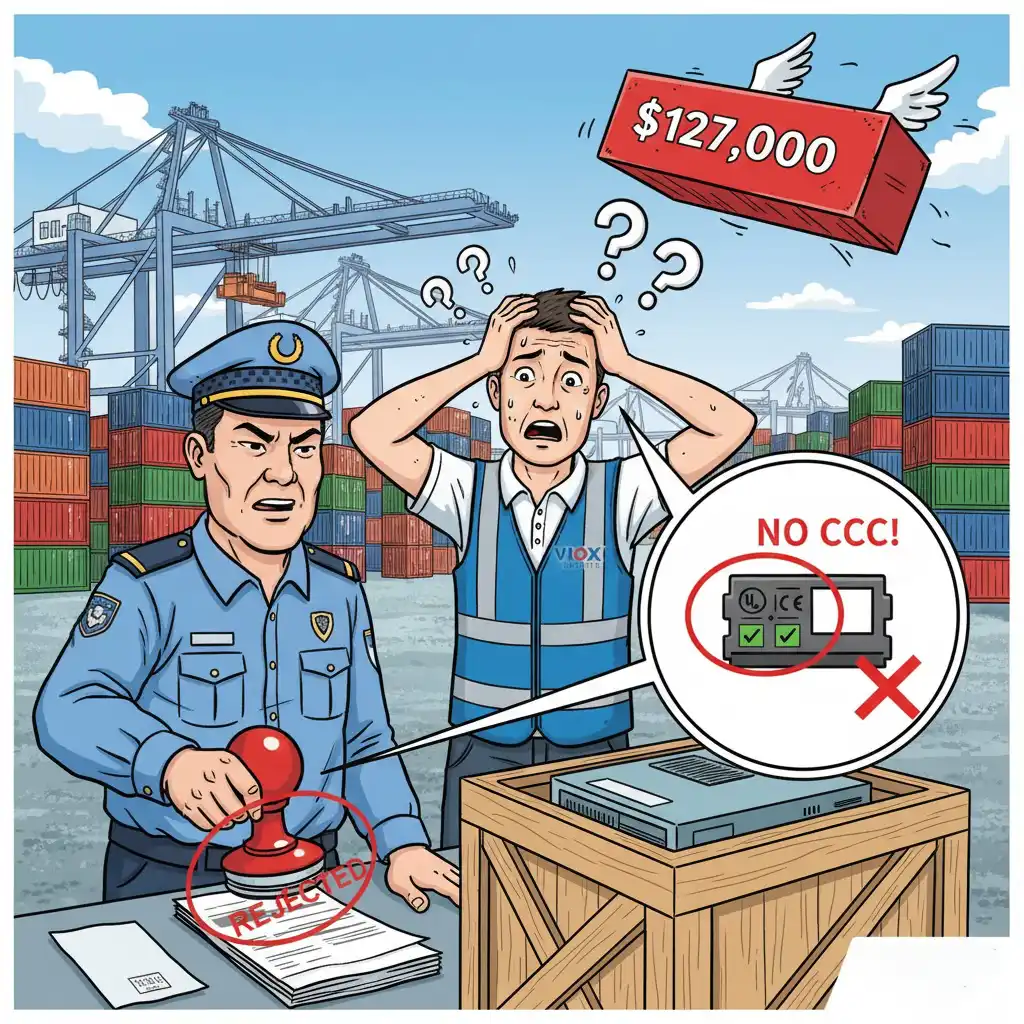

The container ship was scheduled to depart Shanghai in 72 hours. Your 20 control panels—bound for a new semiconductor fab in Wuxi—were already at the port. Then the freight forwarder called.

“Customs has flagged your shipment. The terminal blocks don’t have CCC marks.”

You pull up the spec sheet. CE marked. UL recognized. Every certification you thought you needed. But not the one that mattered in China. By the time you source compliant replacements, air freight them to Shanghai, and clear the original rejection, you’re looking at $127,000 in demurrage fees, expedited shipping, and penalty clauses for late delivery.

