Circuit protection is fundamental to electrical safety, and at the heart of most protection systems lies a critical component: the fuse holder. Whether you’re designing automotive electrical systems, building industrial control panels, or working on consumer electronics, understanding fuse holders is essential for creating safe, reliable electrical installations.

This comprehensive guide covers everything you need to know about fuse holders, from basic principles to advanced selection criteria, helping you make informed decisions for your specific applications.

What is a Fuse Holder?

A säkringshållare is a specialized electrical component designed to securely mount, house, and provide electrical connections for fuses within electrical circuits. Acting as the interface between the fuse and the circuit, fuse holders ensure proper electrical contact, protect the fuse from environmental factors, and facilitate safe fuse replacement.

De primära funktionerna hos en säkringshållare inkluderar:

- Säker montering: Prevents fuse displacement due to vibration or movement

- Electrical Connection: Provides reliable current path through the fuse

- Miljöskydd: Shields fuses from moisture, dust, and corrosion

- Förbättrad säkerhet: Enables safe fuse replacement without circuit modifications

- Standardization: Ensures only properly rated fuses can be installed

How Fuse Holders Work

Fuse holders operate through a straightforward mechanism. When a fuse is inserted into the holder, internal contacts make electrical connection with the fuse terminals, creating a complete circuit path. The holder’s design ensures consistent contact pressure and proper alignment, maintaining low resistance connections essential for effective circuit protection.

During normal operation, current flows through the holder’s contacts, through the fuse element, and continues to the protected circuit. When an overcurrent event occurs, the fuse element melts or breaks, interrupting the current flow and protecting downstream components.

Types of Fuse Holders: Complete Classification

Understanding different fuse holder types is crucial for selecting the right component for your application. Fuse holders are classified based on mounting method, fuse type compatibility, and application requirements.

PCB Mount Fuse Holders

PCB mount fuse holders are designed for direct installation onto printed circuit boards, making them ideal for electronic equipment and control systems.

Viktiga egenskaper:

- Surface mount (SMT) and through-hole (THT) options

- Compact footprint for space-constrained designs

- Automated assembly compatibility

- Various fuse size accommodations (5x20mm, 6.3x32mm, ATO blade)

Vanliga applikationer:

- Konsumentelektronik

- Strömförsörjning

- Control modules

- LED drivers

- Automotive ECUs

Selection Considerations:

- Board space constraints

- Assembly process requirements

- Current and voltage ratings

- Miljöförhållanden

Säkringshållare för panelmontering

Säkringshållare för panelmontering are designed for installation through enclosure walls or control panels, providing external access for fuse inspection and replacement.

Design Variations:

- Threaded cylindrical holders: For cartridge fuses (3AG, 5AG series)

- Rectangular snap-in holders: For blade fuses (ATO, ATC, mini)

- Dead-front holders: Enhanced safety with covered live parts

- Indicating holders: Visual or LED indicators for blown fuses

Applikationer:

