The 2 AM Call You Never Want to Receive

You’ve spent weeks designing a control panel. Every motor starter, every relay, every sensor—meticulously spec’d and double-checked. The commissioning went smoothly. Your customer signed off. You moved on to the next project.

Then, at 2 AM on a Saturday, your phone rings. Production is down. The overnight supervisor is frantic. When the maintenance tech opened the enclosure, he found a melted terminal block, its housing charred black, three circuits completely dead. Your carefully designed system just cost your customer $50,000 in lost production, and now you’re being asked the question every engineer dreads: “How did this pass inspection?”

Here’s the uncomfortable truth: terminal block failures in the field almost never trace back to manufacturing defects. They trace back to selection errors made at the specification stage. The wrong current rating. The wrong connection type for a high-vibration application. The wrong IP rating for a humid environment. Small decisions that cascade into catastrophic failures.

So how do you choose a terminal block that won’t melt, won’t loosen, and won’t corrode—no matter what your system throws at it?

Why Terminal Blocks Fail: The Three Silent Killers

Before we dive into the solution, you need to understand why terminal blocks fail, because the “why” reveals exactly what to look for when selecting them.

Thermal stress from undersizing is the number one killer. When a terminal block carries current beyond its rated capacity—even for brief periods during motor startup or inrush events—the contact resistance generates heat faster than the housing can dissipate it. The plastic softens. The connection loosens. Resistance increases further. The feedback loop accelerates until something melts or catches fire. This is thermal runaway, and it starts with an engineer who spec’d a 10A terminal for a circuit that spikes to 12A.

Mechanical failure from vibration is the second killer, and it’s insidious because it happens slowly. Screw terminals rely on constant clamping force to maintain low-resistance contact. But in vibrating equipment—pumps, conveyors, motor-driven machinery—that screw gradually loosens. Each tiny vibration shifts the wire a fraction of a millimeter. Over months, the connection degrades until intermittent faults appear. By the time you troubleshoot it, you’ve already lost days of uptime.

Environmental degradation is the third killer. A terminal block designed for clean, climate-controlled enclosures will corrode rapidly when exposed to coolant mist, salt spray, or even high humidity. Corrosion increases contact resistance. Resistance generates heat. You’re back to thermal runaway—just with a different root cause.

The good news? All three failure modes are completely preventable if you follow a disciplined selection process. And that’s exactly what the 3-Step Method gives you.

The 3-Step Terminal Block Selection Method

This isn’t proprietary magic. It’s the battle-tested approach used by veteran panel builders and automation engineers who’ve learned—often the hard way—that shortcuts in terminal block selection always come back to haunt you. The method forces you to systematically address electrical requirements, mechanical constraints, and safety validation in the correct order, so nothing falls through the cracks.

Step 1: Lock Down Your Electrical Requirements (The Foundation)

Everything starts here. Get your electrical specs wrong, and nothing else matters—your terminal block will fail regardless of how cleverly you mount it or how pretty the color coding looks.

Calculate Your TRUE Maximum Load Current

Don’t just copy the motor nameplate FLA (Full Load Amps) and call it done. You need to account for inrush current during startup, which can be 5-7x the running current for motors. If you’re switching inductive loads like solenoids or transformers, factor in their surge characteristics too. For control circuits with multiple devices, add up the simultaneous worst-case load—not the average load.

Once you have your true maximum current, here’s the rule that will save you from thermal disasters:

⚡ Pro-Tip #1: The 150% Rule is Non-Negotiable

Always spec terminal blocks rated for at least 1.5x your maximum expected load current. If your circuit draws 10A at peak, you need a 15A terminal minimum. This isn’t overcautious engineering—it’s your insurance against thermal runaway. Some engineers use a 120% margin, but that’s cutting it too close. The extra headroom accounts for ambient temperature variations, aging effects, and current harmonics you didn’t anticipate.

Verify Wire Gauge Compatibility (The Detail That Kills Projects)

Here’s where engineers commonly fail: they select a terminal block with the right current rating but forget to verify the wire gauge compatibility. The result? They try to force a 12 AWG wire into a terminal designed for 14-18 AWG, creating a loose, high-resistance connection that overheats.