All because of terminal blocks.

This isn’t a worst-case scenario. It’s Tuesday for panel builders shipping globally. Terminal block certifications look straightforward on paper—until they’re not. The certification marks seem interchangeable—until a customs inspector or electrical inspector says otherwise. And the cost of getting it wrong isn’t just inconvenience. It’s five-figure delays, failed inspections, and panels that can’t legally be installed.

So what’s actually tripping up engineers? Here are the five certification mistakes that get panels rejected, plus how to avoid them before your next shipment leaves the dock.

Mistake #1: The UL Confusion – “Listed” vs. “Recognized” (They’re Not the Same Thing)

You specify “UL listed terminal blocks” for a control panel build. Your vendor confirms the quote. The terminal blocks arrive with a UL mark. Everything looks fine.

Then the panel shop’s UL 508A inspection fails.

The terminal blocks are UL Recognized—not UL Sarakstā iekļauts. Subtle difference in wording. Massive difference in compliance. Your panel builder now has to rework every terminal block connection or source different blocks, and you’re explaining to the client why their delivery just slipped three weeks.

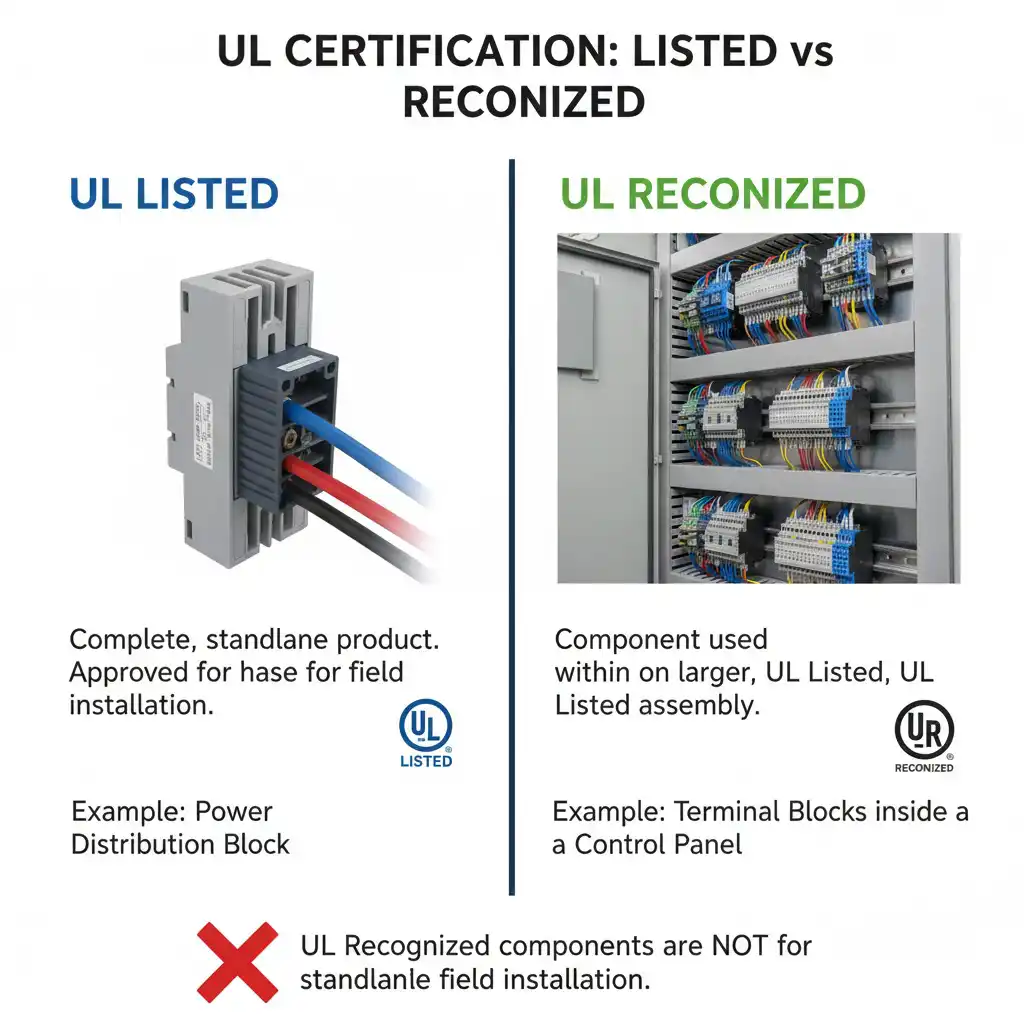

What’s the difference?

UL Recognized components are intended for use inside a larger assembly that will itself be UL listed. Think of them as ingredients. A UL Recognized terminal block is designed to be part of a control panel, motor drive, or other equipment that gets its own UL listing. The terminal block alone isn’t approved for field installation.

UL sarakstā products are complete, standalone items approved for installation by themselves. Power distribution blocks, for instance, are often UL Listed because electricians install them directly in the field.

For terminal blocks inside control panels, UL Recognized (covered by UL 1059) is actually what you should be using. The confusion happens when engineers see “UL Listed” in competitor spec sheets and assume that’s the premium certification. It’s not wrong, but UL Recognized is the correct designation for component-level terminal blocks.

But here’s where it gets messier: CSA sertifikācija follows similar logic. CSA certified terminal blocks are recognized components. If your panel needs to ship to Canada, you need CSA C22.2 No. 158 compliance—and not all UL-recognized blocks carry CSA marks.

The real trap: Assuming “UL” alone is sufficient documentation. It’s not. The actual file number and recognition category matter.