- Industriella kontrollpaneler

- Utrustning för kraftdistribution

- Motorstyrningscentraler

- Test equipment

- Marina elektriska system

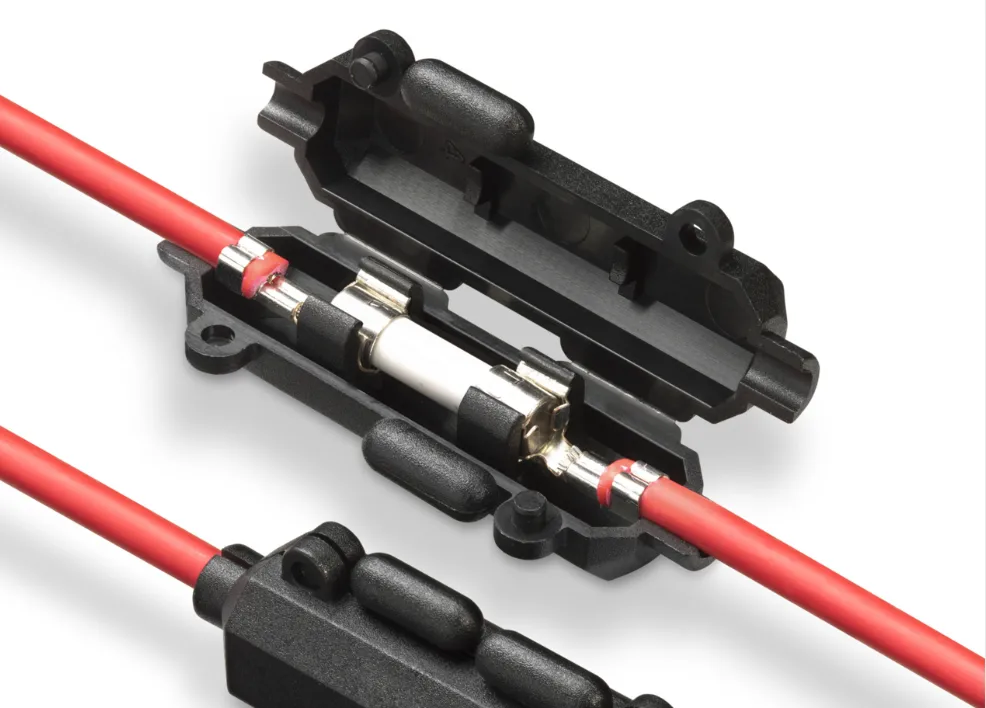

In-Line Fuse Holders

In-line fuse holders integrate directly into wiring harnesses, providing circuit protection without requiring panel space or PCB mounting.

Types:

- Cylindrical in-line: For glass tube and ceramic fuses

- Blade fuse in-line: For automotive-style blade fuses

- Waterproof in-line: Environmental sealing for harsh conditions

- High-current in-line: For applications requiring 30A+ protection

Fördelar:

- Flexible installation locations

- No panel modifications required

- Ideal for retrofit applications

- Available with pigtail or splice connections

Specialty Fuse Holder Types

DIN Rail Mount Holders Designed for standard DIN rail installation in industrial environments, these holders integrate with modular wiring systems and offer easy maintenance access.

High-Voltage Fuse Holders Engineered for applications above 1000V, featuring enhanced insulation, arc suppression, and safety interlocks for utility and industrial power systems.

Military/Aerospace Holders Built to withstand extreme temperatures, vibration, and environmental conditions while meeting stringent reliability requirements for critical applications.

Fuse Holder Selection Guide: Critical Factors

Selecting the appropriate fuse holder requires careful consideration of multiple technical and application factors. Making the wrong choice can lead to poor performance, safety issues, or premature failure.

Elektriska specifikationer

Aktuellt betyg

The fuse holder’s current rating must meet or exceed the maximum current expected in your application. Standard ratings range from milliamps for electronic circuits to hundreds of amps for power distribution.

- Derating considerations: Account for ambient temperature, airflow, and contact resistance

- Continuous vs. peak current: Consider both steady-state and transient current requirements

- Kontaktmotstånd: Lower resistance holders provide better performance and less heating

Spänningsklassning

Voltage ratings determine the maximum safe operating voltage and affect insulation requirements.

- AC vs. DC considerations: DC applications often require higher voltage ratings due to arc extinction challenges

- Safety margins: Select holders rated significantly above operating voltage

- Krav på isolering: Consider creepage and clearance distances for your application

Physical and Environmental Factors

Mounting Configuration

Choose mounting style based on your installation requirements:

- Utrymmesbegränsningar: PCB mount for compact designs

- Accessibility needs: Panel mount for user-serviceable applications

- Installation flexibility: In-line for distributed protection

Miljöskydd

Consider operating conditions and required protection levels:

- IP ratings: For moisture and dust protection

- Temperaturområde: Standard (-40°C to +85°C) or extended ranges

- Chemical resistance: For harsh industrial environments

- Vibrationsbeständighet: Critical for automotive and mobile applications

Fuse Compatibility

Fuse Type Matching

Ensure complete compatibility between holder and fuse:

- Physical dimensions: Exact fuse size accommodation

- Contact design: Proper interface with fuse terminals

- Retention mechanism: Secure fuse mounting under all conditions

Current Rating Coordination

The holder’s current rating should match or exceed the maximum fuse rating it will accommodate, preventing holder damage during fault conditions.

