What is Foot Pedal Switch

Foot pedal switches, often known as foot switches or foot pedals, are devices controlled by foot pressure to control electrical circuits or mechanical systems. Their hands-free operation feature enables users to operate equipment without using their hands, leading to increased productivity and convenience across a range of applications.

II. Types of Foot Pedal Switches

A. Single-pedal switches

The most basic type of foot pedals are single-pedal switches, which have a single pedal that regulates a single function. They are frequently utilized in devices like sewing machines and medical equipment that need a simple on/off control. Depending on the needs of the operation, these switches can be set up as latching or momentary.

B. Multi-pedal switches

Multi-pedal switches consist of two or more pedals, allowing for multiple functions to be controlled simultaneously or independently

C. Momentary vs. latching foot pedal switches

Foot pedal switches can be categorized based on their action type:

- Momentary Foot Pedal Switches: These need constant pressure to stay engaged. The switch goes back to its initial setting when the foot is raised. This kind is often used in devices such as sewing machines and medical equipment that require momentary activation.

- Latching Foot Pedal Switches:Like a light switch, these stay on once pressed and only go off when you press them again. When continued functioning without pressure is necessary, this capability comes in handy.

D. Electronic vs. mechanical foot pedal switches

Foot pedal switches can also be classified based on their internal mechanisms:

- Mechanical Foot Pedal Switches: These are renowned for their endurance and tactile feedback and make use of physical linkages. They are perfect for uses where a sturdy and dependable performance is needed, like in musical instruments or large machinery.

- Electronic Foot Pedal Switches: These leverage electrical connections for actuation and can offer more sensitive and diversified functionality than mechanical switches. They are appropriate for complex applications since they may have features like various circuit options and programmable settings.

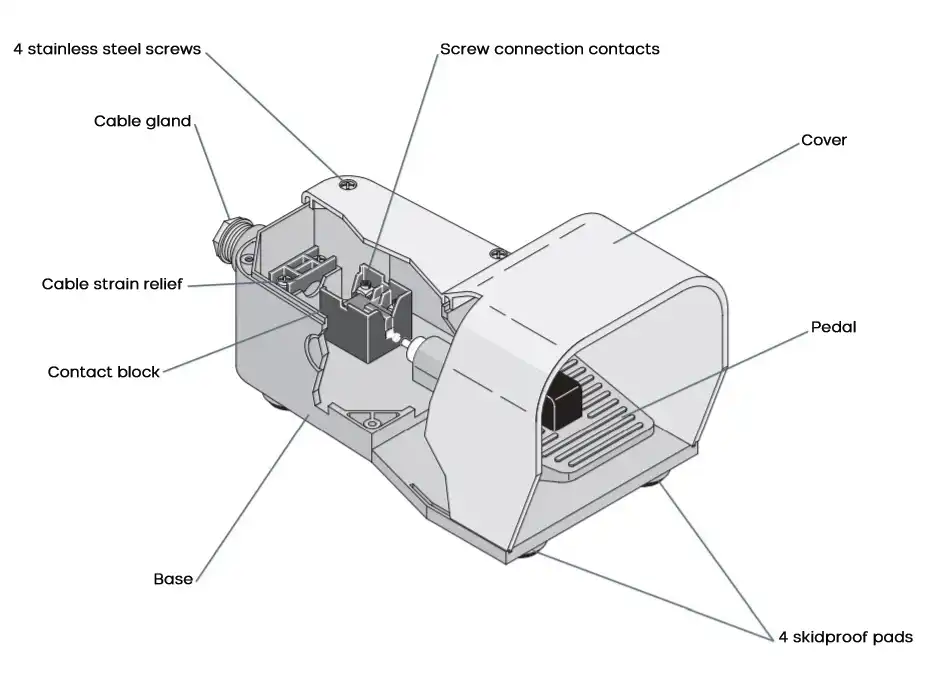

The internal structure of the Foot Switch

- Cover: Provides protection and streamlined design

- Pedal: Ergonomically designed for comfortable operation

- 4 Stainless Steel Screws: Ensure secure assembly and durability

- Screw Connection Contacts: Enable reliable electrical connections

- Cable Gland: Offers strain relief and sealing for cable entry

- Cable Strain Relief: Prevents damage to internal wiring

- Contact Block: Houses the switching mechanism

- Base: Provides a stable foundation for the entire unit

- 4 Skidproof Pads: Ensure stability during use

Functionality and Features

Foot pedal switches are made with a variety of features and functionalities that improve their usability in a range of scenarios. Here’s a thorough examination of some of the main features and functionalities:

A. On/Off switching

Foot pedal switches are primarily used to offer basic on/off control for machinery and equipment. This feature makes it possible for users to operate devices without using their hands, which is especially helpful in scenarios where it’s necessary to operate hands-free, including during live performances or in medical settings.

B. Variable speed control

Variable speed control is a feature that many foot pedal switches include, allowing users to dynamically change the linked device’s speed. This function is very helpful for sewing machines and other similar applications where fine speed adjustments can improve the output quality. Effects pedals can also be used by musicians with variable speed control, enabling subtle performance modifications.

C. Pressure sensitivity

Pressure sensitivity is a feature of some sophisticated foot pedal switches, which allows them to recognize different pressure levels applied to the pedal. With this feature, users can adjust factors like speed, intensity, or volume in response to how hard they push the pedal. This function is especially well-liked in applications related to music, where minute changes can have a big effect on performance.

D. Waterproof and dustproof options

Many foot pedal switches include dustproof and waterproof ratings (e.g., IP ratings) for use in harsh situations. Because of these capabilities, the switches can be used outdoors, in industrial settings, or in medical settings where cleanliness is essential. They also guarantee that the switches will continue to function even in difficult circumstances. Selecting a switch that has the right level of environmental protection will keep it functional and increase its longevity.

E. Safety features (e.g., anti-trip mechanisms)

Safety is the top priority when choosing foot pedal switches, especially for industrial or medical applications. Essential elements are incorporated into contemporary designs to improve operational security. These include sturdy design to endure heavy use and unintentional hits, emergency stop functions for instant operation ceasing in crucial situations, and anti-trip systems to avoid inadvertent activation. In difficult conditions, these safety precautions minimize dangers and guarantee dependable performance.

