lock o mga disenyong anti-vibration

- Suriin ang makasaysayang pagganap sa mga katulad na aplikasyon

- Maghanap ng mga third-party na testing certification para sa vibration

Ang pagpili ng teknolohiya ng koneksyon ay may malaking epekto sa kakayahan ng terminal block na makatiis sa vibration at shock. Ang mga teknolohiyang nakabatay sa tagsibol (spring clamp, push-in) ay karaniwang nag-aalok ng mahusay na panlaban sa vibration, habang ang teknolohiya ng screw clamp ay maaaring madaling lumuwag maliban kung partikular na idinisenyo na may mga anti-vibration feature.

Proteksyon Laban sa Halumigmig at Alikabok (Mga Rating ng IP)

Para sa malupit na kapaligiran:

- Ang mga karaniwang terminal block ay nag-aalok ng pangunahing proteksyon ng IP20 (finger-safe)

- Available ang mga espesyal na variant para sa IP67 (dust-tight at waterproof)

- Isaalang-alang ang mga conformal coating o encapsulated na disenyo para sa matinding kundisyon

- Suriin ang paglaban ng materyal sa mga partikular na kemikal o contaminants

Bagama't ang mga indibidwal na bloke ng terminal ng DIN rail ay hindi karaniwang nagtatalaga ng IP rating sa kanilang sarili (dahil ang mga ito ay mga sangkap na nilayon para sa pag-install sa loob ng isang proteksiyon na enclosure), ang pangkalahatang IP rating ng enclosure ay kritikal para sa kanilang proteksyon sa mahalumigmig o basa na mga kapaligiran.

Mga Accessory ng Terminal Block at Mga Komplementaryong Bahagi

Mga End Plate at Bracket

Mahalaga para sa pag-secure ng mga terminal block assemblies:

- Pinipigilan ng mga end bracket ang paggalaw ng block sa riles

- Ang mga partition plate ay naghihiwalay ng iba't ibang antas ng boltahe

- Pinoprotektahan ng mga takip sa dulo ang mga nakalantad na bahagi ng conductive

- Isaalang-alang ang color-coded na mga opsyon para sa visual na organisasyon

Mga Sistema ng Pagmamarka at Mga Label

Ang malinaw na pagkakakilanlan ay mahalaga para sa ligtas na pagpapanatili:

- Direct-print marker para sa permanenteng pagkakakilanlan

- Snap-in marker carrier para sa mapapalitang label

- I-print ang minsang mga sistema para sa pare-parehong dokumentasyon

- Isaalang-alang ang mga sistema ng pagmamarka na binuo ng software para sa mga kumplikadong pag-install

Mga Jumper at Cross-Connection

Pasimplehin ang mga karaniwang koneksyon sa pagitan ng mga terminal:

- Fixed-pitch jumper para sa mga katabing bloke

- Variable-pitch jumper para sa mga di-katabing koneksyon

- Multi-pole jumper combs para sa pagkonekta ng maraming circuit

- Mga insulated jumper para sa iba't ibang antas ng boltahe

Mga Accessory sa Pagsubok

Pangasiwaan ang pag-verify at pag-troubleshoot ng system:

- Mga test plug para sa pagsukat nang hindi dinidiskonekta

- Subukan ang mga adaptor para sa pagkonekta ng mga instrumento

- Mga module na may built-in na mga punto ng pagsubok

- Isaalang-alang ang mga kinakailangan sa kaligtasan para sa live na pagsubok

Mga Pamantayan at Pagkakatugma ng DIN Rail

Mga Uri ng DIN Riles

Mayroong ilang mga uri ng DIN riles, na ang TS35 ang pinakakaraniwan:

- Top Hat Rail (TS35/IEC/EN 60715 – 35×7.5 at 35×15): Ang pinakakaraniwang uri na ginagamit sa buong mundo. Nagtatampok ng simetriko na profile na kahawig ng isang pang-itaas na sumbrero at 35mm ang lapad. Available sa karaniwang depth (7.5mm) at deep hat (15mm) na bersyon.