Safety Standards and Certifications: Ensuring Compliance

Fuse holders must meet rigorous safety standards to ensure reliable protection and user safety. Understanding these standards is crucial for product compliance and market access.

UL Standards (United States)

UL 4248 – Fuseholders

The primary standard governing fuse holder safety in North America, covering:

- Construction requirements and materials

- Electrical performance criteria

- Environmental testing protocols

- Marking and documentation requirements

Key UL Requirements:

- Temperature rise limits: Preventing overheating during normal operation

- Short-circuit performance: Maintaining integrity during fault conditions

- Mekanisk styrka: Withstanding installation and service stresses

- Flammability resistance: Using appropriate materials and construction

CSA Standards (Canada)

CSA C22.2 No. 39 – Fuseholders

Canadian requirements that often align with UL standards but include specific Canadian requirements:

- Bilingual marking requirements

- Metric dimension standards

- Canadian electrical code compliance

- Environmental condition testing for Canadian climates

IEC Standards (International)

IEC 60127 – Miniature Fuses

International standard covering fuse holders for low-voltage applications:

- Global harmonization of requirements

- Metric sizing standards

- International test procedures

- Worldwide market access facilitation

IEC 60269 – Low-voltage Fuses

Covers industrial and power distribution fuse holders:

- Applikationer med hög strömstyrka

- Industrial environment requirements

- Power quality considerations

- International utility standards

Certification Marks and Their Meaning

- UL Listed: Product tested and approved for specific applications

- CSA Certified: Compliance with Canadian safety requirements

- CE Marking: European conformity declaration

- VDE Approved: German safety certification

- SEMKO Certified: Scandinavian approval for Nordic markets

Installation Guide: Professional Best Practices

Proper fuse holder installation is critical for safety, performance, and longevity. Follow these professional guidelines for different installation types.

Pre-Installation Planning

Safety Preparation

- Power isolation: Verify complete de-energization using lockout/tagout procedures

- Circuit verification: Use multimeters to confirm zero voltage

- Personal protective equipment: Wear appropriate safety gear for voltage level

- Work permits: Obtain necessary permits for industrial installations

Tool and Material Preparation

Essential tools for professional installation:

- Wire strippers (appropriate for wire gauge)

- Crimping tools (matching terminal types)

- Torque drivers (for screw terminals)

- Multimeter (for continuity verification)

