Introduction

Definition of Contactor

An electrical contactor is an electromechanical device used to control the flow of electrical current in high-power circuits. It functions as a switch that can open or close connections in a circuit, allowing for the remote control of electrical devices such as motors, lighting systems, and heating equipment.

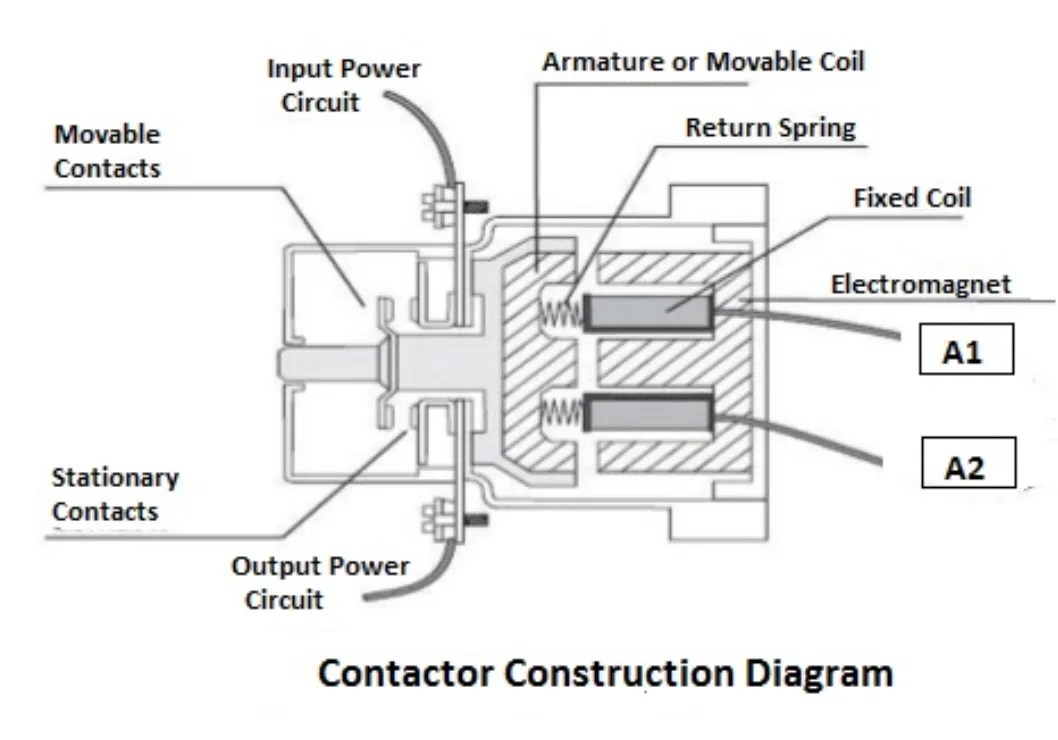

Key Components of a Contactor

- Electromagnetic Coil: This is the core component that generates a magnetic field when energized. This magnetic field attracts a movable armature, which in turn opens or closes the contacts within the contactor.

- Contacts: These are conductive elements that physically make or break the electrical connection. Contactors typically have two types of contacts:

- Main Power Contacts: Responsible for carrying the heavy current to the load.

- Auxiliary Contacts: Used for control and signaling purposes, often interfacing with other devices.

- Enclosure: The contactor is housed in an enclosure that protects its internal components from environmental factors like dust and moisture, and ensures safety by preventing accidental contact with live parts.

- Arc Suppression Mechanism: To prevent arcing when contacts open or close, contactors often include mechanisms like arc chutes designed to extinguish arcs quickly.

