Провідний виробник і постачальник шин: VIOX Electric

VIOX Electric - провідний китайський виробник і постачальник, що спеціалізується на високоякісних мідні гребінчасті шини, фазні розподільні шиниі шини автоматичних вимикачів. Маючи багаторічний досвід роботи в галузі, ми пропонуємо надійні, безпечні та високопродуктивні шинопроводи, пристосовані до різноманітних електричних систем. Як завод, сертифікований ISO, UL, CE, RoHS і CSA, ми прагнемо до інновацій та виняткового обслуговування клієнтів, що робить VIOX Electric вашим ідеальним партнером для стандартних і нестандартна шина потреби. Ознайомтеся з нашим асортиментом штирьових і вилочних шин або зв'яжіться з нами для отримання індивідуальної пропозиції вже сьогодні.

Сертифіковано

Наш асортимент шинопроводів

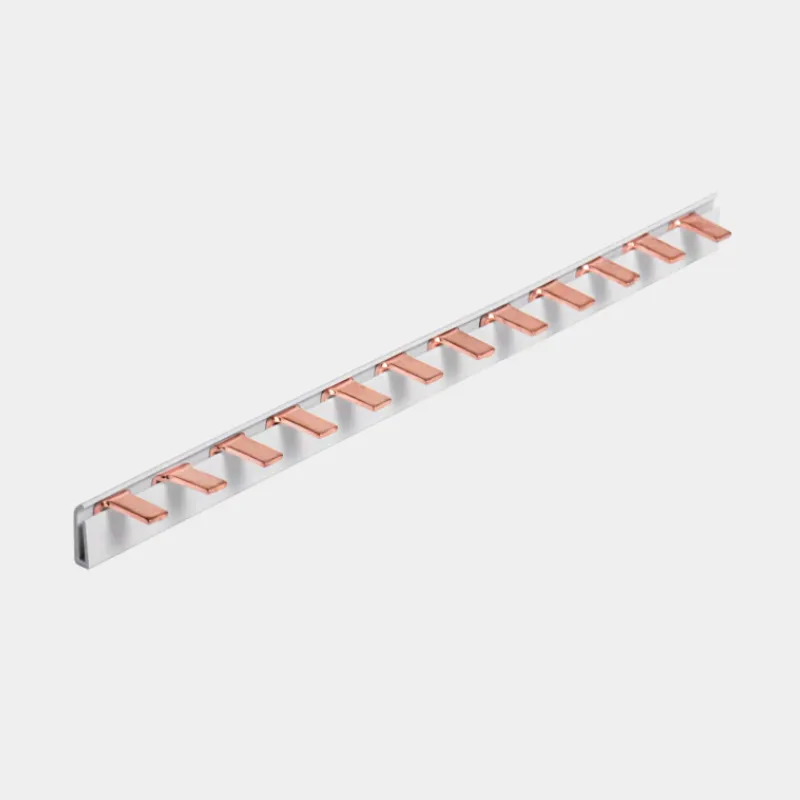

Штирьові шини автоматичних вимикачів

Ідеально підходить для безпосереднього вставляння в клеми MCB, забезпечуючи простий монтаж і надійне з'єднання.

Шини автоматичних вимикачів вилочного типу

Має U-подібну конструкцію для легкого з'єднання і роз'єднання, підходить для різних конфігурацій клем.

З'єднувачі та аксесуари для шин

Доповніть свою інсталяцію нашим асортиментом високоякісних роз'ємів та аксесуарів.

Чому варто співпрацювати з VIOX Electric для задоволення ваших потреб у шинопроводах?

Компанія VIOX Electric спеціалізується на постачанні високоякісних шин для автоматичних вимикачів та індивідуальних рішень, підкріплених галузевим досвідом і прихильністю до якості.

Індивідуальні рішення: Ми зосереджені на наданні рішень, які вирішують ваші унікальні електротехнічні завдання. Якщо вам потрібні певні конфігурації, розміри або можливості шин вимикачів, ми можемо створити індивідуальне рішення саме для вас.

Експертне керівництво: Наша команда підтримки клієнтів складається з галузевих експертів. Вони тісно співпрацюватимуть з вами, щоб зрозуміти ваші вимоги та запропонувати обґрунтовані, практичні рішення для задоволення ваших потреб.

