Кабельні хомути з нержавіючої сталі - це міцні, універсальні кріпильні елементи, які широко використовуються в різних галузях завдяки своїй міцності, корозійній стійкості та здатності протистояти суворим умовам експлуатації. У цьому вичерпному посібнику розглядаються типи, застосування, методи монтажу та обслуговування цих надійних хомутів як для професійного, так і для домашнього використання.

VIOX Кабельні стяжки з нержавіючої сталі

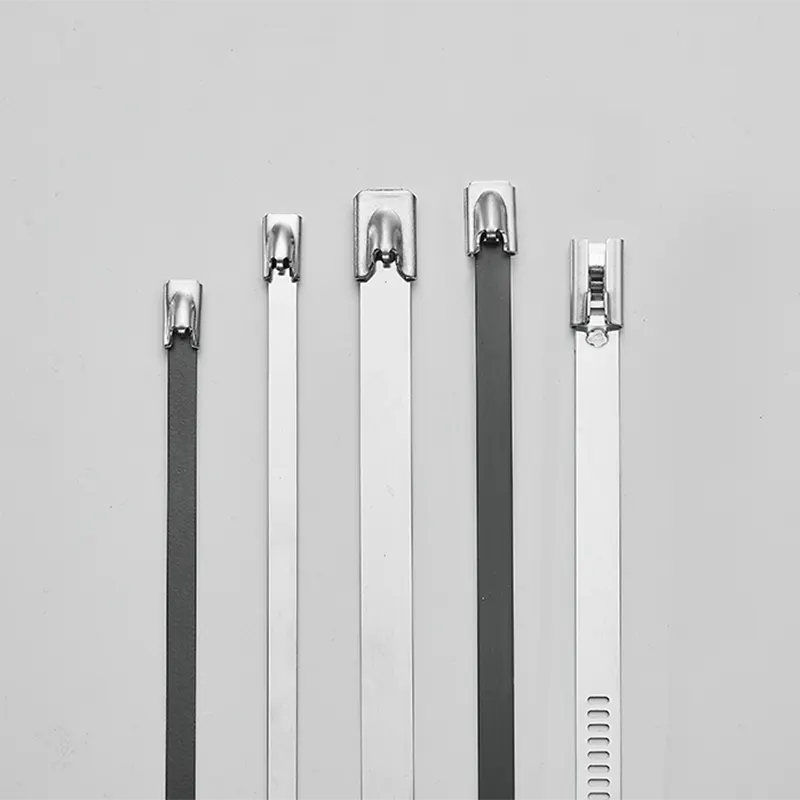

Типи кабельних стяжок

Три основні типи кабельних хомутів з нержавіючої сталі відповідають різним потребам:

- Стандартні стяжки з кульковим замком: Оснащені кульковим замком для надійної фіксації, доступні в довжині від 100 мм до 1200 мм і шириною від 4,6 мм до 12 мм. Витримує навантаження понад 160 кг у затягнутому стані.

- Роликові краватки: Мають роликовий кульковий механізм для посиленого натягу, що ідеально підходить для важких умов експлуатації, які потребують додаткової міцності. Легше встановлюється за допомогою спеціальних натяжних інструментів.

- Кабельні стяжки з покриттям: Пропонують додатковий захист завдяки ПВХ або епоксидному покриттю, що зменшує ризик стирання та забезпечує додаткову ізоляцію. Доступні в різних кольорах для легкої ідентифікації, підходять для середовищ, що вимагають хімічної стійкості.

Властивості та характеристики матеріалу

Кабельні хомути з нержавіючої сталі відомі своїми винятковими властивостями матеріалу, що робить їх придатними для складних застосувань у різних галузях промисловості. Дві основні марки сталі, що використовуються для цих хомутів, - AISI 304 і AISI 316L, кожна з яких має свої переваги.

- AISI 304: Також відома як нержавіюча сталь А2, вона є найпоширенішою маркою, що використовується для кабельних стяжок. Вона має чудову корозійну стійкість і витримує температури від -80°C до 538°C (-112°F до 1000°F). Ідеально підходить для універсального застосування.

- AISI 316L: Нержавіюча сталь формату А4 забезпечує чудову корозійну стійкість, особливо до хлоридів та інших агресивних хімічних речовин. Цьому сорту надають перевагу для застосування в прибережних районах, на хімічних заводах та в інших агресивних середовищах.

Міцність на розрив кабельних стяжок з нержавіючої сталі залежить від їхнього розміру та конструкції. Зазвичай вони можуть витримувати навантаження понад 160 кг, а деякі надміцні варіанти здатні витримувати ще більші зусилля. Щоб забезпечити правильний вибір для конкретного застосування, важливо звернутися до специфікацій виробника для отримання точних даних про міцність і вантажопідйомність.