How to Avoid This

- ✓ Specify the full designation: “UL Recognized per UL 1059” (or “UL 1059 Ed. 6” for the latest December 2024 standard)

- ✓ Request the UL file number: Should be printed on the terminal block or listed in the datasheet (format: E123456)

- ✓ Verify CSA certification separately: If shipping to Canada, confirm the blocks carry CSA C22.2 No. 158 recognition

- ✓ Check the panel builder’s UL 508A listing: Their certification specifies which component categories they’re allowed to use

Profesionāļu padoms: UL 1059 Edition 6, published December 11, 2024, is now the active standard. If your panel builder’s documentation references Edition 5 or older, flag it. Inspectors are transitioning to the new requirements.

Mistake #2: The CE Mark Illusion – One Symbol, Multiple Meanings

Your panel is heading to Germany. The terminal blocks have a CE mark. Problem solved, right?

Not quite.

The CE mark on a terminal block indicates conformity with European Union directives—primarily the Low Voltage Directive (LVD) 2014/35/EU. But which specific standard the manufacturer self-declared conformity to makes all the difference.

Most terminal blocks claim CE conformity based on IEC 60947-7-1 (Low-voltage switchgear and controlgear: Terminal blocks for copper conductors). But here’s the issue: CE marking is largely self-declared by manufacturers in the EU. There’s no mandatory third-party testing like UL requires. A manufacturer tests their product, prepares a Declaration of Conformity, affixes the CE mark, and ships.

This creates two problems:

Problem 1: The Counterfeit CE Mark

You see a CE mark on the terminal block housing. Looks legitimate. But some manufacturers—particularly those outside the EU trying to access European markets—print CE marks without actually performing the required conformity assessments. It’s not always intentional fraud; sometimes it’s misunderstanding the requirements. Either way, when your panel gets inspected at the installation site in Munich and the electrical contractor asks for the Declaration of Conformity, you’re stuck.

Problem 2: The Post-Brexit UKCA Maze

If your panel is shipping to the UK (England, Scotland, Wales), CE marks are being phased out in favor of UKCA (UK Conformity Assessed) marking. As of January 1, 2025, most products require UKCA marks for the British market. CE marks are still accepted temporarily, but relying on CE alone for UK projects is increasingly risky.