Передові технології виробництва: Щоб гарантувати, що ви отримаєте шинопроводи найвищої якості, ми використовуємо найсучасніше обладнання, матеріали та виробничі процеси. Це гарантує ефективність і довговічність наших рішень.

Шинопроводи VIOX повного діапазону Mcb

VIOX Electric пропонує широкий асортимент аксесуарів для наших шин MCB, включаючи торцеві заглушки, з'єднувачі, 5-полюсні захисні кришки і перемички, збірні шини, мідні шини, латунні клемні колодки, латунні шини, клемні коробки, а також сталеві та алюмінієві DIN-рейки. Обирайте VIOX Electric для надійних та ефективних електричних рішень.

- Кінцеві заглушки шин

- Роз'єми

- 5-ти полюсний захисний кожух та перемички для крил

- Збірна збірна шина

- Мідний пруток

- Латунна клемна колодка

- Латунна планка

- Клемна коробка

- Сталеві та алюмінієві DIN-рейки

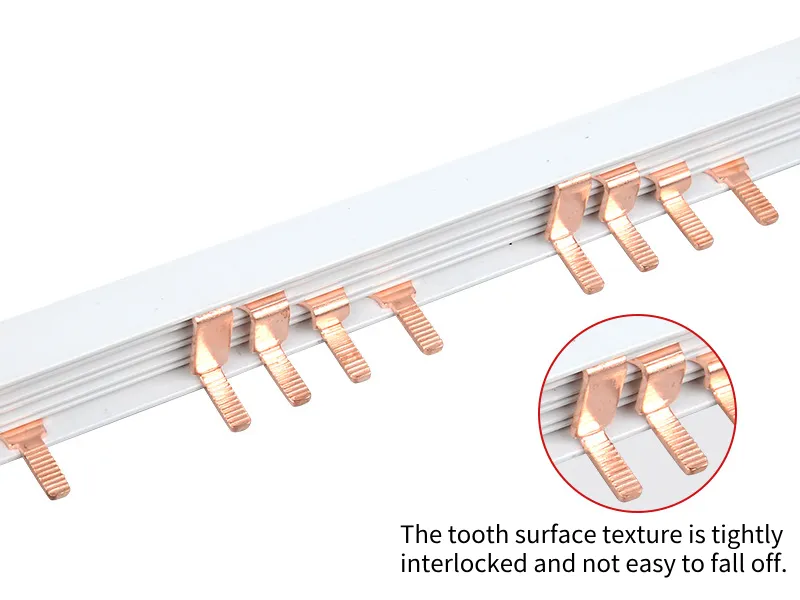

Точне виконання та високоякісні матеріали

Високопровідна мідь преміум-класу

Ми використовуємо високоміцну рулонну мідь (або спеціальний алюміній), що забезпечує оптимальну провідність і механічну цілісність.

Flawless Finish & Dimensional Accuracy

Наші шини мають гладку поверхню, без задирок і дефектів. Суворий контроль процесу гарантує високу стабільність ширини та площинності з точним дотриманням стандартних розмірів.

Стабільна якість

Ретельне виготовлення забезпечує однорідну текстуру та незмінно високу якість шин, на яку ви можете покластися.