- Heat shrink tubing and applicator

PCB Mount Installation

Överväganden om design

- Thermal management: Position away from heat sources

- Tillgänglighet: Ensure fuse replacement access

- Trace routing: Size copper traces for full current capacity

- Component spacing: Allow clearance for fuse insertion/removal

Assembly Process

- Paste application: Apply solder paste using appropriate stencil

- Component placement: Use pick-and-place equipment for SMT types

- Reflow profile: Follow manufacturer’s temperature recommendations

- Inspection: Verify solder joint quality and component alignment

- Testning: Perform electrical continuity and insulation tests

Panel Mount Installation

Panel Preparation

- Hole sizing: Follow manufacturer’s cutout specifications exactly

- Edge finishing: Deburr holes to prevent wire insulation damage

- Material thickness: Verify compatibility with holder mounting depth

- Environmental sealing: Apply appropriate gaskets or sealants

Monteringsförfarande

- Test fit: Verify proper hole alignment and component fit

- Sealing installation: Apply gaskets or O-rings per specifications

- Component mounting: Secure with specified torque values

- Wire connection: Use appropriate terminals and connection methods

- Protection verification: Test environmental sealing integrity

In-Line Installation

Förberedelse av tråd

- Circuit isolation: Ensure complete power disconnection

- Wire routing: Plan installation path for minimal stress

- Strip length: Match conductor preparation to terminal requirements

- Insulation integrity: Maintain wire insulation throughout installation

Connection Methods

Crimped Connections

- Terminal selection: Choose appropriate crimp terminal type

- Strip length: Follow terminal manufacturer specifications

- Crimping: Use proper crimp tool and technique

- Inspection: Verify crimp quality and conductor retention

- Isolering: Apply heat shrink or electrical tape as needed

Soldered Connections

- Surface preparation: Clean and tin wire ends

- Joint formation: Create mechanical connection before soldering

- Solder application: Use rosin-core solder and proper technique

- Kylning: Allow joints to cool without movement

- Isolering: Cover joints with appropriate insulation

Troubleshooting Common Fuse Holder Problems

Understanding common fuse holder issues and their solutions is essential for maintaining reliable circuit protection. Here’s a comprehensive troubleshooting guide for the most frequent problems.

Overheating and Thermal Issues

Symtom:

- Discolored holder materials

- Melted plastic components

- Burnt wire insulation

- Fuse holder deformation

Root Causes and Solutions:

Poor Contact Resistance

- Cause: Oxidation, corrosion, or loose connections

- Lösning: Clean contacts with appropriate solvents, replace corroded components

- Prevention: Use anti-oxidant compounds, select appropriate contact materials

Oversized Fuse Installation

- Cause: Installing fuses with higher current ratings than holder specifications

- Lösning: Replace with properly rated fuse, verify holder current capacity

- Prevention: Use rejection-type holders that prevent incorrect fuse installation

Inadequate Wire Sizing

- Cause: Undersized conductors creating voltage drop and heating

- Lösning: Upgrade to properly sized conductors per NEC/local codes

- Prevention: Calculate wire ampacity including derating factors

Contact and Connection Problems

Intermittent drift

- Symptoms: Flickering loads, periodic power loss, erratic operation

- Causes: Loose connections, worn contacts, vibration-induced movement

- Solutions: Retorque connections, replace worn holders, improve mounting

Complete Circuit Failure

- Symptoms: Total loss of power, open circuit readings

- Causes: Corroded contacts, broken internal connections, fuse holder failure

- Solutions: Contact cleaning, holder replacement, circuit rewiring

Environmental Damage

Moisture Ingress

- Symptoms: Corrosion, electrical leakage, insulation breakdown

- Solutions: Improve sealing, use waterproof holders, add drainage

- Prevention: Select appropriate IP ratings, proper gasket installation

Chemical Exposure

- Symptoms: Material degradation, contact corrosion, insulation failure

- Solutions: Replace with chemically resistant materials, improve ventilation

- Prevention: Use appropriate holder materials for environment

Mechanical Failures

Fuse Retention Problems

- Symptoms: Fuses falling out, poor fuse contact, mechanical play

- Solutions: Replace retention mechanisms, upgrade to better holders

- Prevention: Select holders with appropriate retention force

Mounting Failures

- Symptoms: Loose panels, vibrating components, mechanical stress

- Solutions: Retighten mountings, add vibration dampening, redesign mounting

- Prevention: Proper torque application, appropriate fastener selection

Advanced Selection Criteria for Specific Applications

Different applications have unique requirements that influence fuse holder selection. Understanding these application-specific needs ensures optimal performance and reliability.

Automotive Applications

Utmaningar för miljön

Automotive fuse holders must withstand extreme conditions:

- Temperature cycling: -40°C to +125°C ambient temperatures

- Vibrationsbeständighet: Continuous and shock vibration per automotive standards

- Kemisk exponering: Fuels, oils, cleaning solvents, road salt

- Moisture protection: Rain, humidity, pressure washing

Recommended Features

- Sealed construction: IP67 or higher protection ratings

- Vibration-resistant mounting: Secure retention under all conditions

- Terminal options: Weather-pack, metri-pack, or sealed connectors

- Val av material: UV-resistant, chemical-resistant plastics

Common Automotive Fuse Holder Types

- Mini blade holders: For modern automotive applications (5-30A)

- Standard blade holders: For higher current applications (20-40A)

- Maxi blade holders: For high-current circuits (40-120A)

