It makes no sense.

You’re holding a standard industrial contactor, a gray plastic block that’s the workhorse of every control panel. But it’s a walking contradiction.

On the side, next to the small terminals labeled “A1” and “A2,” it clearly says 24V AC.

On the front, next to the heavy-duty terminals labeled “L1” and “T1,” it’s rated for 600V.

Is it a typo? Is it some kind of tiny transformer? How can one device be ambele 24V and 600V at the same time?

This isn’t just a textbook question. It’s a real-world puzzle that recently stumped a user on Reddit, and it happens to be the single most important “Aha!” moment in electrical automation.

You’ve just stumbled on the fundamental secret of automation. Let’s solve it.

The “Brain vs. Muscle” Principle: How a Contactor Really Works

Here’s the solution: A contactor isn’t one device. It’s two completely separate and electrically isolated systems living in the same house.

The community on Reddit nailed the analogy: you have to separate the “Brain” from the “Muscle.”

1. The “Brain” (The Control Circuit)

- This is your 24V AC part.

- Terminale: A1 and A2.

- What it is: A simple electromagnet, called a coil.

Think of this as the “trigger.” Its numai job is to receive a low-energy, safe signal (in this case, 24V AC). When it gets that signal, the coil energizes and becomes a magnet. That’s it. It does no heavy lifting. It’s the “boss” that sits in an office and gives an order.

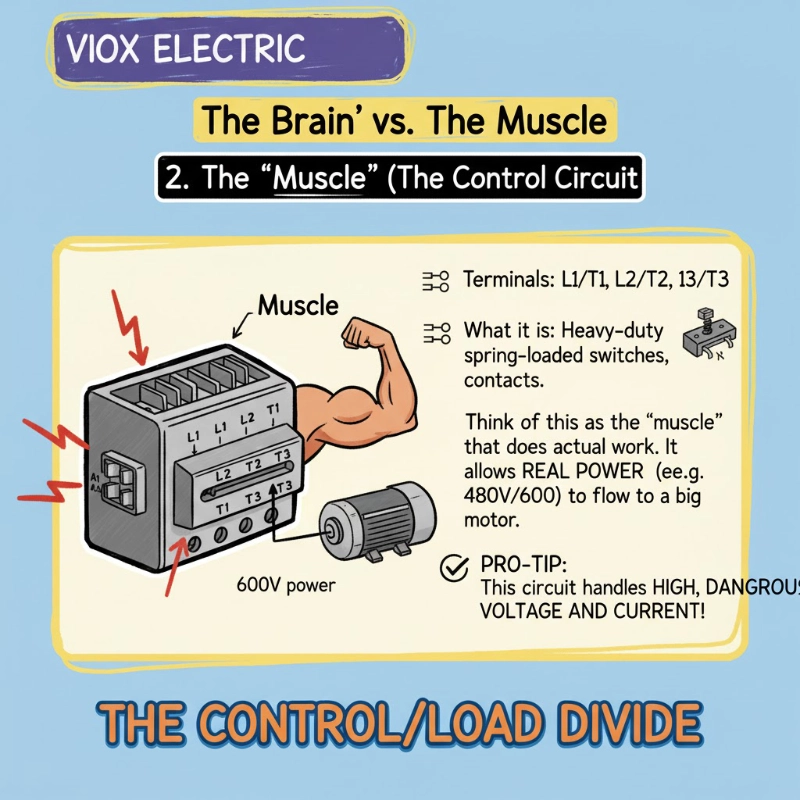

2. The “Muscle” (The Load Circuit)

- This is your 600V part.

- Terminale: L1/T1, L2/T2, L3/T3.

- What it is: A set of heavy-duty, spring-loaded switches, called contacts.

This is the “muscle” that does the actual work. These contacts are just a thick, conductive bridge. They are completely “dumb” and have no power of their own. When the “Brain” (the 24V coil) energizes, its magnetic pull yanks this switch closed with a satisfying thunk.

When the switch is closed, it allows the real power—like 480V or 600V—to flow through it to a big motor or heater.

This fundamental separation is what engineers call The Control/Load Divide.

PRO-TIP: That 600V rating is a limit, not a supply. It doesn’t mean the contactor provides 600V. It means the “Muscle” (the contacts) is built with enough “beef” and insulation to safely handle up to 600V flowing through it without melting or arcing over.

The “HVAC Translator”: Why Your Thermostat Doesn’t Melt

If this “Brain vs. Muscle” thing still feels a bit abstract, I guarantee you have this exact system in your home. It’s the hero of your air conditioning system.

An HVAC expert in that same Reddit thread called it “The HVAC Translator.”

Think about the journey of a “cool” signal:

- You (The User): You feel warm. You tap “Cool” on your sleek, smart thermostat.

- The Thermostat (“Weak Brain”): Your thermostat is a delicate piece of electronics. It runs on safe, low-voltage 24V AC. It’s a “weak” brain.

