The manufacturing process of electrical Ready Boards involves a series of carefully planned steps, from initial design to final testing, ensuring the production of safe and efficient pre-wired electrical systems for rapid deployment in developing areas.

Σχεδιασμός και προγραμματισμός

The foundation of the Ready Board manufacturing process lies in meticulous design and planning. Engineers create detailed schematics and drawings that specify the precise layout for all components, including sockets, switches, and lamp holders. This crucial initial step ensures that all elements fit seamlessly within the compact unit while adhering to stringent safety standards. The design phase also takes into account environmental specifications, such as the ability to withstand temperatures ranging from 10°C to 40°C, relative humidity between 60% and 96%, and operation at altitudes up to 1600m above sea level. By carefully considering these factors, manufacturers can produce Ready Boards that are not only efficient but also durable and suitable for diverse deployment scenarios.

Προμήθεια υλικών

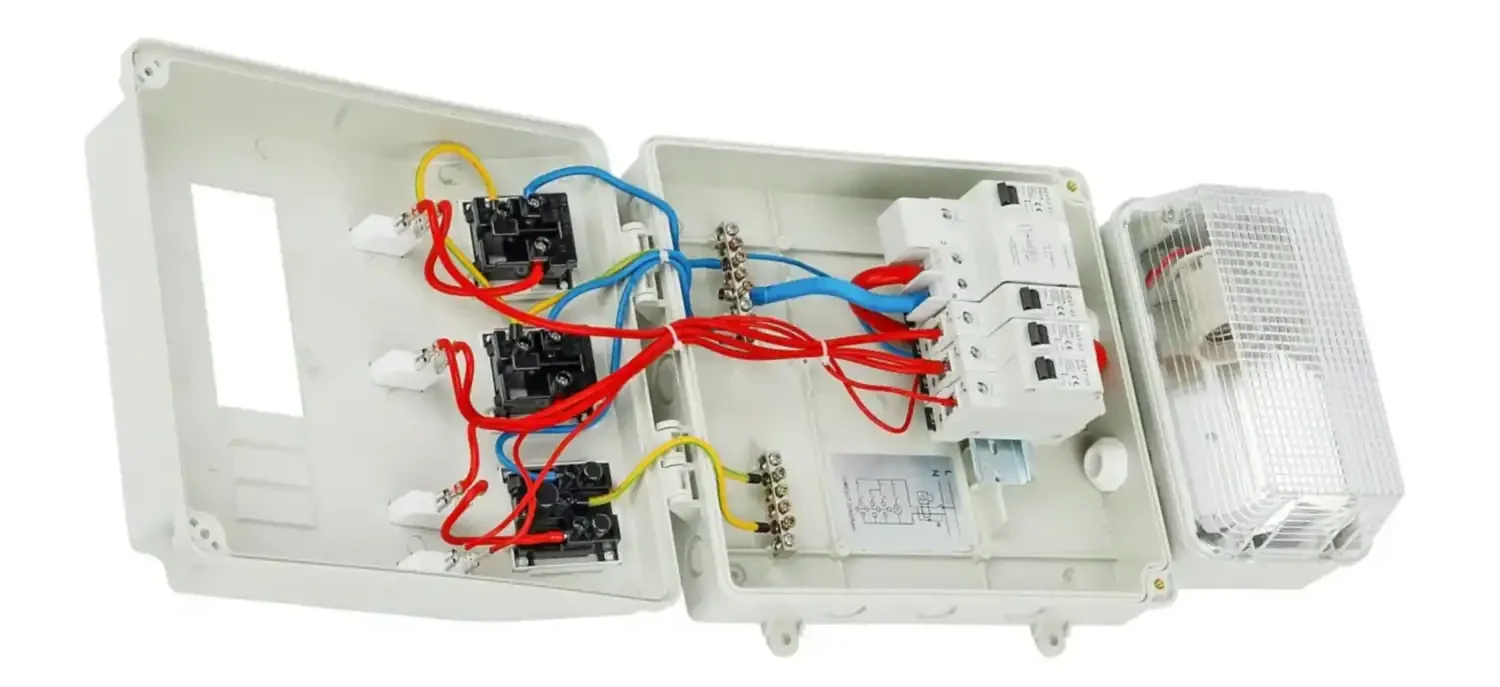

The Ready Board manufacturing process begins with sourcing high-quality materials and essential components from reliable suppliers. Key elements include:

- Main Switch

- Διακόπτης κυκλώματος

- Earth Leakage System

- Large Lamp

- Three Switch Sockets

- Metering Unit

Careful selection of these components ensures the durability and safety of the final product. The procurement phase also involves preparing materials for assembly, with a focus on maintaining a manufacturing environment free from corrosive gases, dust, salt fog, and excessive vibration to guarantee optimal product quality.

Assembly and Quality Control

The assembly process begins with component mounting, where sockets, switches, and lamp holders are securely attached to base units. Skilled technicians then meticulously install internal wiring according to design specifications, with each connection thoroughly tested for continuity and safety. A comprehensive quality control check follows, verifying component functionality, wiring connections, safety features, and overall craftsmanship. This rigorous approach ensures that each Ready Board meets the highest standards of performance and reliability before moving on to final testing and packaging stages.

Testing and Packaging

Following assembly and quality control, each Ready Board undergoes rigorous testing to verify component functionality and adherence to technical specifications. This critical phase ensures the unit’s reliability and safety for end-users. Once approved, the completed Ready Boards are carefully packaged to prevent damage during transportation, ensuring they arrive in optimal condition for rapid deployment in residential or community settings. This final step is crucial for maintaining the integrity of the product and facilitating efficient installation in developing areas where quick electrification is essential.