- G-Type Rail (TS32/EN 50035): May asymmetrical na profile at karaniwang 32mm ang lapad. Ginagamit para sa pag-mount ng mas malaki at mas mabibigat na mga de-koryenteng bahagi.

- C-Type Rails (EN 50024): Nagtatampok ng hugis-C na cross-section at may iba't ibang taas (C20, C30, C40, C50). Bumaba ang kanilang paggamit sa TS35 rails na nagiging mas nangingibabaw.

- Miniature Rails (TS15/EN 50045): Isang mas maliit na bersyon ng TS35 rail na may lapad na 15mm, perpekto para sa mga application na limitado sa espasyo.

Tiyakin na ang iyong mga terminal block ay tugma sa iyong partikular na uri ng DIN rail upang maiwasan ang mga problema sa pag-install.

Materyal at Tapos ng DIN Rails

Ang DIN rails ay karaniwang ginagawa mula sa mga materyales na nag-aalok ng mahusay na mekanikal na lakas at paglaban sa kaagnasan:

- Bakal (Cold-Rolled Carbon Steel): Karamihan sa karaniwan, ay nagbibigay ng mahusay na lakas at tigas.

- Aluminum: Mas magaan kaysa bakal na may mahusay na paglaban sa kaagnasan.

- Hindi kinakalawang na asero: Para sa malupit, kinakaing unti-unti na mga kapaligiran.

- Mga Pang-ibabaw na Tapos: Ang mga bakal na riles ay karaniwang may proteksiyon na zinc plating o chromate passivation.

Step-by-Step na Gabay sa Pagpili ng Tamang Terminal Block

Pagtukoy sa Mga Kinakailangang Elektrisidad

Magsimula sa iyong mga pangunahing pangangailangan sa kuryente:

- Ilista ang pinakamataas na boltahe at kasalukuyang kinakailangan

- Tukuyin ang mga uri at laki ng wire na wawakasan

- Tukuyin ang kinakailangang espasyo para sa paghihiwalay ng boltahe

- Isaalang-alang ang mga espesyal na kinakailangan (mataas na temperatura, panginginig ng boses)

- Suriin ang mga pangangailangan sa proteksyon ng circuit (fused o non-fused)

Pagsukat ng Available na Space

I-optimize ang layout ng iyong panel:

- Sukatin ang magagamit na haba ng DIN rail

- Kalkulahin ang kinakailangang dami ng terminal at espasyo

- Isaalang-alang ang mga accessory at ang kanilang mga kinakailangan sa espasyo

- Payagan ang pagpapalawak sa hinaharap (karaniwang 20%)

- I-verify ang cabinet depth clearance para sa wire routing

Pagsusuri ng Mga Paraan ng Koneksyon

Piliin ang tamang teknolohiya ng pagwawakas:

- Suriin ang antas ng kasanayan ng installer at mga magagamit na tool

- Isaalang-alang ang dalas ng pagpapanatili at pagiging naa-access

- Suriin ang mga alalahanin sa panginginig ng boses at paggalaw

- Timbangin ang oras ng pag-install kumpara sa pagiging maaasahan ng koneksyon

- Salik sa mga kondisyon sa kapaligiran na nakakaapekto sa mga koneksyon

Isinasaalang-alang ang Mga Pangangailangan sa Pagpapalawak sa Hinaharap

Magplano para sa mga kinakailangan bukas:

- Magreserba ng espasyo para sa karagdagang mga bloke ng terminal

- I-standardize ang mga uri ng block para sa pamamahala ng imbentaryo

- Idokumento nang lubusan para sa mga pagbabago sa hinaharap

- Isaalang-alang ang mga modular system na tumanggap ng mga pagbabago

- Magpatupad ng ekstrang kapasidad para sa mga hindi inaasahang pangangailangan

Mga Pamantayan at Sertipikasyon

Ang mga bloke ng terminal ay dapat sumunod sa iba't ibang internasyonal at panrehiyong pamantayan:

- Mga Pamantayan ng IEC: IEC 60947-7-1 (karaniwang terminal blocks), IEC 60947-7-2 (ground terminal blocks), IEC 60947-7-3 (fused terminal blocks)

- UL Standards: UL 1059 (terminal blocks), UL 486A-486B (wire connectors)

- Mga Pamantayan ng CSA: Serye ng CSA C22.2 para sa mga merkado sa Canada

Mga pangunahing sertipikasyon na hahanapin:

- CE Marking: Para sa pagsunod sa European Economic Area

- UL Recognized Component Mark (RU mark): Component na sinusuri ng UL para magamit sa mas malalaking system

- CSA Certified Mark: Nakakatugon sa mga pamantayan sa kaligtasan ng Canada

- Mga Marka ng ATEX at IECEx: Para sa mga kagamitan sa mga kapaligirang maaaring sumasabog

Mga Nangungunang Manufacturer at Pagsasaalang-alang sa Kalidad

Nangungunang Mga Brand ng Terminal Block

Maraming mga tagagawa ang nagtatag ng mga reputasyon para sa kalidad:

- Pakikipag-ugnayan sa Phoenix

- VIOX ELECTRIC

- Wago

- ABB

- Schneider Electric

- Rockwell Automation

- TE Connectivity

Mga Sertipikasyon ng Kalidad na Hahanapin

I-verify ang pagsunod sa mga nauugnay na pamantayan:

- Mga pag-apruba ng UL/CSA para sa mga instalasyon sa Hilagang Amerika

- Mga sertipikasyon ng IEC/EN para sa mga internasyonal na aplikasyon

- Mga certification na partikular sa industriya (marine, railway, explosion-proof)

- Mga sertipikasyon ng sistema ng pamamahala ng kalidad (ISO 9001)

- Pagsunod sa mga pamantayan sa kapaligiran (RoHS, REACH)

Mga Pagsasaalang-alang sa Gastos kumpara sa Kalidad

Balansehin ang mga hadlang sa badyet sa mga kinakailangan sa pagganap:

- Isaalang-alang ang kabuuang halaga ng pagmamay-ari, hindi lamang ang presyo ng pagbili

- Suriin ang pagtitipid sa paggawa mula sa mas madaling pag-install

- Salik sa mga gastos sa downtime mula sa mga potensyal na pagkabigo

- Suriin ang pagkakaroon ng mga ekstrang bahagi at pangmatagalang suporta

- Isaalang-alang ang mga benepisyo sa standardisasyon sa mga proyekto

Mga Karaniwang Pagkakamali na Dapat Iwasan Kapag Pumipili ng Mga Terminal Block

Tinatanaw ang Voltage Drop

Ang mahabang pagtakbo ng maliliit na konduktor ay maaaring lumikha ng makabuluhang pagbaba ng boltahe:

- Kalkulahin ang pagbaba ng boltahe para sa mga kritikal na circuit

- Isaalang-alang ang pagpapalaki ng mga terminal block para sa pamamahagi ng kuryente

- Gumamit ng mga tansong jumper sa halip na nickel para sa mas mahusay na conductivity

- Magpatupad ng hiwalay na power at control terminal group

- Subaybayan ang temperatura bilang tagapagpahiwatig ng mahihirap na koneksyon

Hindi pinapansin ang Heat Generation

Ang mga isyu sa thermal ay maaaring magdulot ng maagang pagkabigo:

- Payagan ang sapat na espasyo sa pagitan ng mga high-current na bloke

- Isaalang-alang ang pagpapababa ng mga salik para sa mataas na temperatura

- Gumamit ng mas malalaking bloke para sa mga high-current na application kahit na pinahihintulutan ng laki ng wire ang mas maliit

