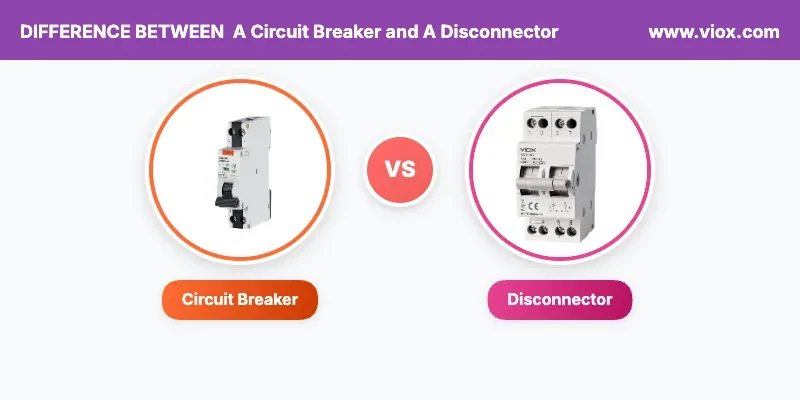

Otsene vastus: A circuit breaker automatically interrupts electrical current during fault conditions and can operate under load, while a disconnector (isolator) provides visible isolation for maintenance purposes and should only operate when circuits are de-energized. Circuit breakers offer protection; disconnectors provide isolation.

Understanding the difference between circuit breakers and disconnectors is critical for electrical safety, proper system design, and code compliance. Both devices control electrical circuits, but they serve fundamentally different purposes in electrical systems.

Key Definitions: Circuit Breakers vs Disconnectors

Mis on kaitselüliti?

A kaitselüliti is an automatic electrical switching device designed to protect electrical circuits by interrupting current flow when fault conditions occur. It can make, carry, and break currents under normal and abnormal (fault) conditions.

Peamised omadused:

- Automatic operation during faults

- Arc extinction capability

- Can operate under full load conditions

- Provides overcurrent and short-circuit protection

- Resettable after tripping

What is a Disconnector (Isolator)?

A disconnector, also called an isolator, is a mechanical switching device that provides isolation of circuits for maintenance and safety purposes. It creates a visible gap between electrical contacts when open.

Peamised omadused:

- Manual operation only

- Visible isolation gap

- Operates only when circuits are de-energized

- No fault interruption capability

- Prevents accidental energization during maintenance

Põhjalik võrdlustabel

| Funktsioon | Kaitselüliti | Disconnector (Isolator) |

|---|---|---|

| Primary Purpose | Protection against faults | Isolation for maintenance |

| Operatsioon | Automaatne ja manuaalne | Ainult käsiraamat |

| Kaare väljasuremine | Yes (SF6, vacuum, oil, air) | No – minimal or none |

| Load Breaking | Yes – full load capability | No – load-free operation only |

| Fault Current | Interrupts fault currents | Ei saa katkestada rikkevoolusid |

| Visible Gap | Ei nõuta | Required for safety |

| Standardid | IEC 62271-100, IEEE C37 | IEC 62271-102, IEEE C37.30 |

| Typical Voltage | All levels (LV to EHV) | Medium to high voltage |

| Paigaldamiskulud | Kõrgemad | Alumine |

| Hooldus | Complex mechanism | Simple mechanism |

Critical Differences Explained

1. Fault Interruption Capability

Kaitselülitid:

- Designed to interrupt fault currents up to their rated capacity

- Use arc extinction media (SF6 gas, vacuum, oil, or air)

- Can break currents many times their normal rating during faults

- Essential for system protection

Disconnectors:

- Cannot interrupt fault currents safely

- May create dangerous arcing if opened under load

- Used only after circuit is de-energized by other means

- Primarily isolation, not interruption

2. Operating Conditions

Kaitselülitid:

- Operate under normal and fault conditions

- Can make and break full load currents

- Function automatically during abnormal conditions

- Suitable for frequent operation

Disconnectors:

- Operate only under no-load or minimal load conditions

- Require circuit to be de-energized before operation

- Manual operation with visible position indication

- Infrequent operation for maintenance purposes

⚠️ Ohutushoiatus: Never operate a disconnector under load conditions. This can cause dangerous arcing, equipment damage, and severe safety hazards.

Rakendused ja kasutusjuhtumid

When to Use Circuit Breakers

Tööstuslikud rakendused:

- Motor protection and control

- Feeder protection in distribution systems

- Generaatori ja trafo kaitse

- Fault current interruption in power systems

Kommertsrakendused:

- Main service disconnect protection

- Haruahela kaitse

- Load center applications

- Automatic transfer switch integration

Elamurakendused:

- Peamise elektripaneeli kaitse

- Individuaalne vooluahela kaitse

- GFCI and AFCI protection

- Whole-house surge protection integration

When to Use Disconnectors

Substation Applications:

- Bus sectionalizing

- Equipment isolation for maintenance

- Visible isolation requirements

- Line switching in transmission systems

Tööstuslikud rakendused:

- Motor disconnect switches

- Seadmete isolatsioon

- Maintenance safety isolation

- Emergency disconnection points

Maintenance Applications:

- Creating safe work zones

- Lukustuse/märgistuse protseduurid

- Equipment servicing isolation

- Visual confirmation of de-energization

Selection Criteria and Expert Guidelines

Choosing Circuit Breakers

Key Factors to Consider:

- Rated Current: Must exceed normal operating current

- Breaking Capacity: Must exceed maximum fault current

- Voltage Rating: Must match or exceed system voltage

- Type of Load: Motor, resistive, capacitive considerations

- Environmental Conditions: Indoor/outdoor, temperature, contamination

Eksperdi nipp: Always consult fault current studies when selecting circuit breakers. The breaking capacity must exceed the maximum available fault current at the installation point.