🔥 Pro-Tip #3: Wire Gauge Mismatch is a Silent Killer

A wire that’s too thick for the terminal creates a high-resistance “hot spot” because the clamping mechanism can’t achieve full contact. A wire that’s too thin rattles loose under vibration. Always check BOTH the wire gauge range AND the actual entry hole diameter in the datasheet before ordering. If you’re using stranded wire, confirm the terminal is rated for stranded conductors—some push-in types only accept solid wire or ferrules.

Quick reference for matching wire size to terminal current rating:

| Circuit Current | Minimum Wire Gauge (AWG) | Minimum Terminal Current Rating |

|---|---|---|

| 5A - | 18-16 | 8A (with 150% margin) |

| 10 அ | 16-14 | 15 அ |

| 20அ | 14-12 | 30அ |

| 30அ | 12-10 | 45A |

| 50அ | 10-8 | 75A |

Confirm Voltage Rating (Including Surge Capacity)

Your terminal block’s voltage rating must exceed your system voltage with enough margin to handle transient surges. For 24 VDC control systems, a 300V-rated terminal provides massive headroom. For 480 VAC motor circuits, you need terminals rated for at least 600V. Don’t forget: voltage rating and pitch (terminal spacing) are linked. Smaller pitch terminals have lower voltage ratings because the creepage and clearance distances are tighter.

Step 2: Match Mechanical & Environmental Constraints (The Reality Check)

Now that your electrical foundation is solid, it’s time to face the real world: vibration, space constraints, accessibility, and the environment where this terminal block actually lives.

Choose the Right Connection Method for Your Application

This is where the screw-vs-spring-vs-push-in debate matters, and the answer depends entirely on your application’s mechanical stresses and maintenance requirements.

திருகு முனையங்கள் are the workhorse—widely available, accept a huge range of wire sizes, and provide adjustable clamping force. But they have a fatal weakness in vibrating equipment: that screw will loosen over time. You’ll need periodic inspection and re-torquing, which means downtime and labor costs. If you over-torque during installation, you’ll damage the wire. If you under-torque, the connection starts loose.

Spring-clamp terminals eliminate the torque guesswork because the spring provides constant, calibrated clamping force. They’re 80% faster to install than screw types and they resist vibration far better. But they cost more upfront.

புஷ்-இன் டெர்மினல்கள் are the fastest option—no tools required, just strip and push. They’re ideal for applications with frequent changes or repairs. Most accept solid wire and ferrule-tipped stranded wire, but verify compatibility before committing.

⚙️ Pro-Tip #2: Vibration Kills Screw Terminals

If your equipment moves, shakes, or runs 24/7 in an industrial environment, spring-clamp or push-in terminals aren’t a luxury—they’re a necessity. A loose screw terminal in a conveyor control panel will fail. It’s not “if,” it’s “when.” The vibration resistance and maintenance-free operation pay for the higher upfront cost within the first year.