How to Avoid This

- ✓ Demand the Declaration of Conformity (DoC): European customers or inspectors may request this document. Ensure your supplier can provide it

- ✓ Verify the standard: The DoC should reference IEC 60947-7-1 (or -7-2 for protective conductor blocks, -7-3 for fuse blocks)

- ✓ Check for UKCA if shipping to UK: Don’t assume CE is sufficient post-Brexit

- ✓ Use reputable manufacturers: Major brands (Phoenix Contact, Weidmüller, Wago, VIOX) have legitimate CE certification processes and can provide documentation on demand

The “Arizona Clause”: Many CE-marked terminal blocks are rated for 40°C ambient temperature. If your panel is installed in a hot environment—say, a factory in Arizona or the Middle East—that rating doesn’t hold. The CE mark itself doesn’t guarantee your application conditions are covered.

Mistake #3: The China Blindspot – Ignoring CCC Requirements

Let’s return to that $127,000 container delay in Shanghai.

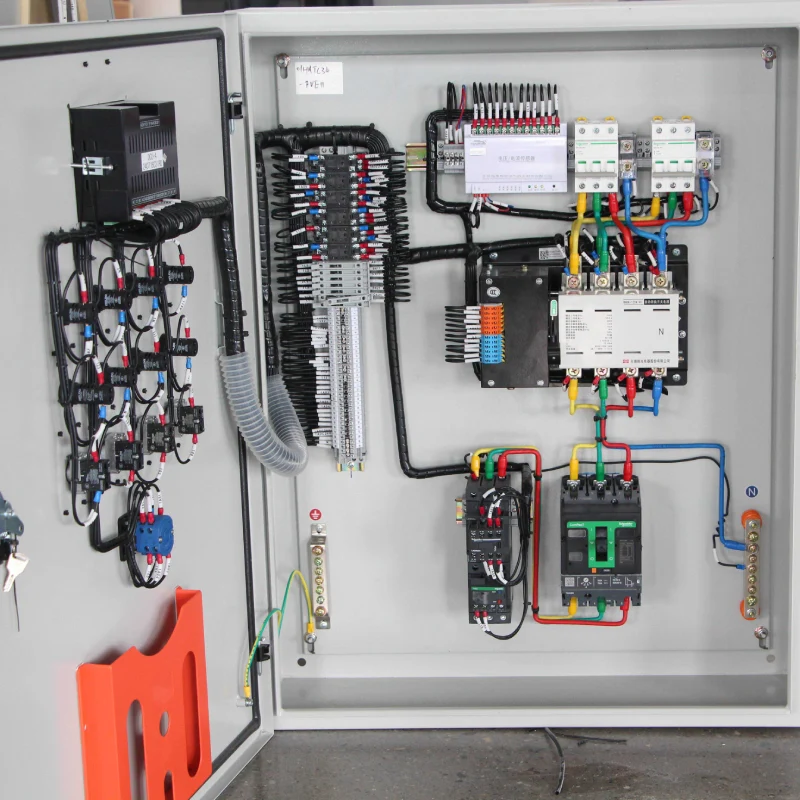

China requires CCC certification (China Compulsory Certificate) for many electrical products sold or used in the Chinese market. The CCC mark isn’t optional—it’s mandatory for specific product categories, and “Low-voltage apparatus” (which includes terminal blocks) is one of them.

Here’s what makes CCC tricky:

CCC applies to products used in China, not just manufactured there. If you’re building control panels in the US or Europe and shipping them to China for installation, the terminal blocks inside those panels need CCC marks if they fall under the mandatory categories.

But the requirements keep changing. In 2024, China expanded CCC requirements for lithium-ion batteries and battery packs. While terminal blocks have been on the CCC list longer, the enforcement has become stricter, and customs inspections are catching more non-compliant shipments.

The certification process is complex: Unlike UL recognition (which a manufacturer can obtain through testing labs globally), CCC certification requires testing in China-accredited labs and ongoing factory audits. It’s administered by the China Quality Certification Center (CQC) and involves both product testing and annual follow-up inspections.