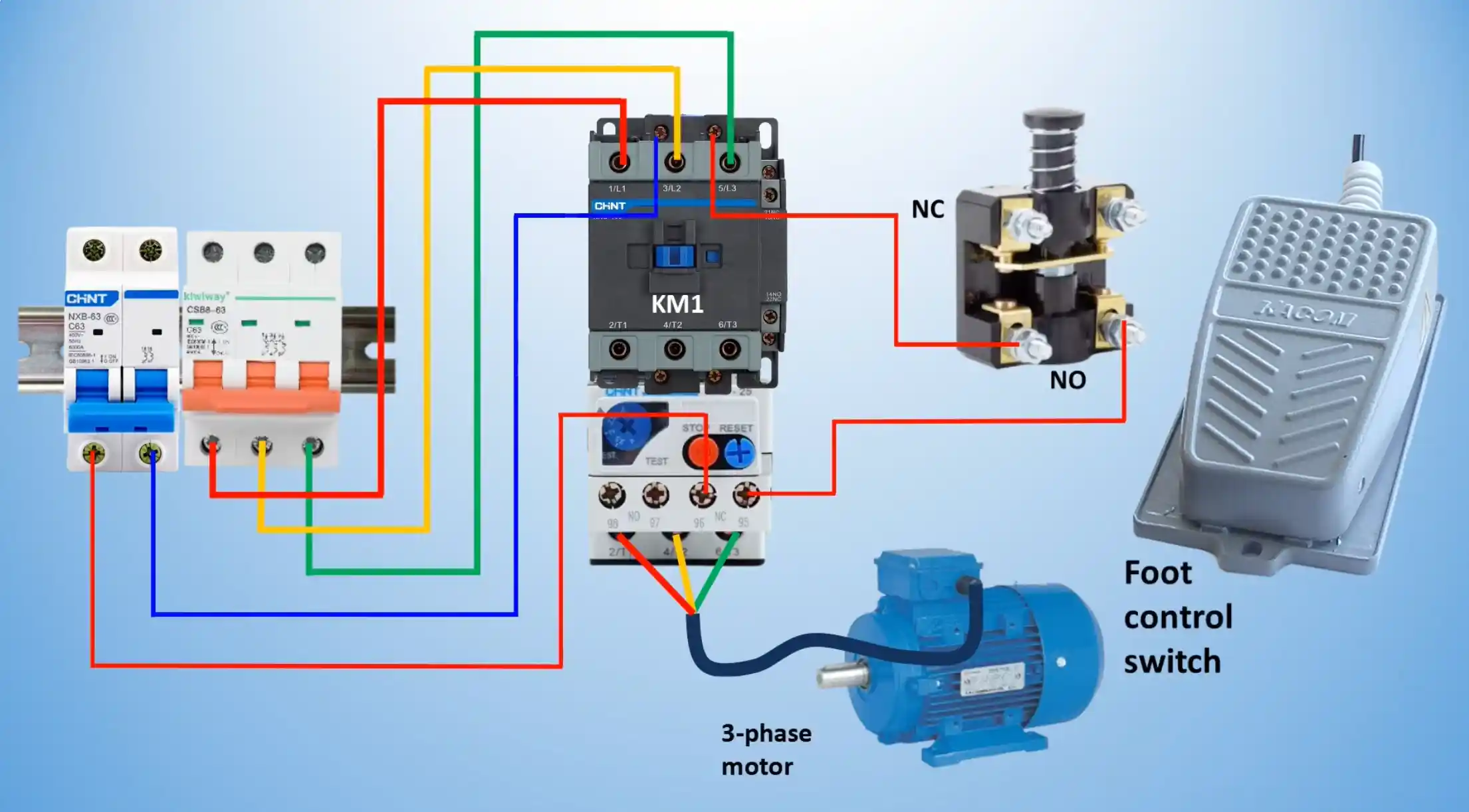

How to Wire a foot switch and motor

Source: https://www.youtube.com/watch?v=j3GkB9QzHy4

Connection Method:

- Power Supply:

- The main power supply is connected to the circuit breakers on the left (blue dual-pole and orange triple-pole).

- From the circuit breakers, power is fed to the contactor (KM1) input terminals.

- Contactor (KM1):

- The contactor serves as the main switching device for the motor.

- Its input terminals (top) are connected to the circuit breakers.

- Its output terminals (bottom) are connected to the three-phase motor.

- Motor Connection:

- The three-phase motor is connected to the output terminals of the contactor.

- Each phase (U, V, W) is connected to a corresponding terminal on the contactor.

- Control Circuit:

- The contactor’s coil is connected to the control circuit.

- The foot control switch is wired into this control circuit.

- It’s connected to the NC (Normally Closed) and NO (Normally Open) auxiliary contacts of the contactor.

- Foot Control Switch:

- This switch is used to start and stop the motor.

- When pressed, it completes the control circuit, energizing the contactor’s coil.

Operation:

- When the foot switch is pressed, it energizes the contactor’s coil.

- This closes the main contacts of the contactor, allowing power to flow to the motor.

- Releasing the foot switch de-energizes the coil, opening the contacts and stopping the motor.

Industries and Applications

Foot pedal switches are versatile devices used across various sectors:

- Industrial Machinery: Control equipment, manage processes, and enhance safety in manufacturing.

- Healthcare: Operate medical devices hands-free, improving focus during procedures.

- Automotive: Facilitate assembly line operations and diagnostic tool control.

- Music: Enable musicians to control effects and sounds during performances.

- Office Equipment: Enhance ergonomics by allowing hands-free control of computers and devices.

Benefits of Using Foot Pedal Switches

Foot pedal switches offer several key benefits across various applications:

- Hands-Free Operation: Enables multitasking and improves workflow efficiency, particularly in medical and industrial settings.

- Increased Productivity: Streamlines processes and allows simultaneous task management, crucial in fast-paced environments.

- Enhanced Safety: Allows control from a safe distance, reducing risks in hazardous environments. Features like enabling functions ensure deliberate operation.