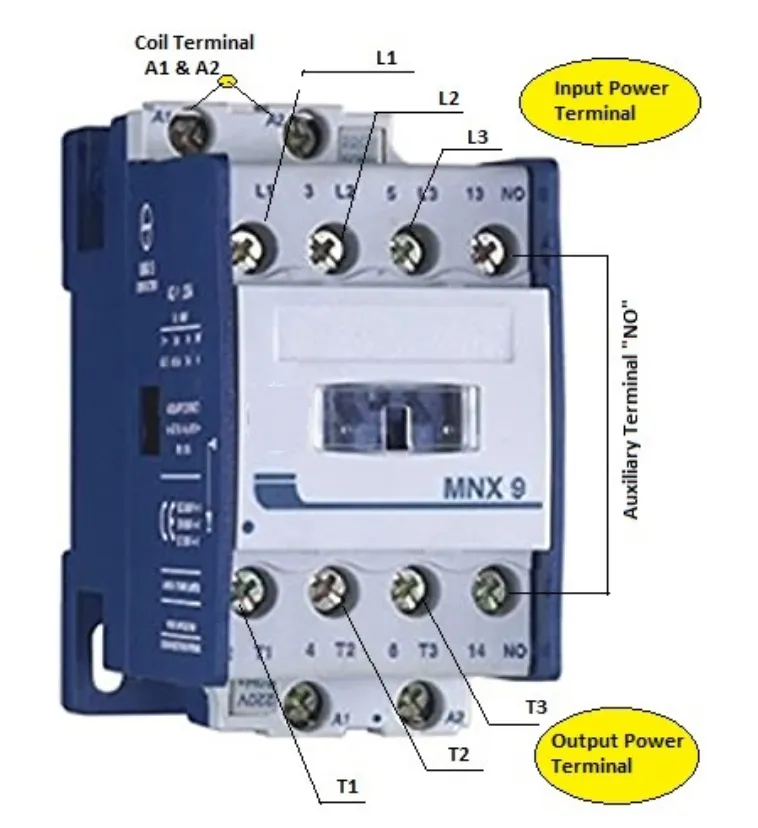

There are 6 power terminals and 2 coil terminals (A1 & A2) for 3-phase AC supply. Out of 6 terminals, 3 terminals L1, L2, and L3 are connected as input with the main power supply generally coming from MCB, and another 3 terminals T1, T2, and T3 as output with Motor, ORL, Timer, and another control circuit.

Additional provision for the auxiliary block is provided with “NO” and “NC” according to the application of the instrument as shown in AC contactor terminal diagram.

Credit to https://peacosupport.com/blog/what-is-contactor

Working Principle

As shown in the diagram, a current supplied in the form of AC or DC to the coil terminal A1 energizes the coil by generating an electromagnetic field to bring the moving part of the coil with the fixed part in contact. Now, current starts to flow from the “R Y B” input terminal of the contactor to the output of the contactor and acts as a switch on. While another terminal of coil A2 is connected to the neutral to complete the circuit.

When the supply to the contactor is stopped, the contactor movable coil returns to its original position due to the spring force exerted by the return spring. At this time, there will not be any flow of current from the input to the output of the contactor and it will act as a switch-off.

Following is the control wire diagram for DOL.

Types of Contactors

- AC Contactors: Designed for alternating current applications, commonly found in industrial machinery and lighting systems.

- DC Contactors: Specifically made for direct current applications, such as electric vehicles and renewable energy systems.

Difference between AC and DC Contactors

The differences between AC contactors and DC contactors are significant, primarily due to their design and operational characteristics. Here’s a detailed comparison:

Key Differences

| Feature | AC Contactor | DC Contactor |

|---|---|---|

| Coil Design | Thin and long coil, made from copper. | Short and fat coil, often made from cast iron or solid material. |

| Core Material | Made of laminated silicon steel sheets to reduce eddy currents. | Made of solid soft iron or cast steel, no lamination required. |

| Electrical Resistance | Lower resistance, generates more heat. | Higher resistance, generates less heat. |

| Arc Suppression | Utilizes grid arc extinguishing devices. | Uses magnetic blowing arc extinguishing devices. |

| Operating Frequency | Typically operates up to 600 times per hour. | Can operate up to 2000 times per hour. |

| Starting Current | Higher starting current, not suitable for frequent operations. | Lower starting current, designed for frequent operation. |

| Use Case | Primarily used for AC circuits (e.g., motors, lighting). | Used for DC circuits (e.g., electric vehicles, photovoltaic systems). |

| Contact Configuration | Generally has more poles (e.g., three-phase). | Usually has fewer poles (e.g., two-pole). |