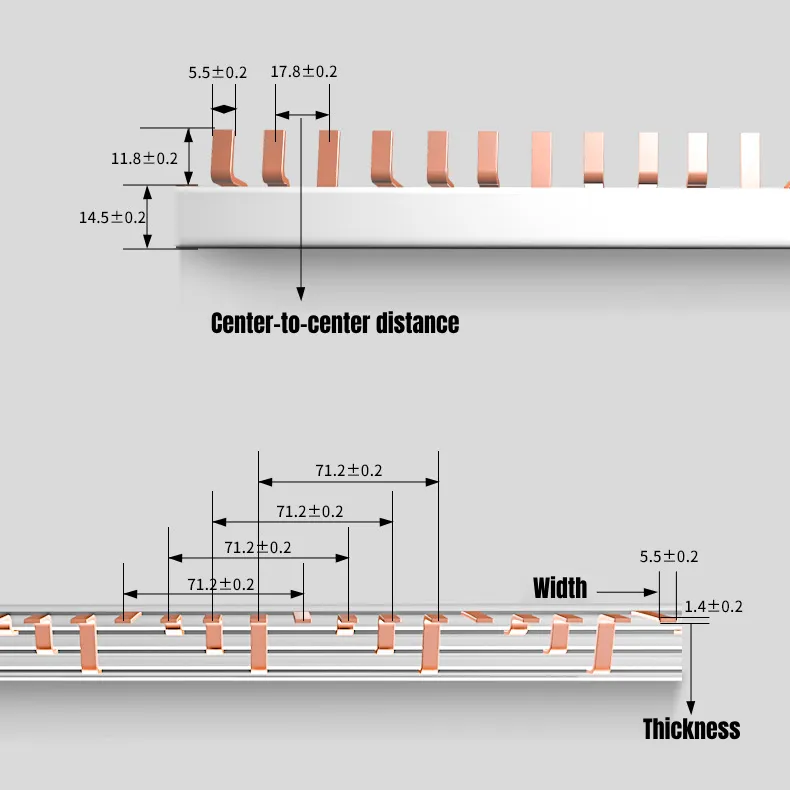

РОЗМІРИ ТА ТАБЛИЦЯ РОЗМІРІВ ШИН MCB

| Серія моделей | Фази | Поперечні перерізи | Варіанти довжини (мм) | Максимальний струм |

|---|---|---|---|---|

| S-1L | 1-фазний | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| S-2L | 2-фазний | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| S-3L | 3-фазний | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| S-4L | 4-фазний | 8-16 мм² | 210, 1016 | 50-80A |

| S-3L+N | 3P+N | 8-16 мм² | 210, 1000 | 50-80A |

| P-1L | 1-фазний | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| P-2L | 2-фазний | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| P-3L | 3-фазний | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| P-4L | 4-фазний | 8-16 мм² | 210, 1016 | 50-80A |

| P-1+N | 1P+N | 8-16 мм² | 210, 1000 | 50-80A |

| P-1+N-LE | 1P+N-LE | 8-16 мм² | 210, 1000 | 50-80A |

| C-1L | 1-фазний | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| C-2L | 2-фазний | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| C-3L | 3-фазний | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| C-4L | 4-фазний | 8-16 мм² | 210, 1016 | 50-80A |

| Серія моделей | Фази | Тип роз'єму | Поперечні перерізи | Варіанти довжини (мм) | Максимальний струм |

|---|---|---|---|---|---|

| F-1L | 1-фазний | Вилка (M6) | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| F-2L | 2-фазний | Вилка (M6) | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| F-3L | 3-фазний | Вилка (M6) | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| F-3L (M5) | 3-фазний | Вилка (M5) | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| F-4L | 4-фазний | Вилка (M6) | 8-16 мм² | 210, 1016 | 50-80A |

| G-1L | 1-фазний | Вилка (M6) | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| G-2L | 2-фазний | Вилка (M6) | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| G-3L | 3-фазний | Вилка (M6) | 8-16 мм² | 210, 1000, 1016 | 50-80A |