- Improved Ergonomics: Reduces strain on hands and arms, decreasing operator fatigue during repetitive tasks.

- Precise Control: Provides accurate modulation of parameters, essential in applications requiring fine adjustments such as music and medical procedures.

Selecting the Right Foot Pedal Switch

When choosing a foot pedal switch, several factors must be considered to ensure it meets the specific needs of your application. Here are the key considerations:

A. Considerations for Different Environments

Foot pedal switches are used in various environments, from clean medical settings to rugged industrial locations. Key factors include:

- Environmental Protection Ratings: Select switches with appropriate IP ratings (e.g., IP54 for dust and water resistance) for outdoor or wet environments.

- Temperature Tolerance: Ensure the switch can operate within the temperature range of your environment, such as -25°C to +70°C for certain models.

- Material Durability: Choose materials that can withstand the specific conditions of your workspace, such as cast aluminum for heavy-duty applications.

B. Durability and Longevity Factors

The longevity of a foot pedal switch is crucial for minimizing replacement costs and downtime. Consider:

- Mechanical and Electrical Lifespan: Look for switches with high mechanical service lives (e.g., ≥100 million cycles) and electrical ratings (≥100,000 cycles) to ensure durability.

- Construction Quality: Durable materials and robust designs can enhance longevity. For instance, models with protective shrouds can withstand impacts from falling objects.

C. Compatibility with Existing Systems

Ensure that the foot pedal switch is compatible with your current equipment:

- Connection Types: Check the type of connectors required (e.g., TS jack, screw connections) and ensure they match your devices.

- Circuit Configuration: Determine if the switch can accommodate your system’s wiring requirements (e.g., normally open or normally closed configurations) to ensure proper functionality.

D. Customization Options

Many manufacturers offer customization features that allow you to tailor foot pedal switches to your specific needs:

- Switch Action Types: Choose between momentary or latching actions based on how you intend to use the switch.

- Number of Pedals: Depending on your application, you may need single or multi-pedal configurations for controlling multiple functions simultaneously.

- Safety Features: Consider options like anti-trip mechanisms or emergency stop functions that enhance safety during operation

Installation and Maintenance

Installation:

- Prioritize safety by disconnecting power before installation.

- Follow manufacturer guidelines for specific models.

- Ensure correct wiring and grounding.

- Test functionality before regular use.

Maintenance:

- Clean regularly with a damp cloth and mild detergent.

- Inspect for wear, damage, and loose connections periodically.

- Perform routine functionality checks.

Troubleshooting:

- For non-responsive switches, check power and connections.

- Address intermittent operation by cleaning and inspecting components.

- Prevent unexpected activation by removing obstructions.

Conclusion

Foot pedal switches have shown to be extremely useful instruments in a variety of sectors, providing improved safety, efficiency, and control in a wide range of applications. From industrial machines to hospital settings, these gadgets continue to play a significant role in simplifying operations and increasing user experience. The variety of foot pedal switch types, features, and capabilities enables tailored solutions to satisfy particular industrial needs. We should anticipate more developments in foot pedal switch design as technology progresses, possibly with the incorporation of more sophisticated features. Foot pedal switches are an indispensable part of any professional’s toolset since they have the potential to significantly increase productivity, safety, and operational efficiency.

Manufacturers of foot switch and their website

- SSC Controls Company

- Specializes in foot switches, foot pedals, and TIG foot controls.

- Website: ssccontrols.com

- VIOX

- Known for high-quality footswitches for various applications including musical equipment and industrial machinery.

- Website: viox.com

- Steute Controltec

- Offers a wide range of foot switches, including wireless and explosion-proof options for various industries.

- Website: steute-controltec.com

- Bernstein AG

- Provides a comprehensive selection of industrial foot switches designed for durability and safety.

- Website: bernstein.eu

- Altech Corp

- Designs and manufactures customizable foot switches for industrial and medical applications.

- Website: altechcorp.com

- AUSMA

- Focuses on efficient and durable foot pedal switches suitable for controlling multiple tools.

- Website: unounomall.co.za