The $50,000 Cable Tie Mistake You Can’t Afford to Make

Picture this: You’re six months into commissioning a new offshore platform. Your instrumentation cables are neatly bundled with hundreds of stainless steel cable ties. Then the maintenance call comes in—half the ties have corroded through, cable bundles are sagging, and exposed wiring is shorting against metal conduit. The culprit? Those “316 stainless steel” ties you purchased at 40% below market price weren’t 316 grade at all. They were cheap knockoffs with fake grade stamps.

This scenario plays out more often than you’d think. In harsh industrial environments—petrochemical plants, wastewater treatment facilities, marine installations, or outdoor substations—cable ties are the unsung heroes holding your electrical infrastructure together. But when quality fails, the consequences cascade: equipment downtime, safety hazards, emergency repairs, and regulatory headaches.

Kľúčový záver: A 50-cent cable tie can trigger a $50,000 system failure. In critical applications, the cost of poor-quality ties isn’t just replacement—it’s the catastrophic bundle collapse, damaged cables, and unplanned shutdowns that follow.

Why Cheap Stainless Steel Cable Ties Fail (And How to Spot Them)

Stránka stainless steel cable tie market is flooded with substandard products. Here’s why:

The Counterfeiting Problem: Unscrupulous manufacturers stamp “304” or “316” on low-grade steel alloys that contain insufficient chromium and nickel. Without proper metallurgical composition, these ties corrode rapidly when exposed to moisture, salt spray, or industrial chemicals. You can’t visually distinguish 201 stainless (a cheap substitute) from genuine 316—the difference only shows up months later when rust appears.

Manufacturing Shortcuts: Precision matters. Poorly manufactured ties have inconsistent thickness, rough-cut edges with burrs, and weak locking mechanisms. These defects cause three immediate problems: they damage cable insulation during installation, they slip under vibration, and they fail prematurely under load.

The Documentation Gap: The most dangerous aspect? Many suppliers provide no material traceability. Without mill test certificates or third-party verification, you’re gambling that the product matches its specification sheet.

For purchasing managers and electrical engineers, the challenge is clear: How do you separate genuine quality from convincing fakes before they’re installed across your facility?

The 5-Pillar Quality Verification Framework

High-quality stainless steel cable ties aren’t just about the grade stamp on the band—they’re the result of controlled metallurgy, precision manufacturing, and rigorous testing. Think of quality verification like inspecting a critical fastener: you wouldn’t bolt together a pressure vessel based solely on the manufacturer’s word. Cable ties deserve the same scrutiny.

Here’s your systematic approach to distinguishing premium ties from pretenders, structured into five verification checkpoints you can apply during the procurement process.

Step 1: Verify Material Grade and Demand Documentation

Before you even look at the tie itself, audit the paperwork.

Your first checkpoint isn’t physical—it’s documentary. Genuine manufacturers of 304 or 316 stainless steel ties provide mill test certificates (also called material test reports or MTRs) that trace the steel composition back to the original mill. These certificates specify the exact percentages of chromium (minimum 16-18% for 304, 16-18% for 316), nickel (8-10.5% for 304, 10-14% for 316), and molybdenum (2-3% for 316 only).

What to Request from Suppliers:

- Mill test certificates showing chemical composition analysis

- Grade markings visible on the tie body or head (not just the packaging)

- Country of origin documentation

- ISO 9001 or AS9100 certification for quality management

Kľúčový záver: The material grade stamp is your first line of defense—but without mill test certificates, that ‘316’ marking could just be wishful thinking. Always request documentation before placing bulk orders.

Grade Selection by Application:

- 304 Stainless Steel: Suitable for indoor industrial environments, general manufacturing, and applications without significant chemical or marine exposure. Cost-effective for most installations.

- 316 Stainless Steel: The mandatory choice for coastal facilities, chemical plants, wastewater treatment, and any environment with chloride exposure or salt spray. The molybdenum content provides superior pitting resistance.

If the supplier hesitates to provide mill certificates or offers vague “certificates of conformance,” that’s your red flag to walk away.