Select the Mounting Style for Your Space

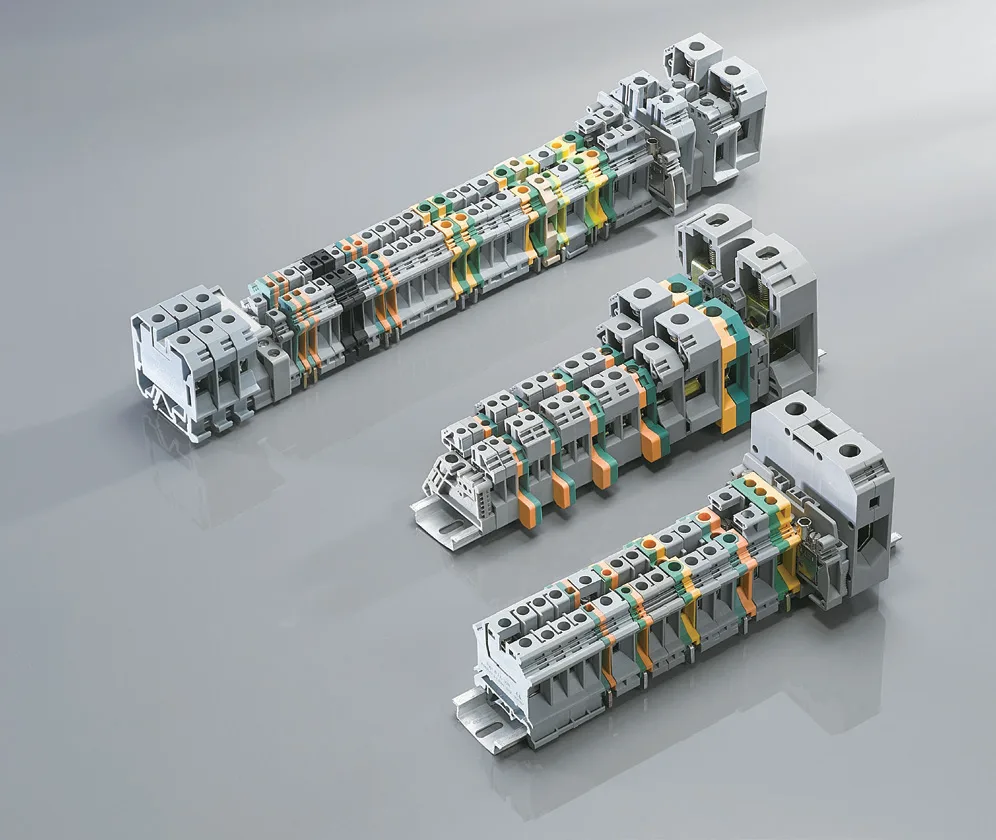

Most industrial control panels use DIN ரயில் பொருத்துதல் because it’s modular, space-efficient, and allows quick replacement without disassembling the entire panel. Just snap the terminal block onto the 35mm rail and you’re done.

For printed circuit boards, use PCB-mounted terminal blocks that solder directly to the board. These are common in compact devices, instrument clusters, and any application where the terminal block is part of a manufactured assembly rather than field wiring.

Barrier strips (panel-mounted terminal blocks) are your go-to for high-vibration environments where the terminal needs to bolt directly to a sturdy surface. They’re bulkier than DIN rail types but mechanically superior when physical shock is a concern.

Determine Pole Count, Pitch, and Wire Entry Orientation

Pole count is simply the number of wire connections you need. Multi-level terminal blocks can stack two or three levels in the same footprint, which is brilliant for space-constrained panels. A three-level block with 3.5mm pitch can fit 60 connections in just 3.5cm of rail width.

Pitch (the spacing between terminals) is a balancing act. Smaller pitch (3.5mm, 5mm) saves space but reduces voltage rating due to tighter clearances. Larger pitch (7.5mm, 10mm) supports higher voltages and makes wiring easier but consumes more rail space.

Wire entry orientation—horizontal (90°), vertical (180°), or angled (45°)—affects panel layout and serviceability. Horizontal entry is common for side-by-side wiring. Vertical entry works well in double-sided panels or where you’re routing wires from above/below. Always leave slack loops at the entry points to prevent strain on the connections.

Assess Environmental Factors and Specify the Correct IP Rating

This is where many projects fail because engineers underestimate the actual operating environment. That “indoor” control panel? It’s in a factory where coolant mist drifts from the machining area. That “dry location” equipment? It’s three feet from a pressure washer station.

🛡️ Pro-Tip #4: IP Ratings Aren’t Optional for Harsh Environments

If your terminal block faces dust, moisture, or washdown procedures, you need IP65 minimum (dust-tight, protected against water jets). For marine applications, flood-prone areas, or food processing with high-pressure washdowns, specify IP67 (dust-tight, protected against temporary immersion up to 1 meter for 30 minutes). An “indoor-only” terminal in a humid environment will corrode within months, leading to high-resistance connections and eventual failure.

Also consider:

– சுற்றுப்புற வெப்பநிலை: High-temperature environments (near ovens, furnaces, or in engine compartments) require terminals with high-temp plastics like glass-fiber reinforced polyamide or technical ceramics.

– Chemical exposure: Oils, solvents, and coolants can degrade standard plastics. Check material compatibility.

– Outdoor/UV exposure: UV-resistant housings prevent brittleness and cracking over time.

Step 3: Validate Safety & Compliance (The Insurance Policy)

You’ve nailed the electrical specs and matched the mechanical requirements. Now it’s time to ensure your selection won’t create liability issues or violate codes—and that it can grow with your project.