Choosing Disconnectors

Key Factors to Consider:

- Isolation Requirements: Visible gap specifications

- Mechanical Endurance: Expected operating cycles

- Environmental Rating: Weather resistance for outdoor units

- Interlocking Requirements: Safety interlocks with other equipment

- Accessibility: Ease of operation and maintenance access

Eksperdi nipp: Specify disconnectors with auxiliary contacts for remote indication of position. This enhances safety and operational awareness.

Ohutus ja eeskirjadele vastavus

Riikliku elektriseadustiku (NEC) nõuded

Artikkel 240 – Ülem-Kaitse:

- Circuit breakers must provide overcurrent protection

- Proper coordination with upstream protective devices

- Arc-fault and ground-fault protection requirements

Artikli 430 – Mootorid:

- Motor branch-circuit short-circuit protection

- Motor disconnect requirements within sight

- Combination motor controllers specifications

IEEE Standards Compliance

IEEE C37 Series Standards:

- C37.04: Standard for circuit breaker rating structure

- C37.06: AC high-voltage circuit breaker standards

- C37.30: Disconnecting switch standards

Peamised vastavuspunktid:

- Proper application within ratings

- Environmental qualification testing

- Seismic qualification where required

- Electromagnetic compatibility requirements

⚠️ Professional Recommendation: Always consult with licensed electrical engineers for medium and high-voltage applications. Improper selection can result in catastrophic failures.

Paigaldamise ja hooldusega seotud kaalutlused

Circuit Breaker Installation Best Practices

Step-by-Step Installation Process:

- Eelpaigaldusplaan

- Verify electrical ratings match application

- Confirm available fault current levels

- Kontrollige keskkonnatingimusi

- Physical Installation

- Follow manufacturer torque specifications

- Ensure proper conductor termination

- Verify mechanical clearances

- Testimine ja kasutuselevõtmine

- Primary injection testing for protection relays

- Mehaanilise töö testimine

- Timing and contact resistance testing

Disconnector Installation Best Practices

Step-by-Step Installation Process:

- Site Preparation

- Verify foundation requirements

- Check clearance to live parts

- Ensure accessibility for operation

- Mehaaniline paigaldus

- Follow manufacturer alignment procedures

- Verify operating mechanism function

- Test interlocking systems

- Elektriühendus

- Use proper conductor termination methods

- Apply specified contact pressure

- Verify auxiliary circuit connections

Tüüpiliste probleemide lahendamine

Circuit Breaker Problems

Symptom: Breaker Won’t Close

- Check control power supply

- Verify spring charging mechanism

- Inspect mechanical interlocks

- Test closing coil continuity

Symptom: Nuisance Tripping

- Analyze load current profiles

- Kontrollige lahtiseid ühendusi

- Verify proper time-current coordination

- Võtke arvesse keskkonnategureid

Disconnector Problems

Symptom: Difficult Operation

- Inspect operating mechanism lubrication

- Check for mechanical binding

- Verify proper adjustment

- Examine contact wear

Symptom: Poor Contact Performance

- Check contact pressure settings

- Inspect for contamination

- Verify proper alignment

- Consider contact material compatibility

Kiirjuhend

Circuit Breaker Quick Facts

- Põhifunktsioon: Automatic fault protection

- Can Operate: Under load and fault conditions

- Arc Extinction: Yes – multiple technologies available

- Tüüpilised rakendused: Protection and switching

- Koodiviited: NEC Article 240, IEEE C37 series

Disconnector Quick Facts

- Põhifunktsioon: Isolation for maintenance

- Can Operate: Only when de-energized

- Arc Extinction: No – relies on air gap

- Tüüpilised rakendused: Isolation and visible disconnect

- Koodiviited: NEC Article 430.102, IEEE C37.30

Korduma Kippuvad Küsimused

Can a disconnector replace a circuit breaker?

No, a disconnector cannot replace a circuit breaker. Disconnectors lack fault interruption capability and cannot provide overcurrent protection required by electrical codes.

When should both devices be used together?

Both devices are commonly used together in medium and high-voltage applications where protection (circuit breaker) and isolation (disconnector) functions are both required for safe operation and maintenance.

What happens if you operate a disconnector under load?

Operating a disconnector under load can cause dangerous arcing, equipment damage, fire hazards, and potential injury. This practice violates safety codes and manufacturer recommendations.

Are there combination devices available?

Yes, some manufacturers offer combination circuit breaker-disconnector devices, particularly for motor applications. These devices provide both protection and visible isolation in a single unit.

How do you determine the proper sequence of operation?

For systems with both devices, always operate the circuit breaker first to interrupt current, then operate the disconnector for isolation. Reverse this sequence when re-energizing.

What are the typical maintenance intervals?

Circuit breakers typically require maintenance every 5-10 years depending on application and manufacturer recommendations. Disconnectors may require maintenance every 10-15 years due to their simpler mechanisms.

Can disconnectors be automated?

Yes, disconnectors can be equipped with motor operators for remote control, but they still should only operate under no-load conditions and typically require additional safety interlocks.

What are the different types of circuit breaker technologies?

Main types include air circuit breakers (ACB), vacuum circuit breakers (VCB), SF6 gas circuit breakers, and oil circuit breakers, each suited for different voltage levels and applications.

Professionaalne soovitus: For any electrical installation or modification involving circuit breakers or disconnectors, consult with a licensed electrical engineer or certified electrician. Proper application of these devices is critical for safety, code compliance, and reliable operation.

Pea meeles: Circuit breakers protect your electrical system from faults, while disconnectors protect you during maintenance. Both are essential components of safe electrical design, but they serve distinctly different purposes and must never be confused or misapplied.