| G-4L | 4-фазний | Вилка (M6) | 8-16 мм² | 210, 1016 | 50-80A |

| G-3L+N | 3P+N | Вилка (M6) | 8-16 мм² | 210, 1000 | 50-80A |

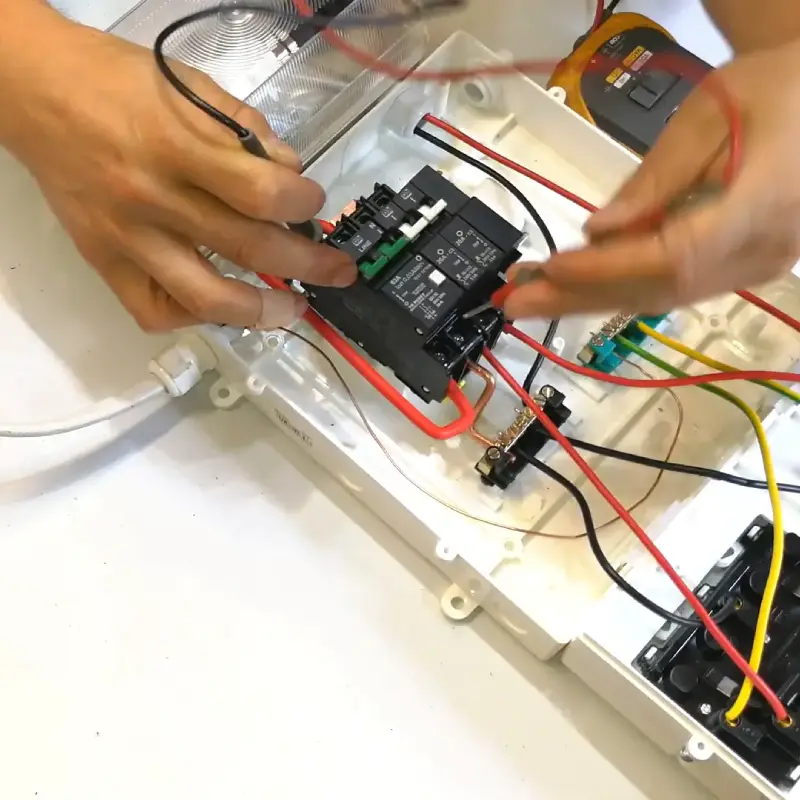

Покрокове встановлення шинопроводу VIOX

Процес встановлення шин MCB вимагає ретельної підготовки та уваги до деталей. Почніть з того, що переконайтеся, що всі гвинти клем повністю відкриті, і розташуйте найпотужніший MCB або RCBO найближче до головного вхідного пристрою12. Для правильного встановлення виконайте такі кроки

01

02

03

04

05

06

Забирай свою Безкоштовний зразок шинопроводів!

Ми надаємо зразки безкоштовно, вам лише потрібно сказати нам, що вам потрібно

Більше, ніж просто виробник шин

Компанія VIOX пишається тим, що надає своєчасну підтримку, дотримується високих стандартів і пропонує індивідуальні рішення, які відповідають потребам наших клієнтів, що є основою нашої зростаючої репутації в галузі виробництва шин.

Сервісна консультація

Якщо ваші вимоги до шинопроводів прості і вам не потрібна зовнішня консультація, наша команда може запропонувати експертну пораду і рекомендації за розумну плату.

Рекомендації щодо шинопроводів

Не знаєте, яку шину вибрати для вашого проекту? Ми надаємо персоналізовані рекомендації, засновані на ваших конкретних потребах, безкоштовно для всіх наших клієнтів.

Логістична підтримка

Якщо у вас немає відповідного експедитора, ми можемо допомогти організувати транспортування ваших індикаторів положення перемикача з нашого заводу на ваш проектний майданчик без будь-яких додаткових платежів за послуги.

Підтримка встановлення

Якщо у вас виникли запитання щодо встановлення шинопроводу, не соромтеся звертатися до нас. Ми пропонуємо допомогу в установці і навіть можемо відправити інженера на ваш об'єкт для надання практичної підтримки.

Технічний семінар з шинопроводів VIOX

Поширені запитання

Ми зібрали кілька поширених запитань від наших клієнтів. Якщо вашого питання тут немає, наша служба підтримки завжди готова допомогти. Ми будемо раді поспілкуватися з вами.

Як отримати пропозицію на шини автоматичних вимикачів?

Щоб отримати пропозицію на наші шини для автоматичних вимикачів, зв'яжіться з нашою службою підтримки клієнтів. Ми доступні 24/7. Просто вкажіть специфіку вашого замовлення, наприклад, тип, розмір і кількість. Ми проведемо вас через весь процес замовлення.

Який ваш MOQ для замовлення?

У нас низький MOQ або мінімальна кількість замовлення. Ви можете замовити лише одну одиницю, і ми доставимо її відповідно до ваших специфікацій.

Який час виконання мого замовлення?

Стандартний термін виконання замовлення на шини для автоматичних вимикачів становить від 7 до 10 робочих днів. Час доставки може збільшитися до 15 робочих днів через транзит. Для нестандартних або оптових замовлень ми можемо обговорити час виконання до завершення вашого замовлення.