- ANL holders: For main power distribution (80-400A)

Industrial Control Applications

Reliability Requirements

Industrial environments demand maximum uptime and safety:

- Mean time between failures (MTBF): Extended operational life

- Environmental protection: Dust, moisture, chemicals, temperature extremes

- Safety compliance: OSHA, NFPA, and industry-specific standards

- Tillgänglighet för underhåll: Easy fuse replacement without system shutdown

Critical Selection Factors

- Dead-front construction: Safety during maintenance operations

- Indication features: Visual or remote fuse status monitoring

- Modular design: Standardized mounting and connections

- Arc suppression: Enhanced safety during fuse operations

Marina och offshore-tillämpningar

Unique Environmental Factors

Marine environments present exceptional challenges:

- Salt corrosion: Accelerated corrosion of metals and connections

- Constant moisture: High humidity and direct water exposure

- Motion and vibration: Continuous vessel movement and engine vibration

- Limited maintenance: Extended periods between service opportunities

Essential Features

- Corrosion resistance: Marine-grade materials and coatings

- Waterproof sealing: IP68 or NEMA 6P protection levels

- Secure mounting: Resistant to shock and vibration

- Ignition protection: For hazardous location compliance

High-Frequency and RF Applications

Special Considerations

RF applications require careful attention to electrical characteristics:

- Impedance characteristics: Minimal impact on signal integrity

- Parasitic elements: Low inductance and capacitance

- Shielding: EMI/RFI protection for sensitive circuits

- Contact materials: High-conductivity, low-resistance materials

Design Requirements

- Coaxial compatibility: For transmission line applications

- Broadband performance: Consistent characteristics across frequency ranges

- Low insertion loss: Minimal signal attenuation

- Thermal stability: Consistent performance across temperature ranges

Cost Considerations and Buying Guide

Understanding the total cost of ownership for fuse holders helps make informed purchasing decisions that balance initial cost with long-term value.

Initial Purchase Costs

Prisintervall per typ

- Basic PCB mount: $0.50 – $5.00 per unit

- Panel mount (standard): $2.00 – $15.00 per unit

- Panel mount (indicating): $10.00 – $50.00 per unit

- In-line holders: $1.00 – $10.00 per unit

- High-current/specialty: $25.00 – $200.00+ per unit

Factors Affecting Price

- Current and voltage ratings: Higher ratings command premium prices

- Special features: Indication, waterproofing, rejection features

- Certification requirements: UL, CSA, CE listings add cost

- Material specifications: Marine-grade, high-temperature materials

- Volume considerations: Quantity breaks and custom options

Total ägandekostnad

Installation Costs

- Labor requirements: Installation complexity and time

- Special tools: Crimping tools, torque drivers, test equipment

- Training needs: Technician certification and skill development

- Quality assurance: Testing and documentation requirements

Maintenance and Lifecycle Costs

- Replacement frequency: Holder reliability and expected life

- Tillgänglighet för underhåll: Easy vs. difficult fuse replacement

- Downtime costs: System outages during maintenance

- Safety considerations: Risk mitigation and insurance implications

Vendor Selection Criteria

Quality and Reliability Factors

- Manufacturing standards: ISO 9001, automotive quality systems

- Testing and certification: Compliance with applicable standards

- Track record: Established reputation in target markets

- Teknisk support: Engineering assistance and application guidance

Supply Chain Considerations

- Tillgänglighet: Stock levels and lead times

- Geographic coverage: Local distribution and support

- Long-term supply: Product lifecycle and obsolescence planning

- Flexibilitet: Custom solutions and engineering modifications

Maintenance and Lifecycle Management

Proper maintenance extends fuse holder life and ensures continued protection reliability. Implementing systematic maintenance procedures reduces unexpected failures and improves system availability.