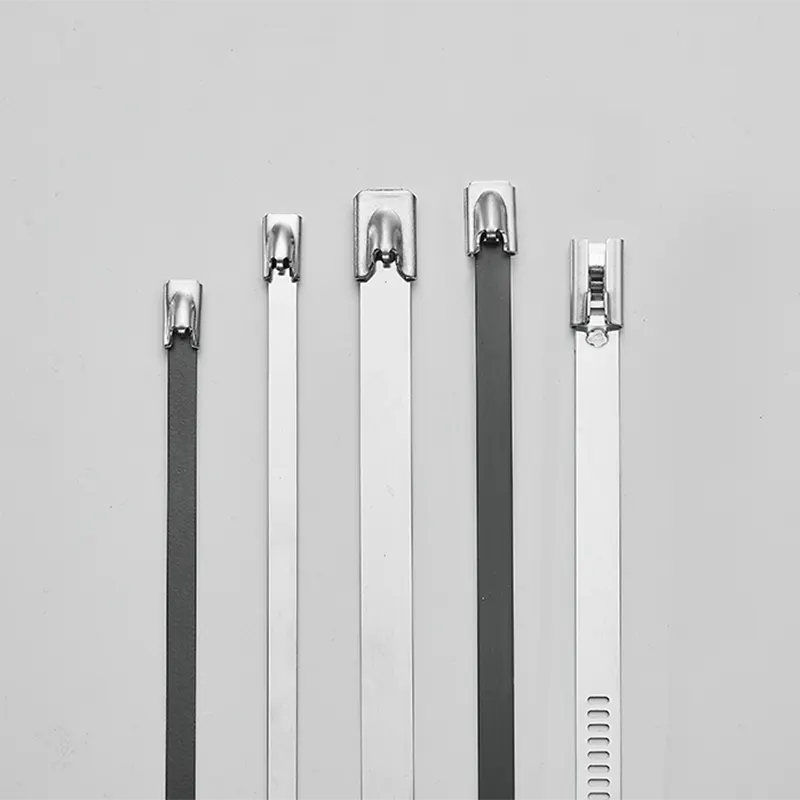

Step 2: Inspect Physical Construction and Surface Finish

With documentation confirmed, now examine the tie itself—because quality shows in the details.

Hold a sample tie up to the light and run your finger along the band. Premium ties have a smooth, burr-free surface with consistent edges. The finish should be uniform, free from pitting, discoloration, or visible weld marks at the head-to-band connection.

Critical Inspection Points:

- Edge Quality: Precision-cut edges should be smooth without sharp burrs. Rough edges are like tiny razor blades—they’ll slice through cable insulation (especially PVC or polyethylene jacketing) during installation or when the bundle vibrates.

- Thickness Consistency: Use a micrometer to spot-check band thickness. High-quality 8mm × 0.5mm ties maintain dimensional tolerance within ±0.05mm. Inconsistent thickness indicates poor die maintenance and predicts slippage under load.

- Povrchová úprava: Look for a bright, polished finish or a consistent matte appearance. Dull patches, rust specks, or discoloration suggest contamination during manufacturing or inadequate passivation treatment.

Kľúčový záver: Smooth finish isn’t about aesthetics—burrs and rough edges will slice through cable insulation like a razor, creating short circuits months after installation. Inspect samples under magnification if possible.

Pro Inspection Tip: Bend the band gently. Quality stainless steel shows controlled elastic deformation and returns to shape. If it kinks, creases, or doesn’t spring back, the temper is wrong—indicating either poor material or improper heat treatment.

Step 3: Confirm Mechanical Strength Ratings and Test Data

Numbers on a datasheet mean nothing without third-party verification.

Tensile strength is the tie’s load-bearing capacity—its ability to hold cable bundles together under stress, vibration, and thermal expansion. For typical 8mm × 0.5mm stainless steel ties, legitimate manufacturers specify 300–500 N (30–50 kgf) minimum tensile strength. But here’s the critical question: Is this value tested or just claimed?

What to Demand:

- Third-Party Test Reports: Look for certified testing from independent labs (SGS, TÜV, UL) showing actual tensile test results. Self-certified data from the manufacturer’s in-house lab carries less weight.

- Batch Testing Records: Premium suppliers conduct regular batch testing and can provide statistical quality control data showing consistency across production runs.

- Test Standards Compliance: Verify testing follows recognized standards like IEC 62275 or UL 62275 for cable management systems.

Real-World Context: A 400 N-rated tie can secure a cable bundle weighing approximately 40 kg (88 lbs) vertically. But don’t select ties at maximum capacity—apply a 2:1 safety factor minimum. If your bundle weighs 20 kg, specify ties rated for at least 400 N, not 200 N. Dynamic loads from vibration, thermal cycling, and shock effectively multiply static weight.

Kľúčový záver: Tensile strength isn’t just a number—it’s your insurance policy against catastrophic bundle collapse. Always request third-party test reports, not manufacturer claims, and apply proper safety factors.

Step 4: Test the Locking Mechanism Reliability

The strongest band is worthless if the lock fails.