Чи можу я отримати зразок перед замовленням?

Так, ми надаємо зразки для оцінки та затвердження. Створення зразків зазвичай займає від 3 до 7 робочих днів.

Чи можете ви зробити індивідуальні шини автоматичних вимикачів?

Так, ми пропонуємо шини для автоматичних вимикачів на замовлення. Повідомте нам про свої вимоги, і наша команда експертів з обслуговування клієнтів буде працювати з вами протягом усього процесу проектування.

Яка гарантія на шини автоматичних вимикачів?

Ми надаємо 5-річну гарантію на всі шини вимикачів, які ми виробляємо. Це гарантує, що ми поставляємо високоякісну продукцію. Кожен продукт ретельно тестується перед відправкою.

Експертні ресурси знань про шини автоматичних вимикачів

Що таке автоматичний вимикач BUSBAR?

Шина автоматичного вимикача - це спеціалізований електричний компонент, призначений для ефективного розподілу електроенергії та з'єднання декількох автоматичних вимикачів в електричних системах. Ці шини, як правило, виготовляються з високопровідних матеріалів, таких як мідь або алюміній, і служать центральними точками з'єднання для вхідних і вихідних електричних струмів.

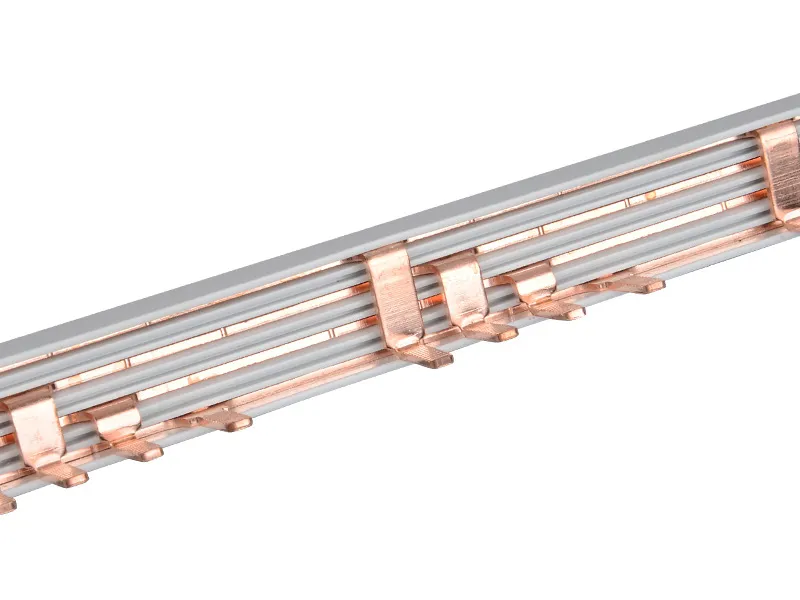

Компоненти шинопроводів MCB

Складаються з металевих провідників, зазвичай виготовлених з міді або алюмінію, шини MCB служать основою для розподілу електроенергії в розподільних щитах і електричних пристроях.. Ці важливі компоненти випускаються з різним поперечним перерізом, найпоширеніші з яких - 10 мм² (розраховані на 63 А) і 16 мм² (розраховані на 80 А).. Система включає в себе такі важливі елементи, як:

- Прямі секції для транспортування та розподілу енергії

- Додаткові аксесуари для завершення системи

- Ізолятори та автоматичні вимикачі для захисту

- Клеми кліткового типу для надійних з'єднань

- Шунтувальні вимикачі для дистанційного відключення

Принципи роботи шинопроводу

Шини автоматичних вимикачів функціонують як ефективні системи розподілу електроенергії, збираючи електроенергію від вхідних фідерів і розподіляючи її до вихідних фідерів. Вони діють як централізовані електричні вузли, де сходяться вхідні та вихідні струми. Система шин включає в себе ізолятори та автоматичні вимикачі для забезпечення безпеки. У разі несправності спрацьовує автоматичний вимикач, відключаючи несправну ділянку від ланцюга.