Verify Safety Certifications for Your Region and Application

Never assume a terminal block is “safe” just because it’s from a major manufacturer. Check for relevant approvals:

- UL, CSA, IEC certifications for general industrial use in North America and internationally

- ATEX and IECEx for hazardous (explosive atmosphere) locations—absolutely non-negotiable in chemical plants, refineries, or grain handling facilities

- CCC (China Compulsory Certificate) if you’re exporting to China

- Marine certifications (DNV, ABS) for shipboard installations

The certification labels aren’t just bureaucratic box-checking. They confirm the terminal block has passed rigorous testing for short-circuit protection, flammability, temperature rise, and environmental exposure. A UL-listed terminal has been torture-tested in ways your bench prototype never will be.

Confirm Insulation Materials and Flame Ratings

The housing material determines how your terminal block performs under thermal stress and whether it becomes a fire accelerant during a fault. Look for:

- Polyamide (PA66) or glass-fiber reinforced polyamide for most industrial applications—high dielectric strength, halogen-free, self-extinguishing (UL 94 V-0 rating)

- பாலிகார்பனேட் for higher insulation requirements

- Technical ceramics for extreme temperatures (up to 250°C) or spark-resistant applications

Check the datasheet for:

– Flammability rating (UL 94 V-0 is the gold standard—self-extinguishing within 10 seconds)

– Tracking resistance (CTI) for contaminated environments (higher is better; 600 is excellent)

– Maximum operating temperature to ensure it won’t soften under your worst-case conditions

Verify Physical Barriers for High-Voltage Applications

If you’re working with high-voltage circuits (over 300V), physical barriers between terminals aren’t optional—they’re a safety requirement. Barrier terminal blocks include built-in dividers that prevent accidental contact or arc-over between adjacent circuits. This is especially critical in motor control centers, where a single fault could cascade across multiple circuits without proper isolation.

Plan for Future Expansion (The Decision Your Future Self Will Thank You For)

Here’s a question that will save you grief: “What happens when this project needs three more I/O points next year?”

If you’ve packed your panel with fixed terminal blocks at maximum density, you’re stuck. But if you’ve used modular DIN rail blocks, you just snap on additional poles. Multi-level terminals give you vertical expansion room. Leaving a few empty slots on your rail isn’t wasted space—it’s cheap insurance against costly panel modifications later.

Also consider:

– Modular designs that let you add or remove poles without rewiring the entire panel

– Color-coded blocks that visually separate circuit types (power, control, analog signals) and speed up troubleshooting

– Built-in test points that let you measure voltages without disconnecting wires

– Permanently, machine-readable labels for circuit identification—especially important in complex panels

The Payoff: Why This Method Prevents Failures

When you follow this 3-step process religiously, here’s what you eliminate:

- ✅ ✅ अनिकालिक अने Thermal failures because you’ve applied the 150% safety margin and verified wire gauge compatibility

- ✅ ✅ अनिकालिक अने Mechanical failures because you’ve matched the connection type to your vibration profile

- ✅ ✅ अनिकालिक अने Environmental failures because you’ve specified the correct IP rating and housing materials

- ✅ ✅ अनिकालिक अने Code violations because you’ve verified certifications upfront

- ✅ ✅ अनिकालिक अने Future redesigns because you’ve planned for expansion with modular components

More importantly, you’ve created a selection process that’s repeatable and defensible. When a customer or a supervisor asks, “Why did you choose this terminal block?” you have a documented answer at every decision point. That’s professional engineering—not guesswork.

Your Next Steps: Apply This Method on Your Next Project

Here’s your action plan:

- Open your current project spec sheet and audit your terminal block selections against Step 1 (electrical requirements). Are you using the 150% safety margin? Have you verified wire gauge compatibility?

- Review your mechanical environment (Step 2). If there’s vibration, switch from screw to spring-clamp terminals. If there’s moisture or dust, upgrade to IP65 or IP67 rated blocks.

- Check your certifications (Step 3). Do you have the required UL/IEC/ATEX approvals for your installation? Is your housing material rated for your operating temperature?

- Build this into your standard specs. Create a terminal block selection worksheet based on these three steps and use it on every project. Consistency eliminates errors.

The engineers who master terminal block selection aren’t the ones who memorize every product datasheet. They’re the ones who follow a disciplined process that addresses electrical requirements, mechanical constraints, and safety validation in the correct order—every single time.

Your control panels will be more reliable. Your maintenance costs will drop. And you’ll never get that 2 AM call about a melted terminal block again. 🔧

Need help selecting terminal blocks for a specific application? Drop your requirements in the comments—voltage, current, environment, and mounting constraints—and I’ll walk through the selection process using this exact method.