Preventive Maintenance Programs

Inspection Schedules

Establish regular inspection intervals based on application criticality:

- Critical systems: Monthly visual inspections

- Standardapplikationer: Quarterly detailed inspections

- Low-priority circuits: Annual comprehensive reviews

- Environmental factors: Adjust frequency for harsh conditions

Inspection Checklist

- Visual examination: Discoloration, cracking, corrosion signs

- Connection integrity: Tightness, corrosion, proper contact

- Environmental damage: Moisture ingress, chemical exposure

- Mechanical condition: Mounting security, retention function

- Thermal indicators: Heat damage, overheating evidence

Documentation Requirements

- Maintenance logs: Date, technician, findings, actions

- Trending analysis: Pattern identification and prediction

- Replacement history: Failure modes and frequencies

- Performance metrics: MTBF, failure rates, cost tracking

Predictive Maintenance Techniques

Thermal Monitoring

Regular thermal imaging identifies developing problems:

- Baseline establishment: Document normal operating temperatures

- Trending analysis: Monitor temperature changes over time

- Threshold setting: Establish action levels for temperature rise

- Dokumentation: Maintain thermal image history

Elektrisk provning

Periodic electrical measurements track performance:

- Kontaktmotstånd: Monitor connection quality degradation

- Isolationsmotstånd: Verify environmental protection integrity

- Kontinuitetstestning: Confirm complete circuit paths

- Load testing: Verify performance under actual conditions

End-of-Life Management

Replacement Indicators

Recognize when fuse holders require replacement:

- Thermal damage: Any evidence of overheating

- Mechanical wear: Loose retention, damaged mounting

- Korrosion: Significant contact or housing corrosion

- Age considerations: Manufacturer recommended service life

Disposal and Recycling

Proper disposal protects environment and may recover value:

- Material separation: Remove recyclable metals and plastics

- Hazardous materials: Proper handling of any toxic components

- Environmental compliance: Follow local disposal regulations

- Dokumentation: Maintain disposal records for compliance

Future Trends in Fuse Holder Technology

The fuse holder industry continues evolving with technological advances and changing application requirements. Understanding these trends helps in long-term planning and technology selection.

Smart Monitoring Integration

IoT-anslutning

Next-generation fuse holders incorporate monitoring capabilities:

- Status reporting: Real-time fuse condition monitoring

- Predictive analytics: AI-driven failure prediction

- Remote diagnostics: Cloud-based analysis and recommendations

- Integration: Compatibility with building management systems

Advanced Indication

Enhanced status indication provides better operational visibility:

- Multi-color LEDs: Status, warning, and fault indications

- Digital displays: Current readings and diagnostic information

- Wireless communication: Status transmission to central monitoring

- Historical data: Trend analysis and performance tracking

Miljömässig hållbarhet

Material Innovations

Environmental considerations drive material development:

- Recycled content: Increased use of recycled plastics and metals

- Biodegradable options: Environmentally friendly material alternatives

- Reduced packaging: Minimal, recyclable packaging solutions

- Energy efficiency: Manufacturing process improvements

Lifecycle Optimization

Extended service life reduces environmental impact:

- Enhanced durability: Improved materials and construction

- Modular design: Replaceable components vs. complete replacement

- Repair capability: Field-serviceable components

- Upgrade paths: Technology refresh without complete replacement

Application-Specific Evolution

Electric Vehicle Integration

EV requirements drive specialized development:

- High-voltage capability: Safe operation at EV voltage levels

- Fast-acting protection: Rapid fault clearing for battery safety

- Thermal management: Enhanced cooling for high-power applications

- Kompakt design: Space optimization for mobile applications

Renewable Energy Applications

Solar and wind power create new requirements:

- DC optimization: Enhanced DC arc extinction capability

- Environmental resistance: Outdoor installation durability

- Surge handling: Lightning and switching surge protection

- Grid integration: Utility-grade performance requirements

Slutsats

Fuse holders represent a critical component in electrical protection systems, requiring careful selection, proper installation, and systematic maintenance to ensure optimal performance. This comprehensive guide has covered the essential aspects of fuse holder technology, from basic principles to advanced application considerations.