Not every terminal block manufacturer bothers with CCC certification, especially smaller Western companies that don’t prioritize the Chinese market.

How to Avoid This

- ✓ Confirm CCC requirements for your specific project: Not all terminal block applications require CCC, but control panels for industrial installations typically do

- ✓ Specify CCC-marked terminal blocks upfront: Don’t wait until the panel is built to discover your blocks lack CCC marks

- ✓ Work with manufacturers who have CCC certification: Major global brands maintain CCC listings; verify with the CQC database

- ✓ Factor in lead times: If you need to source CCC-compliant replacements mid-project, add weeks to your schedule

Concept Handle: “The Factory Code Trap” CCC marks include a factory identification code. If the mark looks right but the factory code doesn’t match the manufacturer’s registration, customs will reject it. Counterfeit CCC marks are a real problem, especially in the electrical components market.

Mistake #4: The Hazardous Area Amnesia – Forgetting Ex Certifications

Your control panel is shipping to an oil refinery. Or a chemical plant. Or a grain processing facility. All the terminal blocks are UL recognized, CE marked, everything looks good.

Then the site engineer asks: “Where are the ATEX certifications?”

You stare at the spec sheet. No mention of ATEX. No Ex markings. The terminal blocks are rated for general industrial use—but not for potentially explosive atmospheres.

Why this happens: Most engineers don’t think about explosion protection certifications until it’s too late. Standard terminal blocks are designed for normal industrial environments (non-hazardous areas). But if your panel is installed in a Zone 1 or Zone 2 area (Europe/IEC classification) or Class I, Division 1/2 area (North America classification), you need terminal blocks certified for those environments.

The certification families:

- ATEX (Europe): Directive 2014/34/EU for equipment in potentially explosive atmospheres. Terminal blocks need Ex certification, typically Ex e (increased safety) or Ex i (intrinsic safety)

- IECEx (International): The global certification scheme based on IEC 60079 standards. Recognized in many countries outside Europe

- UL Class I, Div 1/2 (North America): Per NEC Article 500, equipment in hazardous locations needs UL 1203 (for Div 1) or UL 1604 (for Div 2) certification

- UKCA Ex (UK): Post-Brexit equivalent of ATEX for the British market

Standard terminal blocks won’t pass inspection in hazardous areas. And swapping in Ex-rated blocks after the panel is built isn’t just a parts swap—it affects the entire panel’s certification.

How to Avoid This

- ✓ Ask about the installation environment during project kickoff: “Is this panel going into a hazardous area?” should be part of your standard checklist

- ✓ Specify Ex-rated terminal blocks from the start: Don’t assume standard blocks will work

- ✓ Verify the Ex marking: Look for “Ex e II” or “Ex i” markings on the terminal block housing, and request the type examination certificate

- ✓ Check zone/division classifications: Zone 1 vs. Zone 2 (or Div 1 vs. Div 2) affects which terminal blocks you can use

The Forgotten Test: Ex-rated terminal blocks undergo additional testing for short-circuit withstand current and temperature limits. A standard terminal block might be rated for 10A at 40°C, but an Ex e version of the same block might have a lower current rating or stricter derating requirements. Factor this into your design.

Mistake #5: The Verification Gap – Trusting Marks Without Checking

You receive a shipment of terminal blocks. Each one has a UL mark, CE mark, and the manufacturer’s logo. Everything looks legitimate.

But is it?

Counterfeit certification marks are a persistent problem in the electrical components industry. Some manufacturers print marks they haven’t earned. Others let their certifications lapse but keep using the old marks. And in some cases, distributors substitute non-certified products while claiming they’re certified.

This isn’t paranoia. It happens frequently enough that major OEMs and panel builders now require certified test reports and traceability documentation for all electrical components.

The risk isn’t just failed inspections. It’s liability. If a panel catches fire and the investigation reveals counterfeit UL marks on the terminal blocks, your company is on the hook—not just for the fire damage, but for knowingly (or negligently) installing non-compliant equipment.