Ключові аспекти експлуатації шинопроводів включають в себе

Провідність: Шини служать шляхами для передачі електричного струму від джерел живлення до різних компонентів.

Розподільчі: Вони рівномірно розподіляють потужність між різними частинами електричної системи.

Підключення: Шини з'єднують кілька електричних пристроїв, таких як трансформатори та генератори, з основним джерелом живлення.

Відведення тепла: Конструкція шин допомагає відводити тепло, що генерується електричним струмом, запобігаючи перегріванню та забезпечуючи безпечну роботу системи.

Централізуючи розподіл електроенергії, шинопроводи спрощують складність електропроводки, підвищують безпеку і забезпечують надійну подачу електроенергії в різних сферах застосування, від промислових установок до систем відновлюваної енергетики..

Чим шини відрізняються від інших електричних провідників?

Шинопроводи та інші електричні провідники суттєво відрізняються за своєю конструкцією, застосуванням та експлуатаційними характеристиками. Шинопроводи - це, як правило, більші, плоскі або стрижневі конструкції, призначені для передачі великих струмів, які часто використовуються в промислових умовах для розподілу електроенергії в електричних панелях або розподільних пристроях. Вони, як правило, неізольовані і можуть ефективніше пропускати більші струми завдяки більшій площі поверхні. На відміну від них, традиційні електричні провідники, такі як дроти та кабелі, як правило, циліндричні, ізольовані та більш універсальні в застосуванні, включаючи електропроводку в житлових приміщеннях.

До ключових переваг шинопроводів відносяться їх здатність пропускати більші струми, краще розсіювати тепло і підвищувати ефективність в системах розподілу електроенергії завдяки меншому опору. Вони також забезпечують легший доступ для підключення до електромережі та простіший монтаж у певних умовах. Однак кабелі забезпечують більшу гнучкість і більше підходять для середовищ, де адаптивність та ізоляція мають вирішальне значення. Вибір між шинами та іншими провідниками залежить від конкретних вимог електричної системи, включаючи потужність струму, середовище встановлення та потреби застосування.

Типи шин MCB

Шини MCB бувають різних типів, щоб відповідати різним вимогам і конфігураціям електричних систем. Ось огляд основних типів:

Однофазні (1P): Призначені для однофазних ланцюгів, зазвичай використовуються в житлових і невеликих комерційних приміщеннях.

Двофазний (2P): Підходить для підключення двополюсних MCB або однофазних пристроїв з нульовим з'єднанням.

Трифазні (3P): Використовується в трифазних системах, поширених у промислових і великих комерційних установках.

Чотирифазний (4P): Підходить для трифазних систем з нейтраллю, забезпечуючи комплексний захист усіх провідників.

Штирьового типу: Має мідні штирі, які вставляються безпосередньо в клеми MCB, що забезпечує легке встановлення та зняття.

Гребінчастий: Нагадує структуру гребінця, що дозволяє гнучко під'єднувати кілька пристроїв по всій довжині.

Фіксована довжина: Випускаються в заздалегідь визначених розмірах для конкретних конфігурацій панелей.

Порізані за довжиною: Можна налаштувати на місці відповідно до точних розмірів панелі, що забезпечує більшу гнучкість.

Ці різноманітні типи гарантують, що шини MCB можуть бути адаптовані для задоволення різноманітних потреб електричних систем в житлових, комерційних і промислових приміщеннях.

Сфери застосування шинопроводів

Шини автоматичних вимикачів знаходять широке застосування в різних електричних системах, забезпечуючи ефективний розподіл і захист електроенергії. Основні сфери застосування включають

Розподільні щити в будівлях, де шини розділяють вхідну енергію на окремі ланцюги

Центри обробки даних, що забезпечують надійний розподіл електроенергії до серверів та обладнання

Лікарні, що забезпечують критично важливі потреби в електроенергії для операційних та відділень інтенсивної терапії

Промислове обладнання, що полегшує внутрішній розподіл електроенергії від основних фідерів до компонентів

Системи відновлюваної енергетики, такі як сонячні та вітрові установки, де шини забезпечують ефективну передачу енергії

Електричні транспортні засоби та системи зберігання акумуляторів, що використовують ізольовані алюмінієві шини для зменшення ваги

Ці застосування використовують компактну конструкцію, гнучкість і безпеку шинопроводів, що робить їх важливими компонентами сучасної електричної інфраструктури в житловому, комерційному та промисловому секторах..