Viktiga slutsatser:

- Proper selection based on electrical, environmental, and application requirements ensures reliable protection and optimal performance

- Professional installation following established procedures prevents common problems and ensures safety compliance

- Regular maintenance and monitoring extends service life and prevents unexpected failures

- Understanding standards and certifications ensures compliance and market acceptance

- Total cost considerations beyond initial purchase price optimize long-term value

Whether you’re designing new systems or maintaining existing installations, applying the principles and practices outlined in this guide will help you achieve safe, reliable circuit protection through proper fuse holder selection and management.

For specific application guidance or technical support, consult with qualified electrical engineers and follow all applicable codes and standards for your installation requirements.

Vanliga frågor och svar (FAQ)

What is the difference between a fuse holder and a fuse block?

A säkringshållare is designed to accommodate a single fuse and is typically used for individual circuit protection. Fuse holders can be in-line (integrated into wiring), panel-mounted, or PCB-mounted for single circuit applications.

A fuse block is a larger assembly that holds multiple fuses in one centralized unit, allowing you to manage and protect several circuits from one location. Fuse blocks are commonly used in automotive applications, industrial control panels, and marine electrical systems where multiple circuits need protection and organization.

Viktiga skillnader:

- Capacity: Fuse holders = 1 fuse; Fuse blocks = multiple fuses (2-12+ positions)

- Tillämpning: Fuse holders for simple circuits; Fuse blocks for complex electrical systems

- Installation: Fuse holders often inline; Fuse blocks typically panel or surface mounted

- Kostnad: Fuse holders are less expensive; Fuse blocks cost more but provide centralized management

Can I use any fuse in any fuse holder?

No. Fuse holders are specifically designed for particular fuse types and sizes. A blade fuse won’t fit in a cartridge fuse holder, and vice versa. Many fuse holders include built-in rejection features that prevent installation of incorrectly sized or rated fuses to prevent electrical damage.

Compatibility Requirements:

- Physical size: Exact dimensional match (length, diameter, width)

- Fuse type: Blade, cartridge, glass tube, etc.

- Nuvarande betyg: Holder must meet or exceed maximum fuse rating

- Nominell spänning: Appropriate for circuit voltage

- Terminal type: Proper contact interface

What does it mean when a fuse holder is “current limiting”?

Current limiting fuse holders work with current limiting fuses (like Class CC) that restrict fault current to safe levels. These holders often have rejection features – for example, Class CC holders have a restricted end that only accepts the “pinched down” end of CC fuses, preventing installation of non-current-limiting fuses.

Benefits of Current Limiting Holders:

- Enhanced safety during fault conditions

- Reduced arc flash hazards

- Protection of downstream equipment

- Compliance with electrical codes requiring current limitation

How do I know what current rating fuse holder I need?

Fuse holder selection depends on multiple factors including the fuse type selected, current and voltage ratings, circuit integration method, required certifications, and environmental protection needs.

Selection Steps:

- Determine circuit requirements: Maximum continuous current, voltage, fault current

- Choose fuse type and rating: Based on protection requirements

- Select holder: Must accommodate chosen fuse with appropriate safety margin

- Verify ratings: Holder current rating should meet or exceed maximum fuse rating

- Consider derating: Apply 40% derating for real-world conditions

Can I solder wires directly to fuse holders?

Many fuse holders offer various wire connection types including screw clamp, wire crimp, quick connect, and solder connections. Availability depends on the specific fuse holder model.

Connection Options:

- Solder connections: Available on many PCB and some panel mount holders

- Skruvplintar: Most common for panel mount applications

- Quick connect tabs: Standard on automotive applications

- Crimp terminals: For high-reliability installations

- Wire leads/pigtails: Pre-attached wires for easy connection

Soldering Guidelines:

- Follow industry standards (EN 61760-1:2006)

- Use appropriate soldering temperature profile

- For cartridge fuses, soldering is generally not recommended

- PCB holders designed for wave or reflow soldering

What’s the difference between “fast-acting” and “time-delay” fuse holders?