- Magpatupad ng wastong bentilasyon sa paligid ng mga grupo ng terminal

- Isaalang-alang ang thermal imaging sa panahon ng pag-commissioning

Hindi Tamang Spacing at Arrangement

Pinipigilan ng lohikal na organisasyon ang mga error:

- Pangkatin ang mga terminal ayon sa function at antas ng boltahe

- Gumamit ng mga separator plate sa pagitan ng iba't ibang sistema ng boltahe

- Panatilihin ang pinakamababang clearance para sa ligtas na operasyon

- Iposisyon ang mga high-current na bloke para mabawasan ang thermal impact sa mga sensitibong circuit

- Magbigay ng sapat na espasyo para sa wire bending at routing

Mga Pagsasaalang-alang sa Pagpapanatili at Pagpapalit

Mga Palatandaan ng Terminal Block Failure

Panoorin ang mga tagapagpahiwatig ng mga potensyal na isyu:

- Pagkawala ng kulay o pagkatunaw ng mga bahagi ng plastik

- Maluwag na koneksyon na nangangailangan ng madalas na muling paghigpit

- Nakikitang arcing o nasusunog na marka

- Hindi maipaliwanag na pagbabagu-bago ng boltahe

- Labis na pag-init sa panahon ng normal na operasyon

Mga Pamamaraan sa Inspeksyon

Magpatupad ng mga regular na pagsusuri:

- I-verify ang wastong torque sa mga koneksyon ng tornilyo

- Suriin kung may mga palatandaan ng sobrang init o pagkawalan ng kulay

- Kumpirmahin ang secure na pag-mount sa DIN rail

- Suriin ang mga entry point ng wire para sa pinsala

- Subukan ang mga kritikal na koneksyon para sa pagbaba ng boltahe

Mga Oportunidad sa Pag-upgrade

Isaalang-alang ang mga pagpapabuti sa panahon ng pagpapanatili:

- Palitan ang mga aging screw terminal ng mga alternatibong walang maintenance

- Ipatupad ang color-coding para sa pinabuting kaligtasan

- Magdagdag ng mga punto ng pagsubok para sa mas madaling pag-troubleshoot

- Mag-upgrade sa mga materyal na mas mataas ang temperatura kung naaangkop

- Magpatupad ng mas mahusay na mga sistema ng pag-label

Konklusyon

Ang pagpili ng tamang DIN rail mounted terminal blocks ay nagsasangkot ng maingat na pagsasaalang-alang sa mga kinakailangan sa kuryente, mga kondisyon sa kapaligiran, mga hadlang sa espasyo, at mga pangmatagalang pangangailangan sa pagpapanatili. Sa pamamagitan ng pamamaraang pagsusuri sa bawat salik na nakabalangkas sa gabay na ito, maaari kang magdisenyo ng mahusay, maaasahang mga electrical system na mahusay na gumaganap sa kanilang buong lifecycle. Tandaan na ang pamumuhunan ng oras sa tamang pagpili ng terminal block ay nagbabayad ng mga dibidendo sa pamamagitan ng mas mabilis na pag-install, pinababang maintenance, at pinahusay na pagiging maaasahan ng system.

Palaging kumunsulta sa mga detalye ng tagagawa para sa iyong partikular na aplikasyon, at isaalang-alang ang pakikipagtulungan sa mga supplier na maaaring magbigay ng teknikal na suporta para sa mga kumplikadong pag-install. Gamit ang tamang diskarte sa kung paano pumili ng DIN rail mounted terminal blocks, gagawa ka ng mga electrical system na hindi lang gumagana ngunit na-optimize din para sa performance, kaligtasan, at maintainability.

Mga kaugnay na

Paano Pumili ng Tamang Terminal Block para sa Iyong Electrical Project

Paano Piliin ang Tamang UKK Terminal Block: Isang Komprehensibong Gabay