- The Signal (24V): The thermostat sends that tiny 24V signal through a thin wire out to your outdoor compressor unit.

- The Contactor (“The Translator”): Inside that big, noisy outdoor unit is a contactor. Its 24V “Brain” (the coil) receives the signal.

- CLICK.

- The “Muscle” (240V): The coil’s magnetic pull slams the “Muscle” (the contacts) shut. This instantly completes a totally separate circuit, unleashing the 240V, 30-amp “beast” of a circuit from your home’s breaker panel.

- The Load: That 240V power roars to life, starting the massive compressor and fan.

Without that contactor acting as the “translator,” your delicate 24V smart thermostat would try to switch 240V directly. The result? It would instantly vaporize in a puff of smoke and melted plastic.

The Control/Load Divide is the physical abstraction layer that allows our safe, digital world (a 24V thermostat) to control the dangerous, powerful analog world (a 240V motor).

So… Is a Contactor Just a Big Relay? (Yes, But No)

This is the next logical question.

“Okay,” you’re thinking, “I get it. A 24V ‘brain’ controls a 600V ‘muscle.’ But that’s exactly what a releu does. A 5V signal from my Arduino can control a 120V relay for a lamp. So a contactor is just a big relay.”

This is the most common misconception in the field. And it’s wrong.

While they share the same principle (The Control/Load Divide), their purpose is drastically different. Saying a contactor is a big relay is like saying a pickup truck is just a big sedan. They both have engines and wheels, but one is designed to haul a heavy load, and the other is not.

The “size” or “power” difference is a symptom, not the root cause.

The REAL difference is Arc Suppression.

When you switch a simple lightbulb (a resistive load), the electricity stops cleanly. But when you try to turn off a big motor (an inductive load), the magnetic field in that motor collapses and fights you. It does not want to stop. It will try to keep the electricity flowing by creating a high-voltage, high-temperature spike—a literal bolt of lightning called an arc electric.

- O Releu is a sedan. It’s designed for simple, clean loads. If it tries to switch a big motor, that arc will form between its small contacts, quickly eroding, melting, and welding them together. Game over.

- O Contactor is a pickup truck. It is purpose-built to kill that arc. It’s designed to survive the violent, fiery hell of switching a motor.

PRO-TIP: A relay comutatoare a circuit. A contactor survives switching a motor. It does this with heavy-duty contact materials, a wider contact gap, and often arc chutes—special vents and magnetic coils designed to stretch, cool, and extinguish that arc in milliseconds.

This is why we have Categorii de utilizare (like AC-3 for motors), which is the spec-sheet language that tells you what kind of fire a contactor is designed to put out.

Why 24V AC? And Why Do I See 24V DC and 120V Coils?

This brings us back to the original photo. Why a 24V AC coil?

The voltage of the “Brain” has nothing to do with the “Muscle’s” load. You choose the coil voltage based on your control system’s language.

- 24V AC (The “HVAC Special”): This is the “good enough” legacy standard for residential and commercial HVAC, just like in the Reddit discussion. Why? Because it’s dirt cheap and rugged. In the 1950s, all you needed was a simple step-down transformer to get 24V AC from 120V AC. No rectifiers, no smoothing capacitors. It just worked.

- 24V DC (The “PLC Standard”): This is the king of modern industrial automation. Every PLC (Programmable Logic Controller), sensor, and robot controller runs on 24V DC. It’s the clean, digital-friendly standard for high-speed logic.

- 120V AC / 240V AC (The “Old School”): You’ll also see contactors with high-voltage coils. This is an older method where you just use the available line voltage to control the contactor. It’s simple (no transformer needed), but it’s less safe for technicians to troubleshoot a “hot” 120V control circuit.

The contactor in that photo, with its 24V AC coil, was almost certainly destined for an HVAC unit, not a modern factory PLC cabinet.

From “Contradiction” to “Cornerstone”

That “contradiction” in a gray plastic box isn’t a contradiction at all. It’s the cornerstone of all modern electrical control.

It’s the Control/Load Divide in action.

It’s the “Brain” telling the “Muscle” what to do.

It’s the “Translator” that allows a tiny, safe signal to command a powerful, dangerous load.

Understanding this difference isn’t just about passing an apprentice exam. It’s the moment you graduate from simply changing parts to truly understanding the systems you design and maintain.

That “Aha!” moment is what engineering is all about. But an “Aha!” moment won’t keep your line running when the “Muscle” isn’t tough enough for the job.

If your “Brain” (your PLC or controller) is giving the orders but your “Muscle” (your contactors) can’t handle the load, it’s time to upgrade. VIOX contactors are built to survive the real-world abuse of switching heavy inductive loads, day in and day out.

Don’t let a weak link in the chain cost you thousands in downtime. Check out our lineup of VIOX contactors—the “Muscle” your “Brain” can count on.