Detailed Explanation

- Coil Design and Resistance: AC contactors have coils with fewer turns and lower resistance compared to DC contactors, which have more turns and higher resistance due to the need for a stronger magnetic field to operate effectively in DC circuits.

- Core Material: The core of an AC contactor is made from laminated silicon steel sheets to minimize losses due to eddy currents when alternating current flows through it. In contrast, DC contactors can use solid materials since they do not experience the same losses.

- Arc Suppression Mechanism: AC contactors typically use grid arc extinguishing devices, while DC contactors employ magnetic blowing mechanisms to extinguish arcs that occur when contacts open or close.

- Operating Frequency and Current Handling: AC contactors are limited to approximately 600 operations per hour due to their design constraints, while DC contactors can handle up to 2000 operations per hour, making them suitable for applications requiring frequent switching.

- Application Suitability: AC contactors are ideal for controlling AC loads such as motors and lighting systems, whereas DC contactors are essential in applications involving direct current like electric vehicles and renewable energy systems.

How to Select the Right Contactor

Selecting the right contactor for your application involves several critical considerations to ensure optimal performance and safety. Here’s a structured approach to guide you through the selection process:

Key Considerations for Selecting a Contactor

- Load Characteristics:

- Current Rating: Determine the operating current (le) of the load. The contactor must be rated to handle this current without overheating.

- Voltage Rating: Ensure the contactor’s voltage rating (Ue) matches or exceeds the supply voltage of your application.

- Load Type: Identify whether the load is resistive, inductive, or capacitive, as this affects the choice of contactor type and its ratings.

- Contactor Size:

- Consider the size of the contactor based on the motor’s power and its duty cycle. Frequent on/off operations may require a larger contactor due to higher inrush currents during startup.

- Coil Specifications:

- Check the coil voltage ratings to ensure compatibility with your control circuit. The rated coil voltage should match the voltage supplied to energize the coil.

- Understand the pick-up and drop-out voltages, which indicate the operational thresholds for engaging and disengaging contacts.

- Contact Configuration:

- Assess the number of main contacts needed (normally open or normally closed) based on your circuit requirements.

- Consider auxiliary contacts for additional control and signaling functions, which may not carry the same current as main contacts.

- Environmental Conditions:

- Evaluate ambient temperature, humidity, and potential exposure to dust or chemicals. Choose a contactor with appropriate environmental ratings and enclosures to withstand these conditions.

- Application Type:

- Different applications may necessitate specific types of contactors (e.g., definite-purpose contactors for HVAC systems). Ensure that you choose a contactor suited for your specific application needs.

- Safety Features:

- Look for built-in safety features such as arc suppression mechanisms, overload protection, and thermal relays if applicable. These features enhance reliability and prevent damage during fault conditions.

- Manufacturer Reputation:

- Select a reputable manufacturer known for quality and reliability in their products. This can significantly impact durability and maintenance costs over time.

How to Test a Contactor

Testing an AC contactor is essential to ensure its proper functioning and reliability in electrical systems. Here’s a step-by-step guide on how to test an AC contactor effectively:

Required Tools

- Multimeter: For measuring voltage, resistance, and continuity.

- Screwdriver: To access the contactor.

- Safety Gloves and Glasses: For personal protection during testing.

Testing Procedure

Step 1: Turn Off Power

Before starting any testing, ensure that the power supply to the AC unit is turned off. Locate the circuit breaker or disconnect switch and turn it off to prevent any electrical hazards.