The fuse holder itself doesn’t determine the protection characteristics – this comes from the fuse installed in the holder. However, some holders are optimized for specific fuse types:

Fast-Acting Fuse Applications:

- Holders for semiconductor protection

- Electronic circuit protection

- Applications requiring immediate fault clearing

Time-Delay Fuse Applications:

- Motor starter protection holders

- Applications with inrush current

- Holders designed for slower-acting protection

For North American applications, fuses are characterized as “fast-acting” or “time-delay,” while international fuses use “quick-acting” or “time-lag” designations. The holder must be compatible with the chosen fuse type.

Are fuse holders waterproof?

Waterproof features are available on many fuse holders, particularly those designed for marine, automotive, or outdoor applications. Littelfuse produces in-line and panel-mount fuse holders designed for maximum protection in high humidity and corrosive environments.

Skyddsnivåer:

- IP67: Protected against temporary immersion

- IP68: Protected against continuous submersion

- NEMA 4X: Corrosion resistant, weatherproof

- Marine rated: Salt spray and moisture resistant

Waterproof Applications:

- Marina elektriska system

- Outdoor equipment

- Automotive under-hood applications

- Industrial wash-down environments

How often should I replace fuse holders?

Fuses do not require maintenance until an overcurrent event causes them to open. What are perceived as fuse holder “failures” are mostly reactions to excess heat from loose connections, improper sizing, or operation outside temperature range.

Replacement Indicators:

- Thermal damage: Discoloration, melting, warping

- Contact wear: Poor fuse retention, high resistance

- Korrosion: Visible oxidation on contacts or housing

- Mekanisk skada: Cracked housing, loose mounting

- Age: Following manufacturer’s recommended service life

Underhållsschema:

- Critical systems: Annual inspection

- Standardapplikationer: Every 2-3 years

- Tuffa miljöer: More frequent based on conditions

What certifications should I look for in fuse holders?

Common certifications include UL (United States), CSA (Canada), CE (Europe), VDE (Germany), SEMKO (Scandinavia), and IEC (International). UL 4248 covers fuseholder safety requirements, while IEC 60127 addresses international miniature fuse applications.

Key Certifications:

- UL Listed: Tested to UL 4248 safety standards

- CSA Certified: Canadian safety compliance

- CE Marking: European conformity declaration

- VDE Approved: German safety certification

- IEC Compliant: International standards compliance

- RoHS Compliant: Environmental restriction compliance

Can I use a higher current rated fuse holder with a lower rated fuse?

Yes. Using a higher-rated fuse holder with a lower-rated fuse is generally acceptable and often recommended for safety margins. The holder must accommodate the physical fuse size and provide proper contact.

Överväganden:

- Physical compatibility: Fuse must fit securely

- Contact design: Proper electrical interface

- Cost efficiency: Balance between safety and economics

- Future expansion: Higher-rated holders allow system upgrades

Not Recommended:

- Using a lower-rated holder with higher-rated fuses

- Mismatched fuse types (blade in cartridge holder)

- Exceeding holder voltage ratings

What causes fuse holders to overheat?

Overheating is typically caused by loose or corroded connections, improper component sizing, or operation outside the device’s temperature range rather than actual device failures.

Vanliga orsaker:

- Poor connections: Loose terminals, corroded contacts

- Oversized fuses: Installing higher-rated fuses than holder specifications

- Undersized wiring: Voltage drop causing heating

- Environmental factors: Excessive ambient temperature

- Kontaktmotstånd: Oxidation or contamination

Lösningar:

- Clean and tighten all connections

- Use properly rated fuses and holders

- Upgrade to appropriate wire gauge

- Improve ventilation or use higher-temperature holders

- Apply contact enhancement compounds

Do I need special tools to install fuse holders?

Tool requirements depend on the fuse holder type. Some holders are designed for tool-free operation, while others require specialized tools for installation or fuse access.

Common Tools Needed:

- Wire strippers (appropriate gauge)

- Crimping tools (for terminal connections)

- Torque drivers (for screw terminals)

- Multimeter (for testing)

- Panel cutout tools (for panel mount installation)

Tool-Free Options:

- Push-in terminal connections

- Snap-fit panel mounting

- Quick-disconnect terminals

- Finger-grip fuse access