The locking mechanism is where many cheap ties reveal their true quality. Premium stainless steel ties use either ball-lock heads (a stainless steel ball engages with ratchet teeth on the band) or ladder-type locking heads (interlocking barbs) specifically engineered to resist vibration loosening.

How to Evaluate Lock Quality:

Vizuálna kontrola:

- Examine the locking ball or barbs under magnification. They should be precisely machined, not roughly stamped or cast.

- Check for smooth operation—the band should ratchet through the head with consistent resistance, not catch or skip teeth.

Funkčné testovanie:

- Install the tie around a test bundle and tighten firmly. A quality lock will “click” positively into each ratchet position.

- Apply lateral load (try to twist or shift the installed tie). Premium locks maintain grip without slipping.

- If possible, expose test samples to vibration (a simple bench vise and reciprocating saw for 5 minutes simulates months of pump or motor vibration). Quality ties stay tight; cheap ones loosen or fracture at the head.

Common Failure Modes to Watch For:

- Weak stamped heads: Thin metal heads bend under torque and release the band

- Undersized or soft locking balls: They deform or pop out under sustained load

- Poor barb engagement: Ladder-style locks with shallow teeth slip during thermal expansion

Tip pre profesionálov: The locking mechanism should withstand repeated tightening cycles. Install and remove the same tie 3-4 times. If the lock becomes sloppy or the ratchet teeth show visible wear, durability is questionable.

Step 5: Validate Environmental Resistance and Compliance Certifications

The final test: Will these ties survive your actual operating environment?

Stainless steel ties aren’t universally corrosion-proof—their performance depends on the specific grade, surface treatment, and exposure conditions. Before specifying ties for outdoor, marine, or chemical environments, validate their environmental resistance credentials.

Corrosion Resistance Verification:

- Salt Spray Test Results: Request ASTM B117 salt spray test data. Quality 316 ties should endure 1,000+ hours without red rust formation. Anything less than 500 hours is unacceptable for marine or coastal use.

- Chloride Exposure Rating: If your facility handles chlorides (seawater, de-icing salts, bleach), only 316 grade offers adequate pitting resistance. 304 will fail prematurely.

Temperature and Environmental Ratings:

- Verify the rated temperature range. Quality stainless ties perform from -80°C to +538°C (-112°F to +1000°F), covering everything from cryogenic to exhaust system applications.

- For outdoor installations, confirm UV resistance and flame ratings per UL 62275 or IEC 62275 standards.

Compliance Documentation:

- Industry Certifications: Look for third-party compliance marks:

- Uznanie UL for electrical installations

- ISO 10993 biocompatibility for medical device cabling

- AS9100 certification for aerospace applications

- RoHS and REACH compliance for European installations

Kľúčový záver: Third-party certifications aren’t paperwork overhead—they’re the only proof your ties will survive when salt spray, UV exposure, and temperature swings attack simultaneously. Without them, you’re trusting marketing claims, not metallurgical reality.

Environmental Selection Guide:

| Životné prostredie | Minimum Grade | Critical Certifications |

|---|---|---|

| Indoor industrial, dry | 304 | ISO 9001, UL |

| Outdoor, non-marine | 304 | UV resistance, UL 62275 |

| Coastal/marine | 316 | Salt spray >1000 hrs, UL |

| Chemical processing | 316 | Chemical resistance data, RoHS |

| High-temperature | 316 | Temp rating verification |

The Bottom Line: Quality Pays for Itself

Distinguishing high-quality stainless steel cable ties comes down to systematic verification across five dimensions:

- ✓ Material certification: Insist on mill test certificates proving genuine 304/316 composition

- ✓ Manufacturing precision: Inspect for smooth, burr-free finish and consistent dimensions

- ✓ Mechanická pevnosť: Demand third-party tensile test data with proper safety margins

- ✓ Lock integrity: Physically test the mechanism under load and vibration

- ✓ Dodržiavanie predpisov v oblasti životného prostredia: Verify salt spray testing and industry certifications

Your Action Plan:

Before your next bulk purchase, request the following from every supplier:

- Mill test certificates with full chemical analysis

- Third-party tensile strength test reports

- Salt spray test results (for outdoor/marine use)

- Physical samples for inspection and testing

- Copies of relevant certifications (UL, ISO, etc.)

The price difference between premium and cheap stainless steel cable ties is typically 30-50%. But the cost difference between a successful installation and a catastrophic failure is 10,000%. In critical electrical infrastructure, cable ties aren’t commodity items—they’re reliability insurance.

Need help specifying the right stainless steel cable ties for your application? Contact certified suppliers who can provide complete documentation packages and technical support for your specific environment. The 15 minutes spent verifying quality now saves 15 hours of emergency troubleshooting later.