Step 2: Visual Inspection

Inspect the contactor for any visible signs of damage, such as:

- Burnt or melted contacts

- Discoloration or pitting on contact surfaces

- Loose connections or excessive dirt

If any damage is found, the contactor may need to be replaced.

Step 3: Test Coil Resistance

- Set your multimeter to the resistance (Ω) setting.

- Measure the resistance across the coil terminals of the contactor.

- A reading of 0 Ω indicates a short circuit.

- A reading of infinity (OL) indicates an open circuit.

- A normal reading should fall within the manufacturer’s specified range.

Step 4: Test for Voltage

- With the power turned back on, set your multimeter to measure AC voltage.

- Place the probes on the input terminals of the contactor.

- Verify that the voltage matches the specifications listed on the contactor. If it is significantly lower or higher, there may be a problem with the power supply.

Step 5: Check Continuity

- Set your multimeter to continuity mode (if available).

- With power off, connect probes to the output terminals of the contactor.

- When powered on, activate the contactor (either manually or through its control circuit).

- The multimeter should indicate continuity (a low resistance reading) when the contacts are closed.

Step 6: Inspect Contacts

While activated, visually inspect the contacts for:

- Signs of arcing or pitting

- Smooth operation without hesitation

If you notice irregularities, it may indicate that the contacts are worn out and require replacement.

Step 7: Perform a Load Test (Optional)

- Disconnect wires from the load side of the contactor.

- Measure resistance between line side and load side in both open and closed positions.

- The readings should show significant differences; if not, this indicates a faulty contactor.

For a visual guide, you can refer to this video

Common Brands and Models of Contactor

VIOX Electric

Brand advantage: A Chinese brand recognized for its competitive pricing, reliability, and comprehensive product range.

Recommended models:

- VIOX CJX2-2510 AC Contactor

- VIOX CJX2-3211 AC Contactor

EATON

Eaton Corporation plc is a global power management company headquartered in Dublin, Ireland, specializing in energy-efficient electrical, hydraulic, and mechanical power solutions for diverse industries worldwide.

Recommended models:

- XTCE015B01B: EATON IEC Magnetic Contactor: Non-Reversing, 3 Poles, 15 A, 240V AC Coil, 1NC, B Frame Size

- CE15DNS3AB: Eaton Freedom series IEC contactor

- W+201K5CF: Eaton W+201K5CF Contactor 3 Pole contactor with a current rating of 270 Amps and a voltage rating of 600V

- XTCF200G00T: EATON IEC Magnetic Contactor: Non-Reversing, 4 Poles, 115 A, 24V AC Coil, G Frame Size

Siemens AG

A global leader in electrical engineering and automation, Siemens offers a comprehensive range of high-quality contactors, including AC and DC types, designed for various industrial applications, emphasizing energy efficiency, reliability, and innovative solutions in power distribution and control systems.

Recommended models:

- 3RT20181BB41: SIEMENS IEC Magnetic Contactor: Non-Reversing, 3 Poles, 16 A, 24V DC Coil, 1NO, S00 Frame Size

- LEN00C003120B: Siemens Class LE Contactor 3 pole 3 phase 600V 30A 120V coil

- 3RT2027-1AK60: FURNAS SIEMENS Contactor, 120V, 3 Pole: Fits Furnas Siemens Brand, 3RT2027-1AK60

Conclusion

Contactors play a crucial role in modern electrical systems, serving as the backbone of power control and distribution. Whether AC or DC, these devices offer unique advantages suited to different applications. Understanding the distinctions between AC and DC contactors, knowing how to select the right one for your needs, and being able to properly test and maintain them are essential skills for electrical professionals.

As technology advances, brands like VIOX Electric, EATON, and Siemens continue to innovate, providing more efficient, reliable, and versatile contactor solutions. By staying informed about the latest developments and best practices in contactor technology, engineers and technicians can ensure safer, more efficient electrical systems across various industries.