How to Avoid This

- ✓ Verify UL file numbers: Go to UL’s Product iQ database (productiq.ul.com) and search for the manufacturer’s file number. Confirm the specific terminal block model is listed

- ✓ Request Declarations of Conformity for CE marks: Legitimate manufacturers provide these documents willingly

- ✓ Check the CCC database: For China-bound projects, verify CCC marks at the CQC website (www.cqc.com.cn/en)

- ✓ Inspect the marks physically: Counterfeit marks are often printed poorly—blurry edges, incorrect fonts, wrong positioning on the housing

- ✓ Source from authorized distributors: Buying directly from the manufacturer or their authorized distribution network reduces counterfeit risk

The Batch Code Trick: Reputable manufacturers print batch codes or date codes on terminal blocks. If you receive blocks with no traceability markings, that’s a red flag. Ask for manufacturing documentation.

The Certification Matrix: Quick Reference

Here’s what certifications you actually need based on where your panel is going:

| Destination | Required Certification | Standarta atsauce | Piezīmes |

|---|---|---|---|

| Amerikas Savienotās Valstis | UL Recognized | UL 1059 Ed. 6 (2024) | For panels UL 508A listed |

| Kanāda | CSA sertificēts | CSA C22.2 Nr. 158 | Often combined with UL as cULus |

| Eiropas Savienība | CE Mark | IEC 60947-7-1/-2/-3 | Self-declared, DoC required |

| Apvienotā Karaliste | UKCA Mark | BS EN 60947-7-1 | Phasing out CE acceptance post-Brexit |

| Ķīna | CCC Mark | GB 14048.8 | Mandatory for most control panel applications |

| Hazardous Areas (Global) | ATEX / IECEx / UL Class I | IEC 60079, UL 1203/1604 | Depends on zone/division classification |

| Marine / Offshore | Lloyd’s Register / DNV | Varies by classification society | Additional requirements beyond standard industrial |

Profesionāļu padoms: If your panel is going to multiple countries, look for terminal blocks with multi-certification (UL, CSA, CE, CCC). Many major manufacturers offer globally-compliant products that save you from sourcing different blocks for each market.

The Final Checklist: Before You Spec Your Next Panel

Print this out. Tape it to your monitor. Use it every time you’re selecting terminal blocks for a control panel:

- ☐ Where is the panel being installed? (Country/region)

- ☐ Is it a hazardous area? (Zone/Division classification)

- ☐ Does the panel need UL 508A listing? (Requires UL Recognized components)

- ☐ Is Canada a potential market? (Add CSA certification requirement)

- ☐ Any chance it ships to China? (Specify CCC marks upfront)

- ☐ Post-Brexit UK installation? (UKCA required)

- ☐ Have you requested certification documentation? (UL file number, CE DoC, CCC certificate)

- ☐ Are the marks verifiable online? (Check UL Product iQ, CQC database)

- ☐ Is the manufacturer authorized? (Buy from known distributors)

- ☐ Do you have traceability? (Batch codes, manufacturing dates on the blocks)

If you can check every box, your terminal blocks won’t be the reason your panel gets rejected.

One More Thing: Why This Matters Beyond Compliance

Rejected panels don’t just cost money. They cost trust.

When your client’s production line sits idle because your control panel failed inspection, they remember. When your panel gets flagged at customs and their project timeline slips, they remember. And when they’re selecting vendors for their next project, they remember who made it easy and who made it complicated.

Getting terminal block certifications right isn’t about checking boxes on a compliance form. It’s about being the engineer who delivers panels that work, ship on time, and pass every inspection on the first try. It’s about not being the person who has to explain a six-figure delay over something as simple as a missing CCC mark.

So next time you’re spec’ing terminal blocks, don’t just grab whatever’s on the BOM from the last project. Check the certifications. Verify the marks. Ask for the documentation.

Your future self—the one not on a panicked call with a freight forwarder—will thank you.

Need terminal blocks that ship anywhere without certification headaches? Explore VIOX’s globally-certified product line.