Кабельні стяжки з нержавіючої сталі демонструють виняткову стійкість до впливу навколишнього середовища:

- Стійкість до корозії: Як 304, так і 316L мають чудову стійкість до іржі та корозії.

- Температурна стійкість: Ці зв'язки можуть зберігати свою цілісність при екстремальних температурах.

- Стійкість до ультрафіолету: На відміну від пластикових альтернатив, стяжки з нержавіючої сталі не руйнуються під впливом тривалого сонячного світла.

При виборі кабельних стяжок з нержавіючої сталі важливо враховувати специфічні фактори навколишнього середовища і вимоги до навантаження, щоб вибрати найбільш підходящу марку і розмір.

Встановлення та типові помилки

При монтажі кабельних хомутів з нержавіючої сталі правильна техніка має вирішальне значення для оптимальної продуктивності та довговічності. Почніть з вибору відповідного розміру та марки для вашого застосування, враховуючи такі фактори, як вимоги до навантаження та умови навколишнього середовища. Перед установкою переконайтеся, що поверхні чисті та вільні від сміття, щоб забезпечити надійне кріплення.

При монтажі кабельних хомутів з нержавіючої сталі правильна техніка має вирішальне значення для оптимальної продуктивності та довговічності. Почніть з вибору відповідного розміру та марки для вашого застосування, враховуючи такі фактори, як вимоги до навантаження та умови навколишнього середовища. Перед установкою переконайтеся, що поверхні чисті та вільні від сміття, щоб забезпечити надійне кріплення.

Встановити кабельну стяжку:

- Оберніть краватку навколо пакунка або предмета, який потрібно закріпити.

- Вставте хвостову частину через фіксуючий механізм.

- Потягніть за хвіст, щоб затягнути, забезпечуючи рівномірний розподіл натягу.

- Використовуйте спеціальний натяжний інструмент для точного і рівномірного затягування, особливо для великих стяжок або відповідальних застосувань.

- Відріжте зайву довжину хвоста, залишивши невеликий виступ, щоб запобігти ковзанню.

Поширені помилки встановлення, яких слід уникати:

- Надмірне затягування: Надмірне зусилля може пошкодити як краватку, так і пов'язані з нею предмети.

- Недостатнє затягування: Недостатній натяг може призвести до ковзання або передчасного виходу з ладу.

- Неправильний вибір розміру: Використання краватки, яка замала або завелика для конкретного випадку, може поставити під загрозу її ефективність.

- Неправильне вирівнювання: Переконайтеся, що краватка пряма і відцентрована навколо пачки.

- Нехтування захистом країв: Використовуйте захисні чохли або накладки, щоб запобігти пошкодженню гострими краями.

- Ігнорування температурних міркувань: Враховуйте теплове розширення, залишаючи невелику провисання стяжки.

Для відповідальних застосувань розгляньте можливість використання роликових кулькових стяжок, які мають підвищену здатність до розтягування. У морських або висококорозійних середовищах обирайте стяжки з нержавіючої сталі марки 316L, що забезпечують чудову стійкість до корозії. Регулярний огляд встановлених стяжок має важливе значення для підтримання безпеки та функціональності.

Застосування та обслуговування

Кабельні хомути з нержавіючої сталі знаходять широке застосування в різних галузях промисловості, морського транспорту та будівництва завдяки своїй винятковій міцності та стійкості до суворих умов навколишнього середовища. На виробництві вони кріплять важкі компоненти машин і зв'язують кабелі в пучки в зонах з високими температурами. Морське застосування включає в себе такелаж для човнів і кріплення докового обладнання, де сталь 316L має чудову корозійну стійкість в умовах солоної води.

Для підтримання оптимальної продуктивності дуже важливо проводити регулярний огляд і чищення. Оглядайте стяжки на наявність ознак зносу, корозії або ослаблення, особливо в місцях з високим навантаженням. Очищайте стяжки м'якими миючими засобами або спеціальними розчинами, щоб видалити забруднення, які можуть порушити їхню цілісність. Якщо потрібна заміна, акуратно розріжте стару стяжку за допомогою відповідних інструментів, не пошкодивши при цьому зв'язані елементи, і утилізуйте її належним чином. Дотримуючись цих правил обслуговування, ви можете значно подовжити термін служби кабельних хомутів з нержавіючої сталі та забезпечити їхню безперервну ефективність у складних умовах експлуатації.