Порівняння штирьових і вилочних шин MCB

Штирьові та вилочні шини MCB мають явні переваги для різних електричних застосувань. Штирьові шини мають мідні штирі, які вставляються безпосередньо в клеми MCB, забезпечуючи простий монтаж і демонтаж.. Вони мають більшу площу контакту, що призводить до меншого енергоспоживання та зниження підвищення температури. Вилочні шини, також відомі як лопатеві клеми, мають U-подібну конструкцію, що дозволяє легко під'єднувати і від'єднувати їх без повного зняття клемної колодки..

Ключові відмінності включають в себе:

Монтаж: Штирьові шини, як правило, швидше і простіше встановлюються, в той час як вилочні шини забезпечують більшу гнучкість при демонтажі та заміні..

Провідність: Обидва типи забезпечують хорошу провідність, але шини штирьового типу часто мають нижчий контактний опір.

Застосування: Шини вилочного типу особливо корисні, коли є дві вхідні клеми для напруги, в той час як штирьові шини є більш універсальними для MCB..

Кастомізація: Шини вилочного типу можна легше персоналізувати, зменшивши їх довжину, що забезпечує більшу адаптивність у деяких інсталяціях.

Вибираючи між штирьовими і вилковими шинами, враховуйте такі фактори, як конкретна конфігурація MCB, простота обслуговування і потенційна потреба в майбутніх модифікаціях електричної системи.

Функції безпеки та рейтинги

Функції безпеки в шинопроводах MCB включають вбудовані автоматичні вимикачі, які автоматично спрацьовують під час несправностей, ізолюючи несправні ділянки, щоб запобігти подальшому пошкодженню. Ці системи призначені для роботи при напрузі до 415 В і можуть витримувати струм від 63 А до 225 А, залежно від їх розміру.. Номінальна імпульсна витримувана напруга становить 4 кВ, що забезпечує захист від стрибків напруги. При використанні максимального розміру шини 36 мм² важливо враховувати, що найбільший сумісний кабель - 6 AWG (16 мм²).

Критерії вибору шин

При виборі шин автоматичних вимикачів враховуйте наступні ключові фактори:

Струмова потужність: Вибирайте шини, розраховані на максимальне очікуване струмове навантаження, враховуючи такі фактори, як температура навколишнього середовища та висота над рівнем моря..

Номінальна напруга: Переконайтеся, що шина може витримувати робочу напругу системи, включаючи потенційні перенапруги..

Струм короткого замикання: Виберіть шини, здатні витримати максимальний струм короткого замикання в системі.

Кількість полюсів: Підберіть конфігурацію шини (1P, 2P, 3P, 4P) відповідно до вимог вашої схеми.

Сумісність: Переконайтеся, що шина сумісна з вашими конкретними моделями вимикачів і способами монтажу..

Умови навколишнього середовища: При виборі матеріалів та ізоляції враховуйте такі фактори, як вологість, температура та потенційний вплив корозійних елементів..

Завжди звертайтеся до специфікацій виробника та місцевих електротехнічних норм, щоб забезпечити правильний вибір і встановлення шин автоматичних вимикачів для вашого конкретного застосування.

Переваги мідних шин над алюмінієвими

Мідні та алюмінієві шини мають різні переваги в електричних системах. Мідні шини мають кращу провідність, приблизно на 60% вищу електропровідність, ніж алюмінієві.. Ця чудова провідність дозволяє мідним шинам передавати більший струм у меншому перерізі, що робить їх ідеальними для застосування в умовах обмеженого простору.. Мідь також демонструє чудову корозійну стійкість і терморегуляцію, ефективно розсіюючи тепло і знижуючи ризик виходу системи з ладу.

З іншого боку, алюмінієві шинопроводи перевершують мідні з точки зору економічної ефективності та ваги. Алюміній, як правило, більш доступний, ніж мідь, що робить його привабливим варіантом для великомасштабних проектів або чутливих до бюджету застосувань. Крім того, менша щільність алюмінію робить шини легшими, що може мати перевагу в таких галузях, як аерокосмічна та автомобільна промисловість, де зменшення ваги має вирішальне значення.. Хоча алюміній потребує додаткової обробки поверхні для підвищення корозійної стійкості, його природний оксидний шар забезпечує певний внутрішній захист. Зрештою, вибір між мідними та алюмінієвими шинами залежить від конкретних вимог проекту, балансуючих факторів, таких як провідність, вартість, вага та умови навколишнього середовища.

Критерії якості шин MCB

Високоякісну шину MCB можна визначити за кількома ключовими характеристиками:

- Склад матеріалу: Шини вищого класу зазвичай виготовляються з високопровідної міді або алюмінію, причому міді надається перевага завдяки її чудовим електричним властивостям і корозійній стійкості..

- Ізоляція: Якісні шинопроводи мають надійну ізоляцію, часто з використанням таких матеріалів, як ПЕТ-плівка або термостійкі пластмаси, такі як Cycoloy 3600, що забезпечує безпеку і запобігає витоку електрики..

- Струмовий потенціал: Хороші шини повинні мати відповідні номінальні струми для їх передбачуваного застосування, з загальними номіналами в діапазоні від 63А до 225А.

- Відповідність сертифікаційним вимогам: Високоякісні шини відповідають або перевищують галузеві стандарти, такі як UL489, CSA C22.2 No.5 та вимоги RoHS.

- Довговічність: Високоякісні шини демонструють високу механічну міцність з показниками ударостійкості IK10 і можуть витримувати суворі умови навколишнього середовища.

Якісна шина MCB повинна також пропонувати гнучкість в установці, наприклад, можливість обрізання за розміром, і забезпечувати аксесуари, такі як торцеві заглушки і захисні кришки, для підвищення безпеки і функціональності.. Крім того, він повинен мати низький рівень електромагнітного випромінювання та ефективне відведення тепла, щоб забезпечити надійну роботу в різних електричних системах..

Методи тестування шин

Щоб перевірити, чи правильно працює шина автоматичного вимикача, виконайте такі дії:

Проведіть візуальний огляд на наявність ознак пошкоджень, корозії або ослаблених з'єднань.

Для перевірки напруги використовуйте мультиметр:

Налаштуйте мультиметр на вимірювання змінної напруги

Помістіть один щуп на клему шини, а інший - на нейтральну шину

Показник, близький до номінальної напруги (наприклад, 120 В або 240 В), вказує на те, що шина знаходиться під напругою

Перевірте безперервність:

Переведіть мультиметр у режим безперервності або опору

Випробування між клемою шини та вихідною клемою вимикача

Близьке до нуля значення опору вказує на правильне з'єднання

Проведіть перевірку опору ізоляції:

Використовуйте мегомметр для вимірювання опору ізоляції між фазами та між кожною фазою і заземленням

Показники повинні відповідати специфікаціям виробника

Проведіть перевірку контактного опору за допомогою цифрового омметра низького опору (DLRO), щоб переконатися в низькому опорі в точках з'єднання

Якщо під час цих тестів будуть виявлені будь-які проблеми, зверніться до кваліфікованого електрика для подальшої перевірки та можливого ремонту.

Китайські виробники шин MCB

Китай став провідним світовим виробником шин MCB (мініатюрних вимикачів), причому кілька компаній спеціалізуються на цьому важливому електричному компоненті. Серед них, VIOX Electric вирізняється своїми передовими технологіями виробництва та прихильністю до якості, задовольняючи різноманітні промислові потреби за допомогою точно розробленої продукції. як надійний постачальник на світовому ринку, VIOX Electric пропонує широкий асортимент шинопроводів, пристосованих до різних специфікацій. Акцент на інновації та суворий контроль якості підкреслює лідерство Китаю в галузі виробництва шинопроводів MCB.

Спеціальні шини автоматичних вимикачів OEM

Компанія VIOX Electric готова допомогти вам у вирішенні питань, пов'язаних з шинами для автоматичних вимикачів. Ми пропонуємо високоякісні та економічно ефективні рішення.